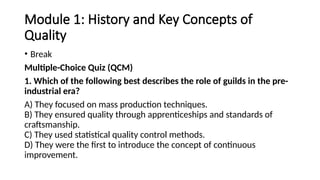

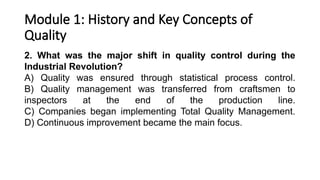

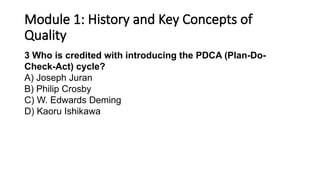

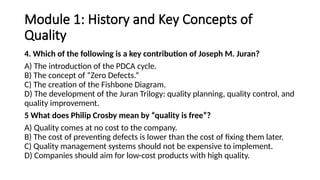

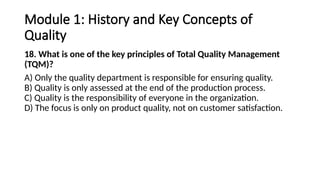

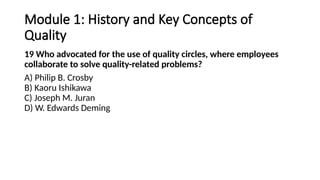

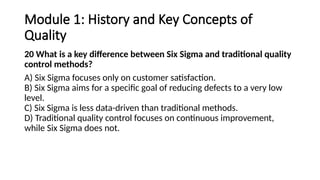

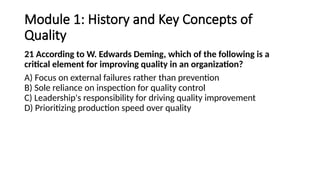

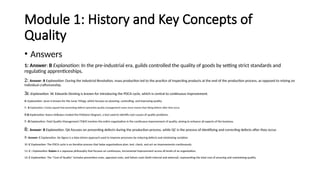

This course aims to provide a comprehensive understanding of quality management concepts, historical developments, and practical tools for promoting quality in organizations. It covers key themes including total quality management, statistical process control, and the contributions of quality gurus like W. Edwards Deming and Joseph Juran. Participants will learn about the evolution of quality practices from craftsmanship to modern continuous improvement methodologies.