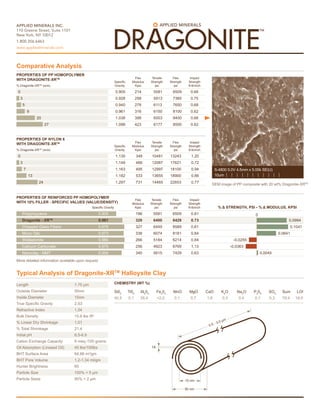

Applied Minerals produces Dragonite-XRTM, a naturally exfoliated halloysite clay additive for polymer reinforcement. Dragonite-XRTM disperses easily in polymers at up to 40% loading without chemical treatment, increasing stiffness, strength, and thermal stability while maintaining toughness. It provides advantages over traditional fillers like glass fibers or organoclays by enabling weight reduction and easier processing at lower cost. Applied Minerals markets Dragonite-XRTM for applications requiring improved mechanical and physical properties in composites.