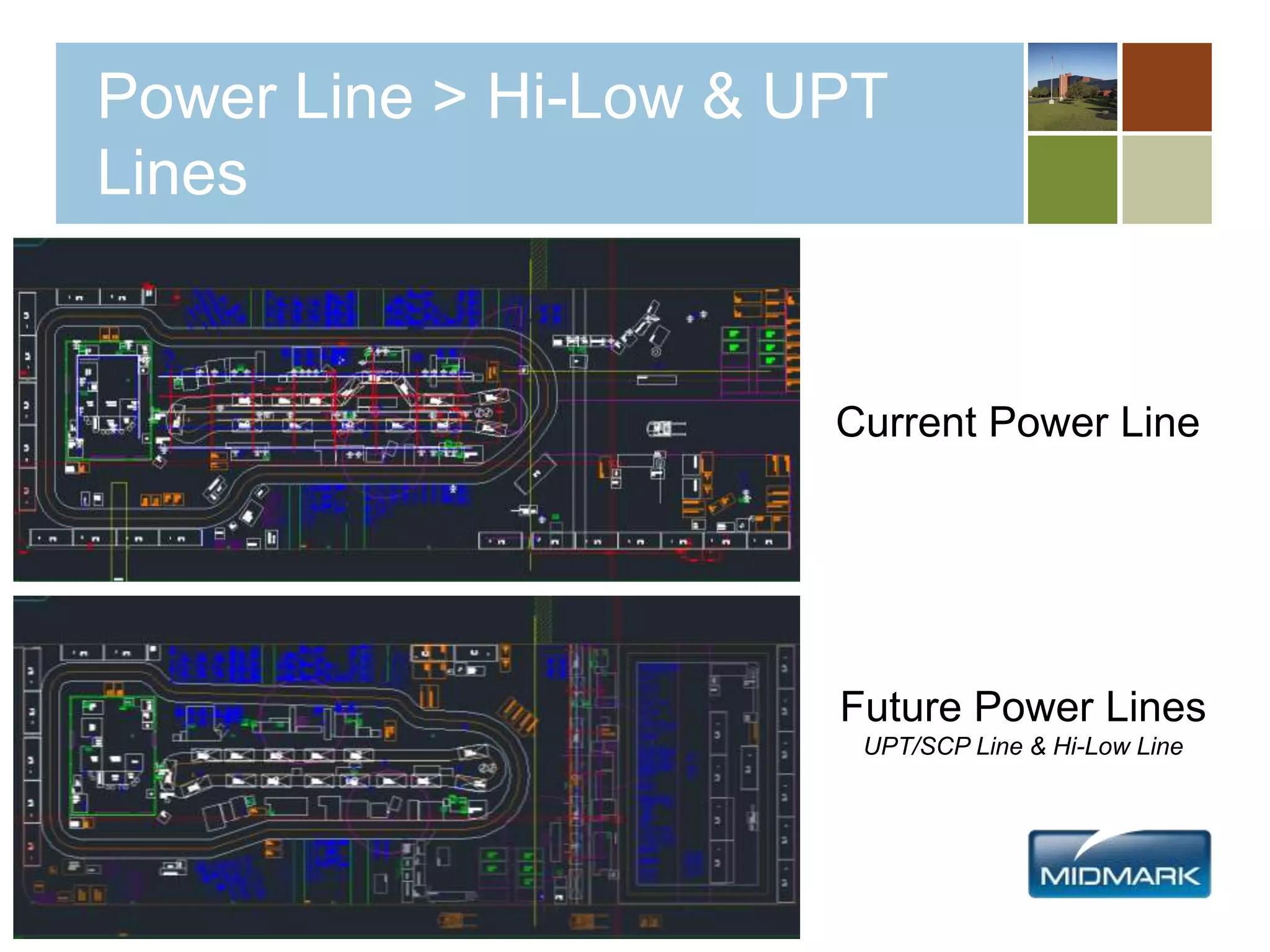

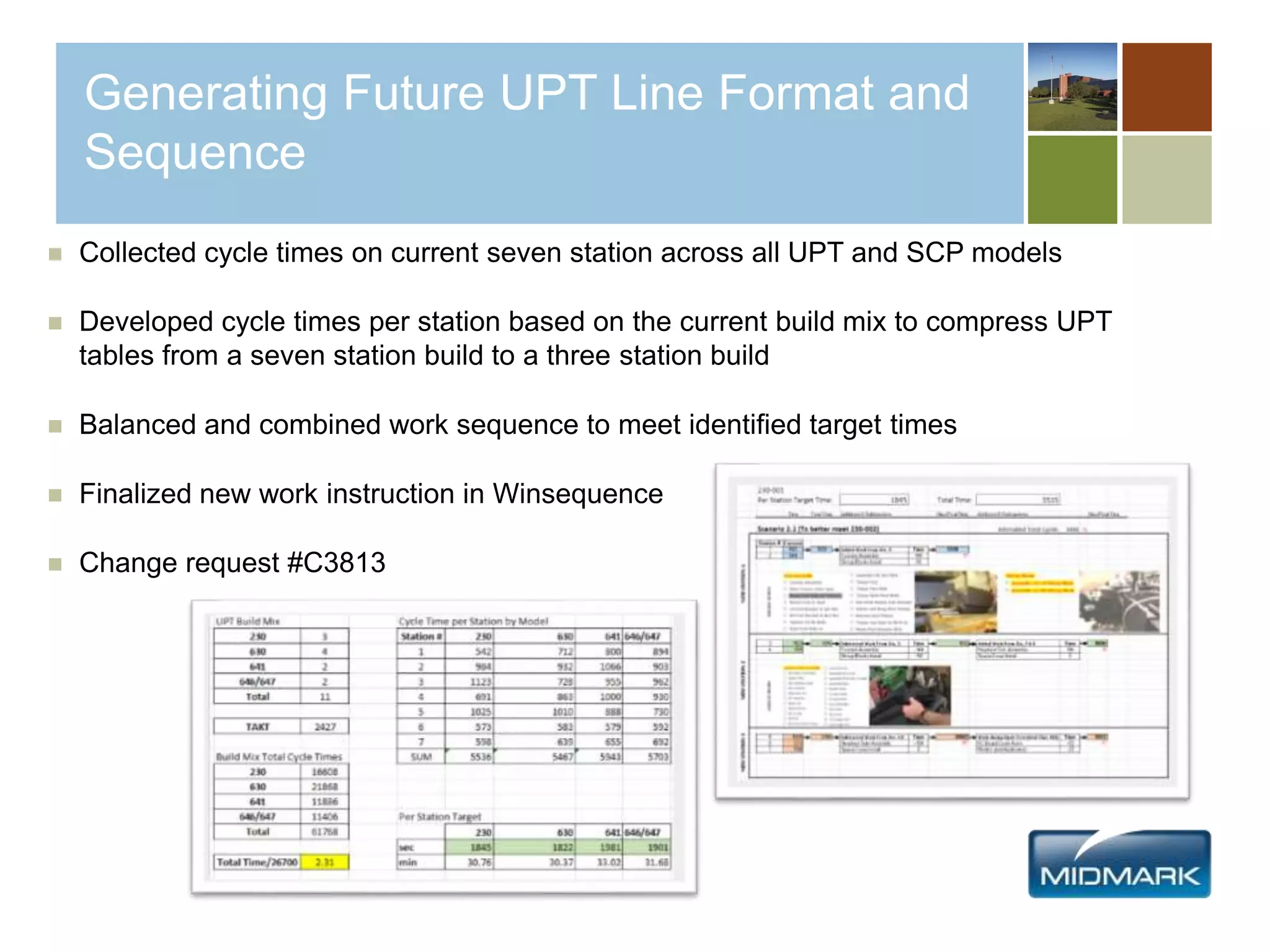

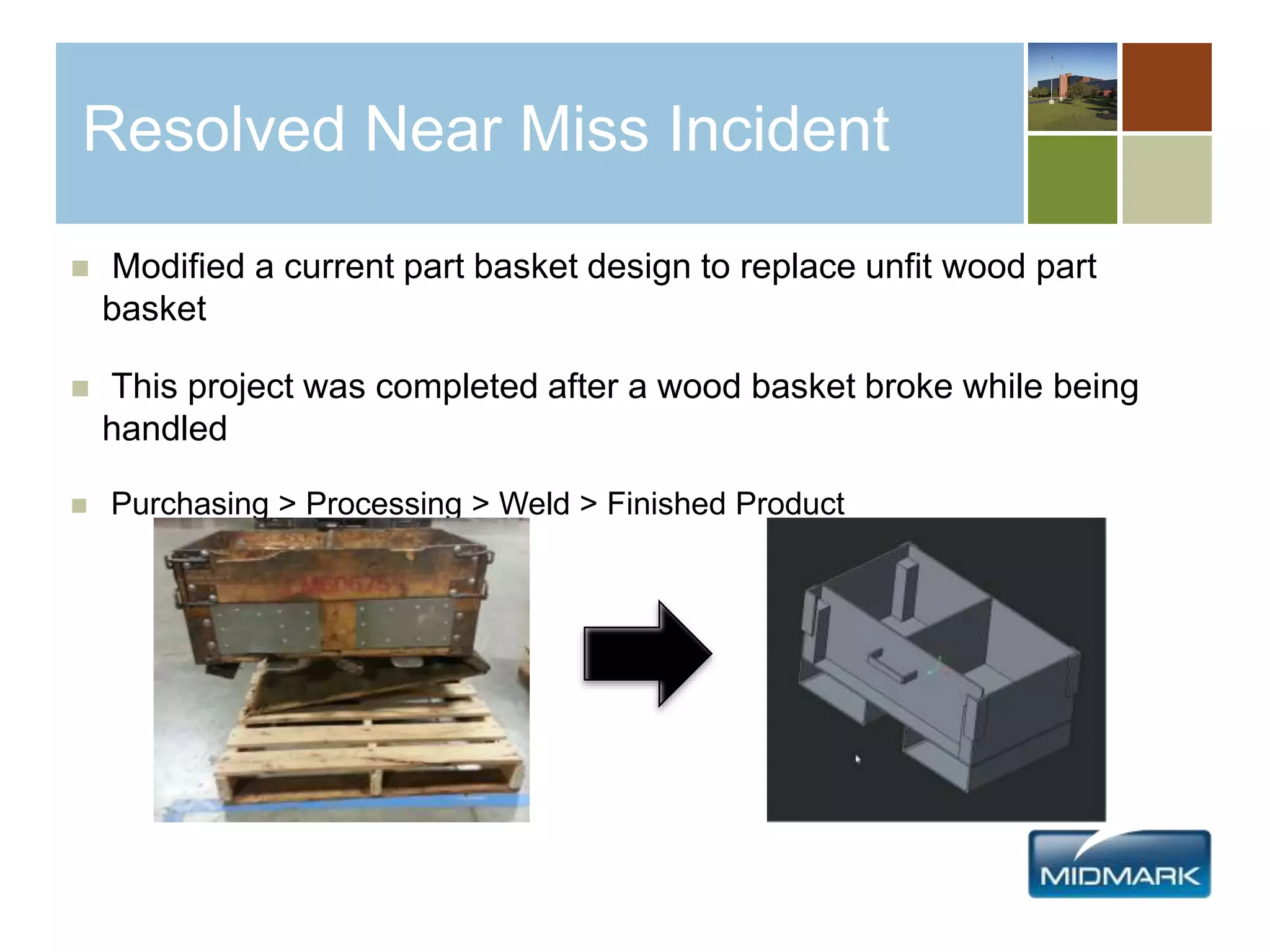

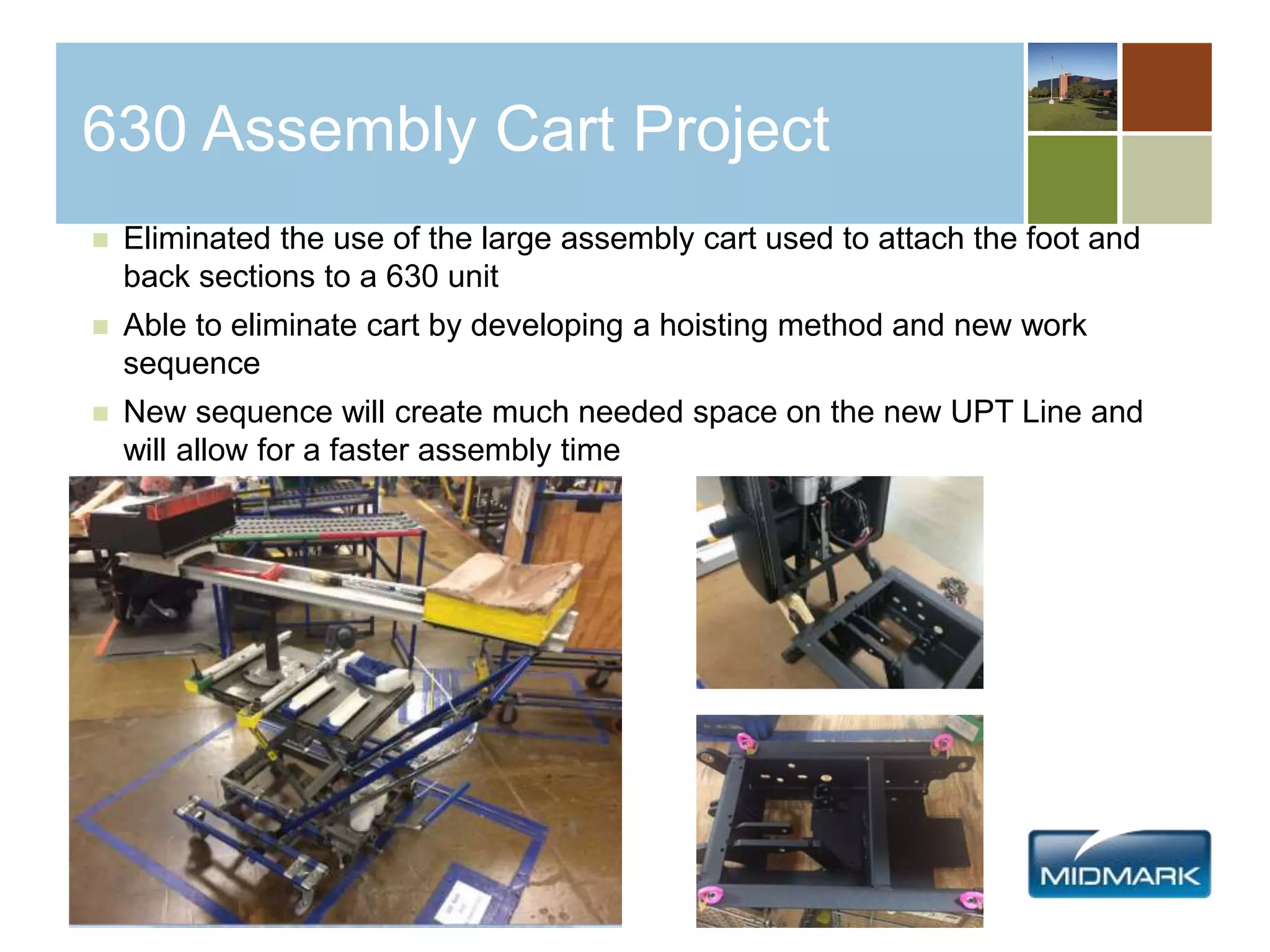

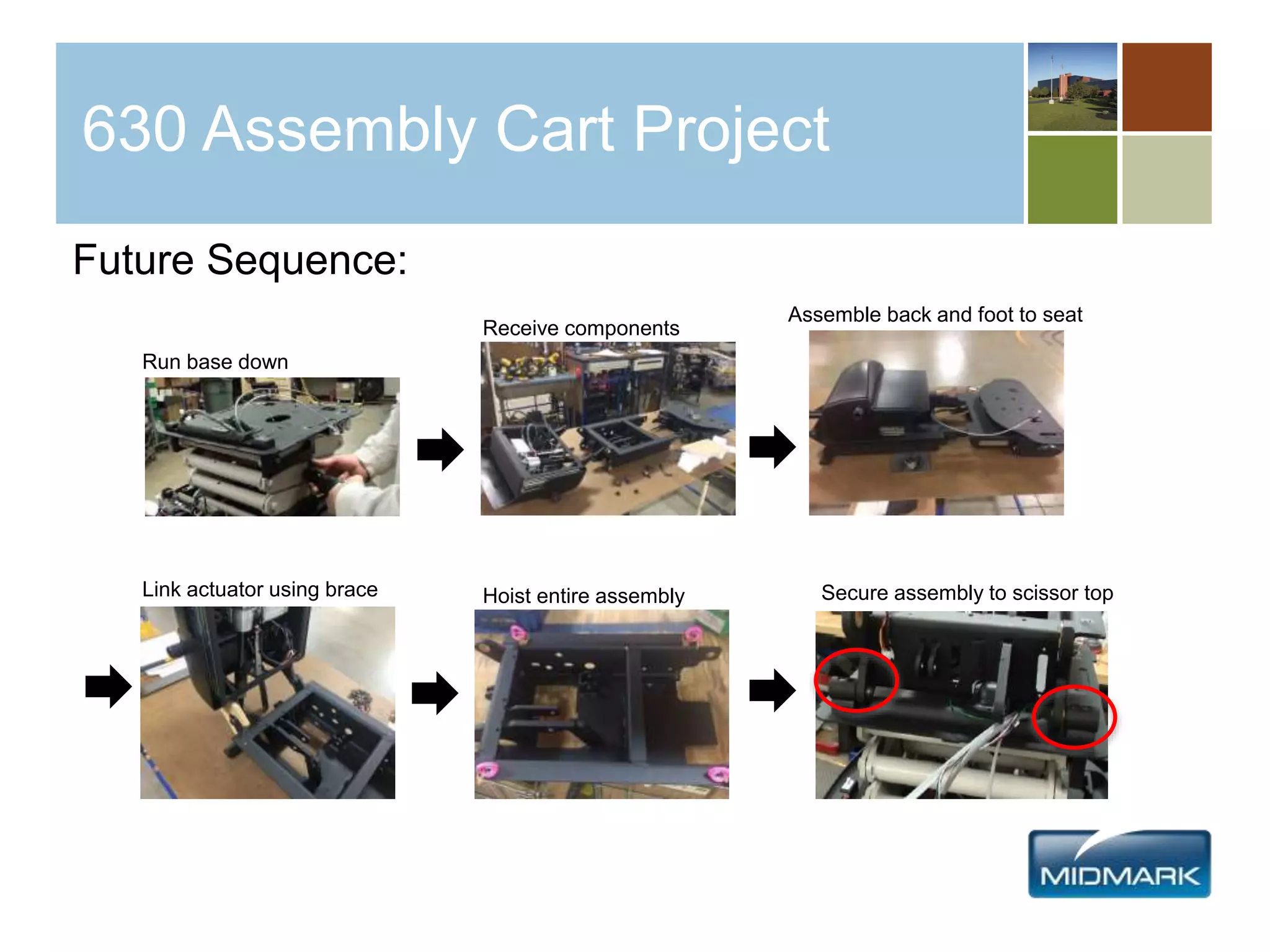

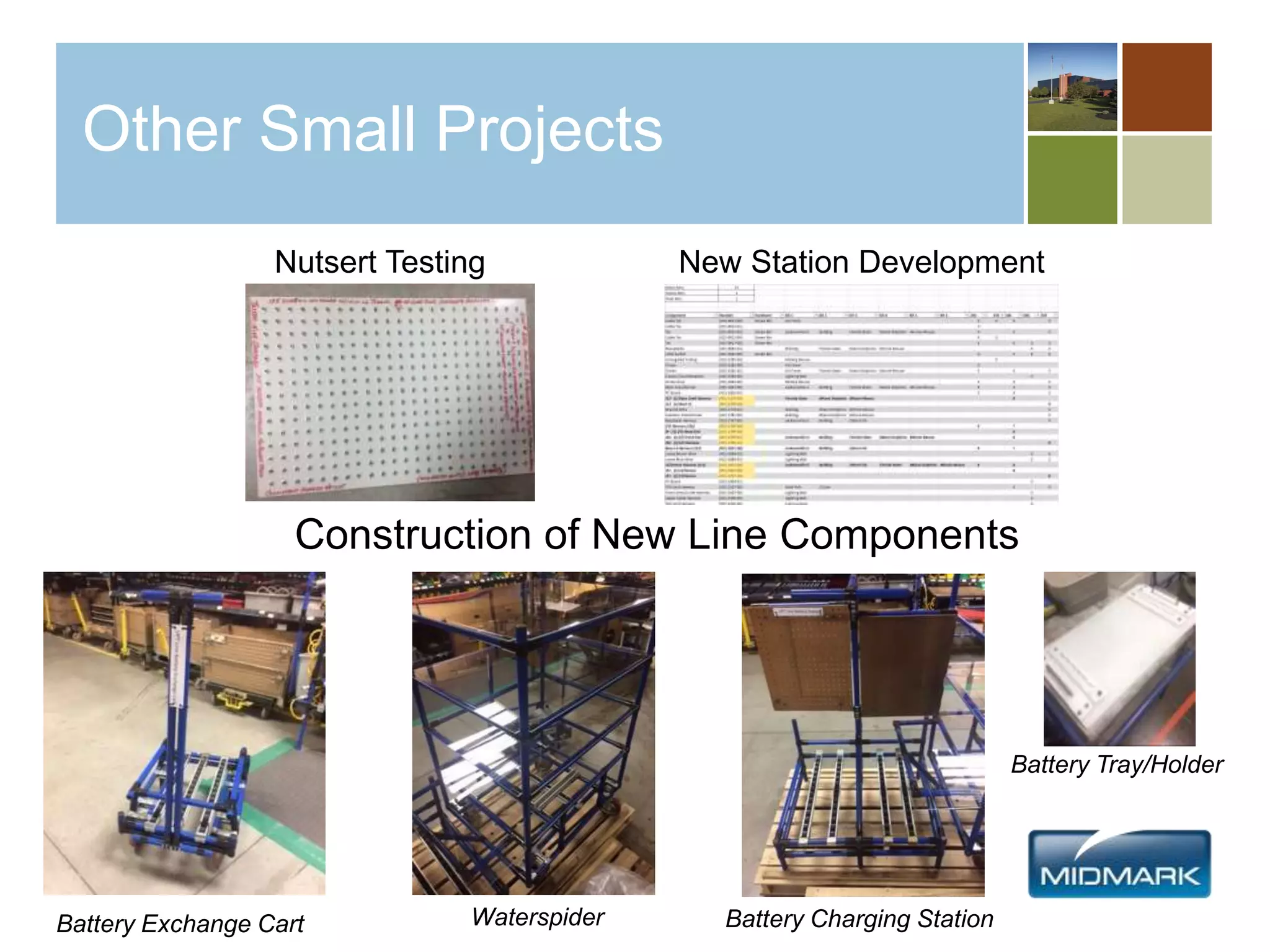

Nick Campbell completed a co-op with Midmark as a Medical Operations intern. During the co-op, he worked on projects like redesigning assembly lines to save time and space, resolving a safety incident, and participating in a Kaizen event. Through the experience, he gained communication, manufacturing, and problem-solving skills. His goals are to continue his education, gain more engineering experience through co-ops, and obtain a mechanical engineering position after graduation.