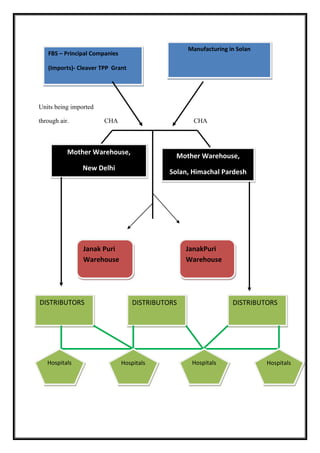

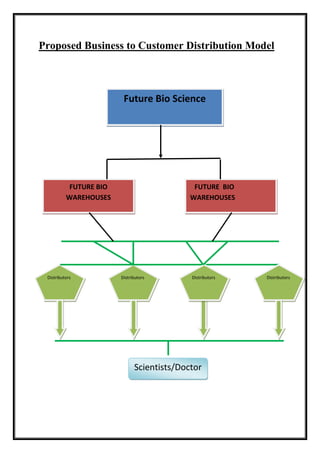

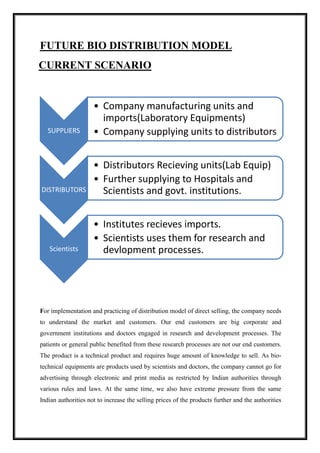

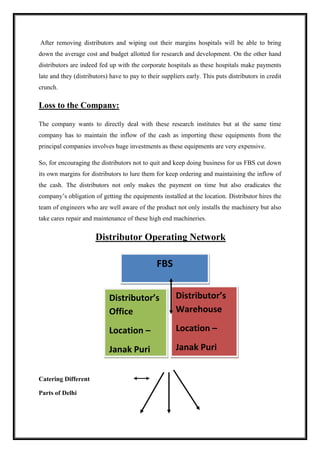

This document provides an overview of a report on understanding procurement and distribution models for a company called Future Bio Science. It discusses direct and indirect procurement, types of distribution channels, and gives profiles of some of Future Bio Science's principal companies that it imports biotechnical equipment from, such as Cleaver Scientific, Techno Plastic Products, and Biocision. The objectives of the report and internship were to analyze Future Bio Science's distribution policy and processes around procurement, imports, inventory management and other supply chain functions.