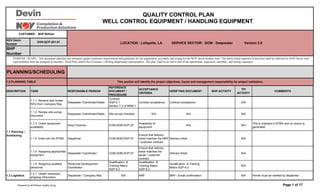

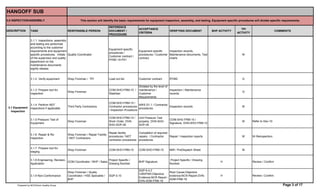

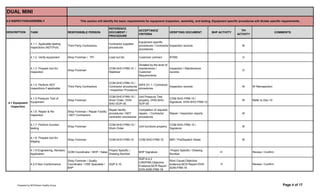

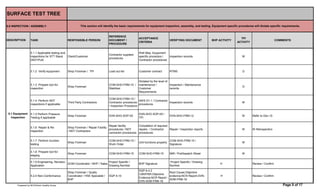

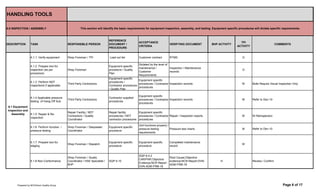

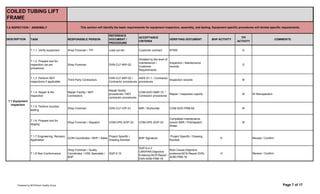

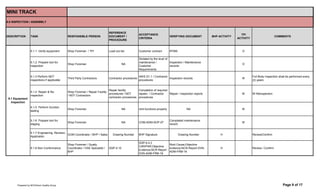

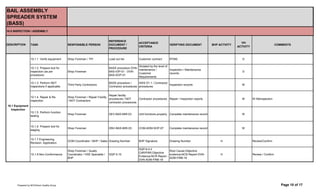

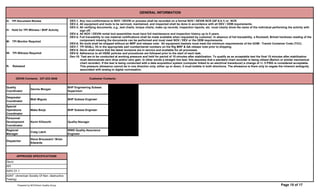

This document outlines the quality control plan for well control equipment provided by NOV Devin. It describes the planning, documentation review, inspection, assembly and testing processes. Key steps include:

1. Planning the project and assigning responsible personnel.

2. Reviewing equipment documentation like data books and maintenance records.

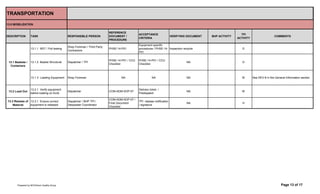

3. Inspecting, assembling and testing equipment according to customer requirements and equipment specific procedures. This includes non-destructive testing, pressure testing, and addressing any non-conformances.

4. Preparing inspected equipment for staging and shipment. Quality inspections are performed with representation from the customer and third parties.