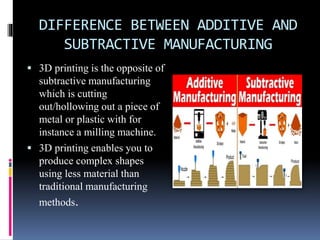

The document discusses fused deposition modeling (FDM), a type of 3D printing where melted plastic filaments are deposited layer by layer to build an object based on a digital design file. FDM was developed in the 1980s and involves a print head that moves in X and Y directions over a build platform, extruding melted plastic through a nozzle to form layers matching the CAD model. The process builds objects using less material than traditional manufacturing methods and can create complex shapes.