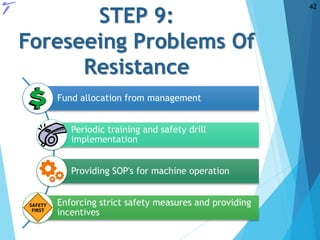

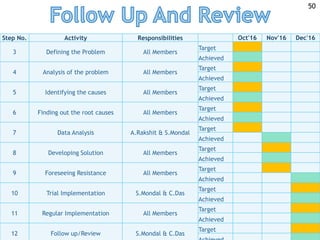

1. The document outlines the steps taken to establish an accident-free production area. It details identifying problems, selecting the highest priority problems, defining and analyzing the problems, identifying causes, developing solutions through trial implementation and follow up.

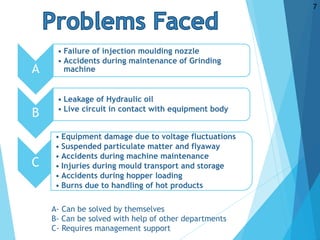

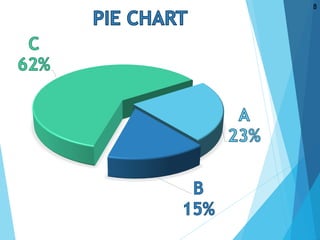

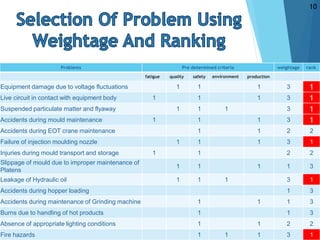

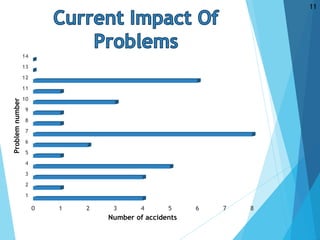

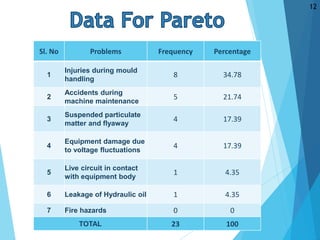

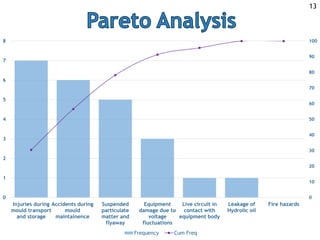

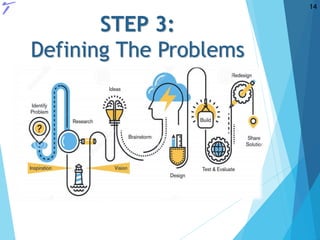

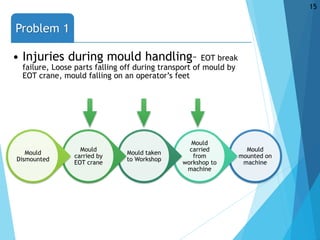

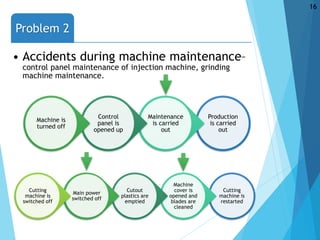

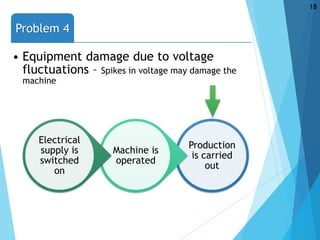

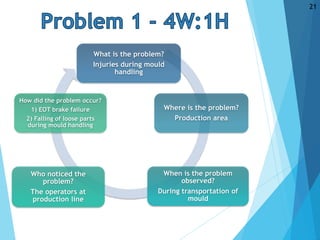

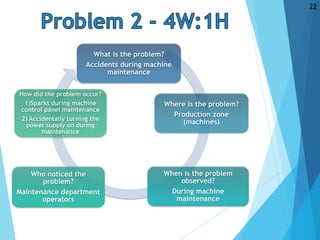

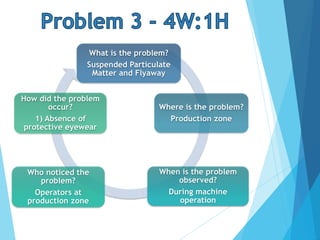

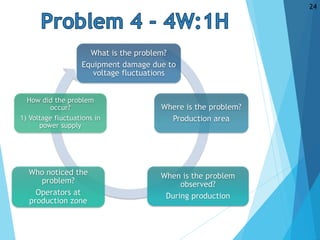

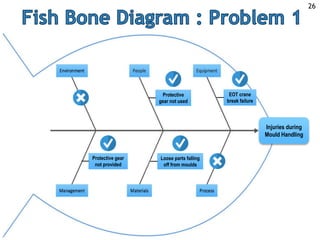

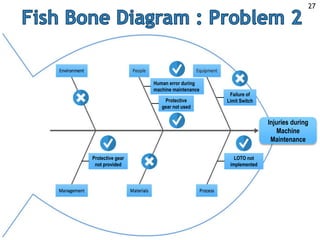

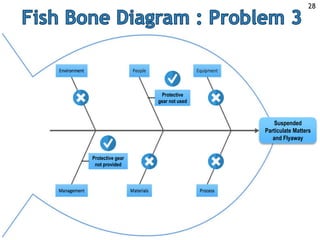

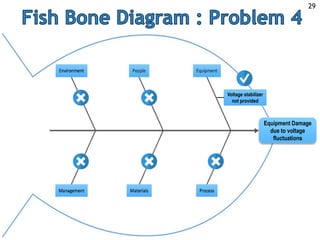

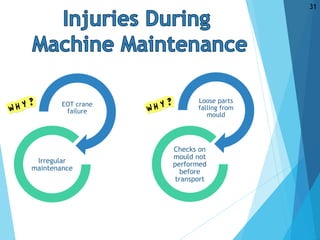

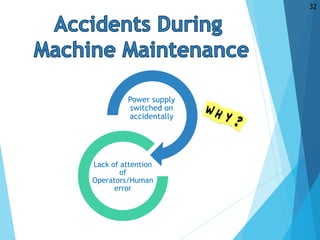

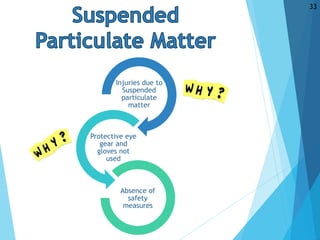

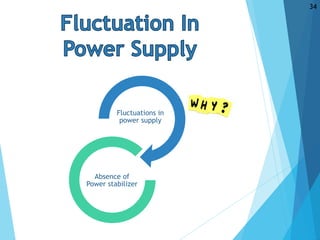

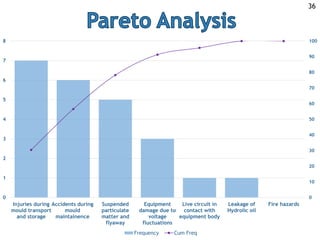

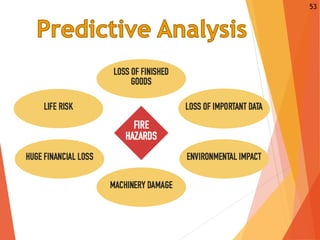

2. The highest priority problems identified were injuries during mould handling, accidents during machine maintenance, suspended particulate matter, and equipment damage from voltage fluctuations.

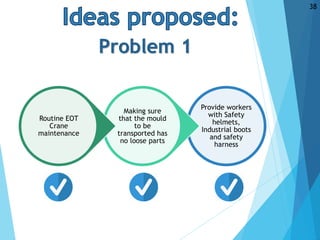

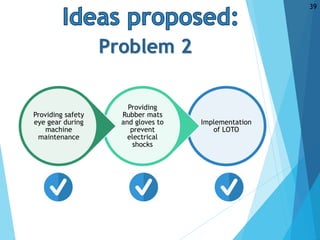

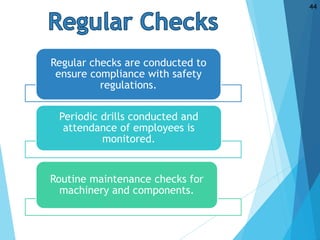

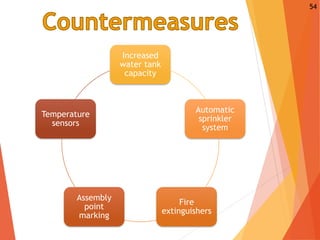

3. Solutions developed and implemented include providing protective gear, implementing lock-out tag-out procedures during maintenance, installing a power stabilizer, and conducting safety trainings and drills.