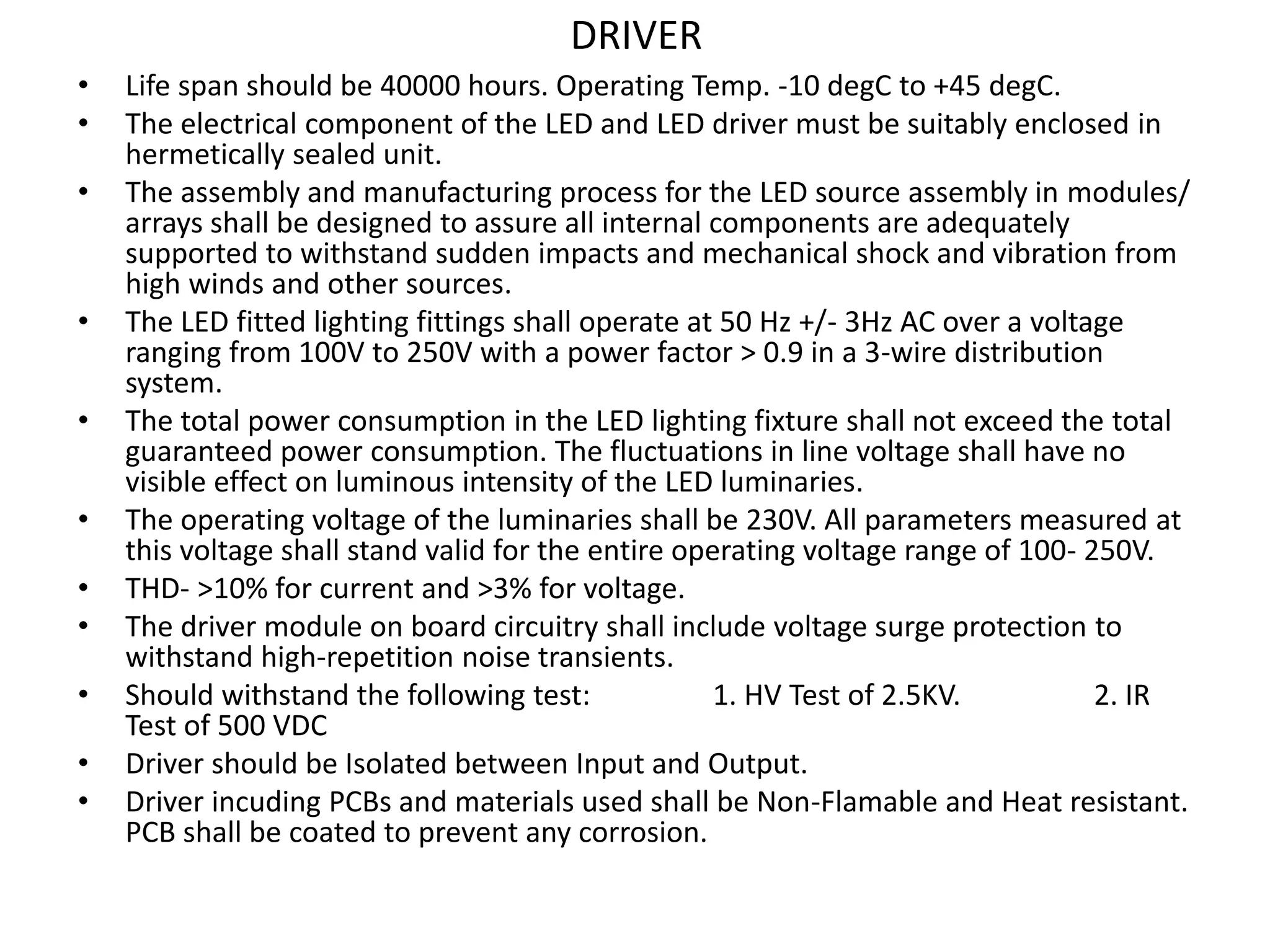

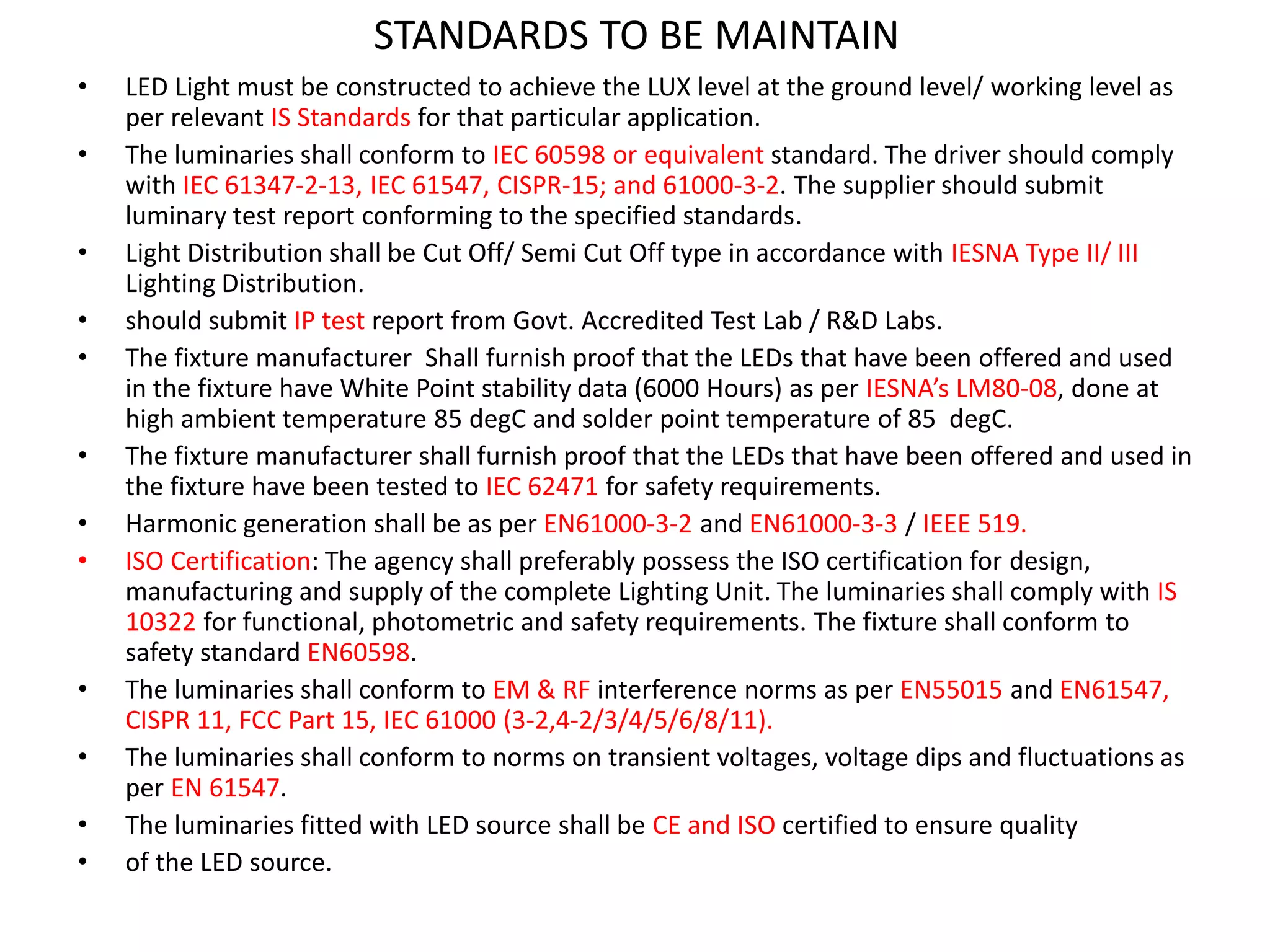

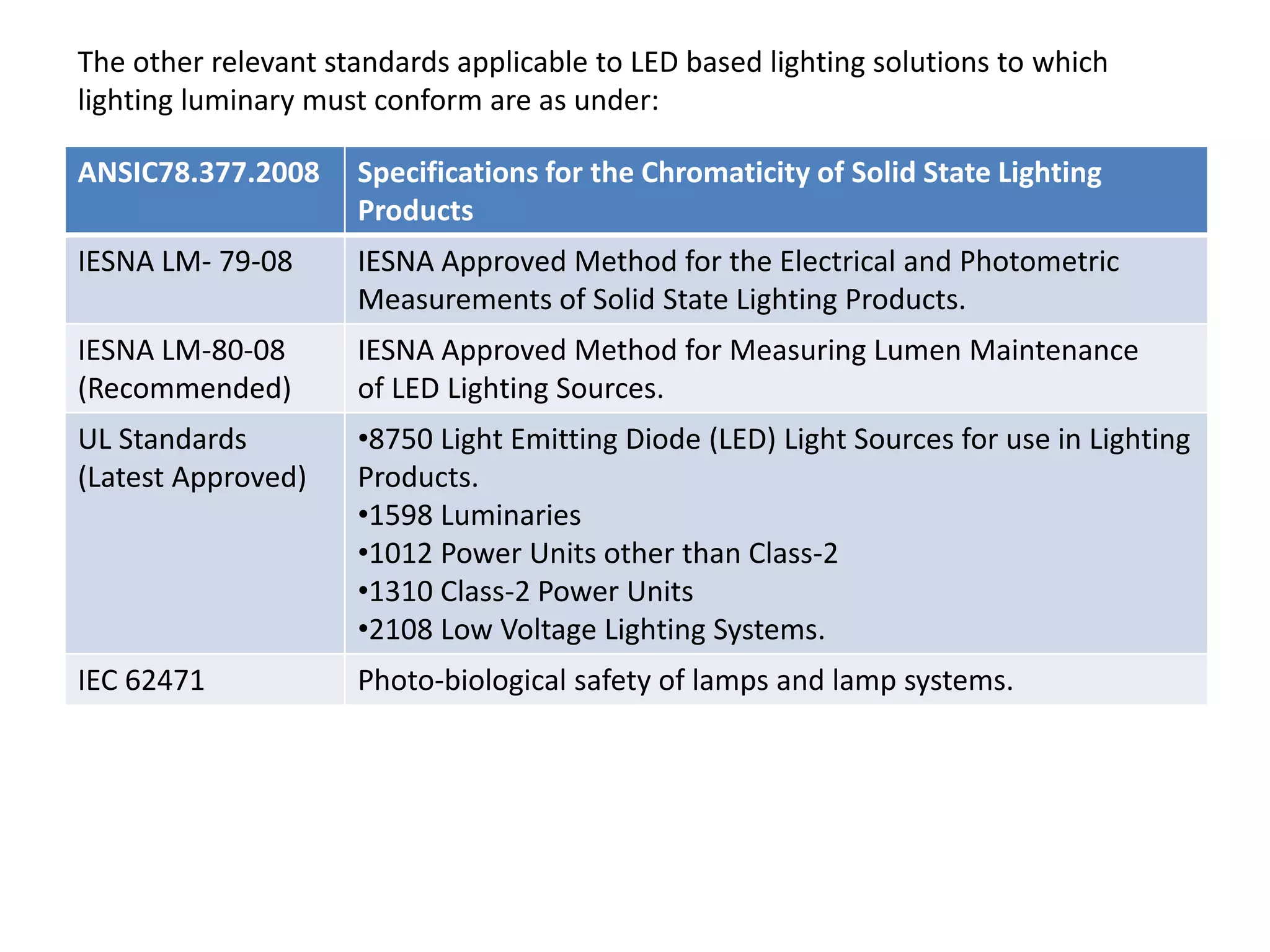

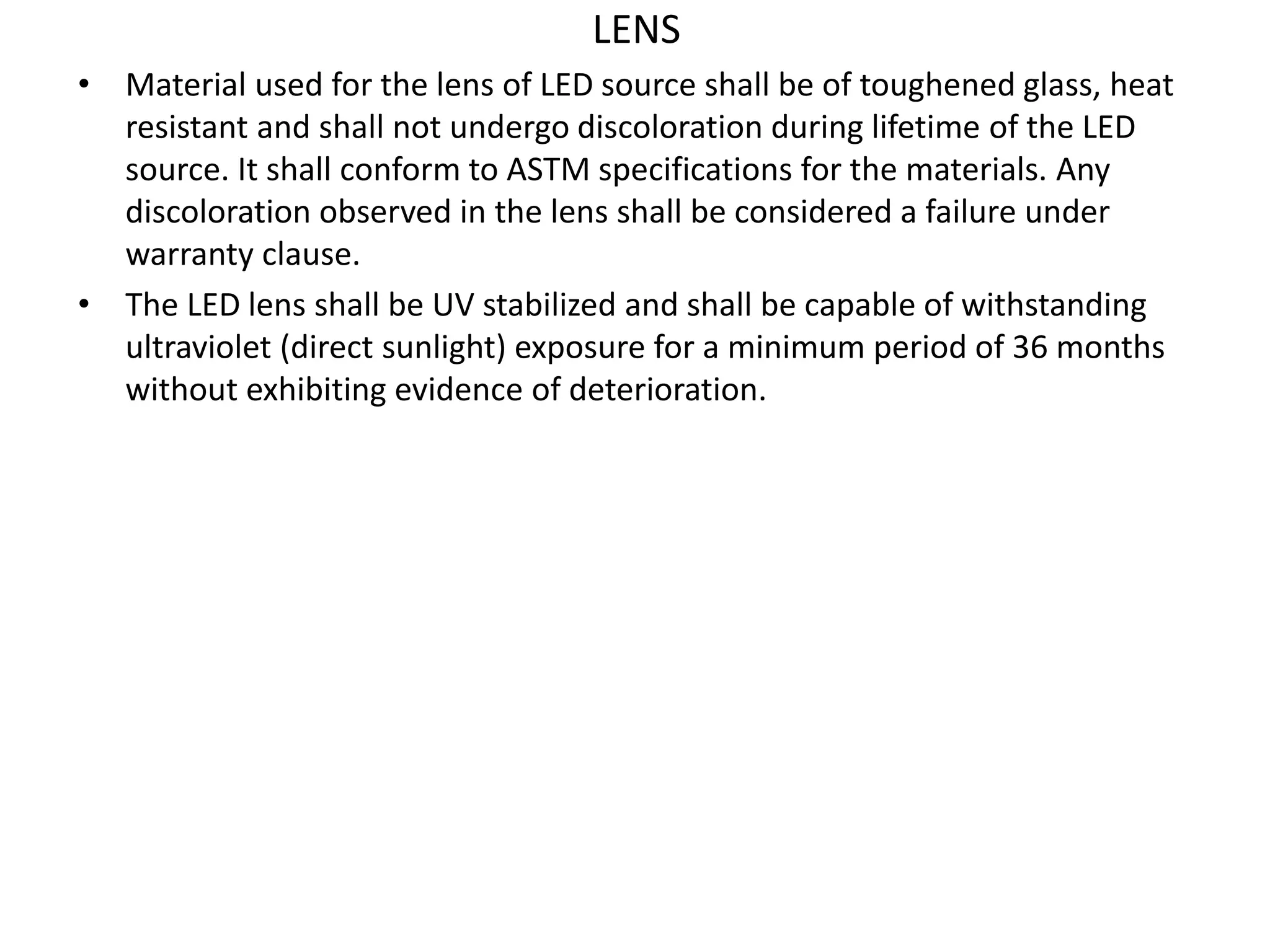

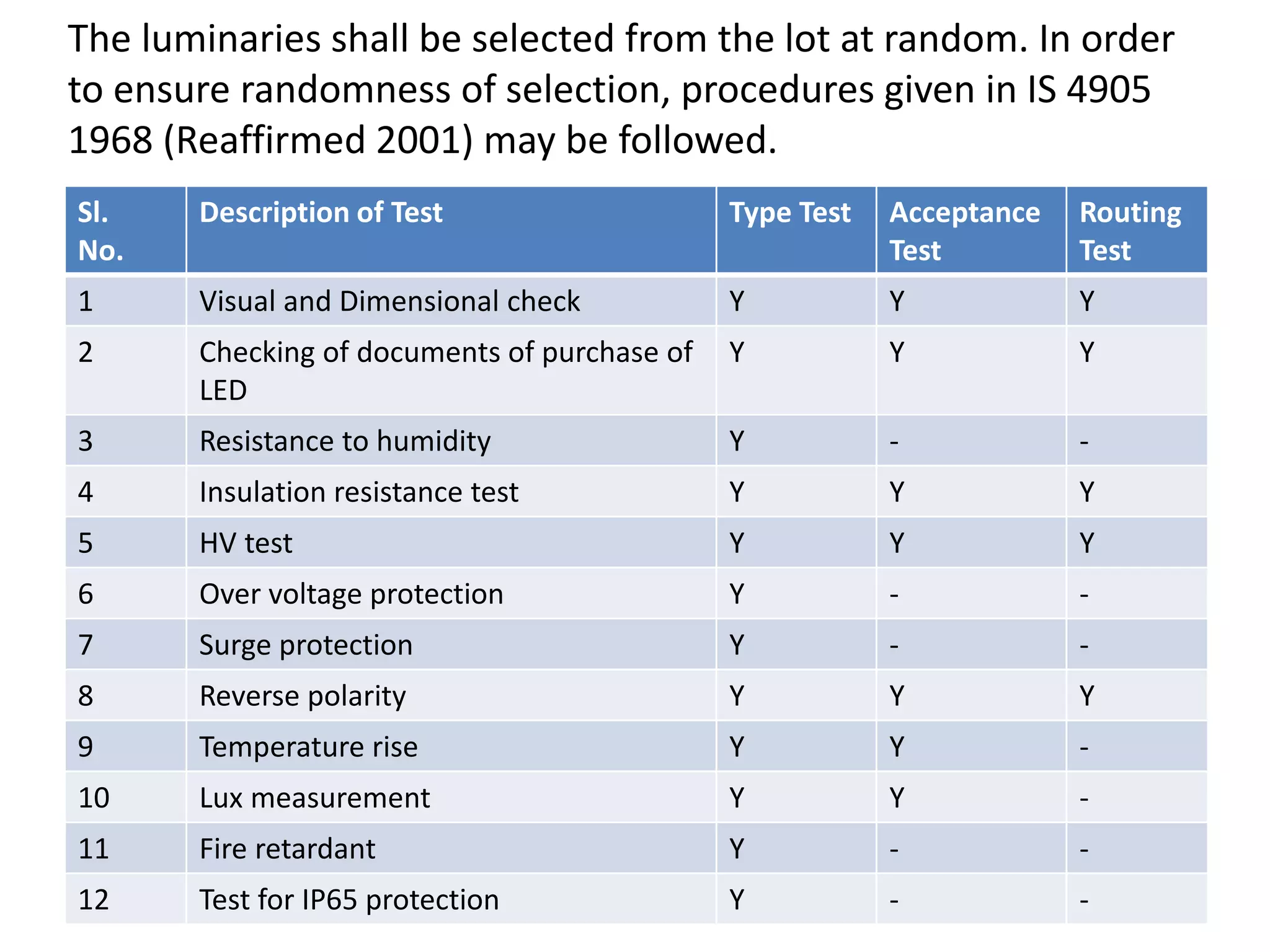

The document outlines specifications for the design, manufacturing, and supply of energy-efficient LED lighting systems, emphasizing high power SMD LEDs with a minimum luminous efficiency of 100 lumens/watt, and a lifespan of 40,000 hours. It details requirements for thermal management, safety standards, and compliance with various international norms, while specifying construction materials and testing protocols for quality assurance. Suppliers are required to provide certification and test reports to confirm adherence to stated performance and safety criteria.