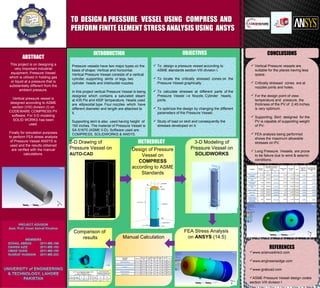

This document discusses the design of a vertical pressure vessel according to ASME standards using various software tools. The pressure vessel is designed to hold saturated steam at 435 Psi and 450F. It includes ellipsoidal heads and four nozzles of varying diameters and lengths. The vessel material is SA-51670 steel. The design is modeled in SOLIDWORKS and analyzed in ANSYS to locate stressed zones and verify stresses are below code limits. The goals are to optimize the design, study loads on the supporting skirt, and compare FEA results to manual calculations.