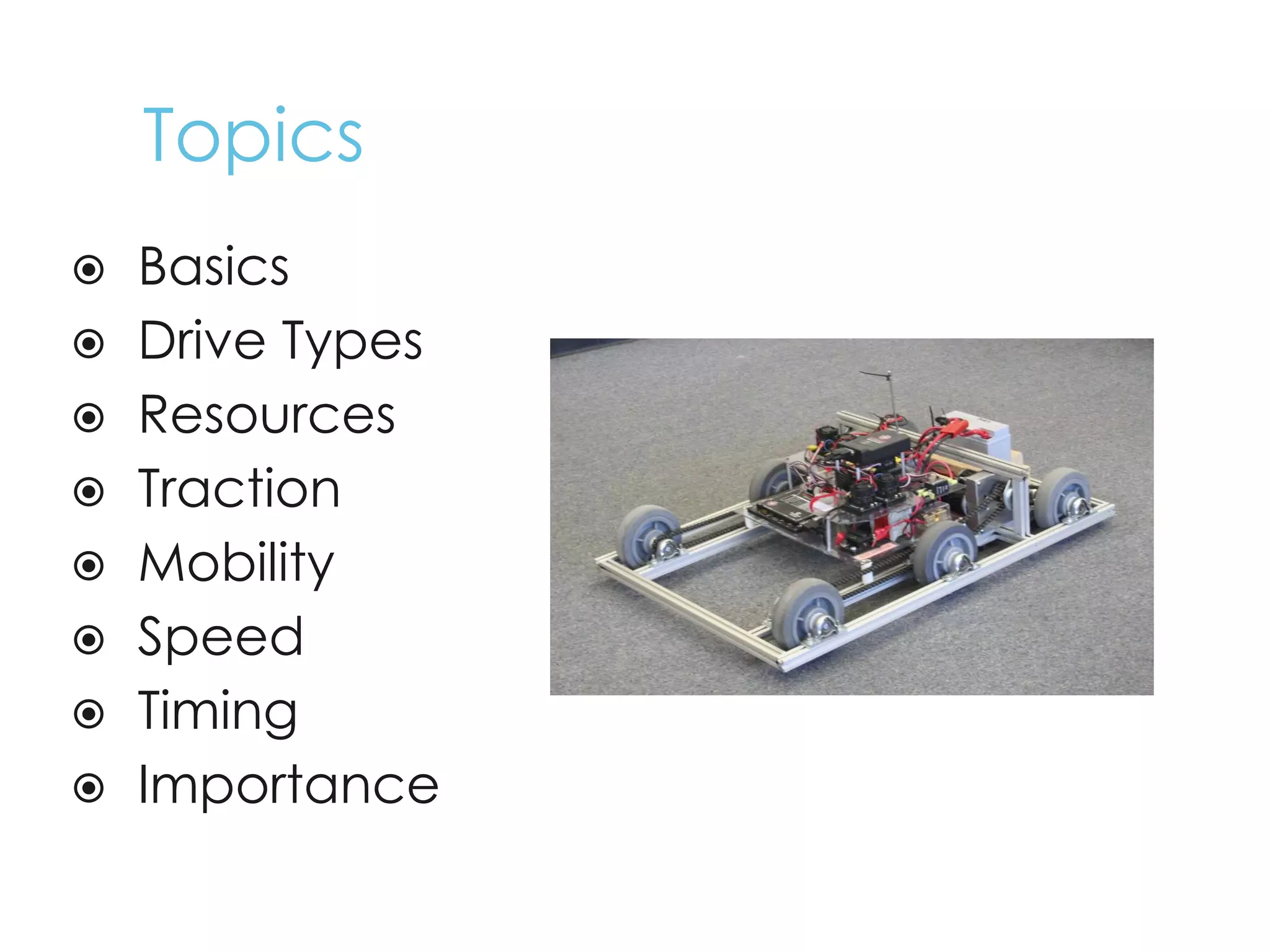

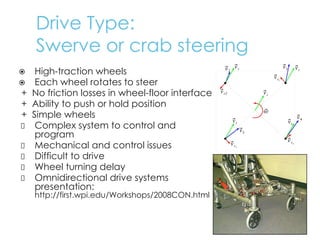

This document provides an overview of important considerations for robot drive systems in FIRST robotics competitions. It discusses different types of drive systems like swerve and crab steering. Key topics covered include choosing drive types based on available resources and priorities for mobility vs traction. The document emphasizes starting drive system development early to allow time for refinement. It also stresses the importance of a reliable drive base, as this can determine whether the robot functions as a useful tool or a "boat anchor" during matches.