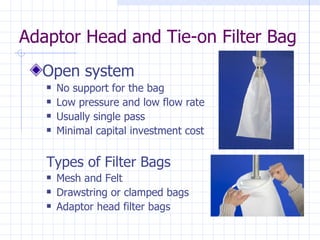

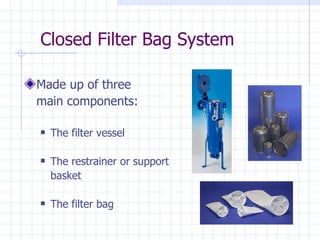

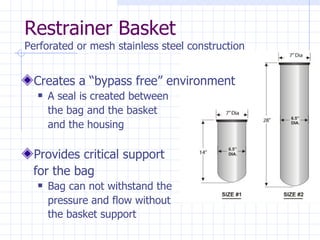

Industrial Filter Manufacturing produces liquid filter bags that offer several advantages for industrial applications. Filter bag technology emerged in the 1960s-1970s and provides ease of installation, low cost, simple operation, and quick filter bag changes. Filter bag systems can be open or closed, with open systems using gravity or low pressure and closed systems using pressurized housings. Closed filter bag systems consist of a filter vessel, restrainer basket, and filter bag. Filter vessels and bags come in various types and materials to suit different flow rates, pressures, temperatures, and contaminants.