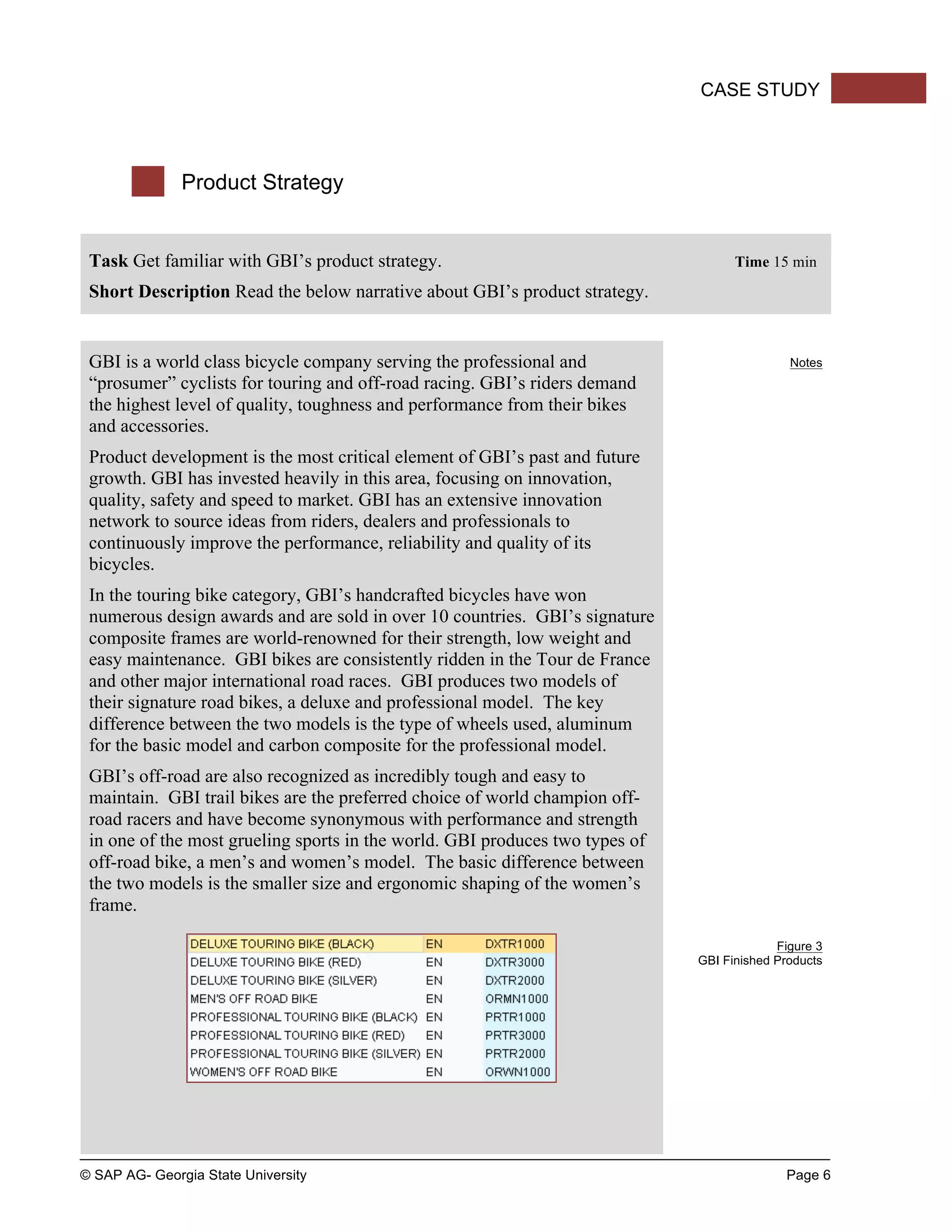

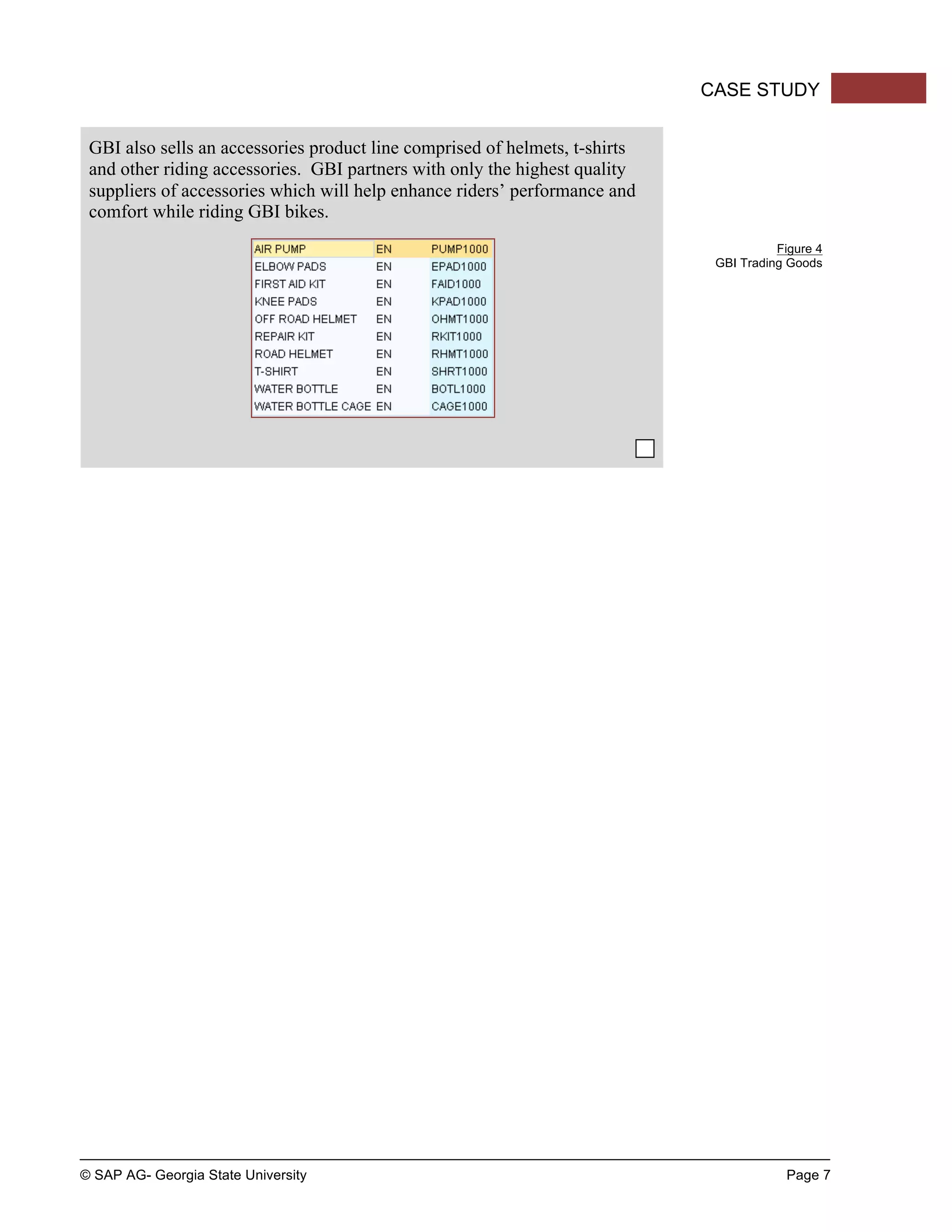

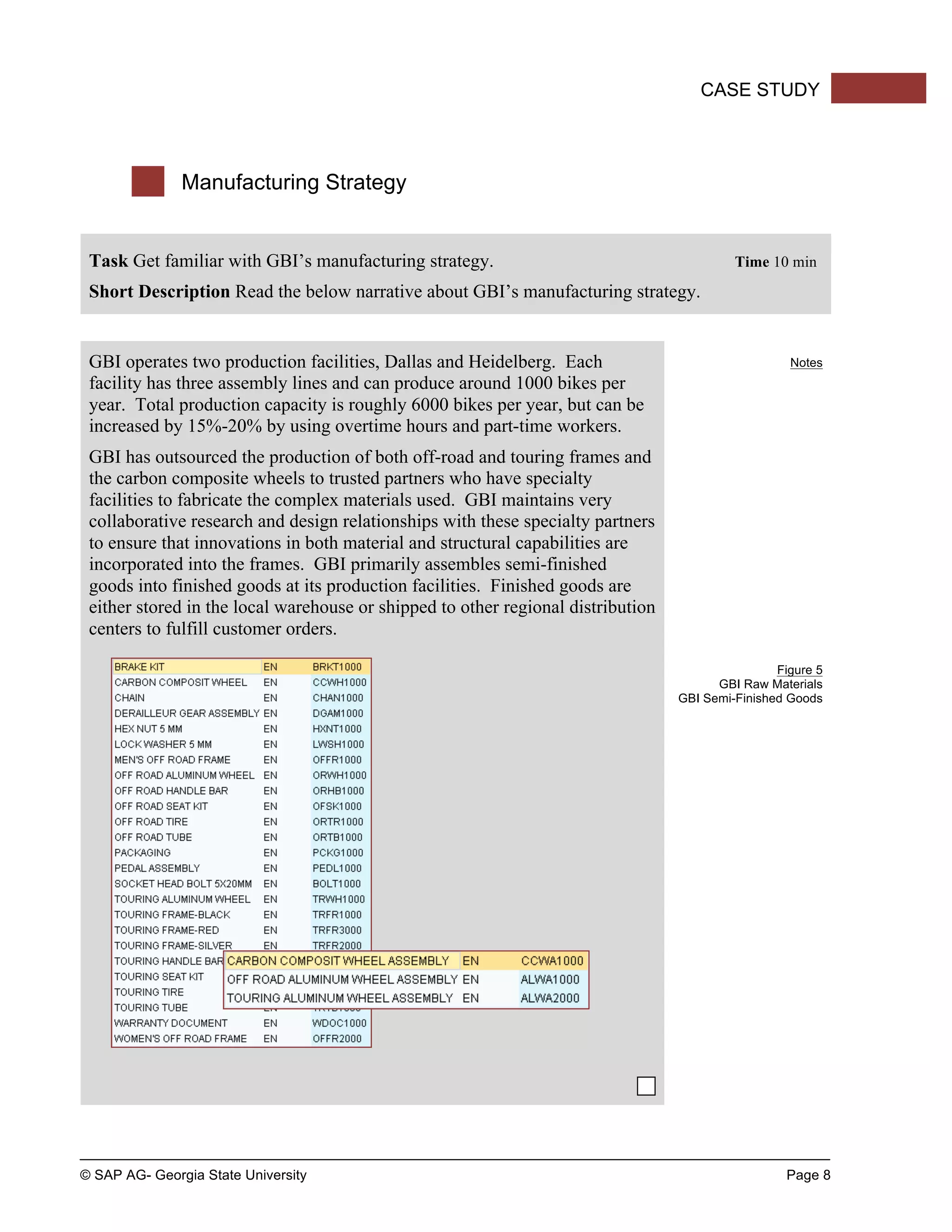

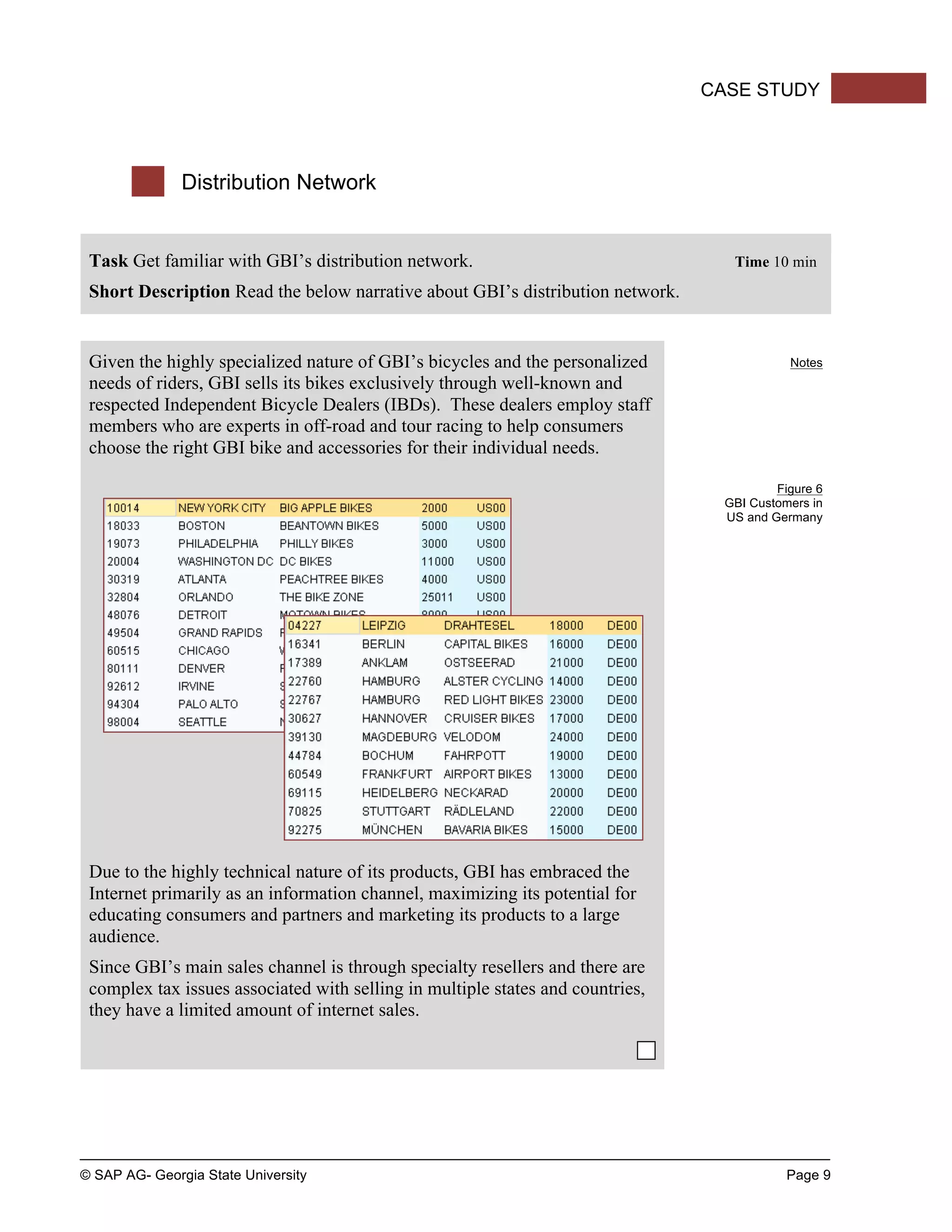

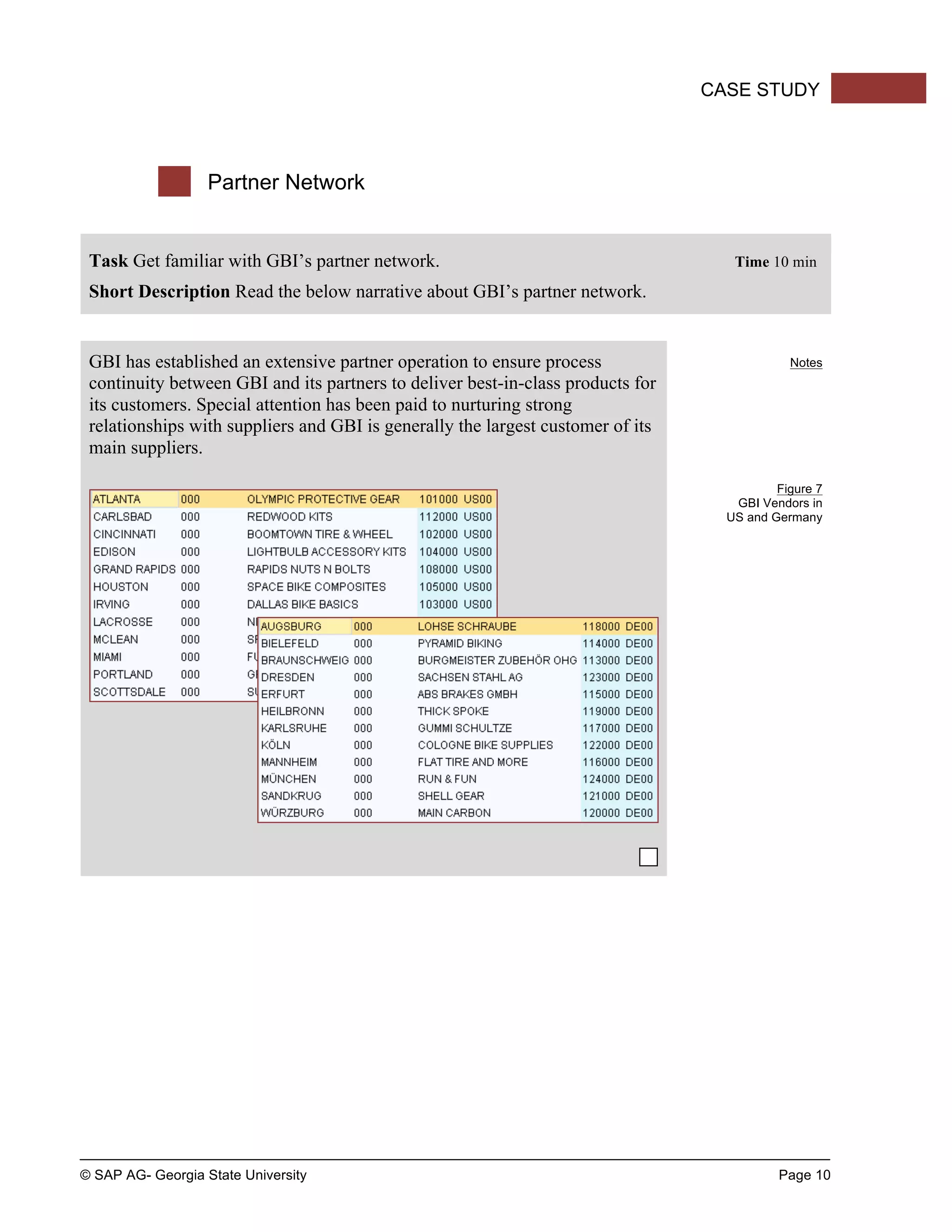

Global Bike Inc. (GBI) is a bicycle manufacturer formed through the merger of Frankenstein Bikes and Heidelberg Composites. GBI produces high-performance road and off-road bicycles and accessories. It has headquarters in Dallas and a subsidiary, GBI Europe, based in Heidelberg. GBI focuses on innovation, quality, and performance and has manufacturing facilities in Dallas and Heidelberg. Each facility has three assembly lines and can produce around 1,000 bikes per year to meet demand from professional and recreational cyclists worldwide.