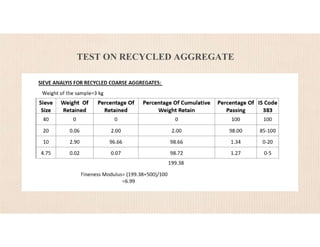

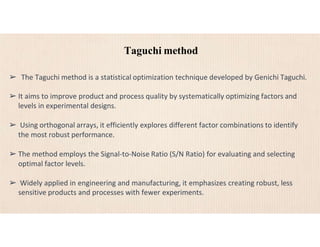

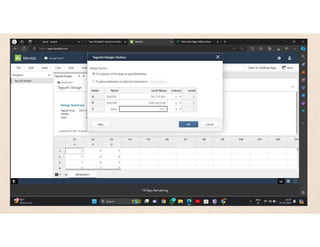

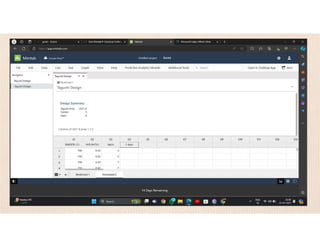

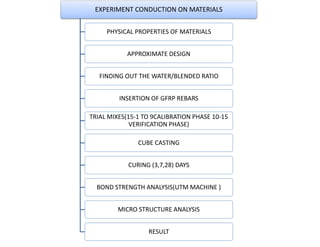

This document explores the bond strength characteristics of glass fiber reinforced polymer (GFRP) rebars in alkali-activated slag concrete mixes, emphasizing the advantages of GFRP as a corrosion-resistant alternative to traditional steel reinforcement. It details the objectives, methodology, and expected contributions to structural engineering, highlighting the significance of bond strength in concrete performance. The research employs the Taguchi method for optimization and outlines various tests conducted on the materials involved.

![REFERENCES

[1] A. Purdon, The action of alkalis on blast-furnace slag, J. Soc. Chem. Ind. Lond. 59(1940) 191-202.

[2] T.F. Pacheco, G.J.Castro, S. Jalali, Alkali-activated binders: a review: Part 1.Historical background, terminology,

reaction mechanisms and hydrationproducts, Construct. Build: Mater. 22 (2008) 1305-1314.

[3] D. Kong, J. Zhang, T. Ni, Research progress on alkali-activated binders andconcrete, J. Chinese Ceram. Soc. 37 (2009)

151-159.

[4] A. Palomo, P. Krivenko, M. Lodeiro, A review on alkaline activation: Newanalytical perspectives, Materials de

Construction 64 (2014) 140-159.

[5] A. Palomo, A. Fernández-Jiménez, H.C. Lopez, Railway sleepers-made of alkaliactivated fly ash concrete, Revista

ingeniería de construcción 22 (2007) 75-80

[6] K. Yang, C. Yang, J. Zhang, Q Pan, L Yu, Y. Bai, First structural use of site-castalkali-activated slag concrete in China,

Struct. Build. 171 (10) (2018) 800-809

[7] J.S. Kim, J.H. Park, An experimental investigation of bond properties of'einforcements embedded in geopolymer

concrete, International Journal ofStructural and Construction Engineering 9 (2) (2015) 92-95.

[8] M. Vinothini, G. Mallikarjun, T.D. Gunneswararao, R.D.Seshu, Bond strengthbehaviour of geopolymer concrete,

Malaysian J. Civ. Eng. 27 (3) (2015) 371-

[9] G. 381. behaviour:case Maranan, A of GFRP Manalo, bars K. in Karunasena geopolymer B. concrete, Benmokrane, J.

Mater. Bond Civ. Eng. stress-slip 27(1)(2014) 1-8

[10] R Manjunath, M.C. Narasimhan, K.M. Umesh, S. Kumar, U.K. Bala Bharathi,Studies on developing of high

performance, self-compacting alkali activated slag concrete mixes using industrial wastes, Constr. Build. Mater. 198

(2019)133-147](https://image.slidesharecdn.com/batch19ppt-240429030934-2a10d847/85/Gfrp-re-bars-major-project-presentation8th-seem-29-320.jpg)

![ [11] R. Manjunath, M.C. Narasimhan, Setting Behaviour of Alkali Activated SlagConcrete mixes - Effect of

chemical admixtures, Indian Concrete Journal 92 (9)(2018) 45-51.

[12] F. Jingchong, Z. Hongguang, S. Jing, L. Zonghui, Y. Sen, Influence of slag contenton the bond strength,

chloride penetration resistance, and interface phaseevolution of concrete repaired with alkali activated slag/fly

ash, Constr. Build,sMater. 263 (2020)

[12] Ding Y, Ning X, Zhang Y, Pacheco-Torgal F, Aguiar J. Fibres for enhancing ofthe bond capacity between

GFRP rebar and concrete. Constr Build Mater2014;51:303e12.

[13] Yang J-M, Min K-H, Shin H-O, Yoon Y-S. Effect of steel and synthetic fibers onflexural behavior of high-

strength concrete beams reinforced with FRP bars.Compos Part B Eng 2012;43(3):1077e86.

[14] Fursa TV, Utsyn GE, Korzenok IN, Petrov MV. Using electric response to mechanical impact for

evaluating the durability of the GFRP-concrete bond during the freeze-thaw process. Compos Part B Eng 1

April 2016;90:392e8.

[15] Won J-P, Lee S-J, Kim Y-J, Jang C-I, Lee S-W.The effect of exposure to alkaline solution and water on the

strengtheporosity relationship of GFRP rebar. Compos Part B Eng 2008;39(5):764e72.

REFERENCES](https://image.slidesharecdn.com/batch19ppt-240429030934-2a10d847/85/Gfrp-re-bars-major-project-presentation8th-seem-30-320.jpg)