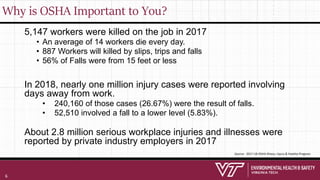

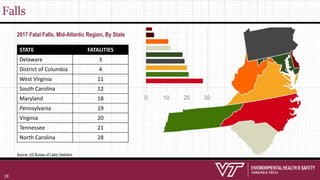

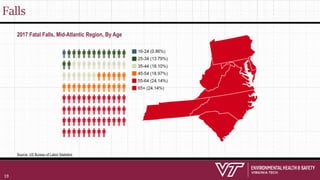

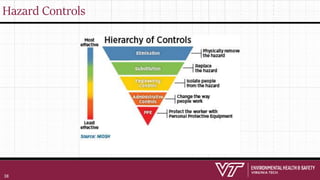

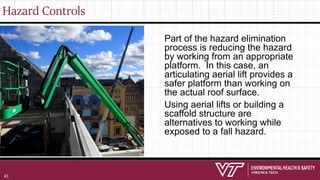

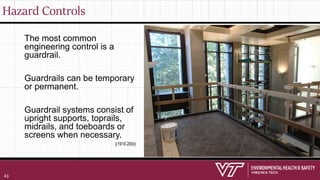

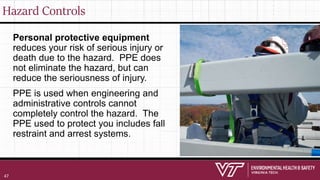

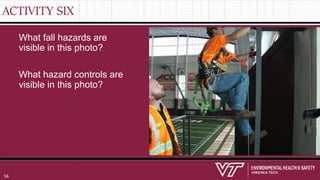

This document discusses fall protection in general industry. It begins with an introduction to OSHA and why workplace safety is important. Falls are a major cause of workplace injuries and fatalities. The document then discusses common fall hazards like falls from heights, falls on the same level, falls into equipment, and holes. It also discusses OSHA standards regarding fall protection and an employer's responsibility to recognize, evaluate and control fall hazards. Methods of controlling hazards include elimination, engineering controls, administrative controls, and personal protective equipment. Specific controls like guardrails, covers, and fall arrest systems are highlighted.

![Fall Protection and Feasibility

Infeasible means that it is impossible to perform the work while using a

conventional fall protection system, or that it is technologically impossible to

use a conventional system.

“Infeasible” is strictly defined by OSHA.

OSHA presumes that fall protection is feasible and will not create a greater hazard

to use at least one of the above-listed fall protection systems specified in

paragraph (b)(1)(i) of this section.

The employer has the burden of establishing that fall protection is not feasible or

creates a greater hazard to provide the fall protection systems specified in

paragraph (b)(1)(i) and that it is necessary to implement a fall protection plan that

complies with §1926.502(k) in the particular work operation, in lieu of

implementing any of those systems. [ §1910.28(b)(1)(i), Note ]

58](https://image.slidesharecdn.com/fgpiworkerpresentation-231225155506-06d5646d/85/FGPI_Worker_Presentation-pptx-58-320.jpg)