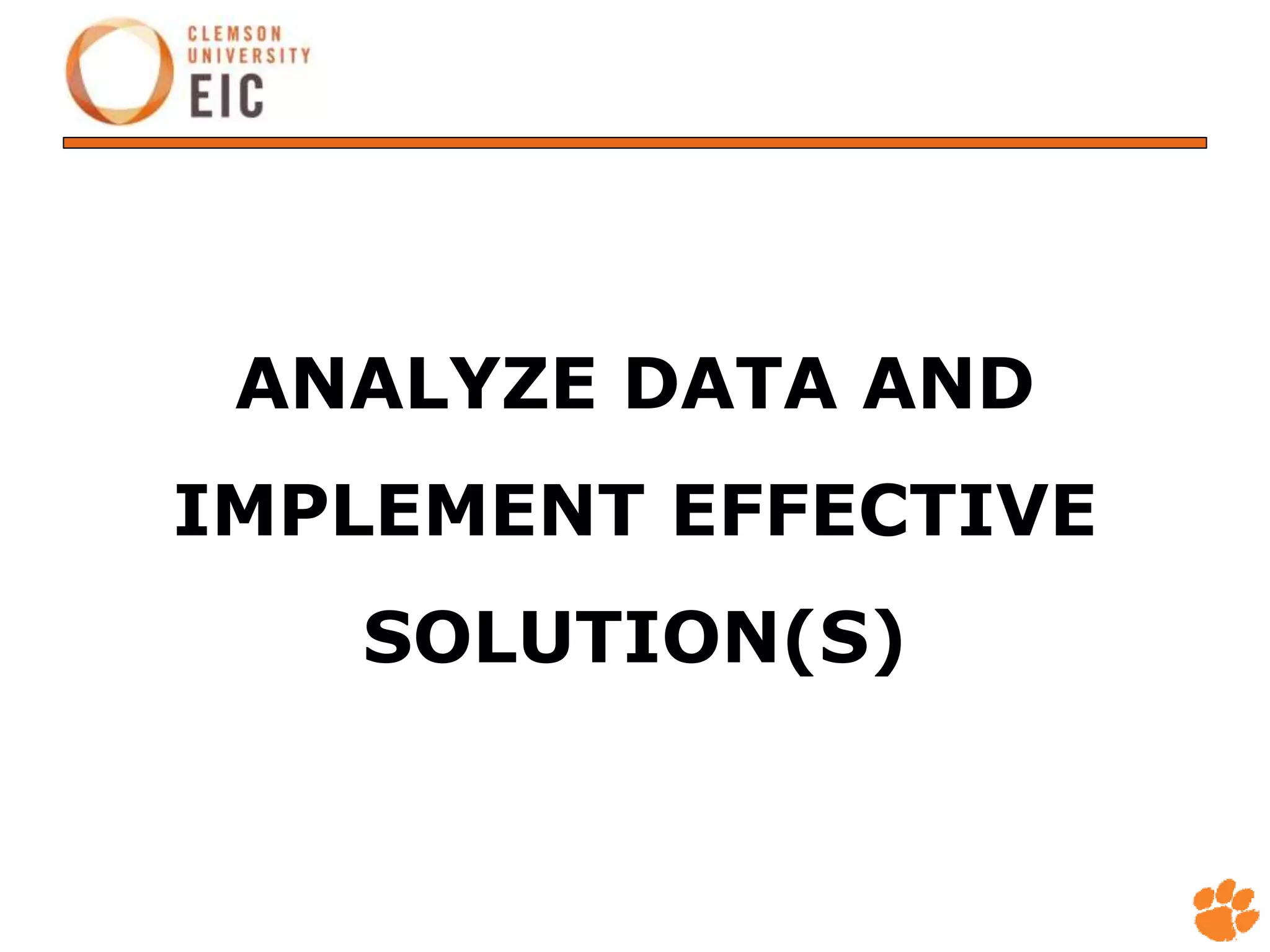

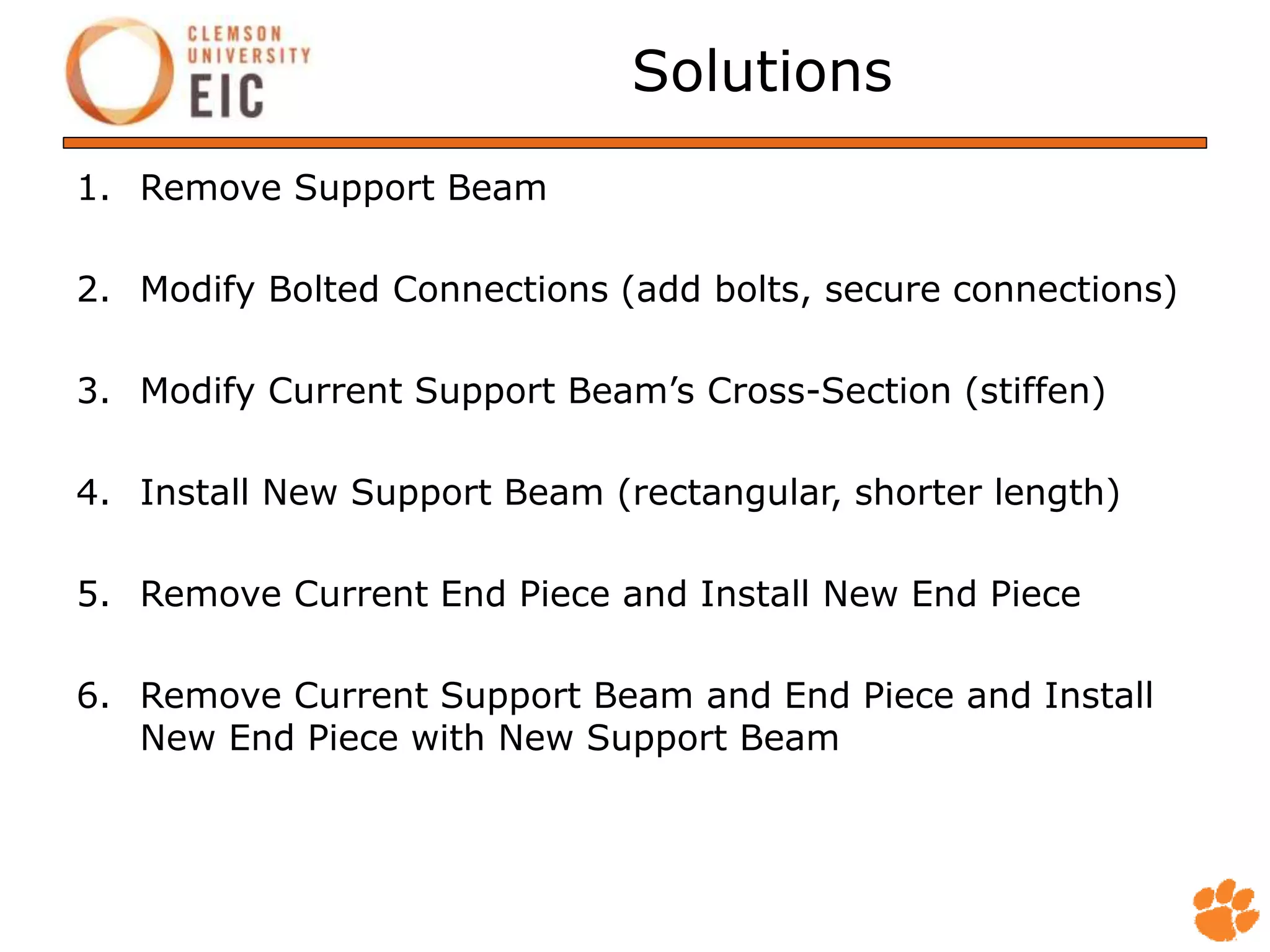

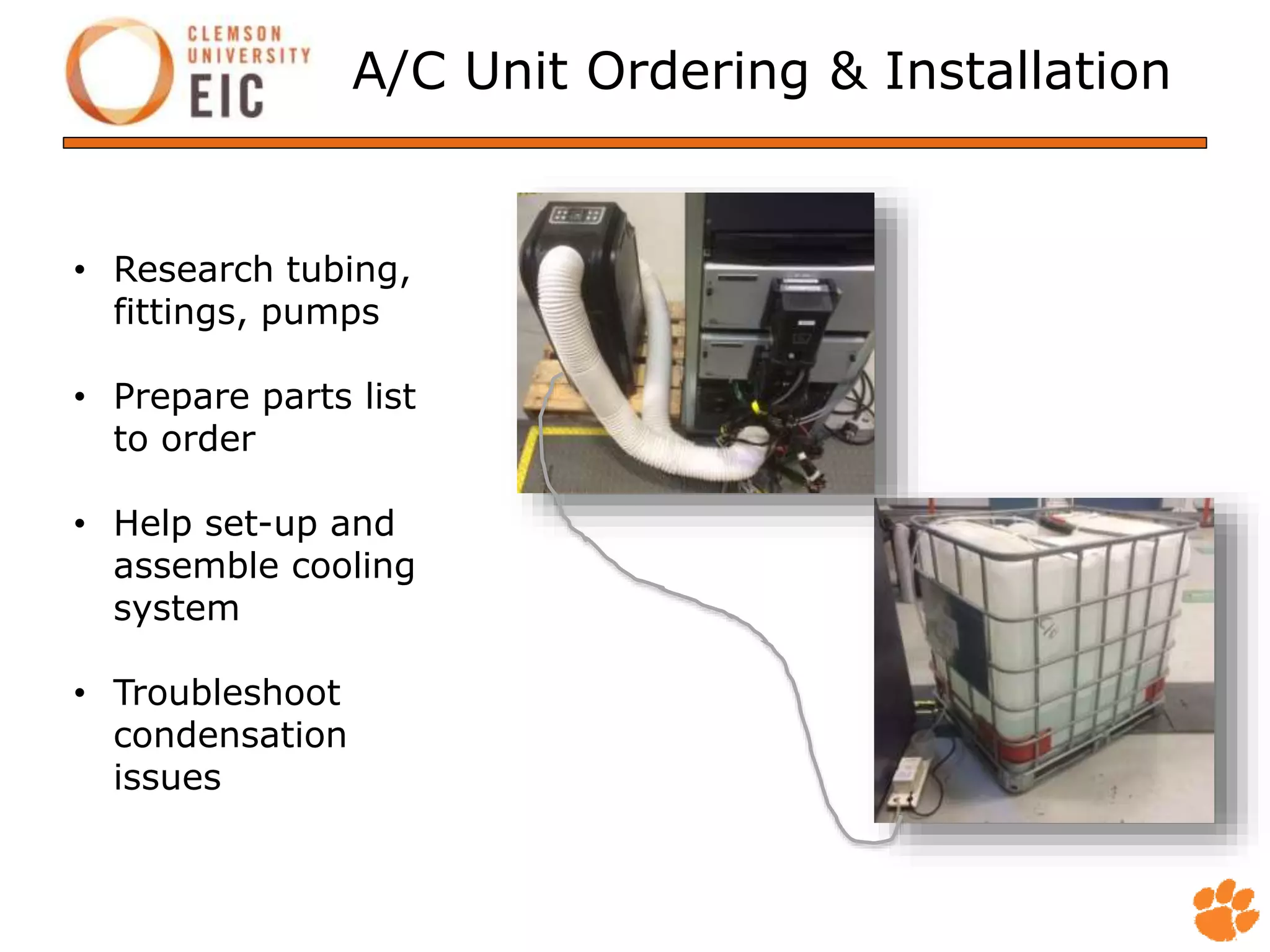

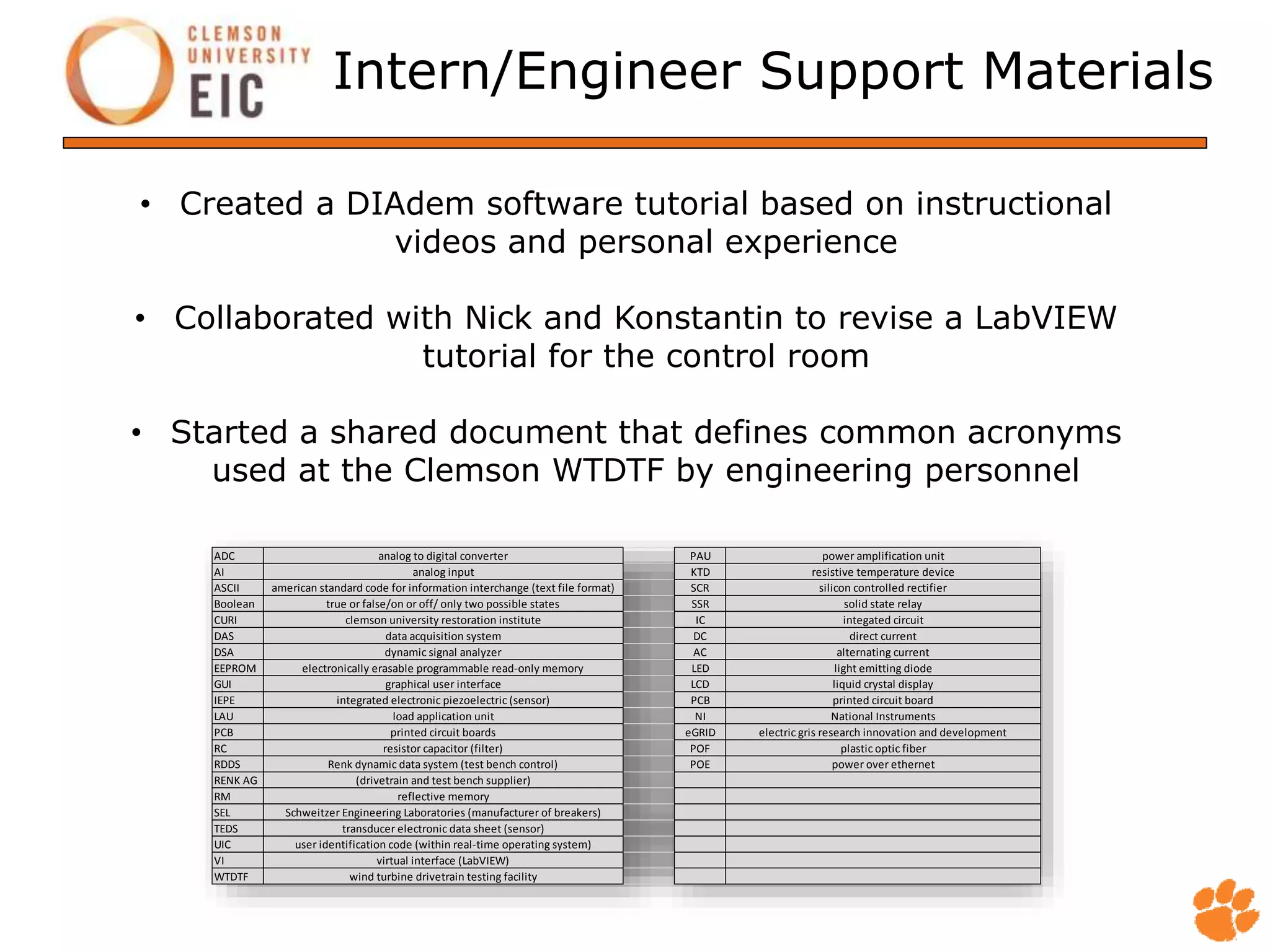

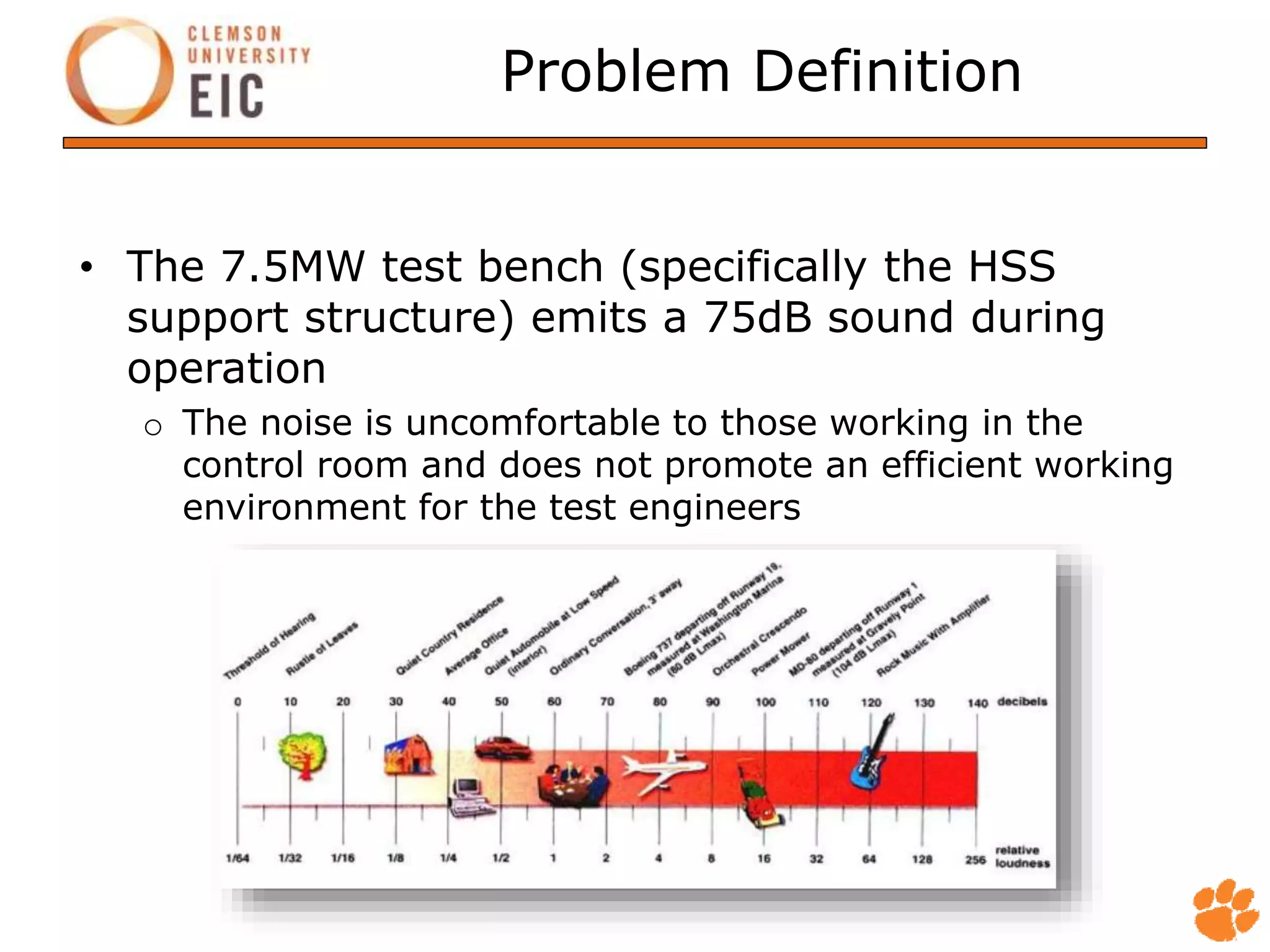

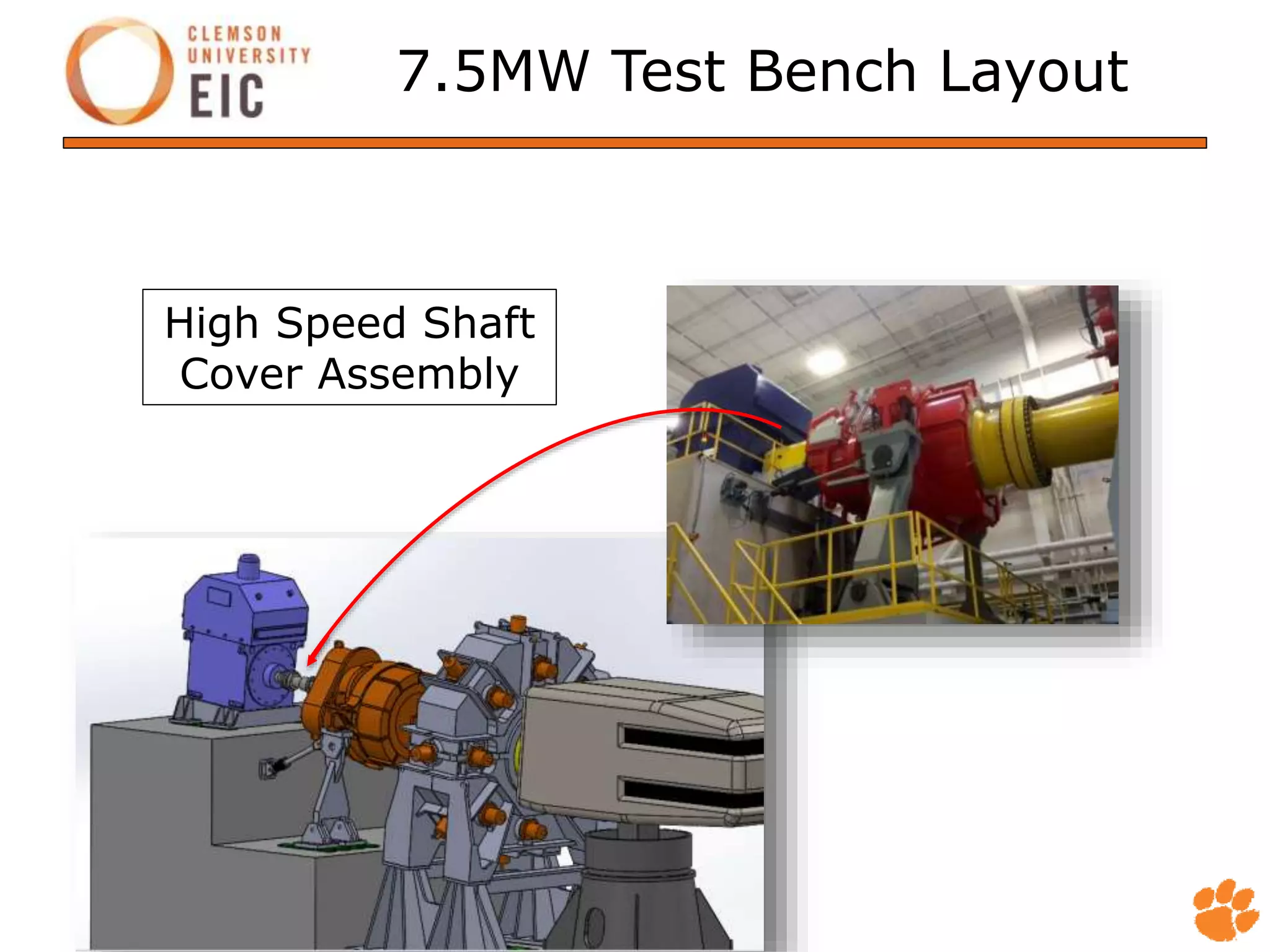

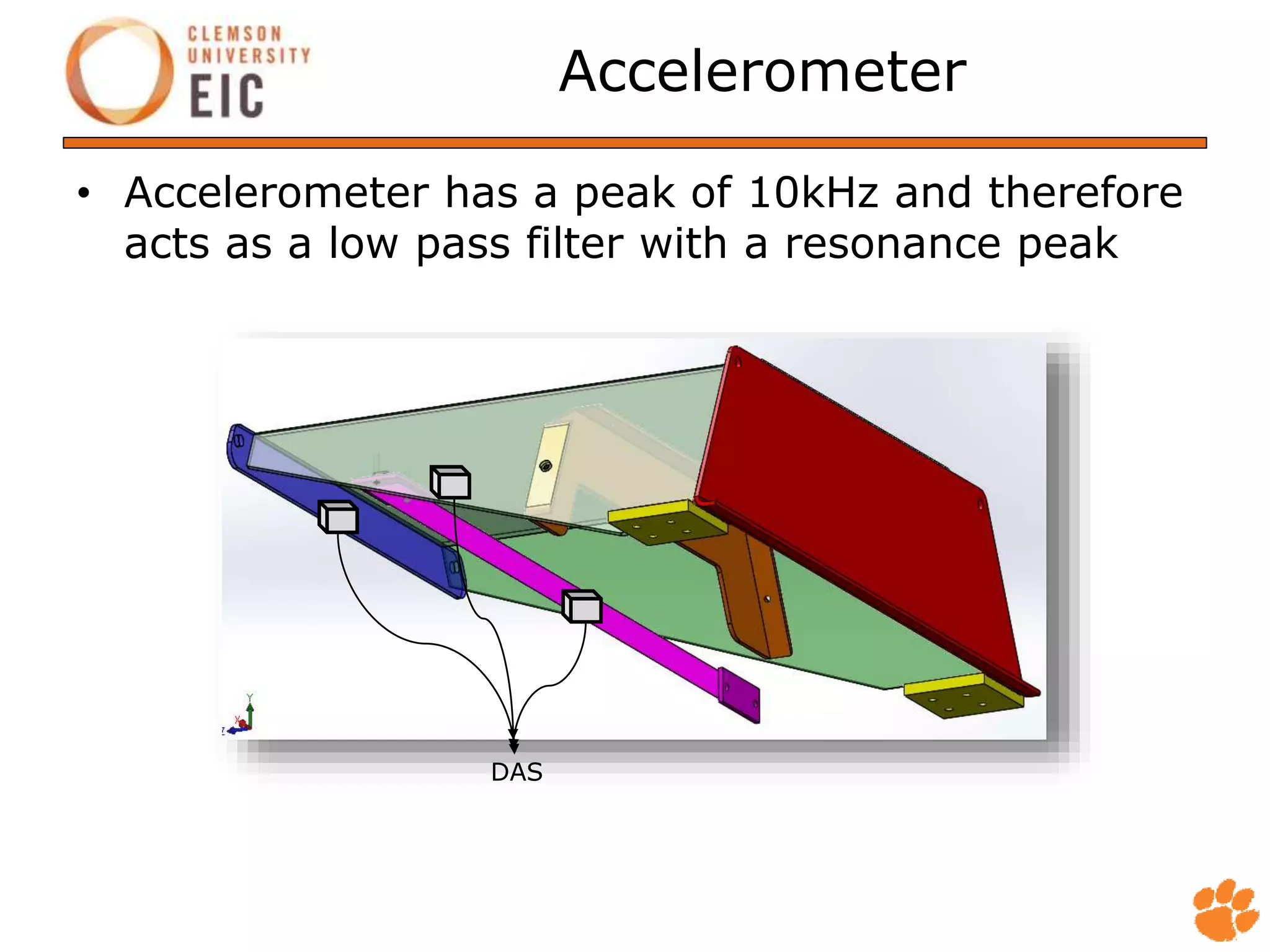

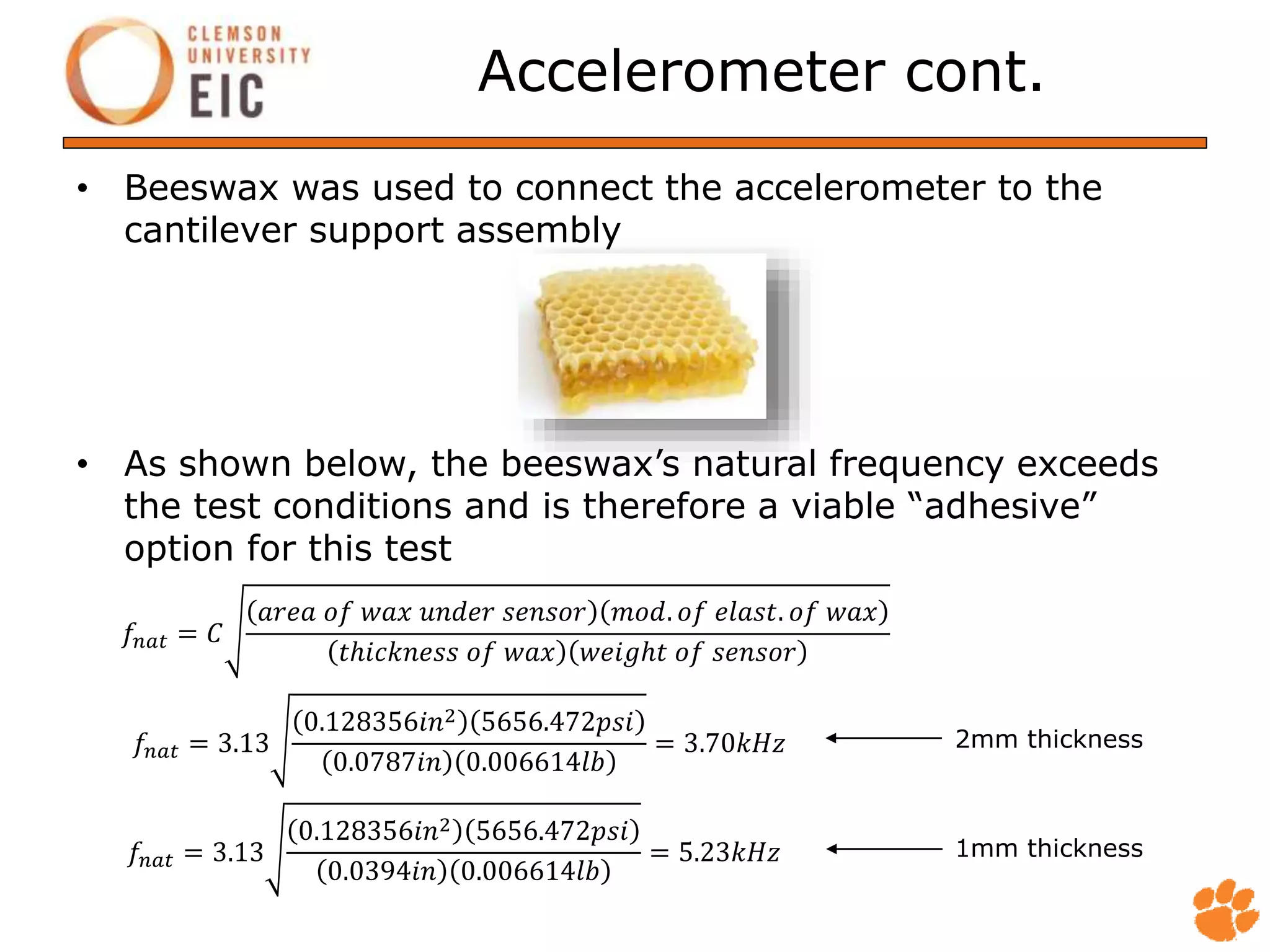

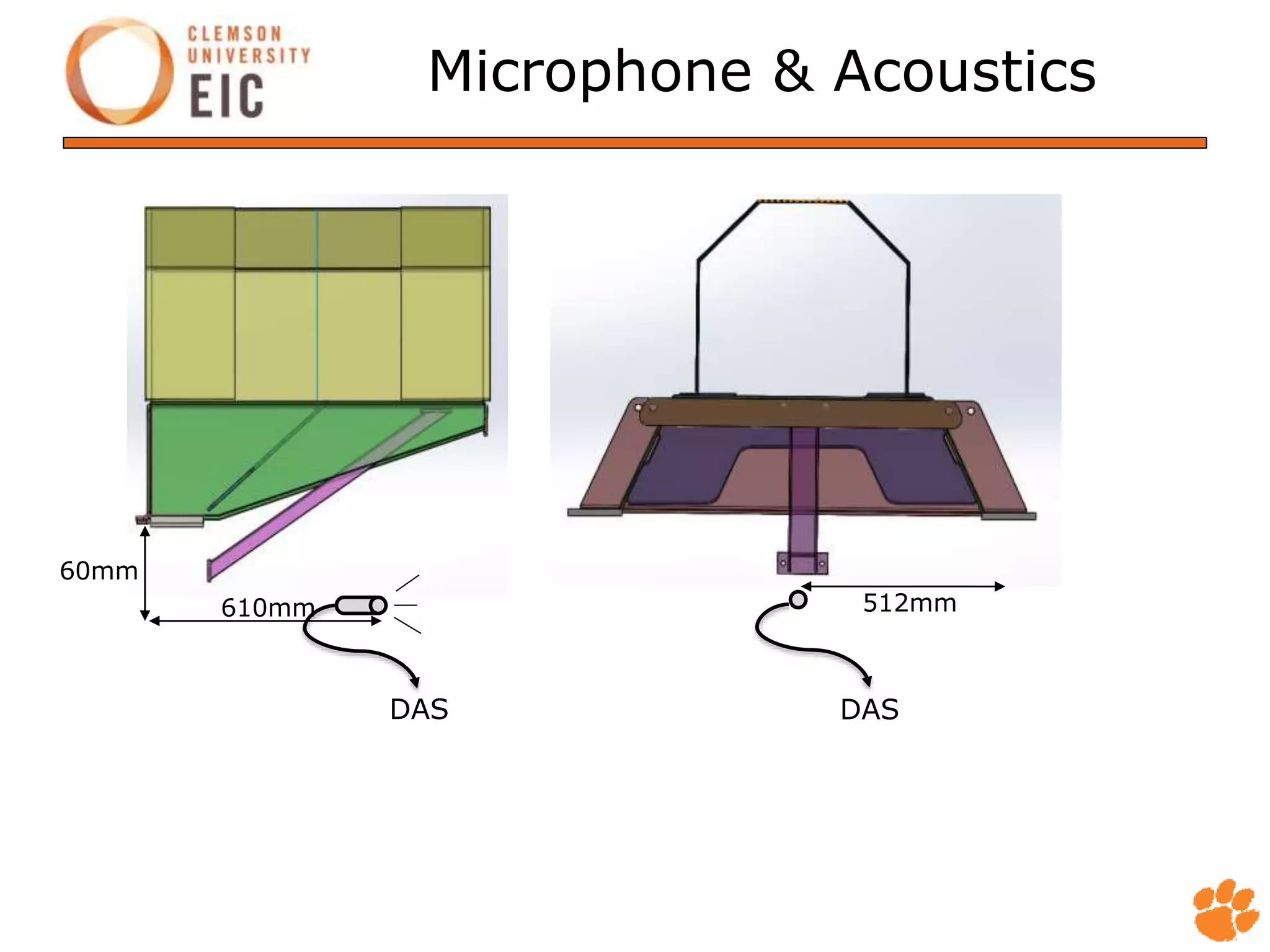

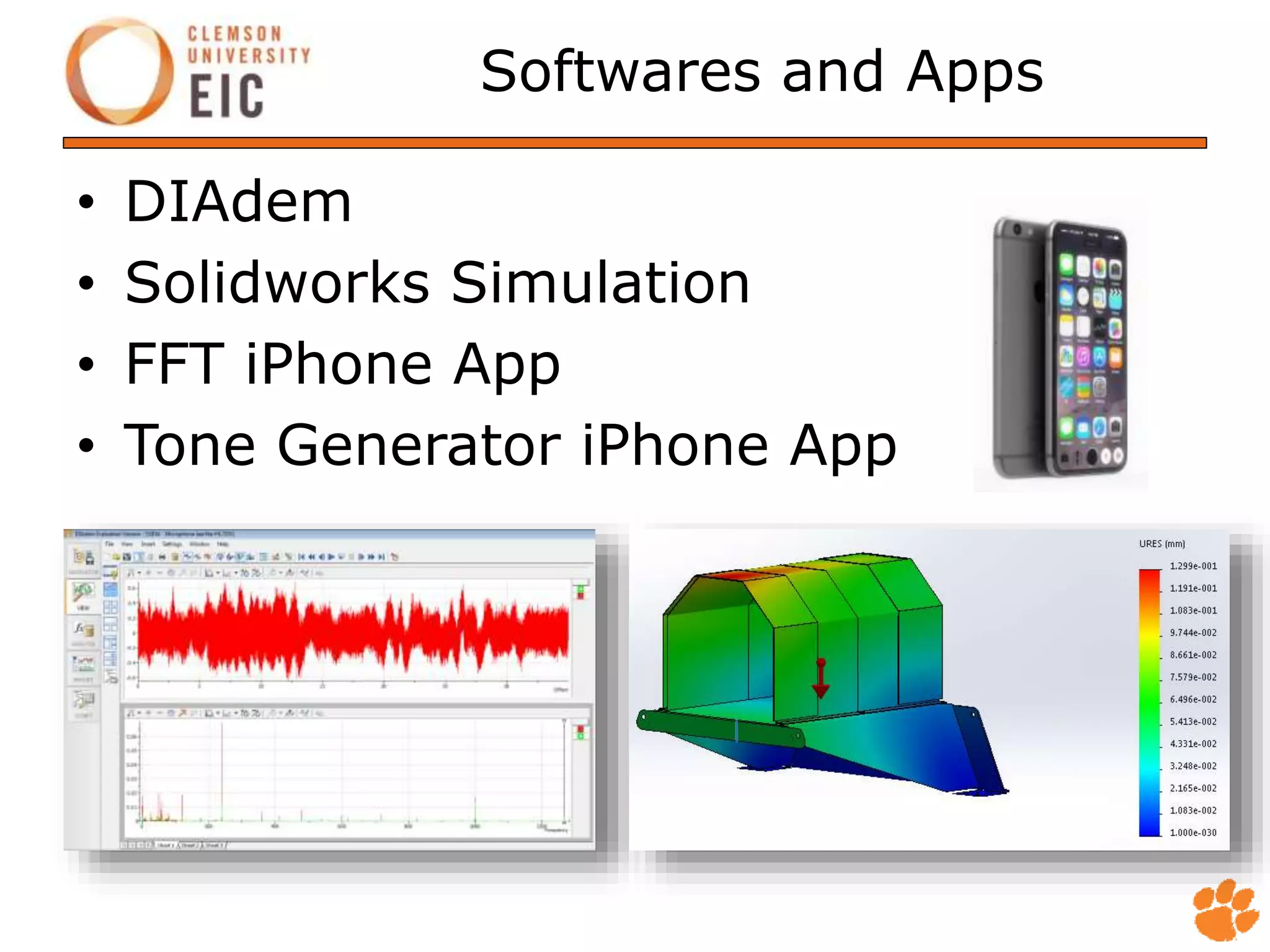

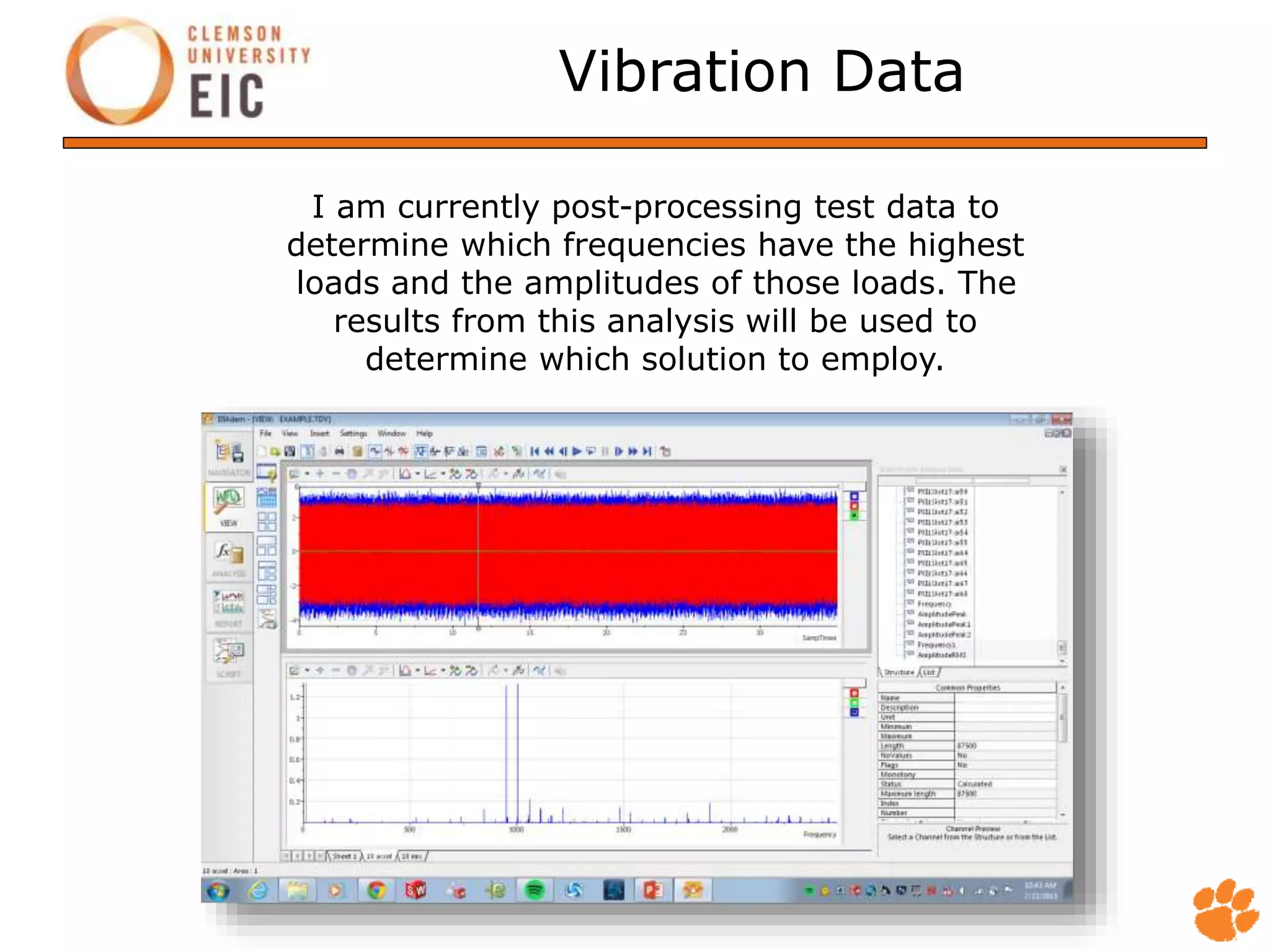

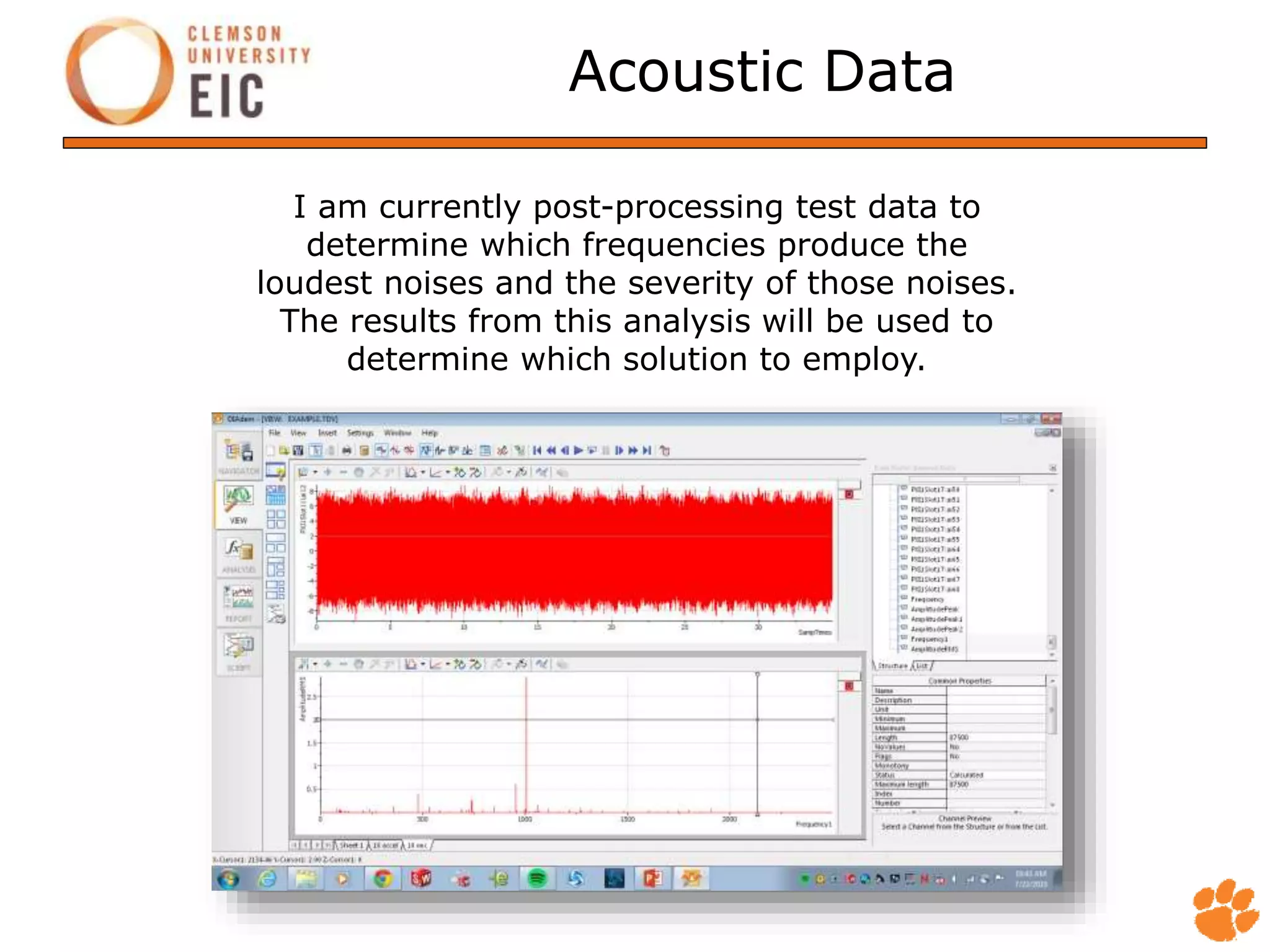

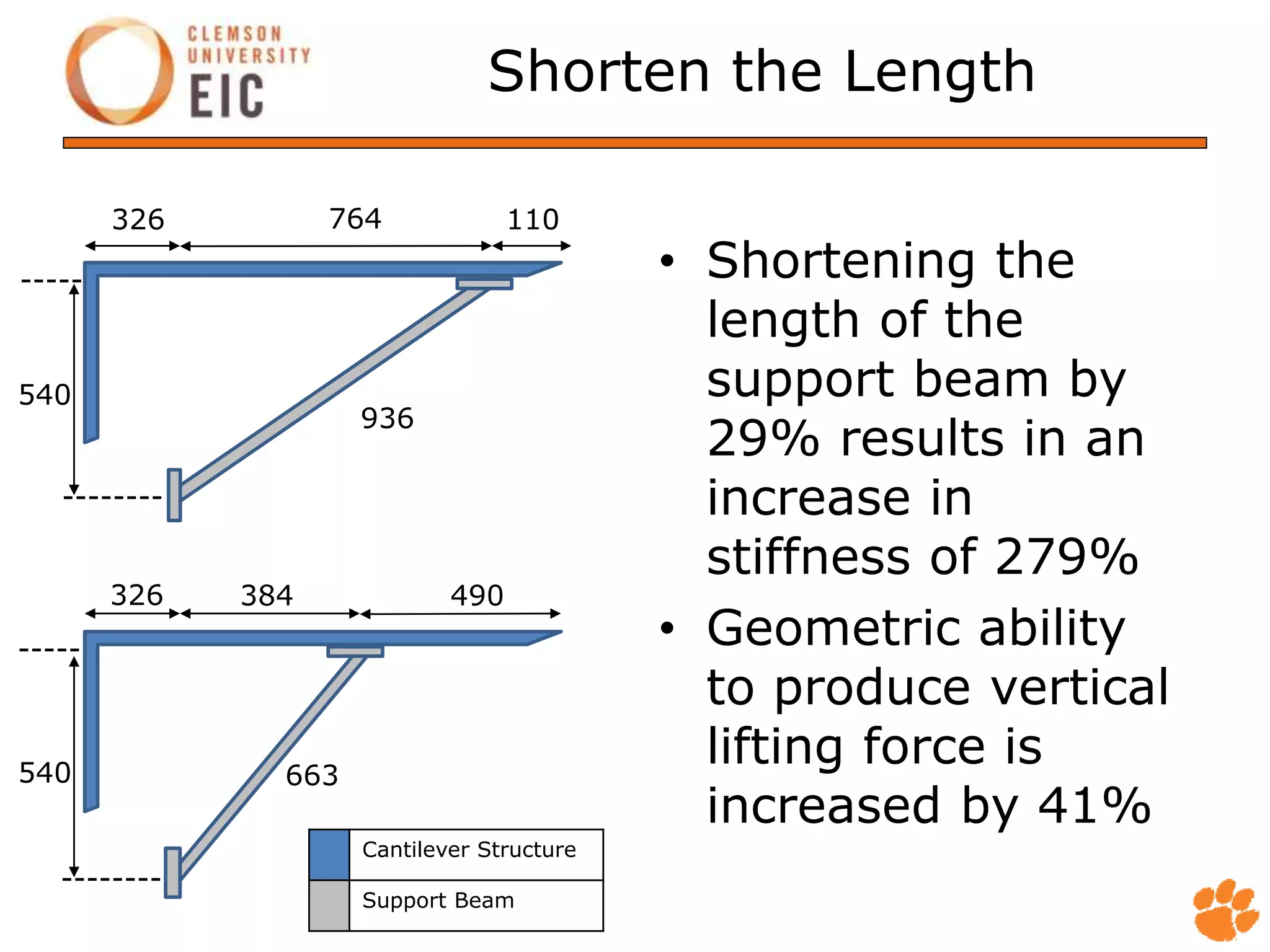

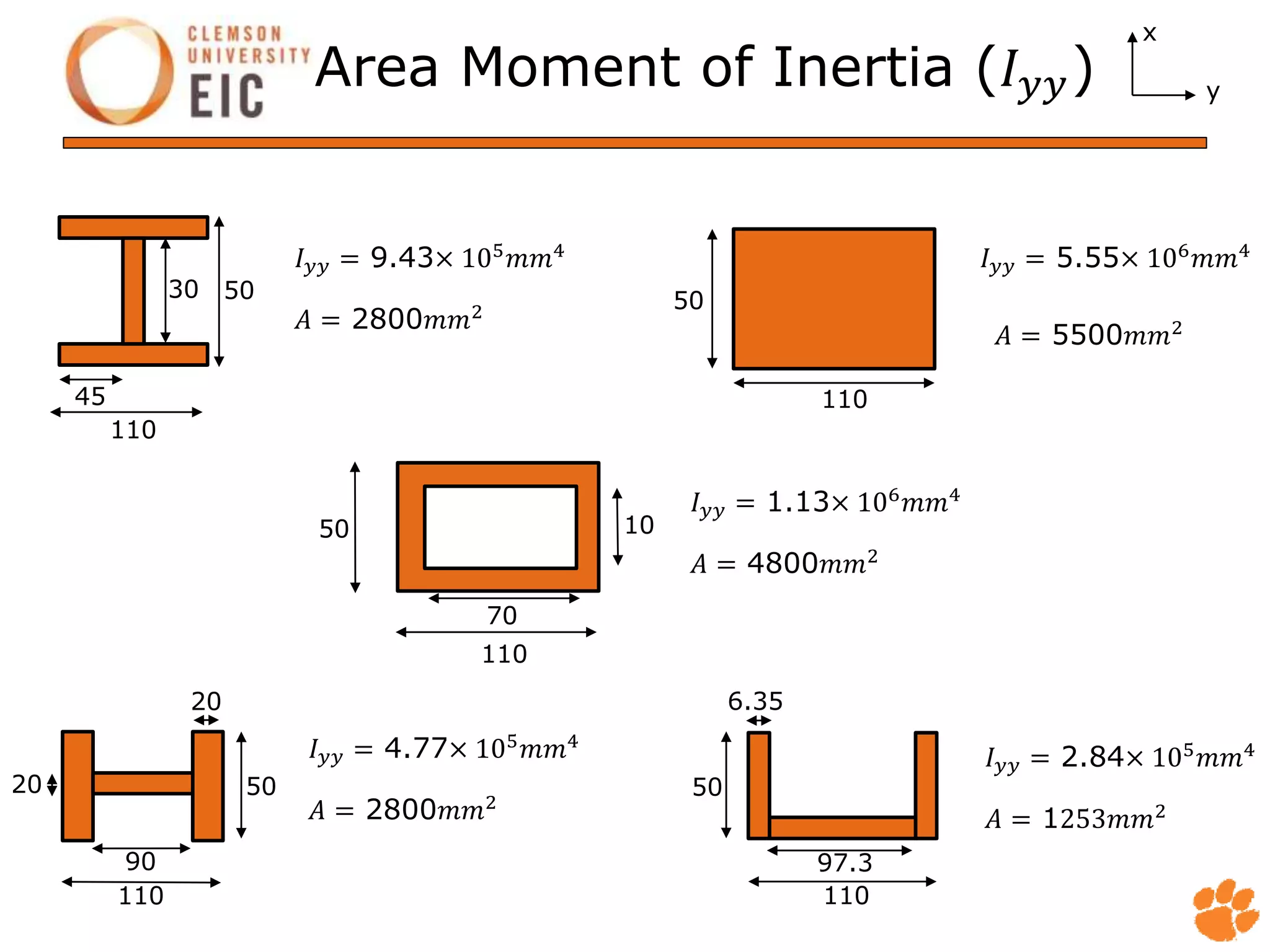

Ash Abel completed a summer internship with Clemson University's Mechanical Engineering department. Their main project involved vibration and acoustic testing of a 7.5MW test bench that emitted uncomfortable noise levels. Through research, testing, and analysis, Ash identified possible causes such as loose connections and resonance. They designed tests using accelerometers and microphones to analyze vibration and acoustic data. Potential solutions like shortening the support beam or changing its cross-section were modeled and tested. Analysis showed modifying connections and the beam's design could effectively reduce noise levels. Ash also assisted engineers and created support materials during their internship.

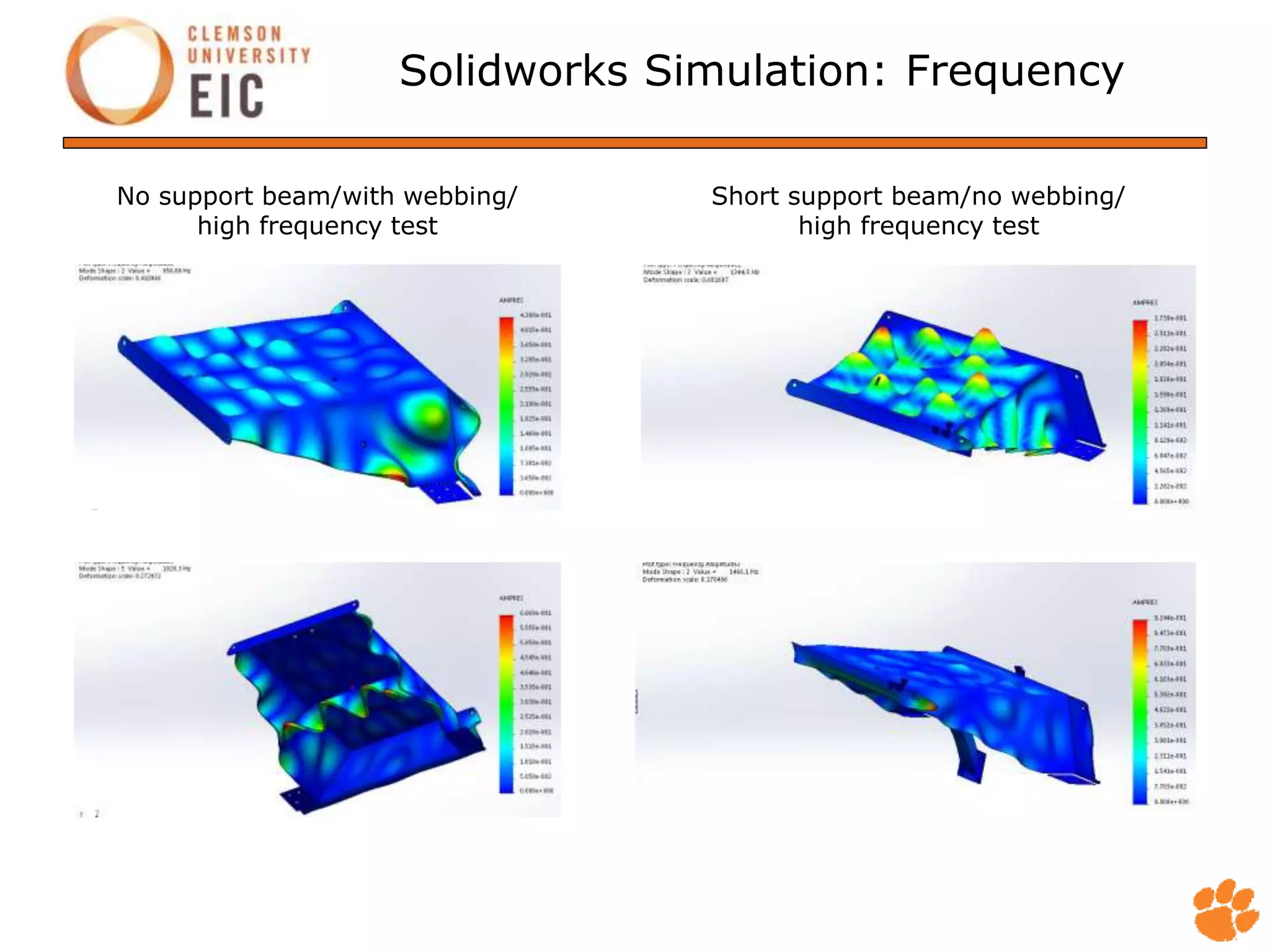

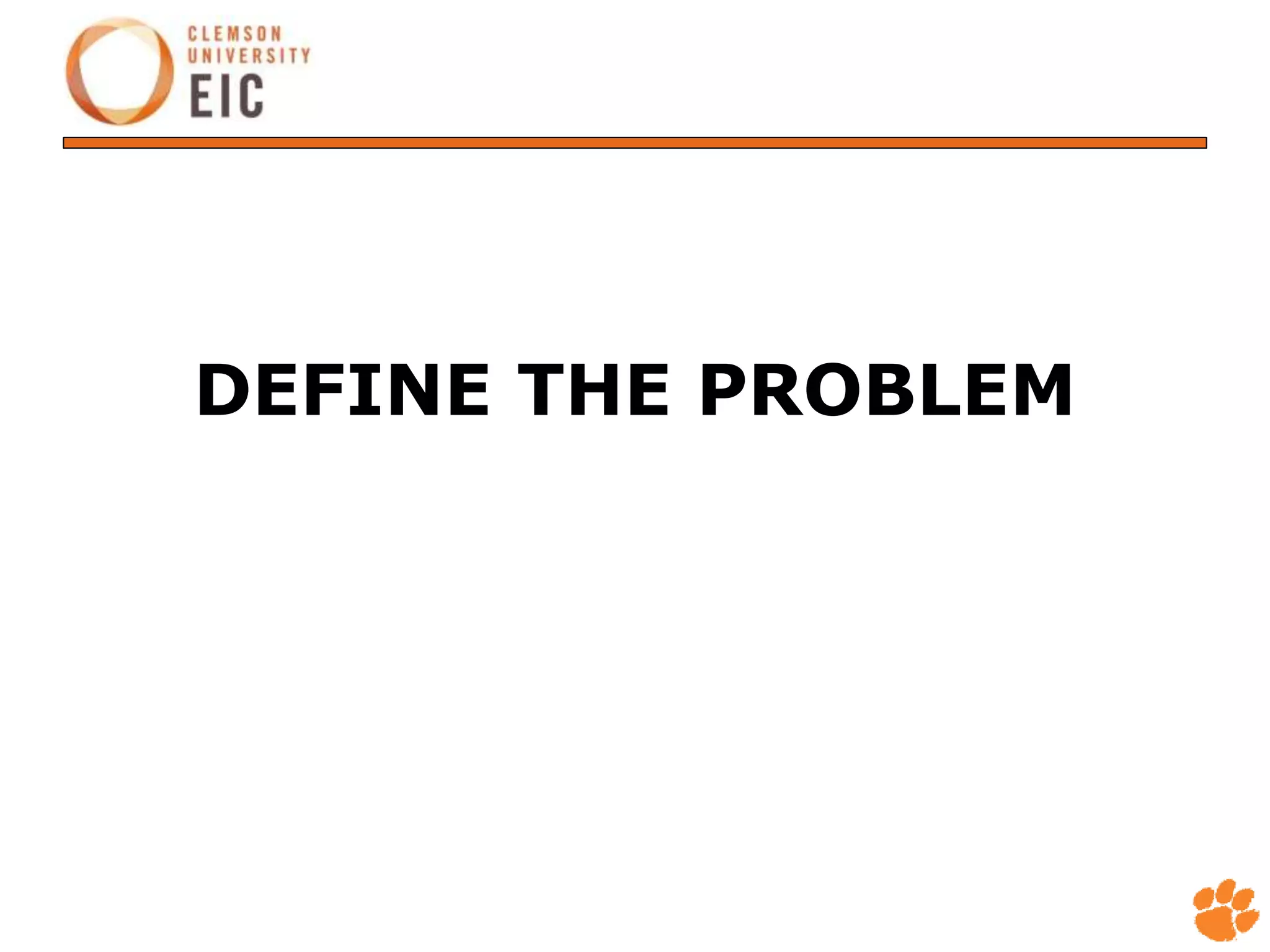

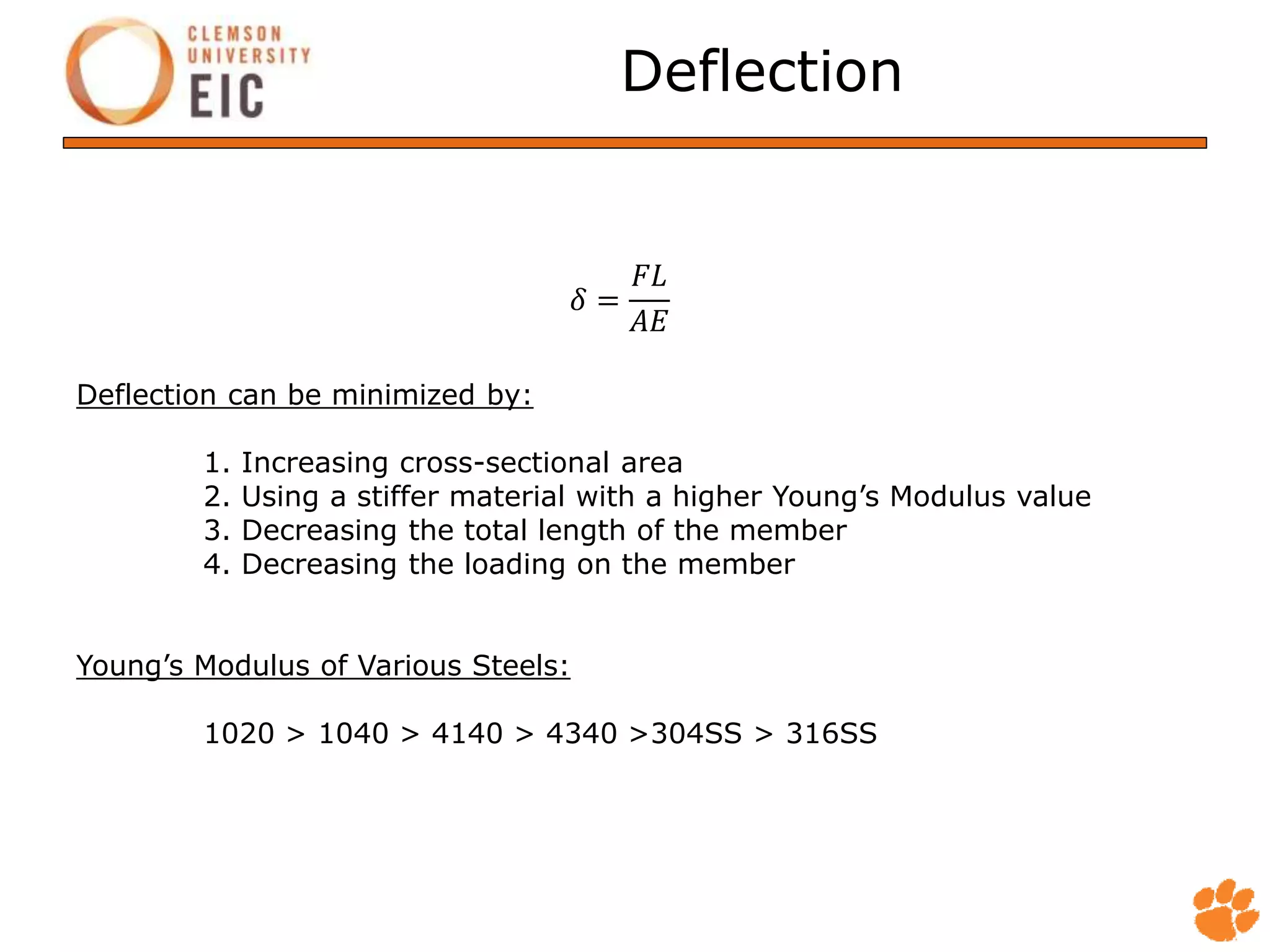

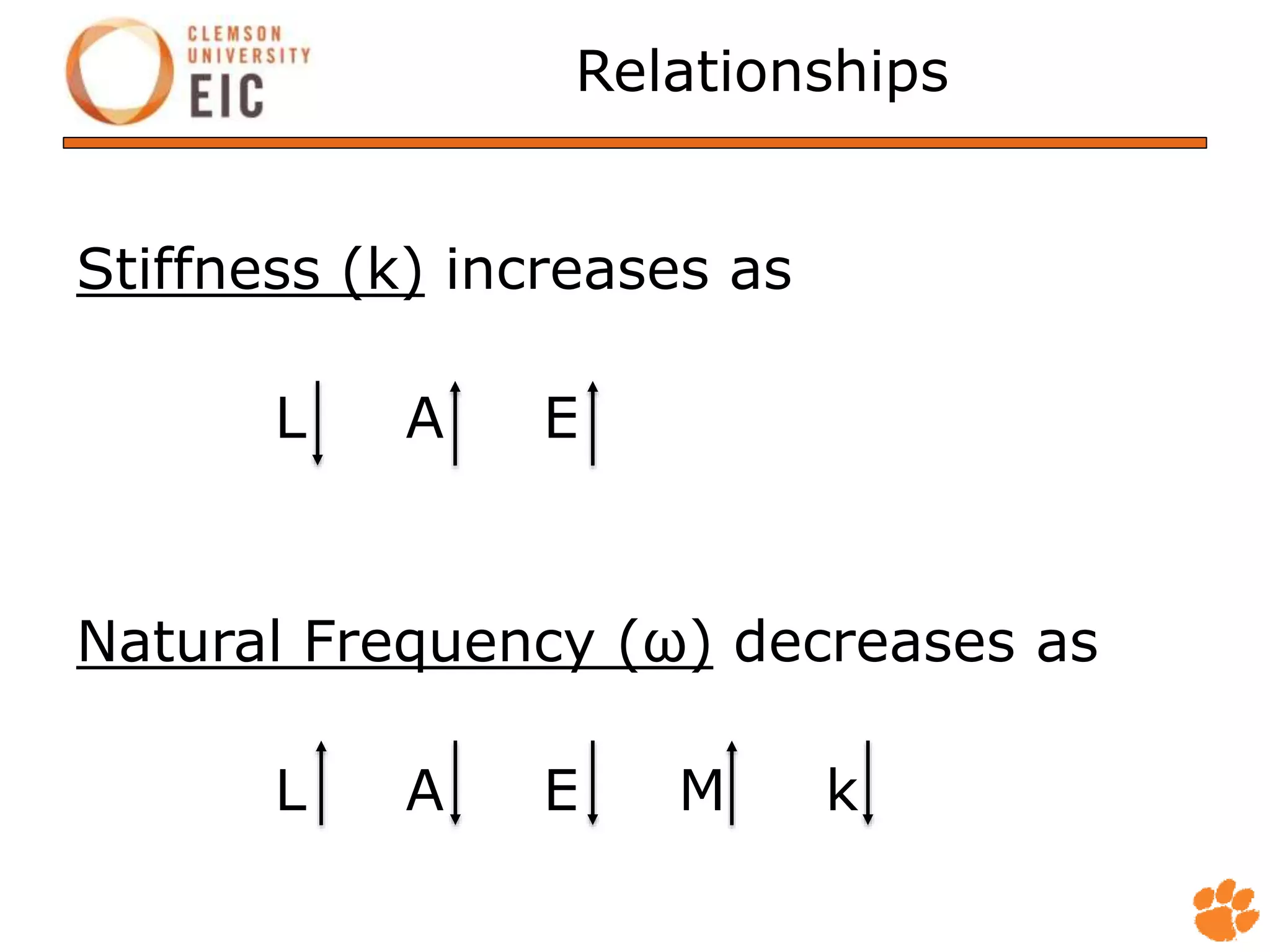

![Acoustics

[Pa]

(from microphone)

[dB]

SPL (Sound Pressure Level)

[dB(A)]

1𝑃𝑎 = 94𝑑𝐵 𝑆𝑃𝐿

𝑊𝐴 = 10𝑙𝑜𝑔

1.562339𝑓4

𝑓2 + 107.652652 𝑓2 + 737.862232

+ 10log

2.242881 × 1016

𝑓4

𝑓2 + 20.5989972 2 𝑓2 + 12194.222 2

𝑃 𝑑𝐵 = 𝑊𝐴 × 𝑃 𝑑𝐵](https://image.slidesharecdn.com/f1b1ac27-bee2-4f61-8c3a-262b0aa3b510-150728154118-lva1-app6892/75/Final-Presentation-20-2048.jpg)

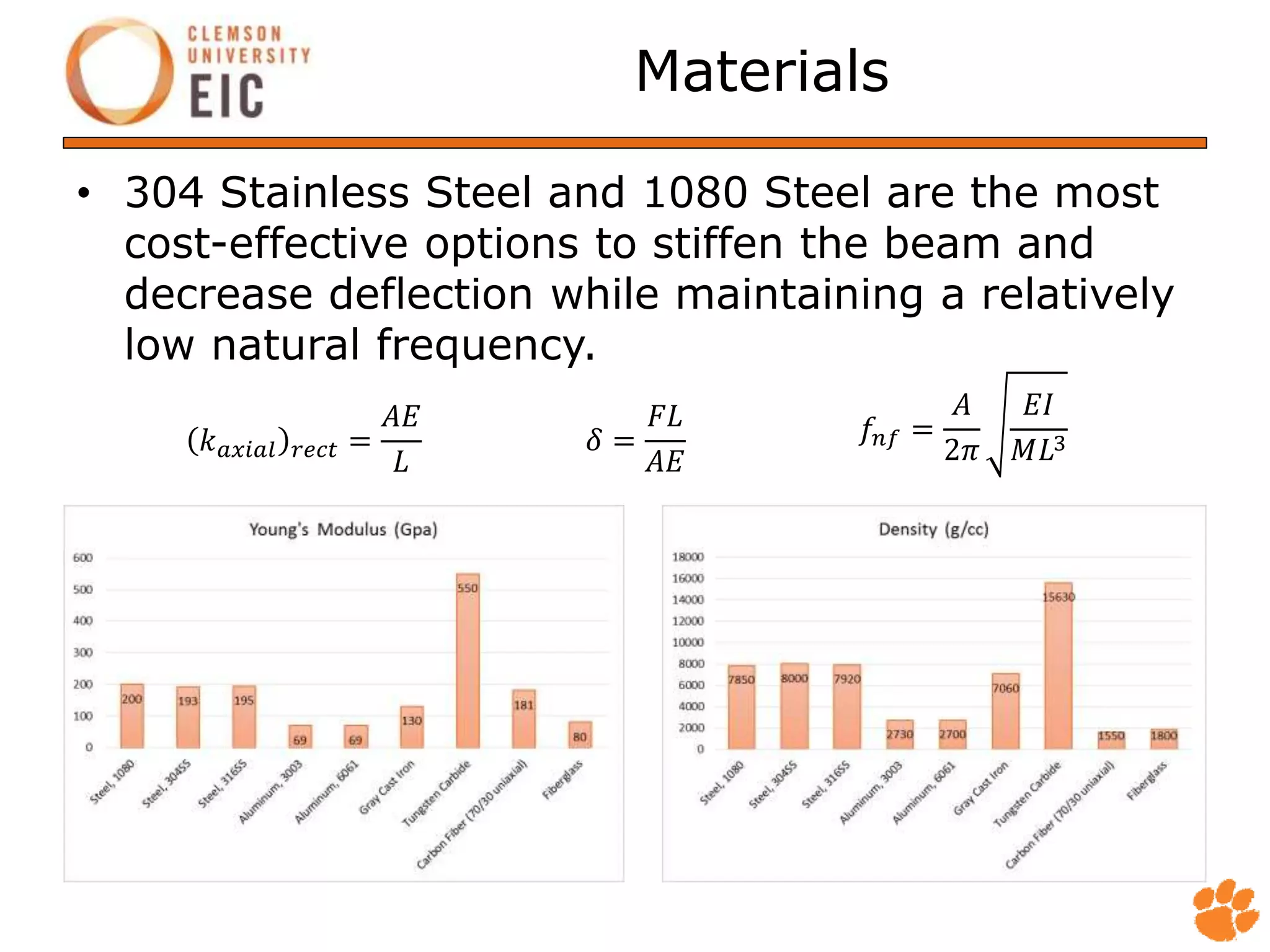

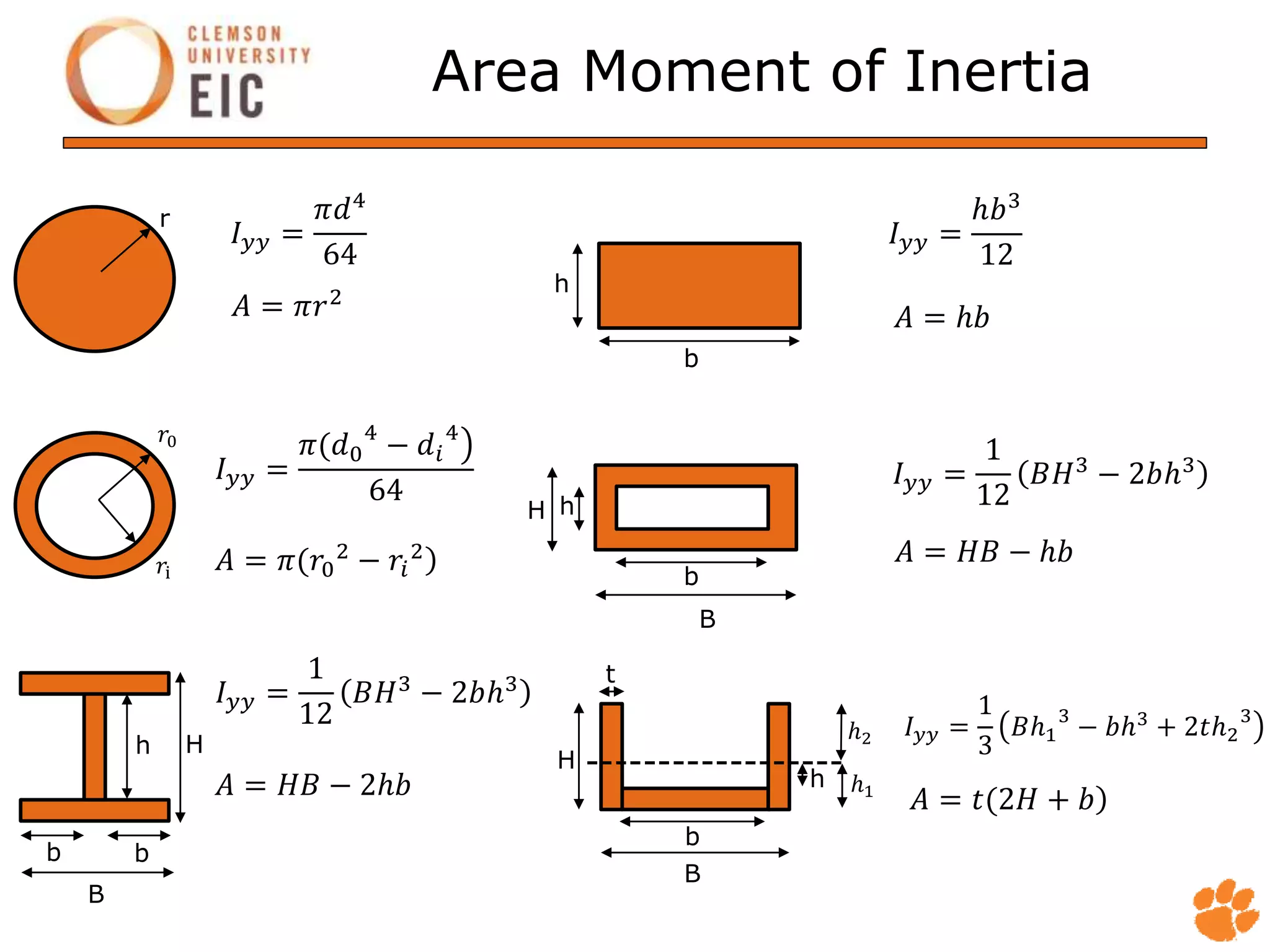

![Solidworks Simulation: Static

Current Setup with Support Beam

Max Stress:2.73E7 [N/m^2]

FACTOR OF SAFETY: 13.39

New Setup with new End-piece and

without Support Beam

Max Stress:3.90E7 [N/m^2]

FACTOR OF SAFETY: 5.66

Current Setup without Support Beam

Max Stress: 2.036E7 [N/m^2]

FACTOR OF SAFETY: 10.83](https://image.slidesharecdn.com/f1b1ac27-bee2-4f61-8c3a-262b0aa3b510-150728154118-lva1-app6892/75/Final-Presentation-33-2048.jpg)