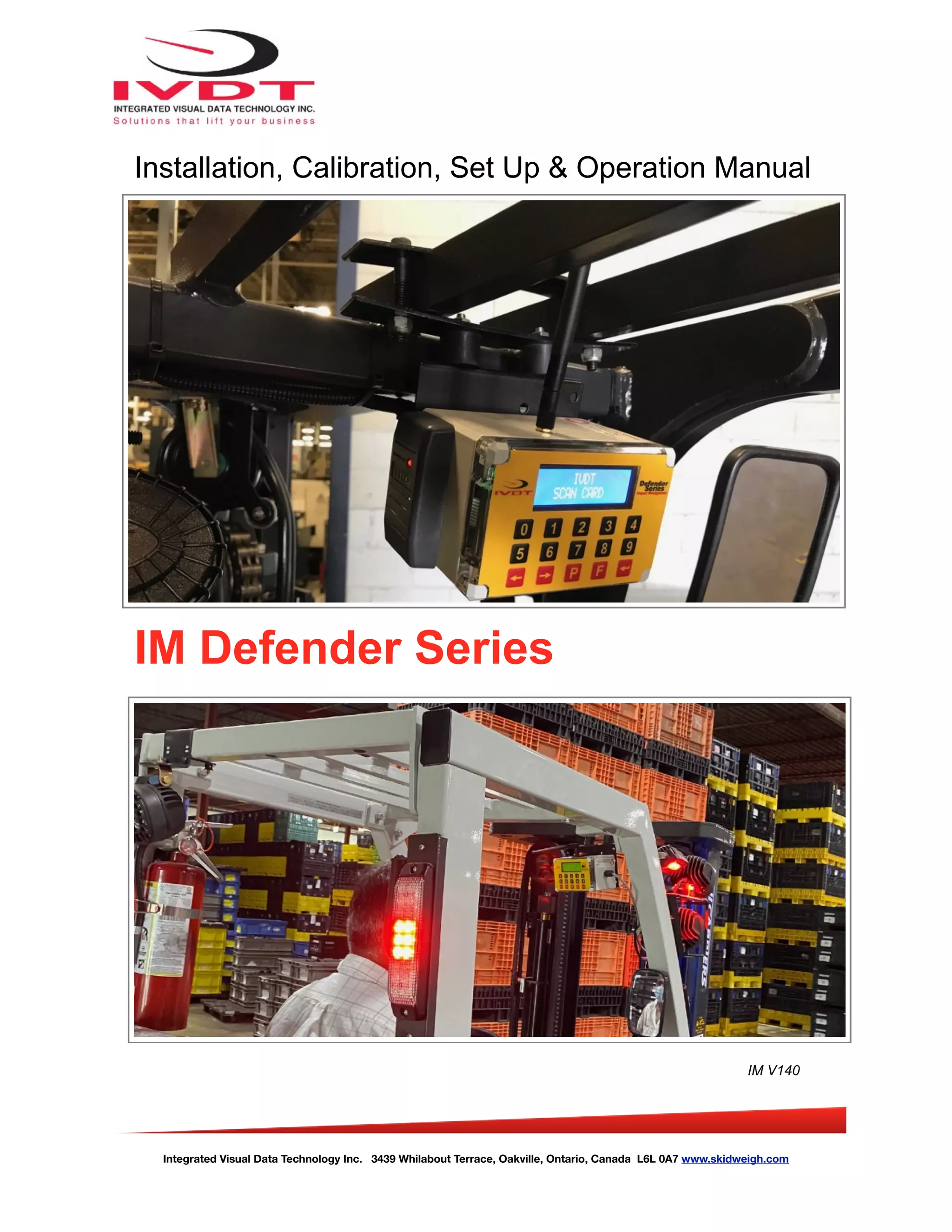

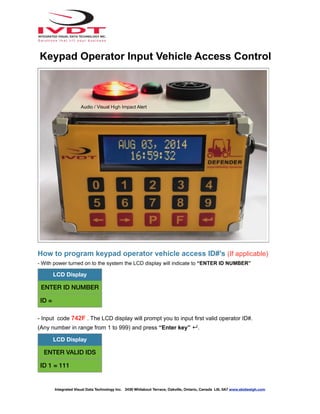

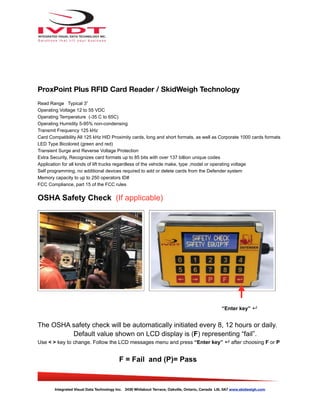

The document provides installation and operation instructions for the IM Defender V140 onboard weighing and monitoring system. It describes how to install the system components, run the administration menu to set up vehicle and operator IDs, calibrate the weight scale, program RFID cards for operator access control, and set impact thresholds. Safety guidelines are provided and the system consists of a digital indicator, pressure transducer, and optional additional hardware depending on the configuration.