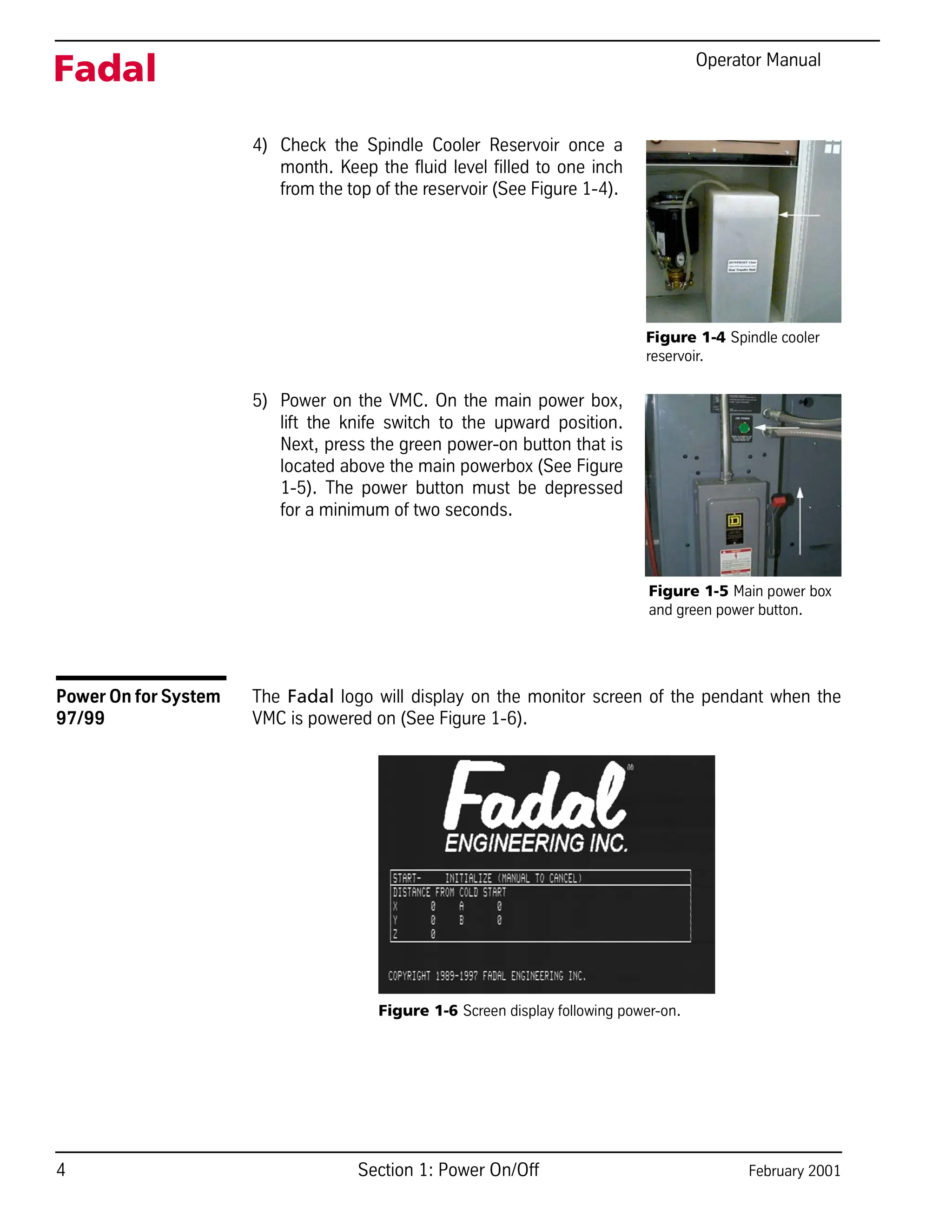

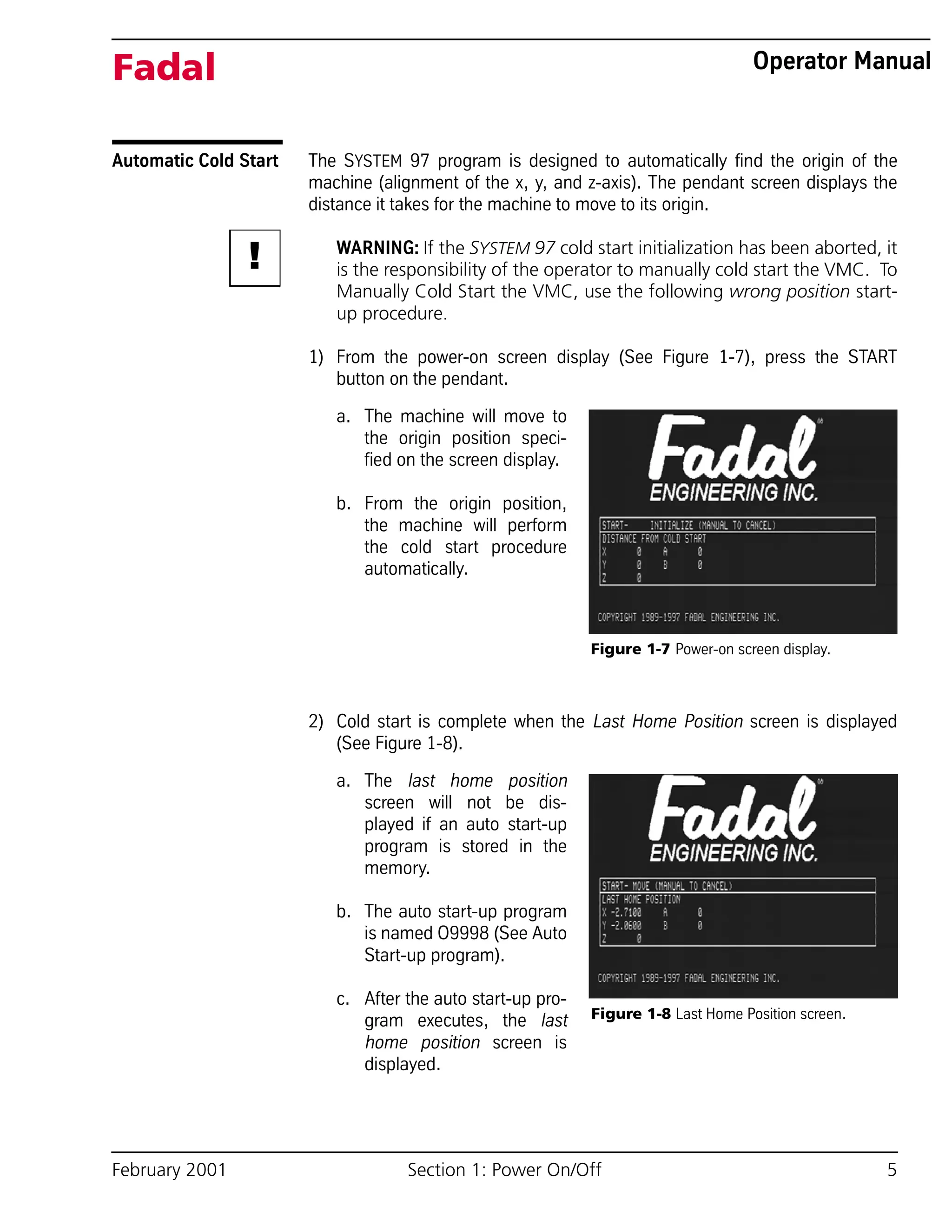

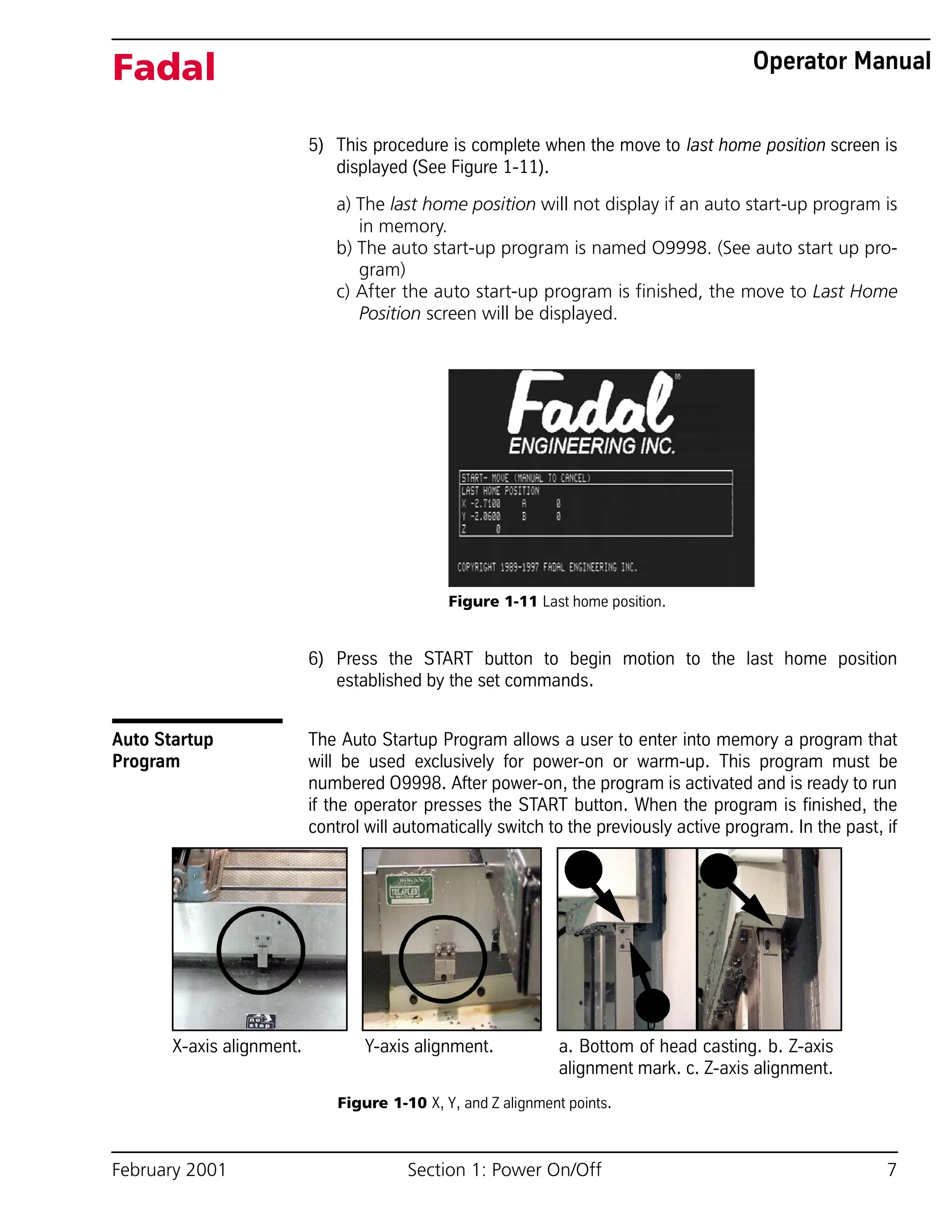

The document provides detailed instructions on the power on/off procedures for a Fadal VMC, including pre-startup checks such as oil levels, air pressure, and coolant levels. It also outlines the automatic and manual cold start processes, as well as proper power off procedures to ensure system integrity. The information aims to guide operators in maintaining and safely operating the machinery.