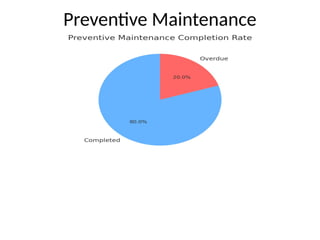

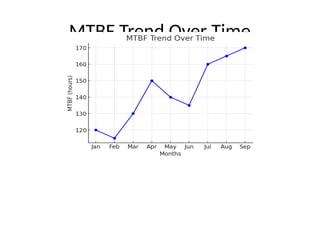

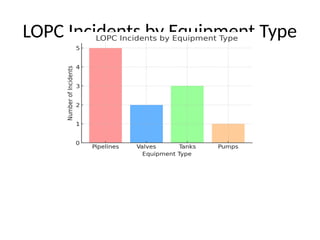

The document outlines executive-level KPIs for asset integrity management within a multinational oil and gas company, aimed at providing senior management with insights aligned to global standards. It details both leading indicators for proactive monitoring and lagging indicators for reactive assessment, alongside visualizations to facilitate executive decision-making. Key performance indicators include compliance rates, maintenance metrics, and incident tracking, presented with various visual formats for clarity.