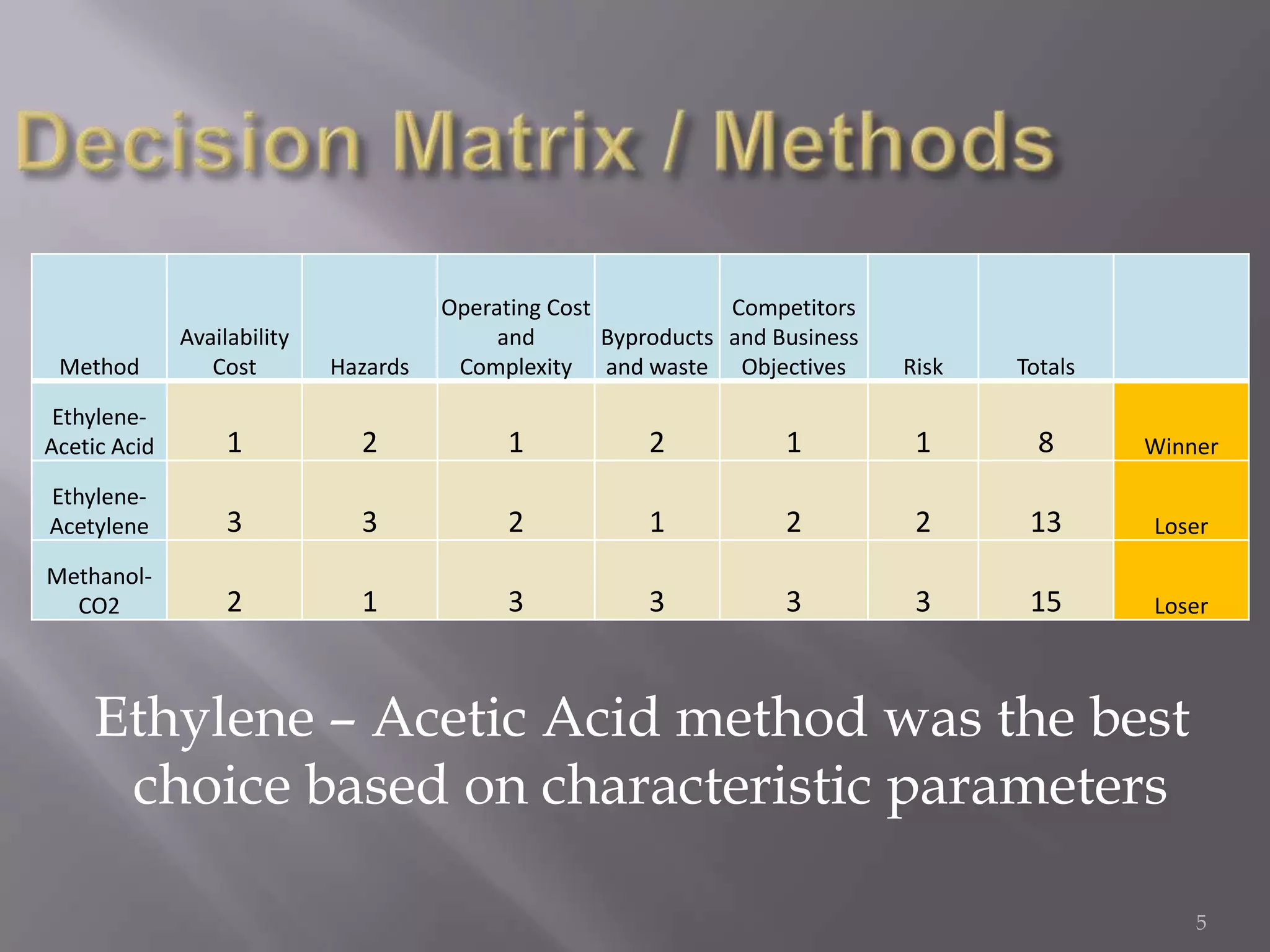

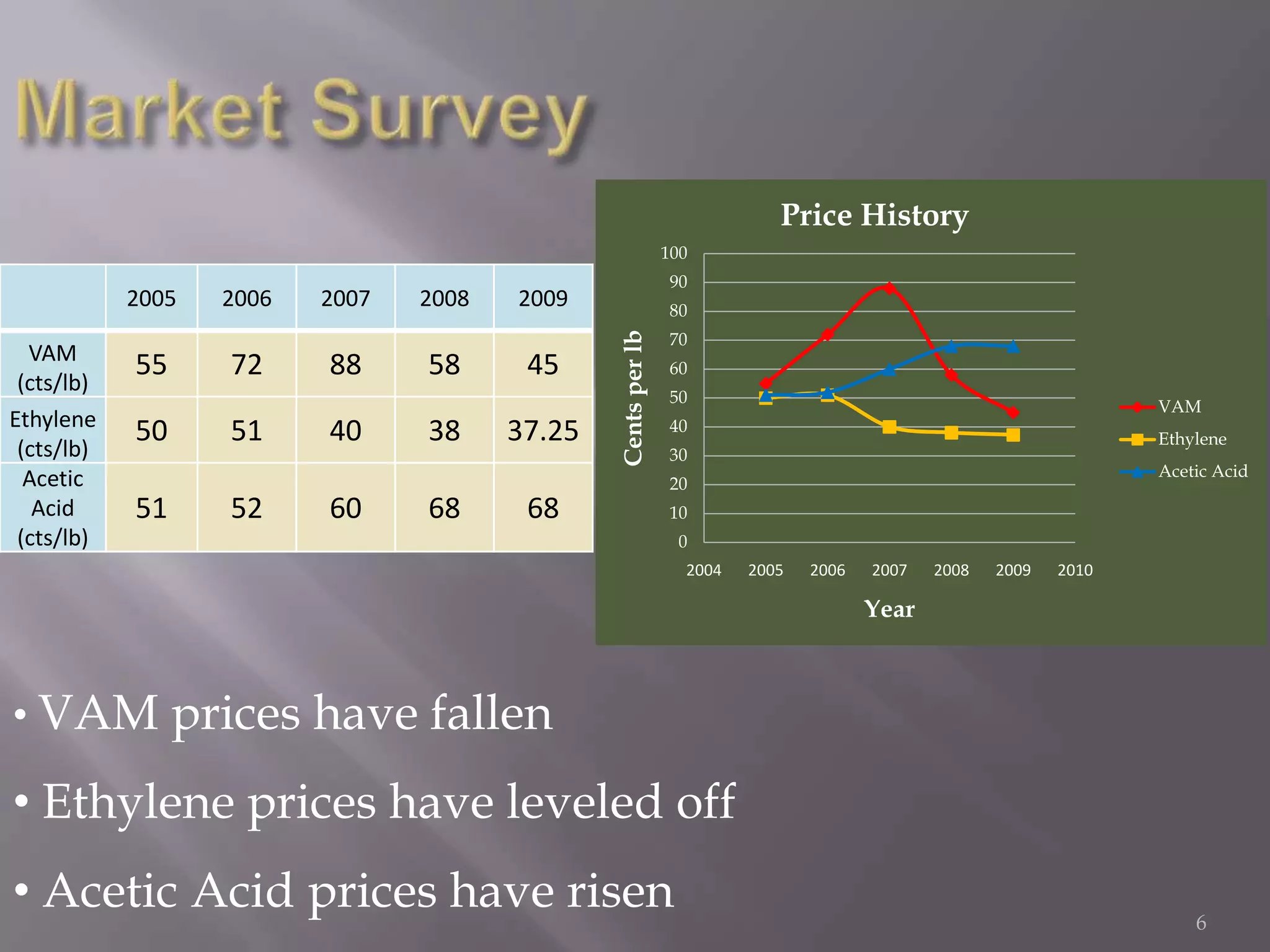

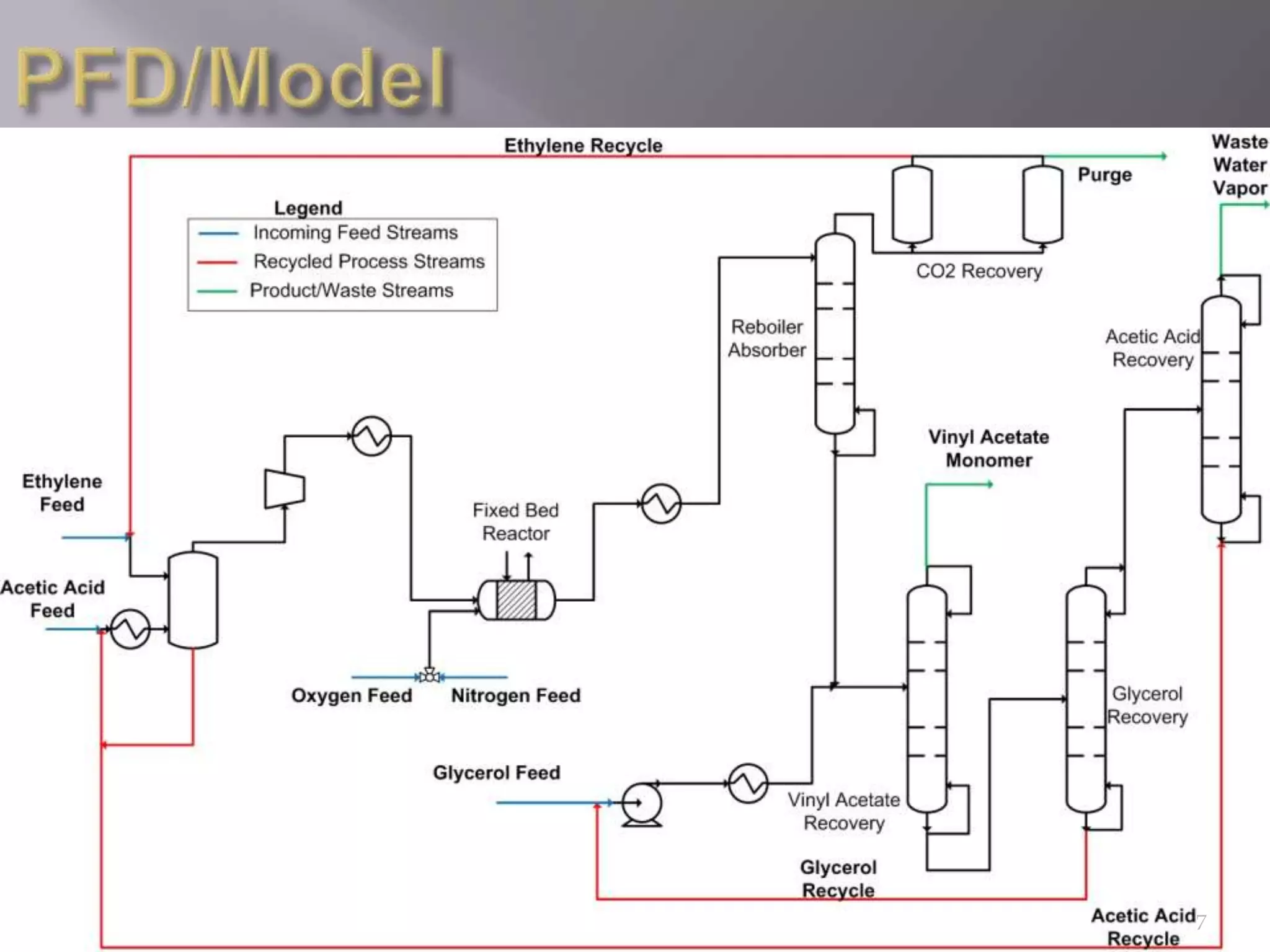

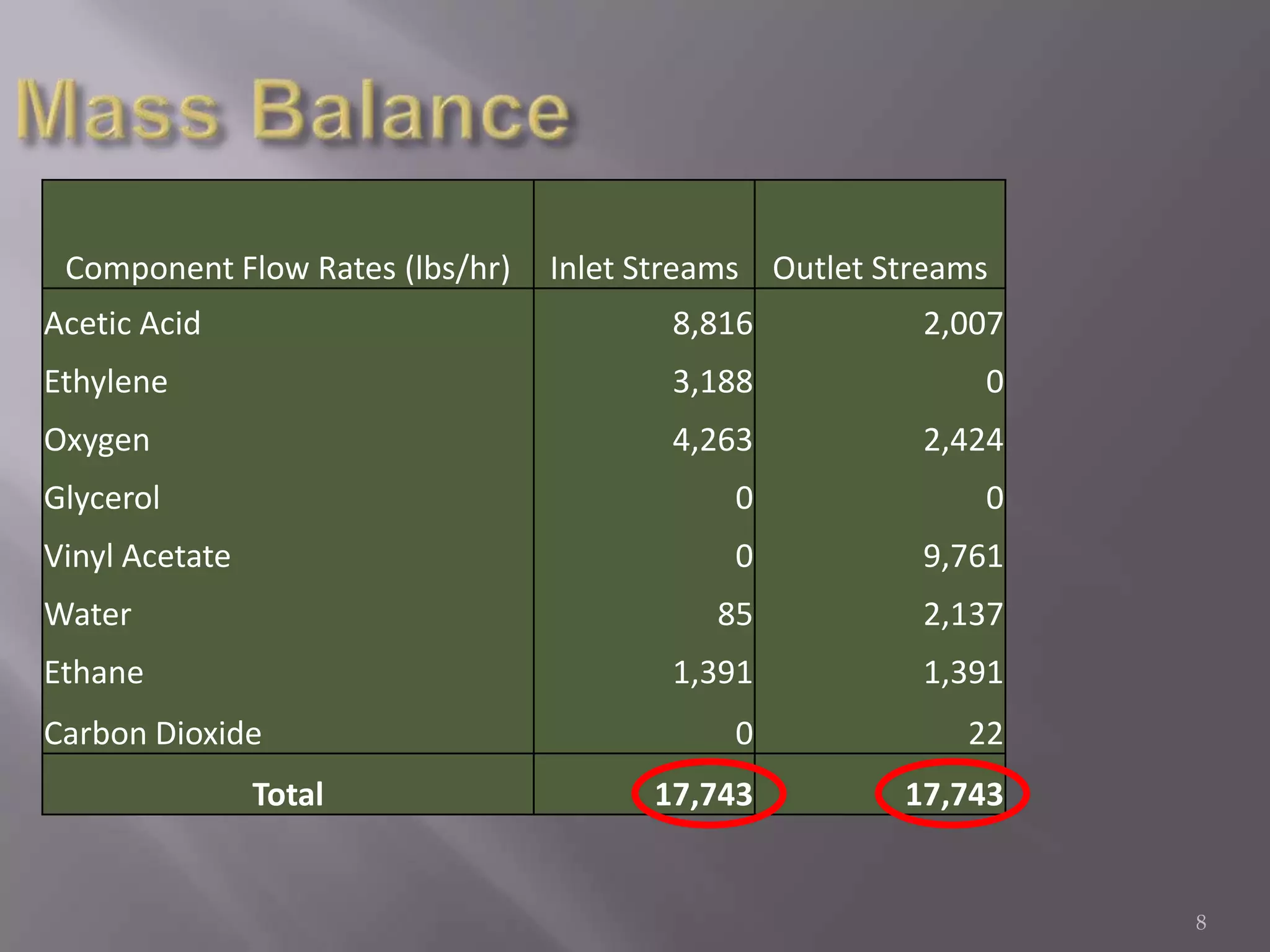

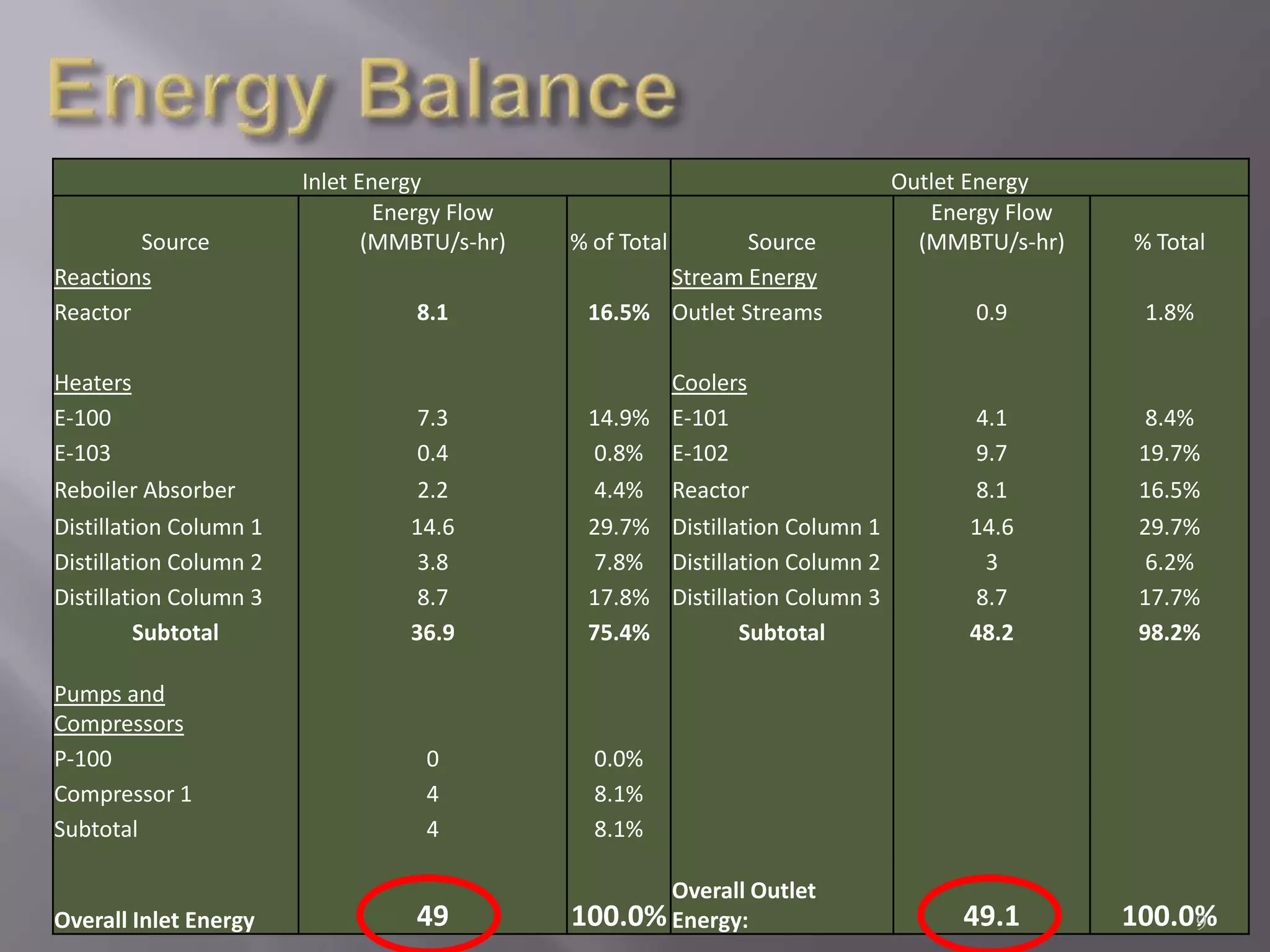

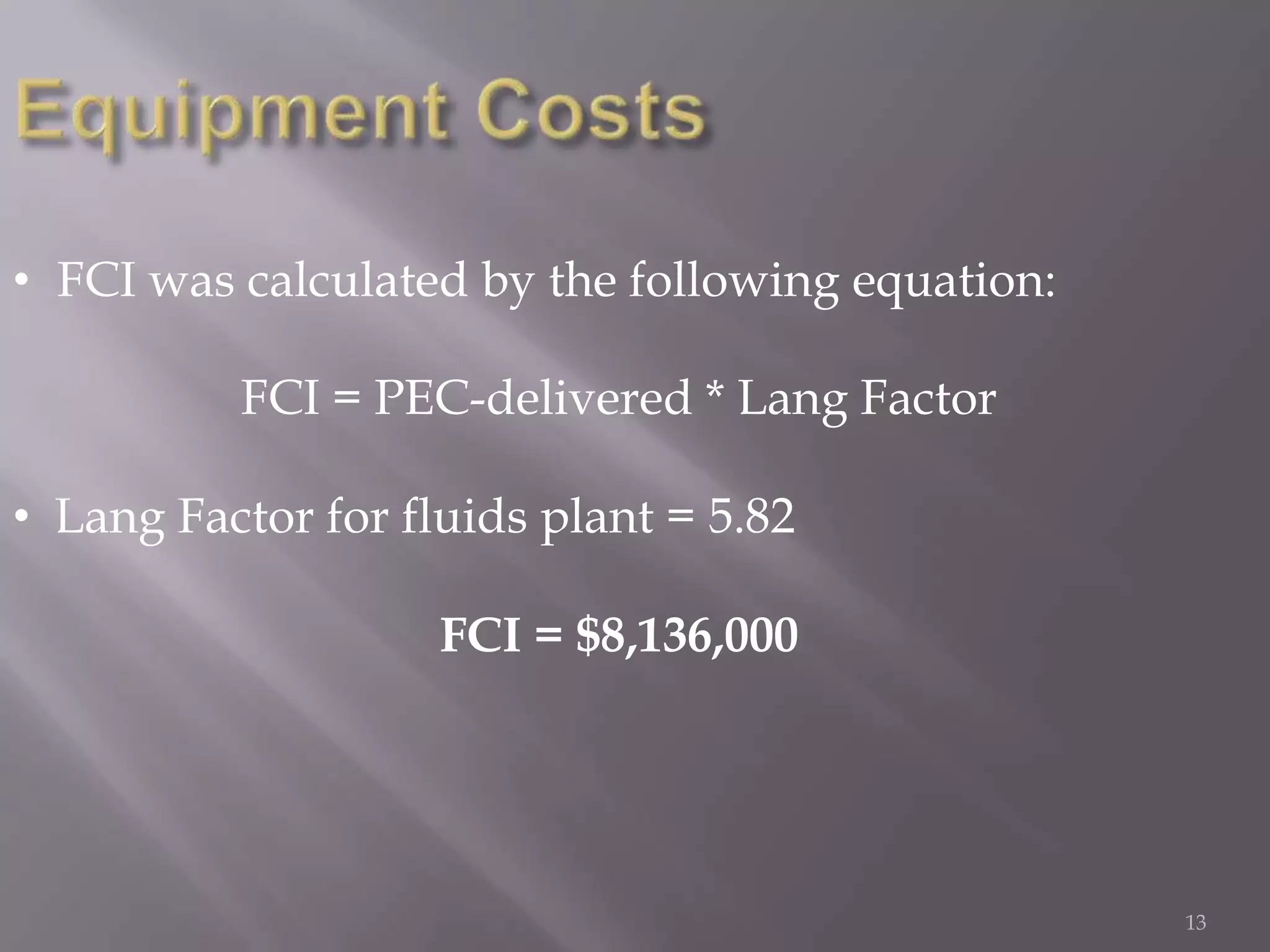

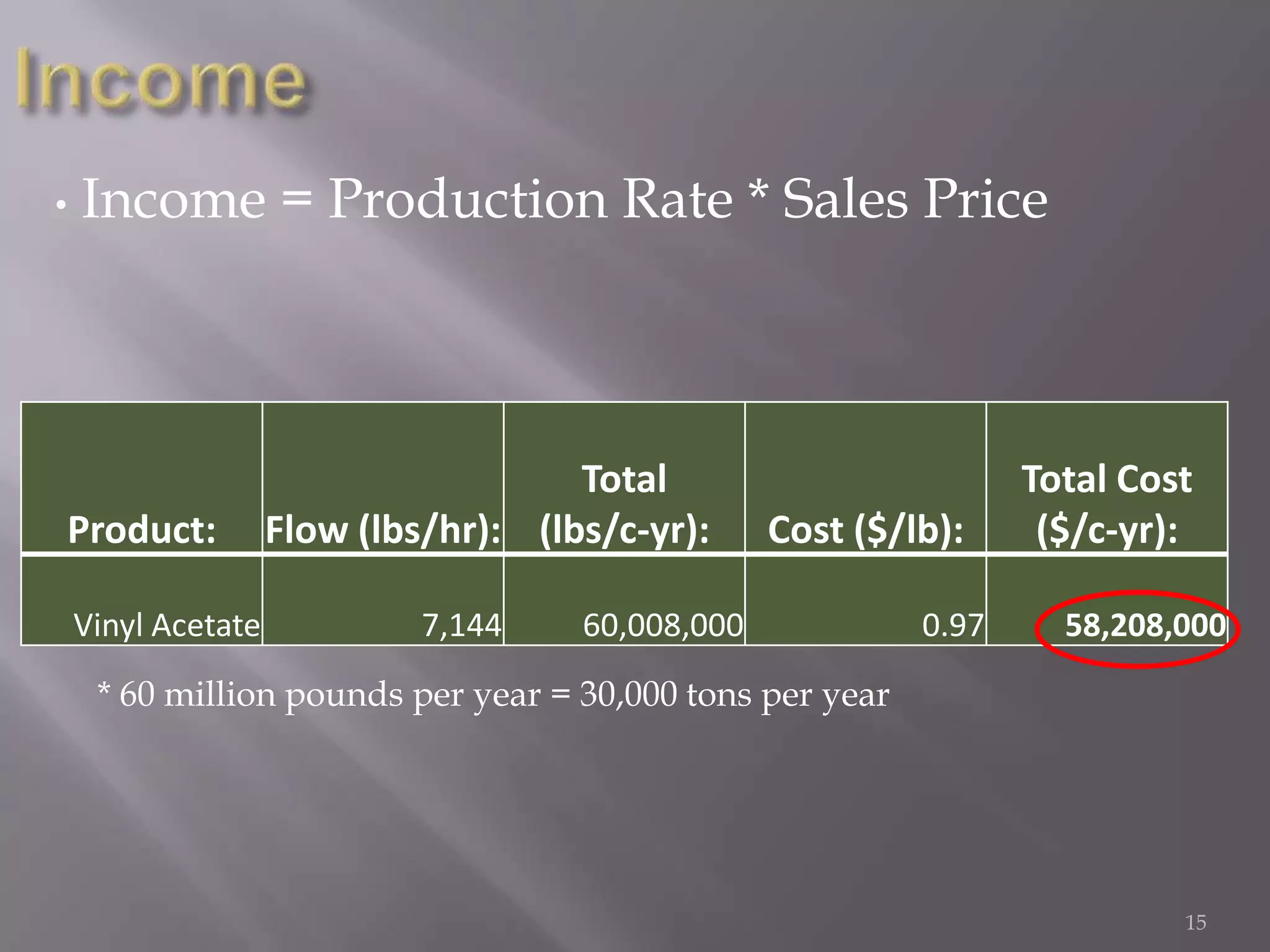

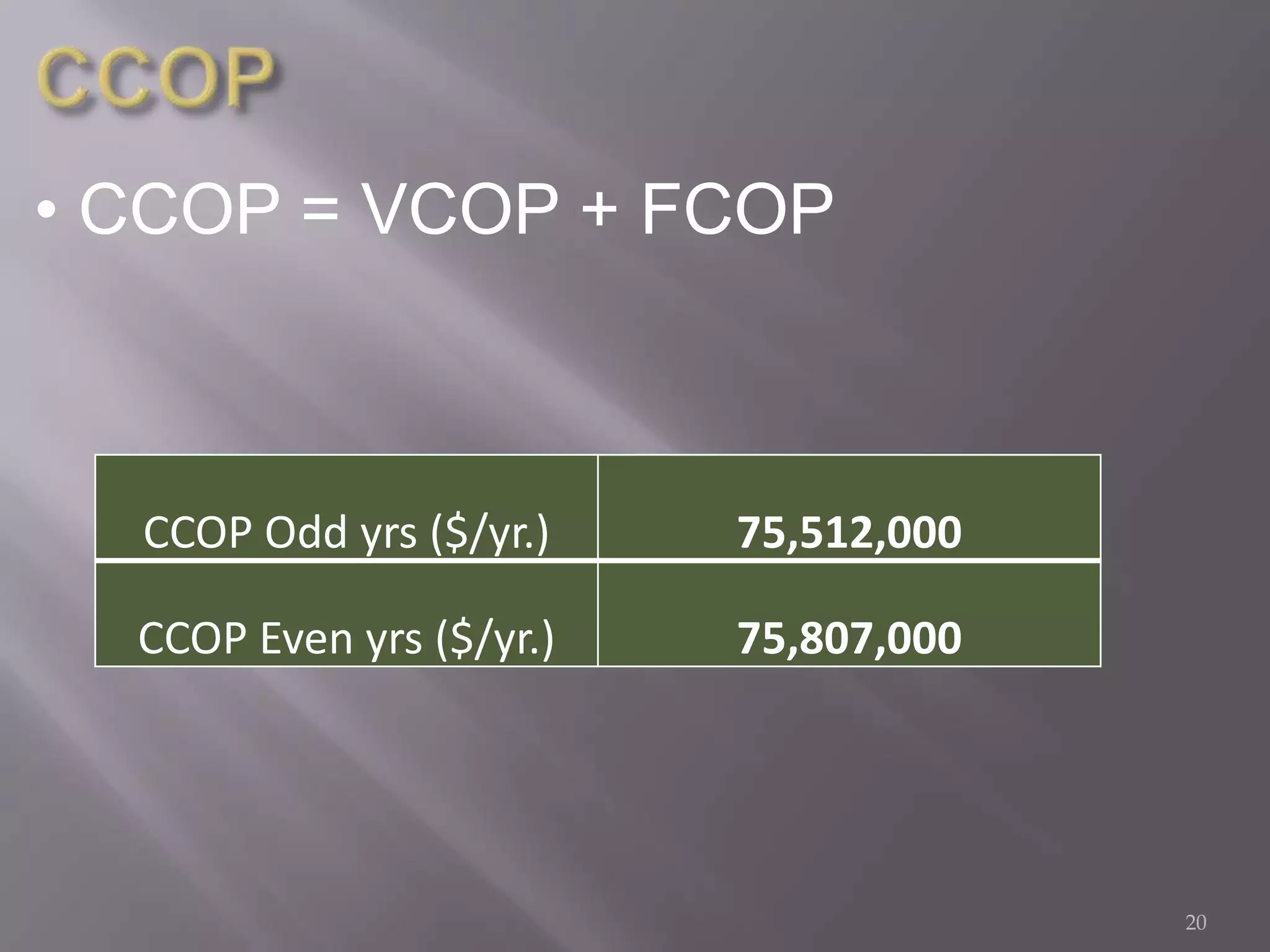

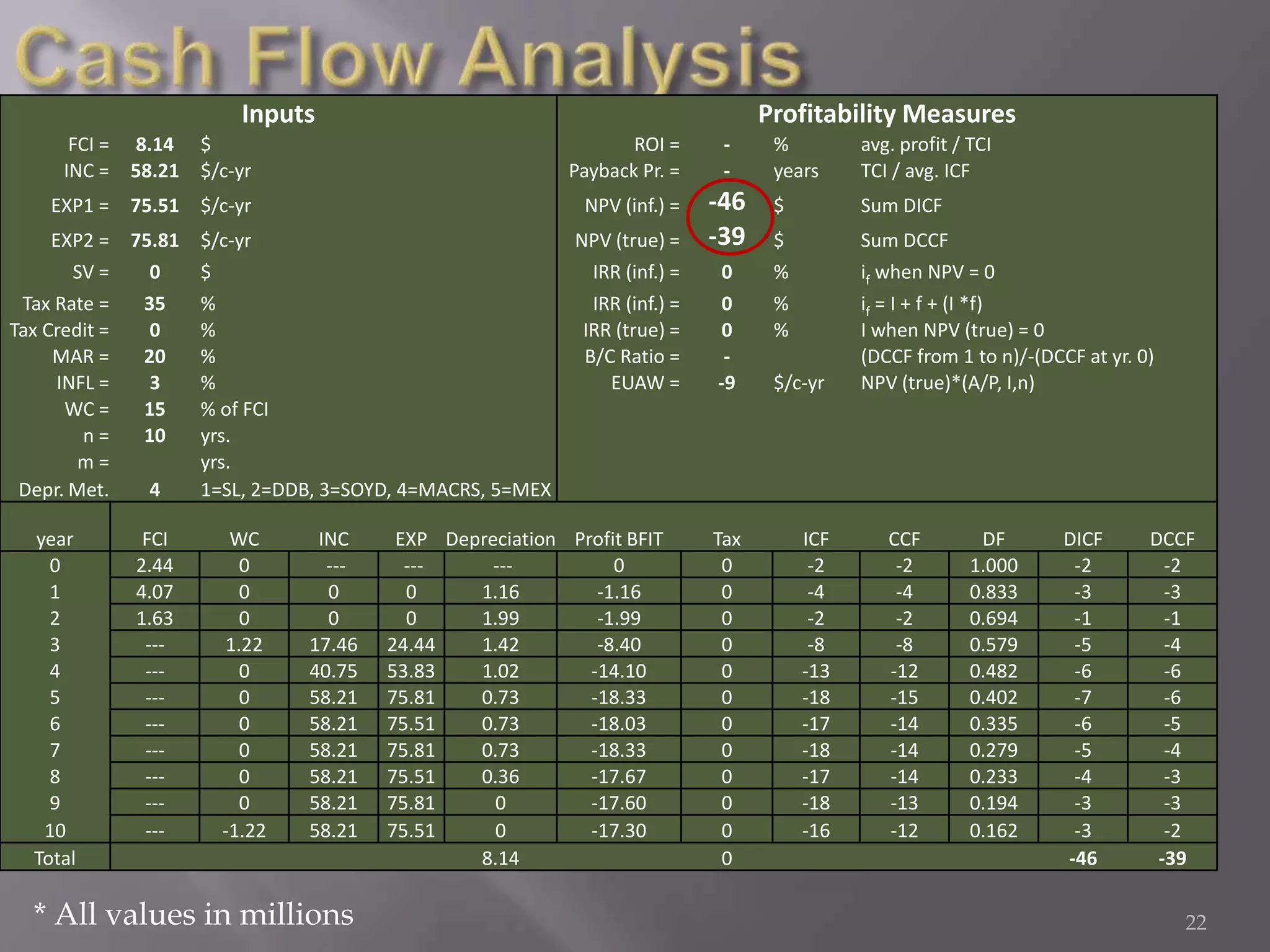

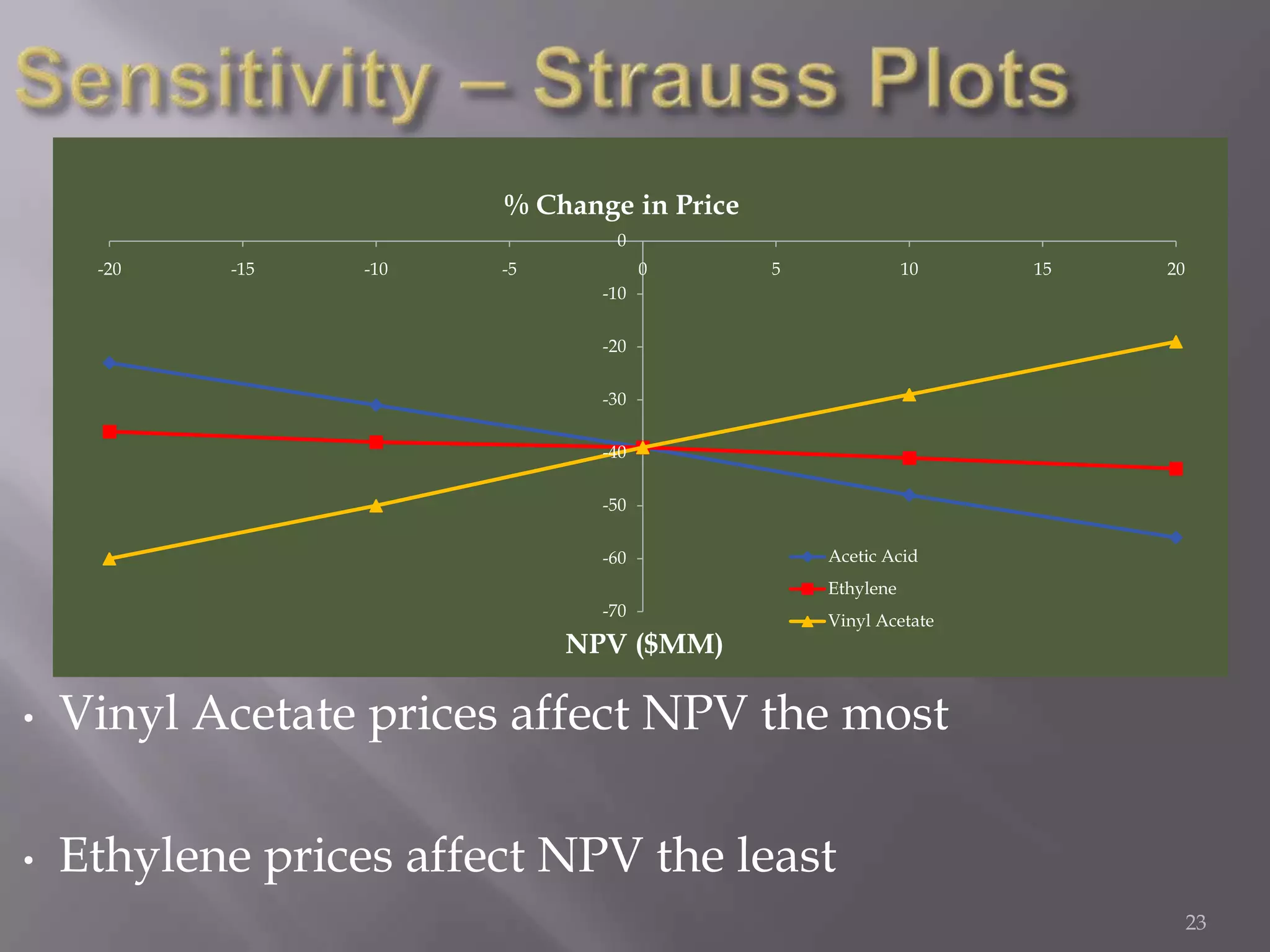

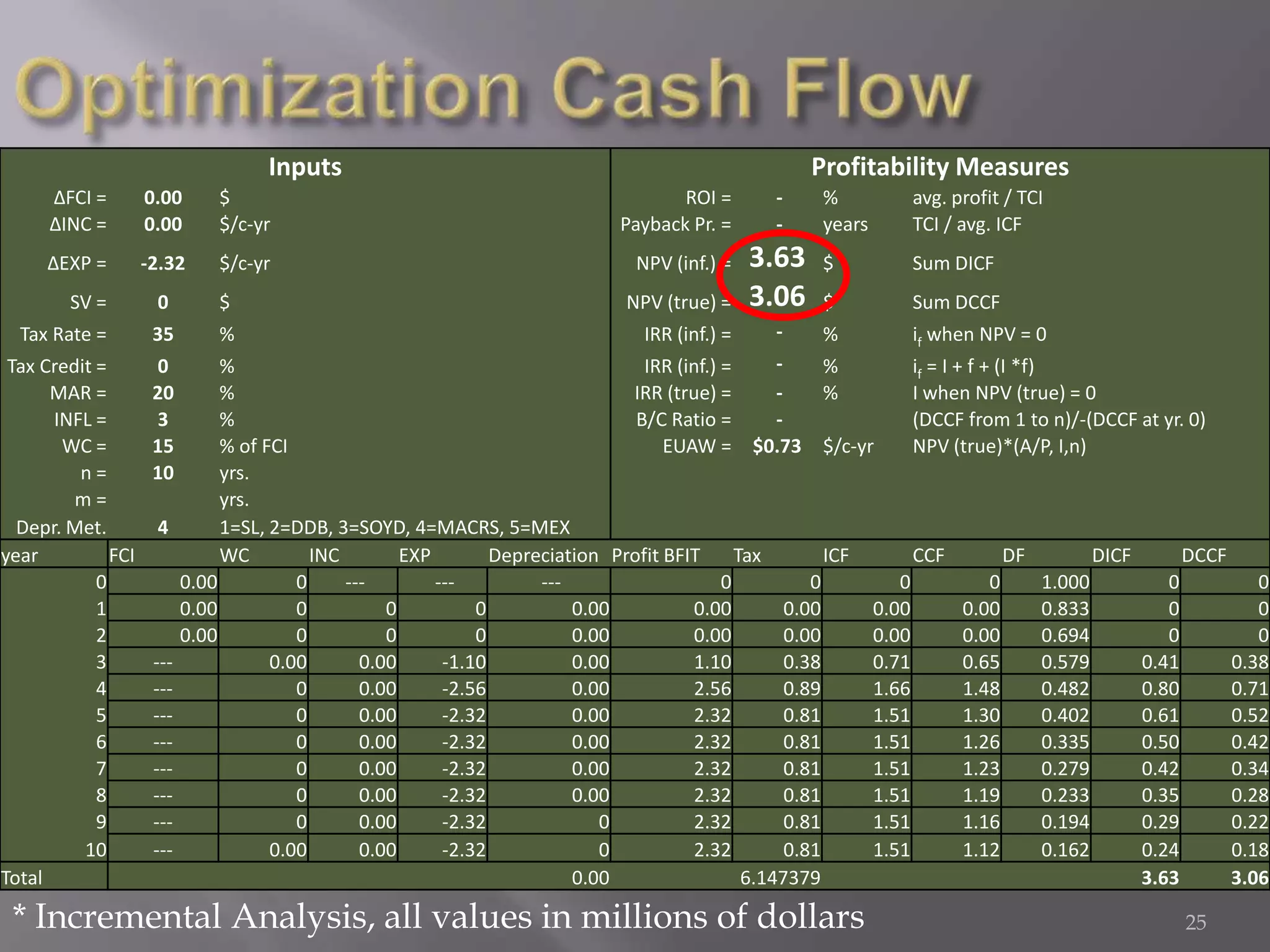

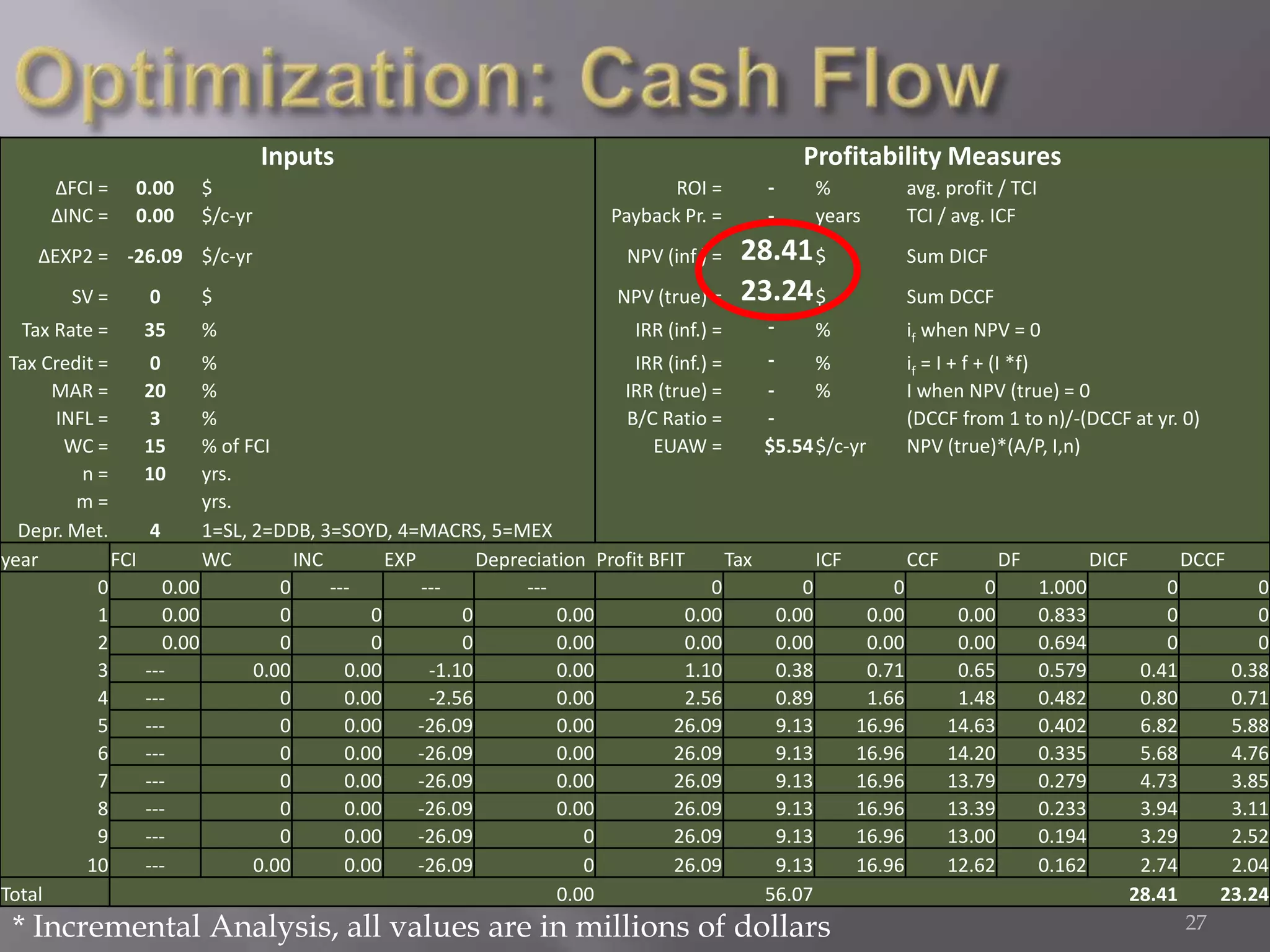

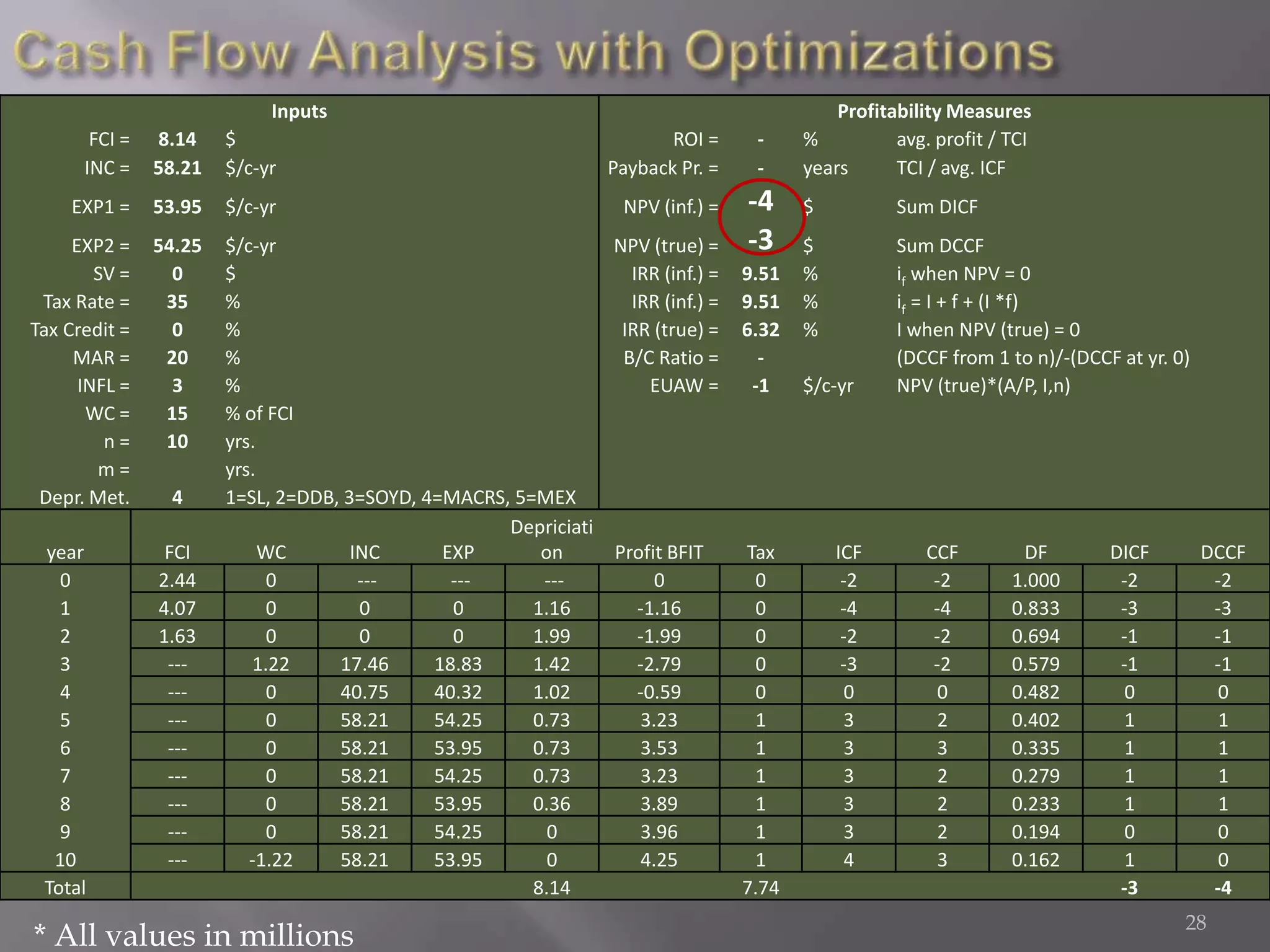

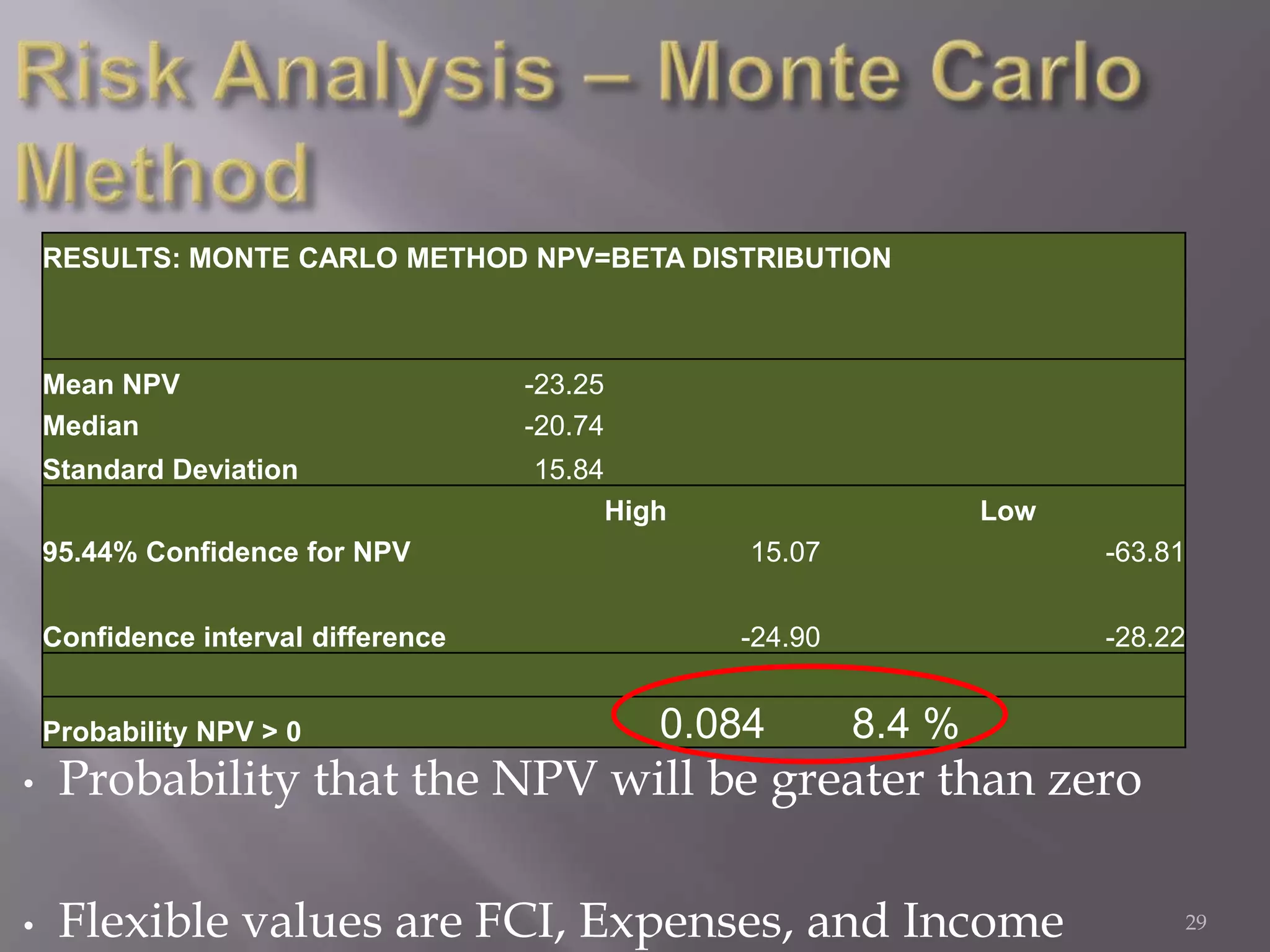

The document outlines the design and feasibility analysis for a proposed vinyl acetate monomer production plant in the U.S., focusing on production methods, safety, environmental considerations, and economic viability. Despite a planned capacity of 30,000 tons per year, the analysis concludes that the plant is not currently feasible due to high costs and low profitability. Recommendations include adjusting acetic acid prices and VOC regulations before reconsidering construction.