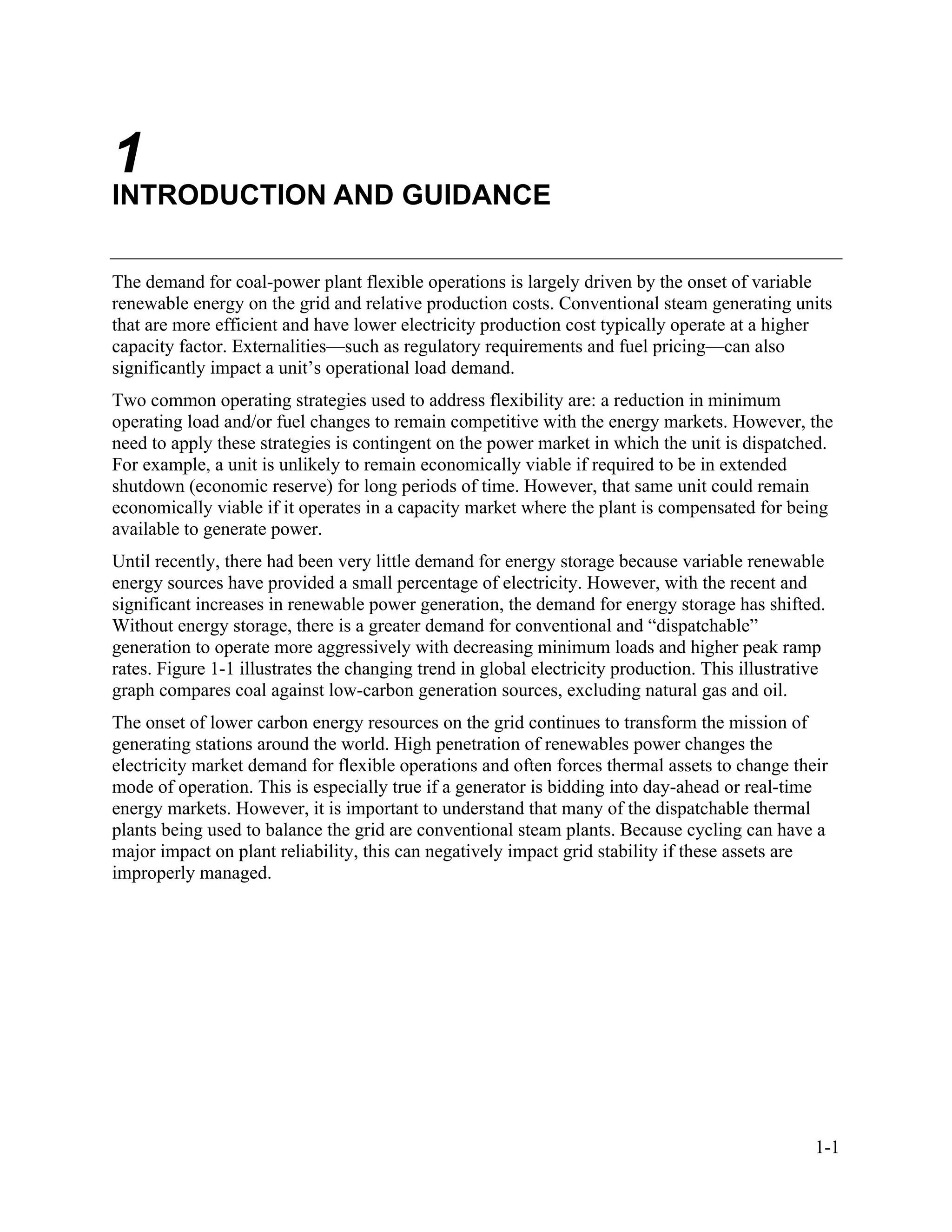

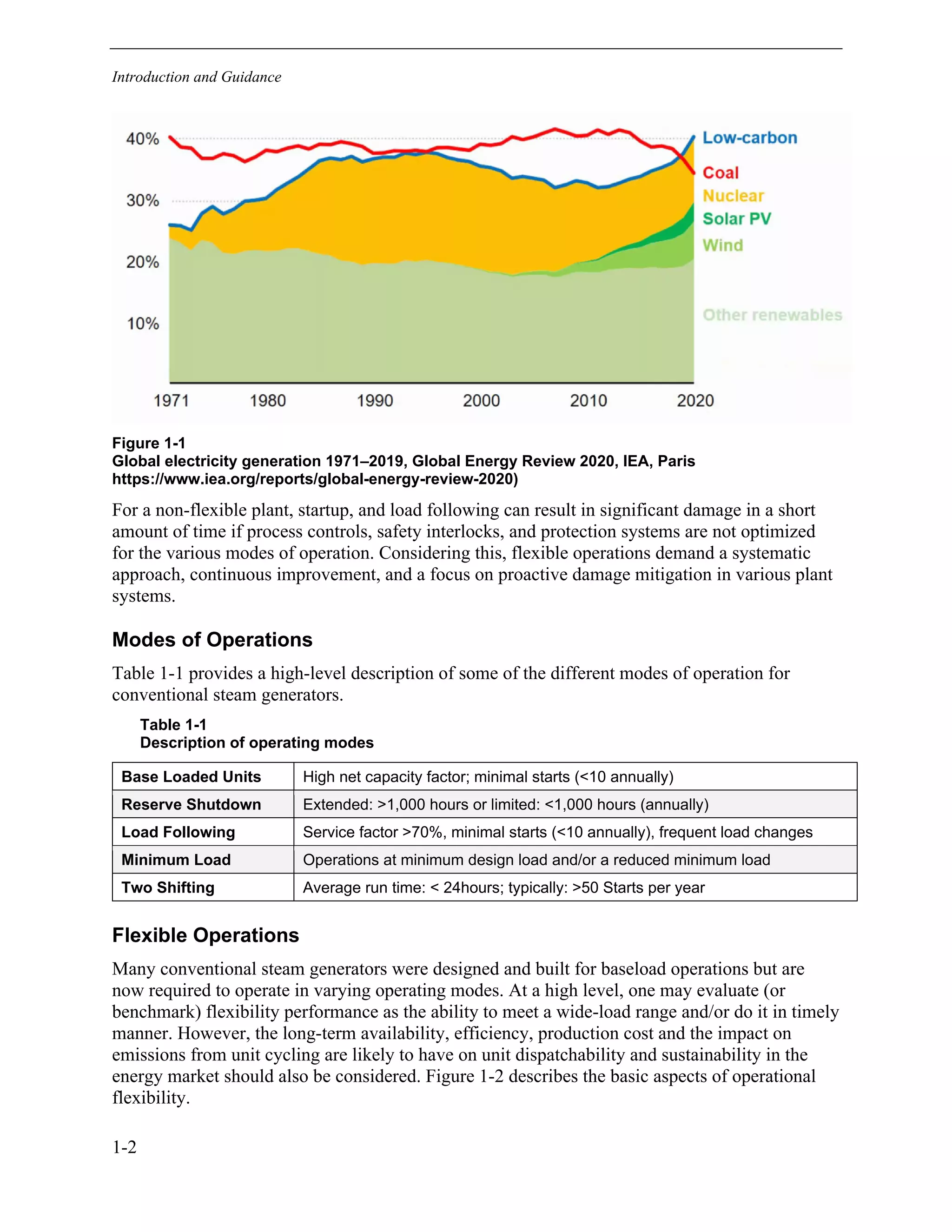

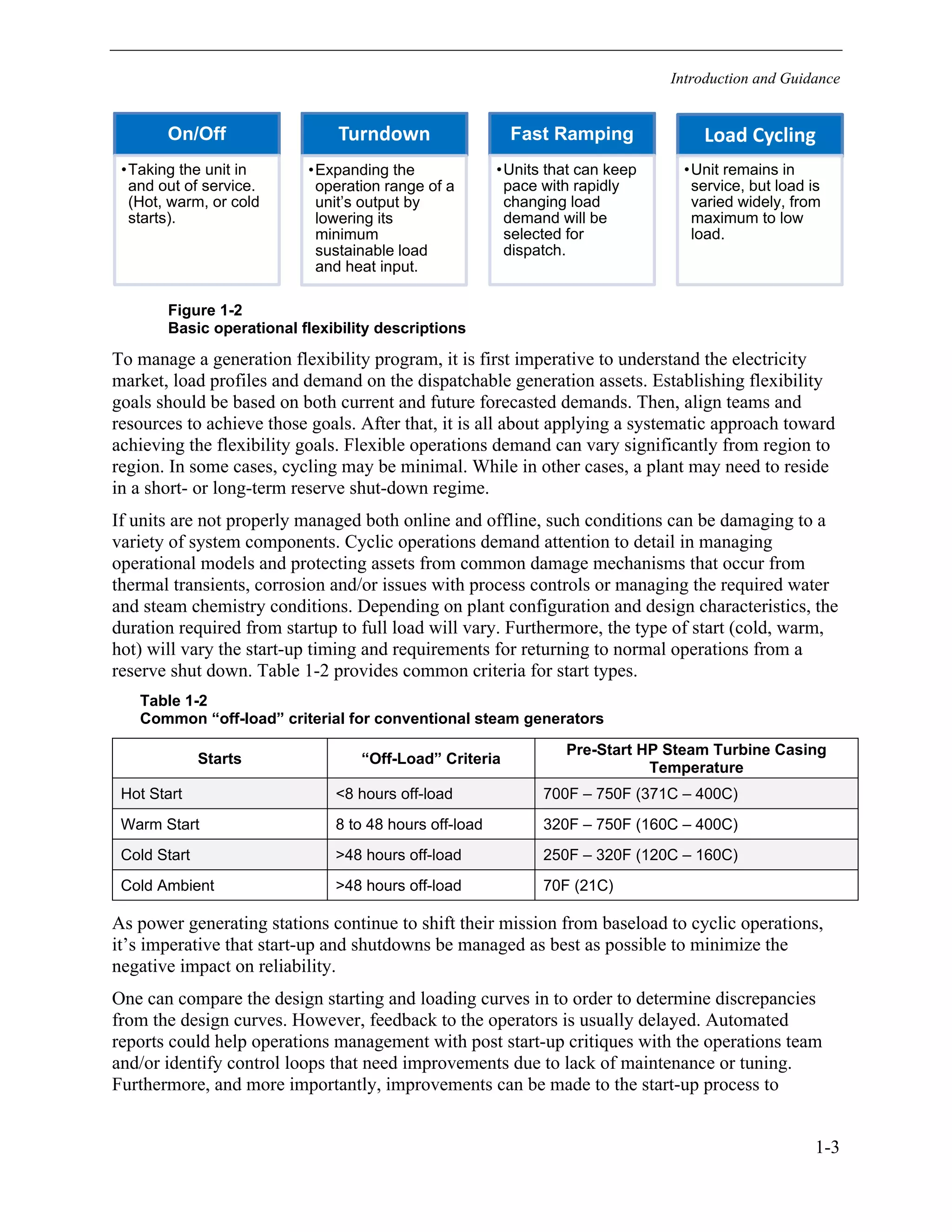

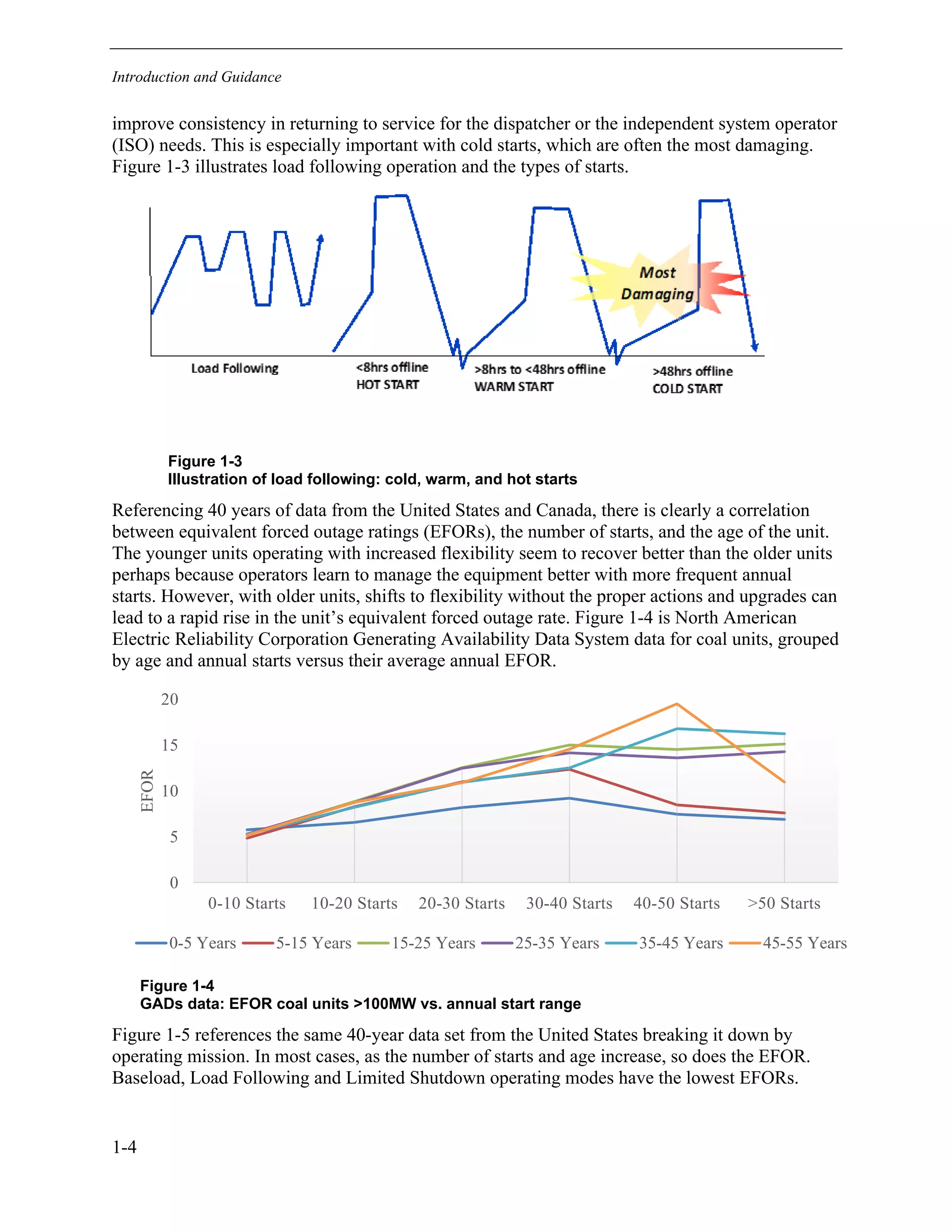

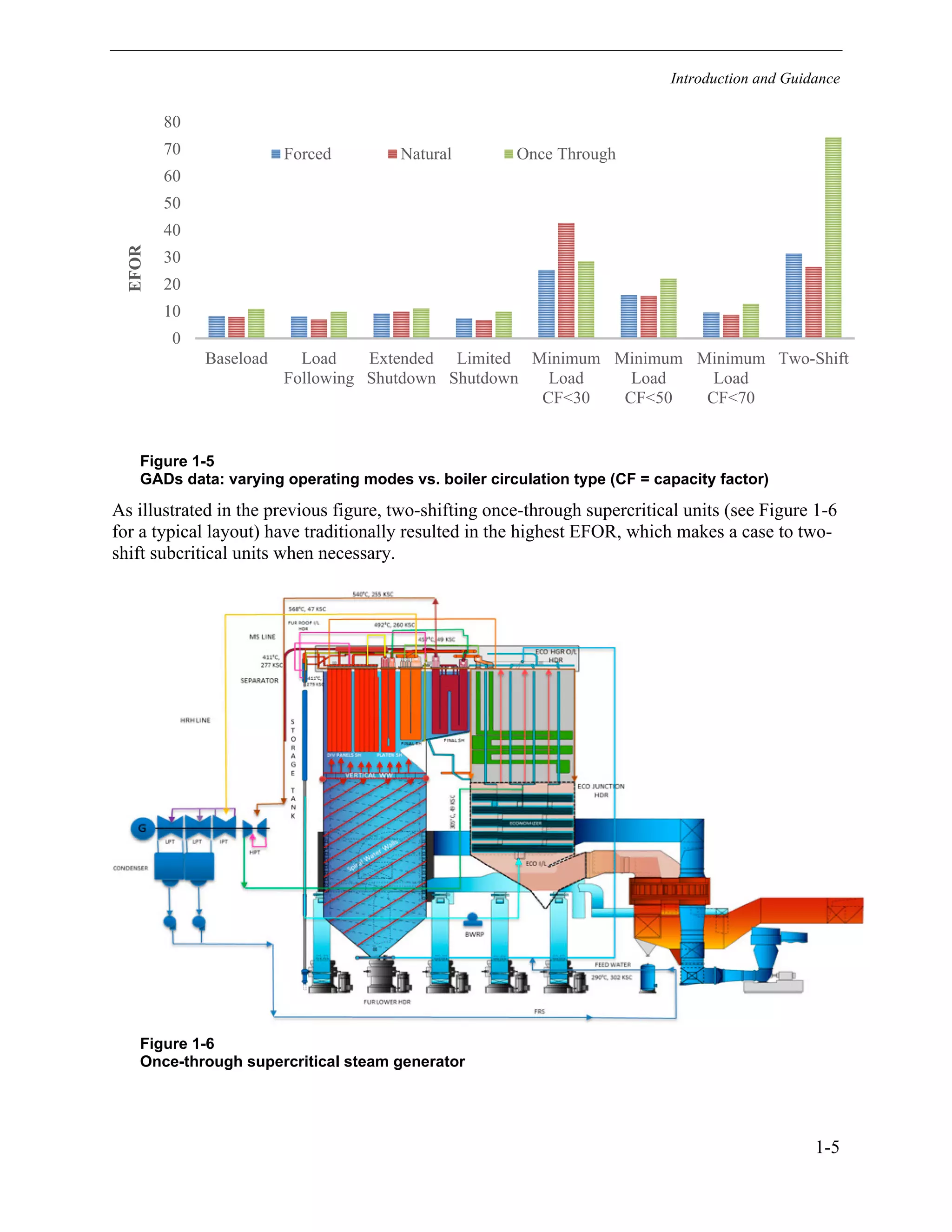

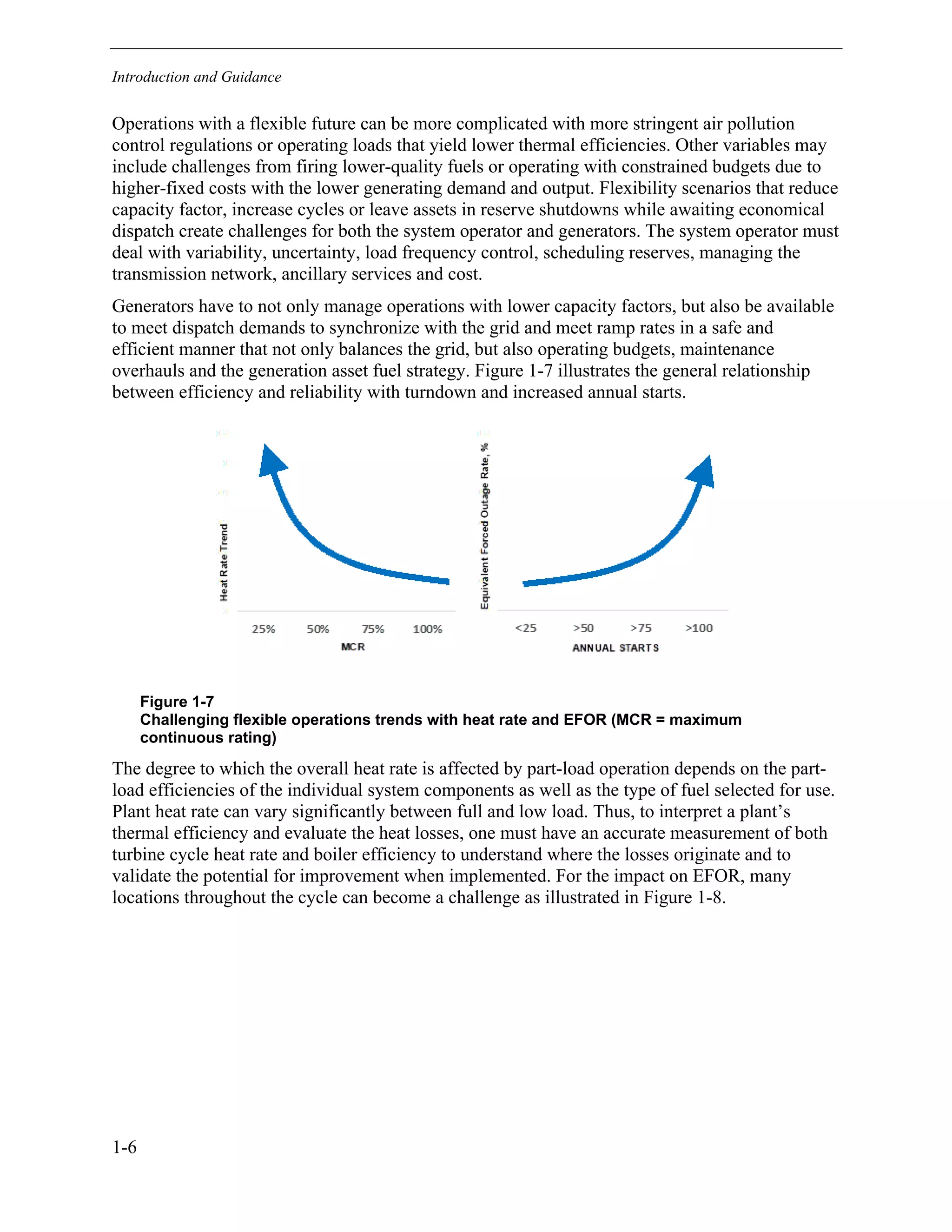

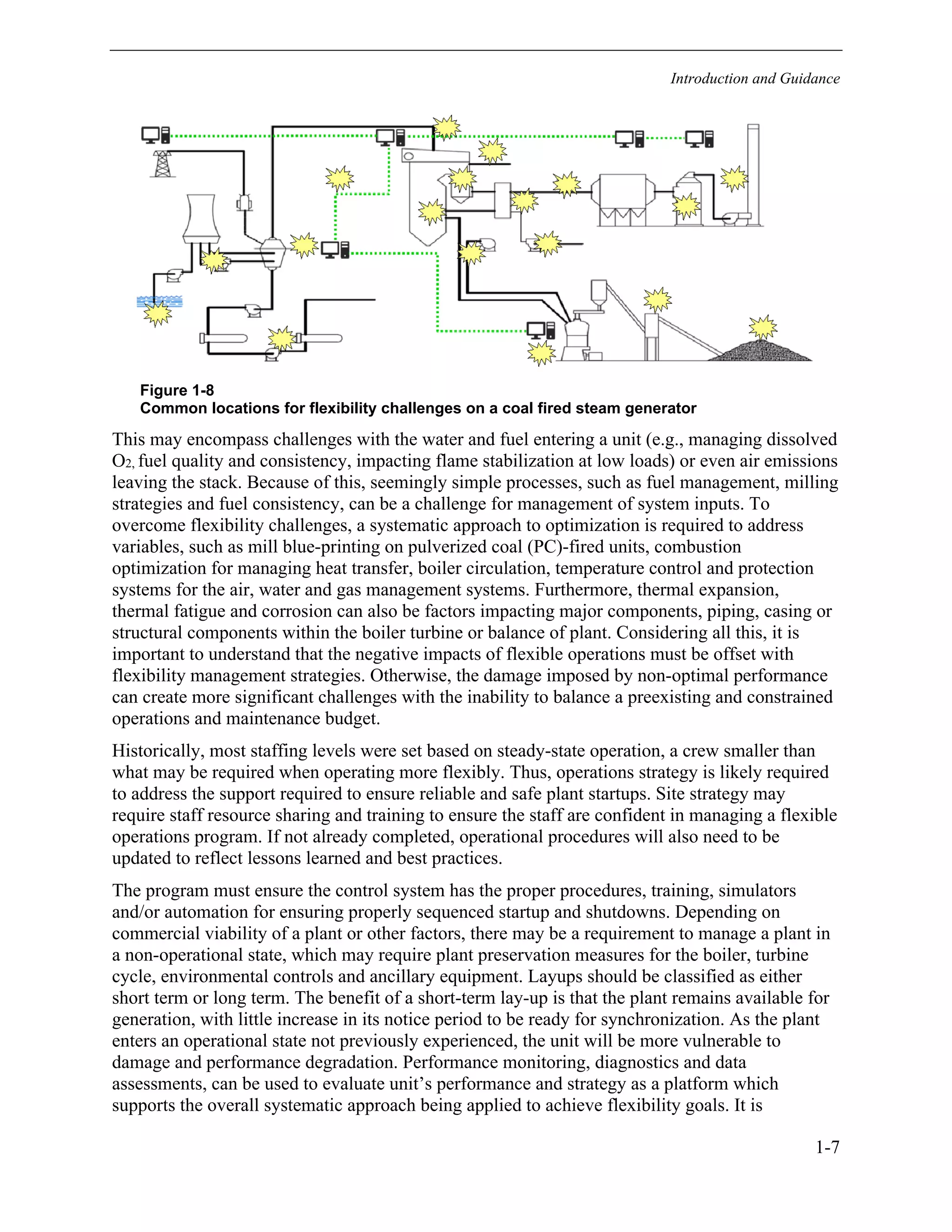

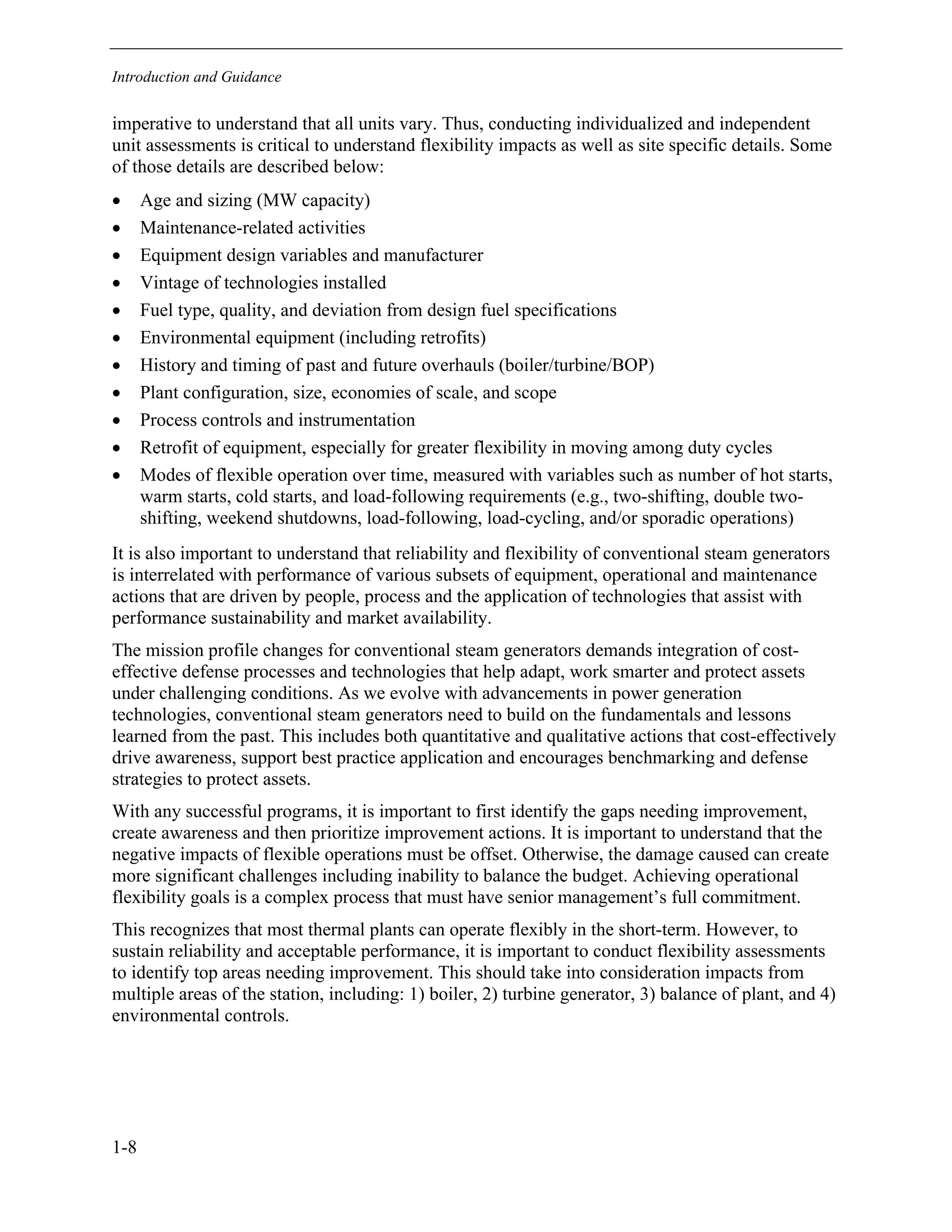

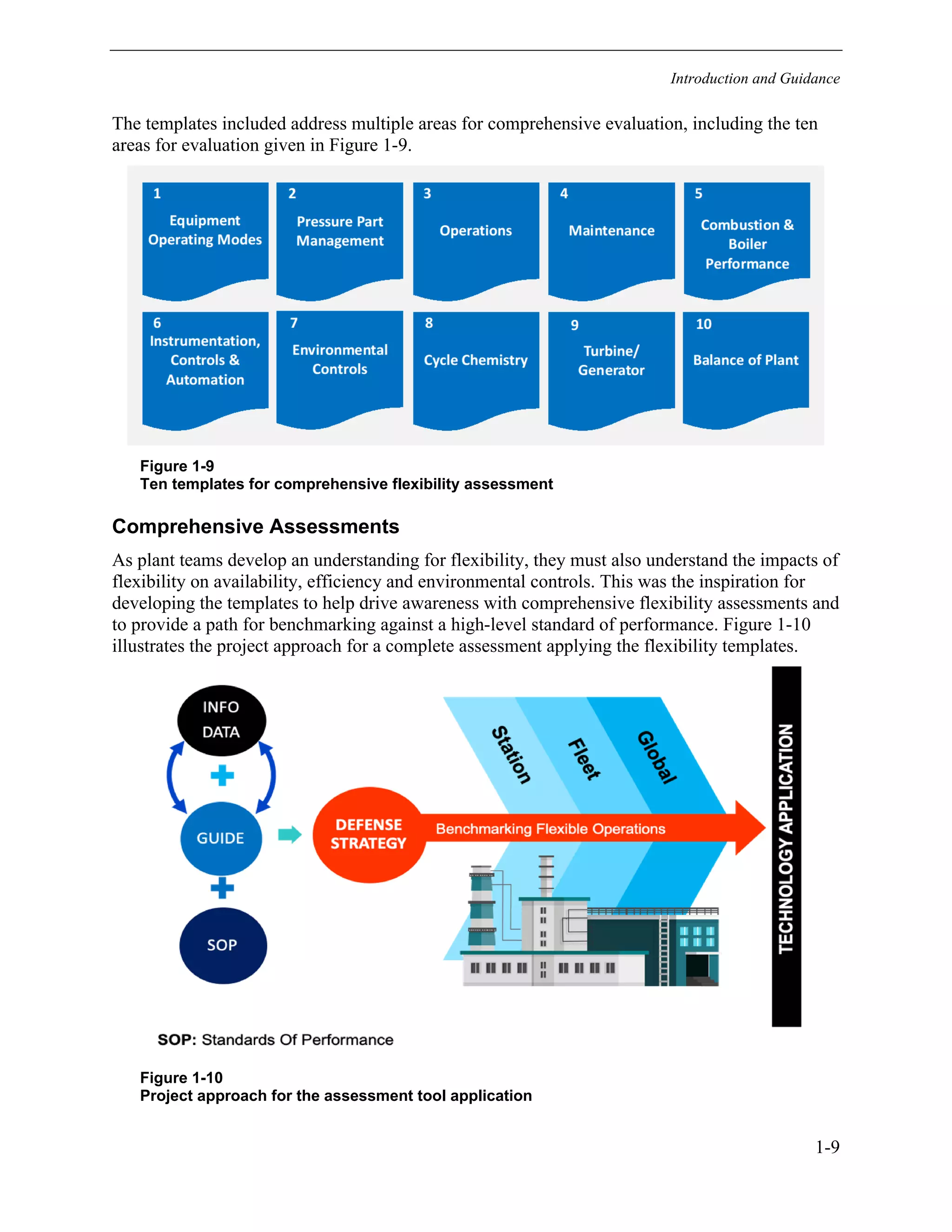

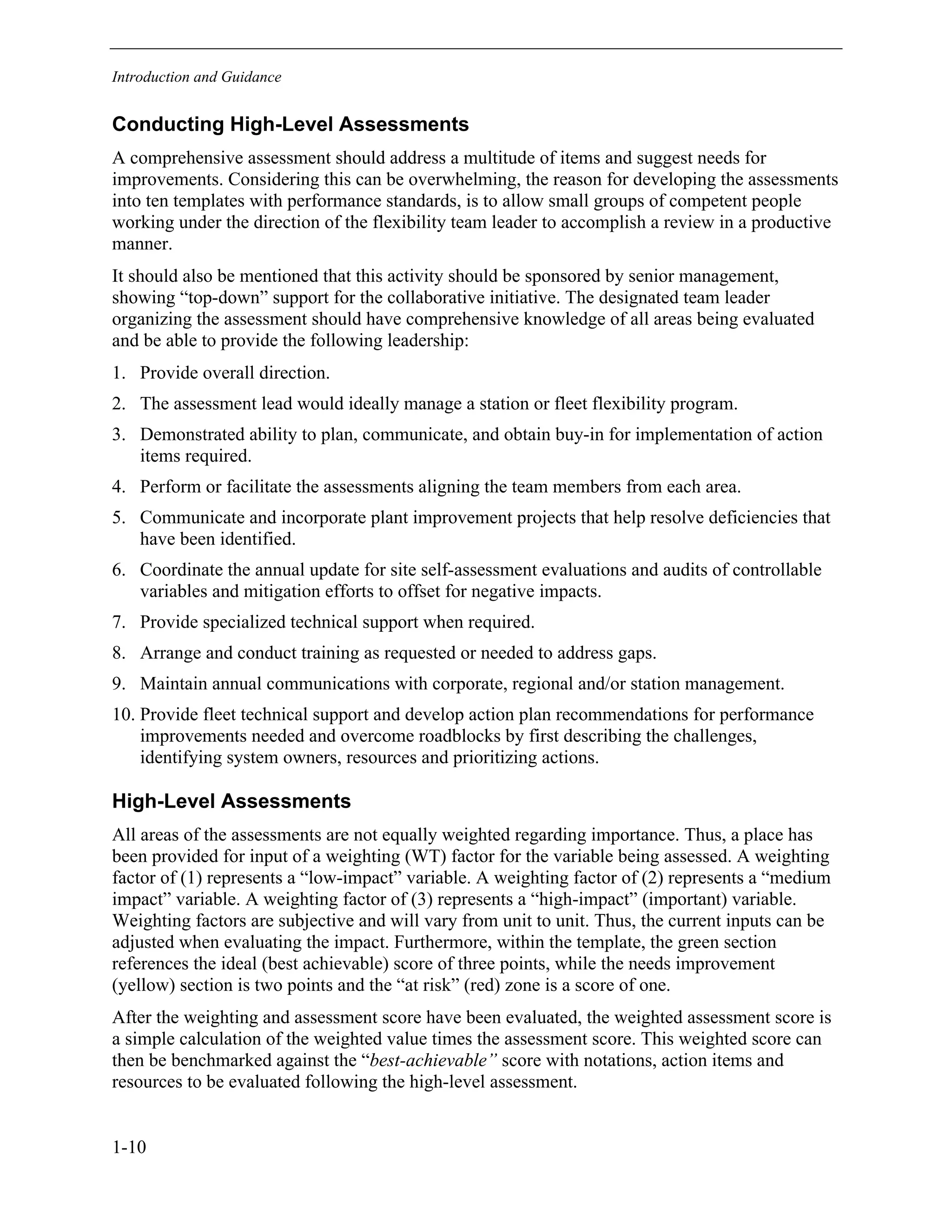

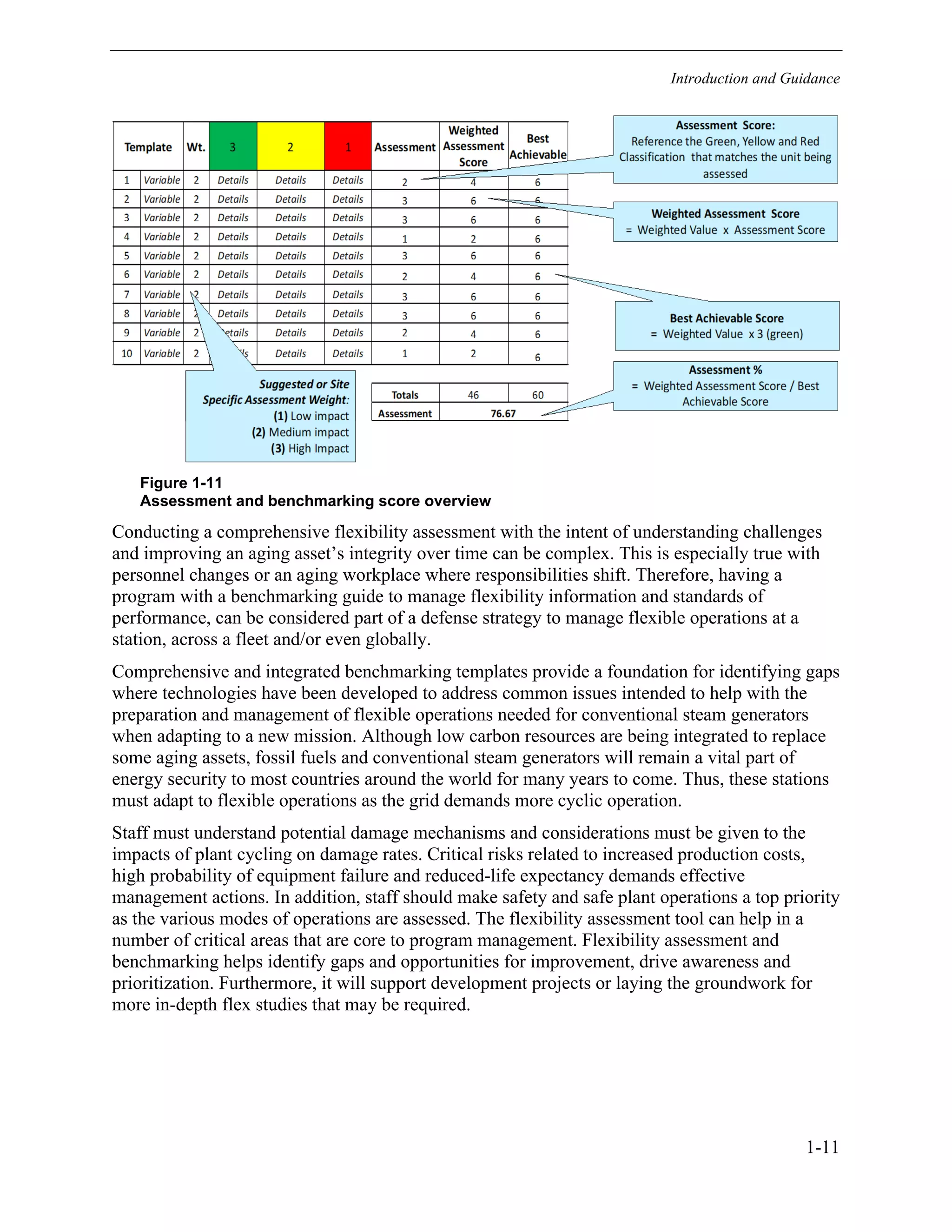

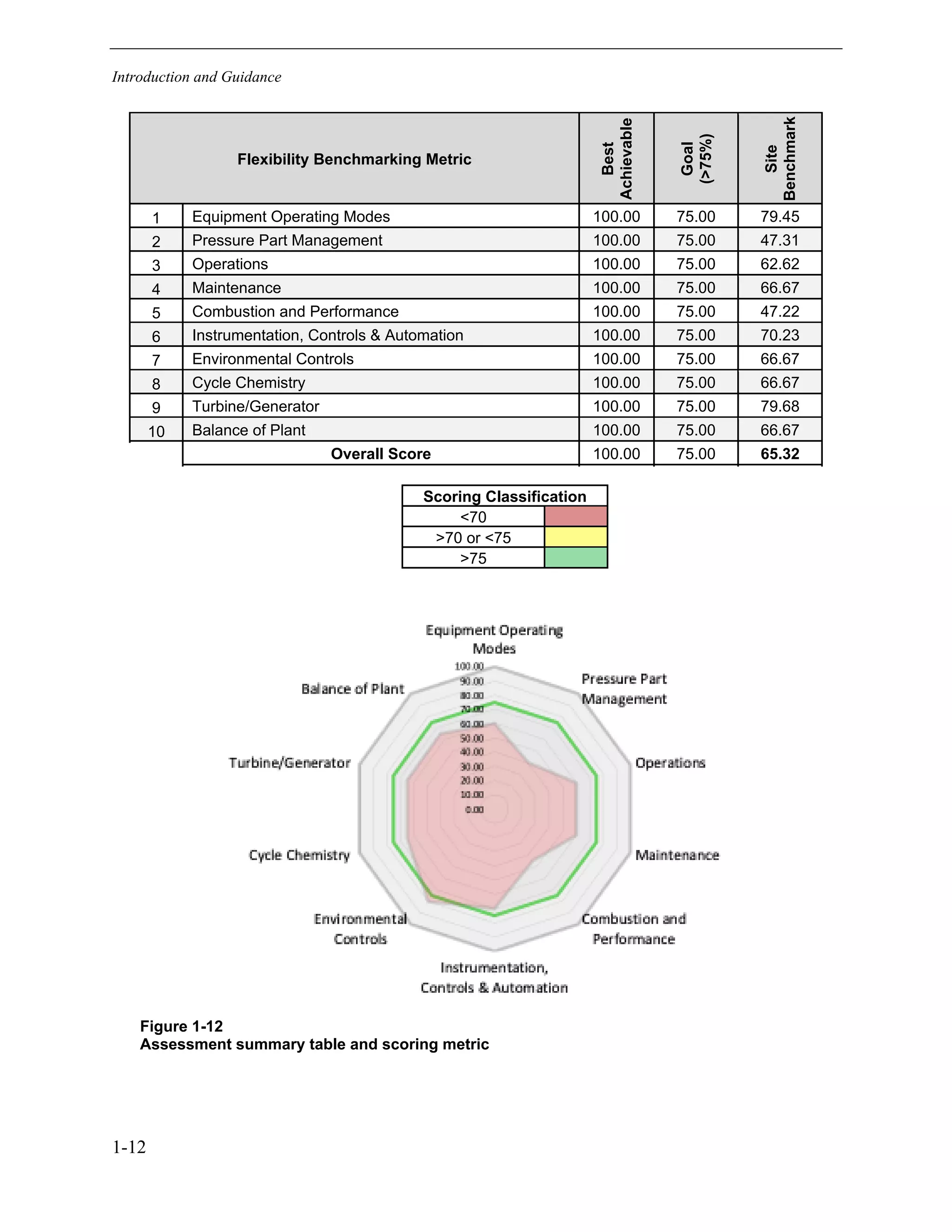

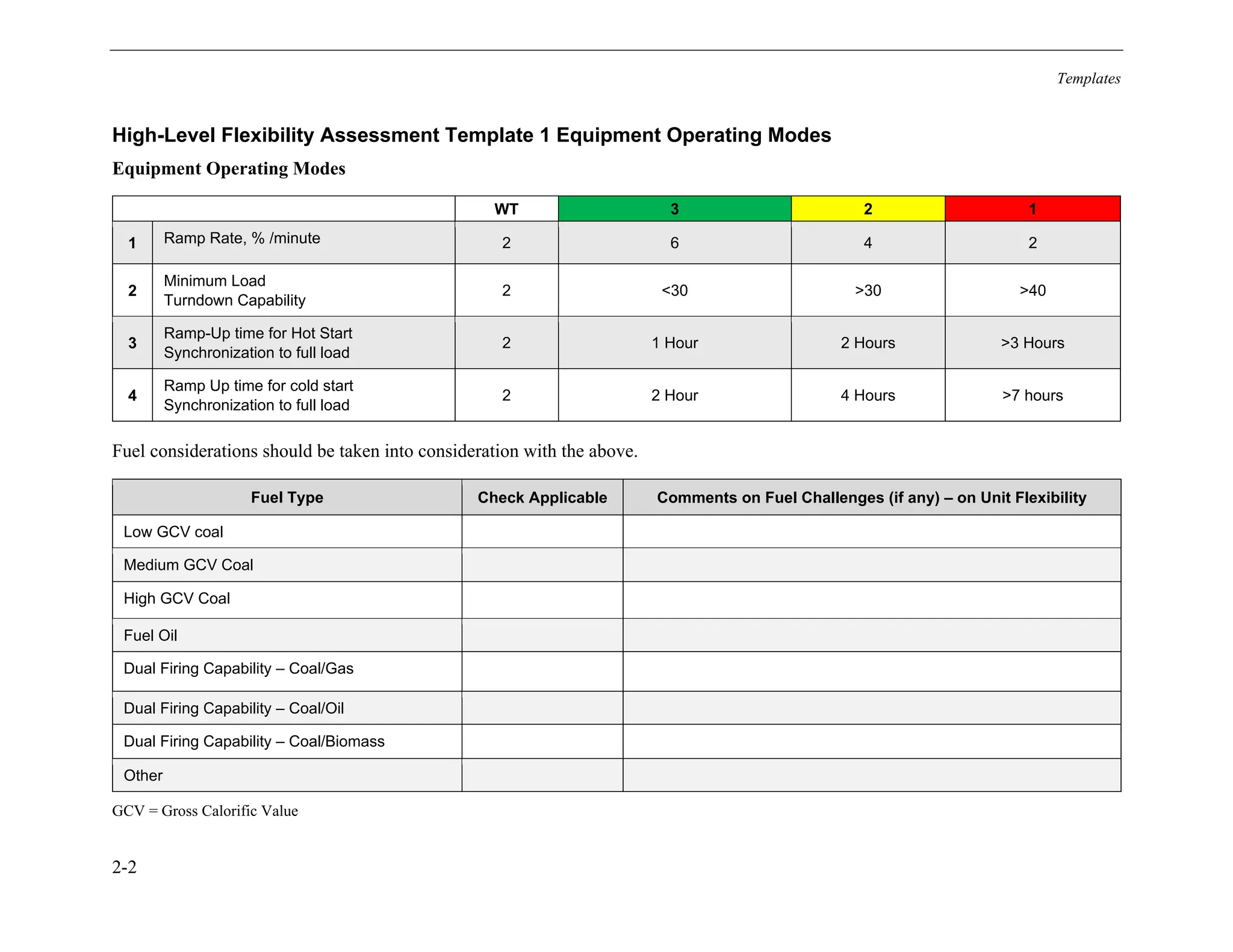

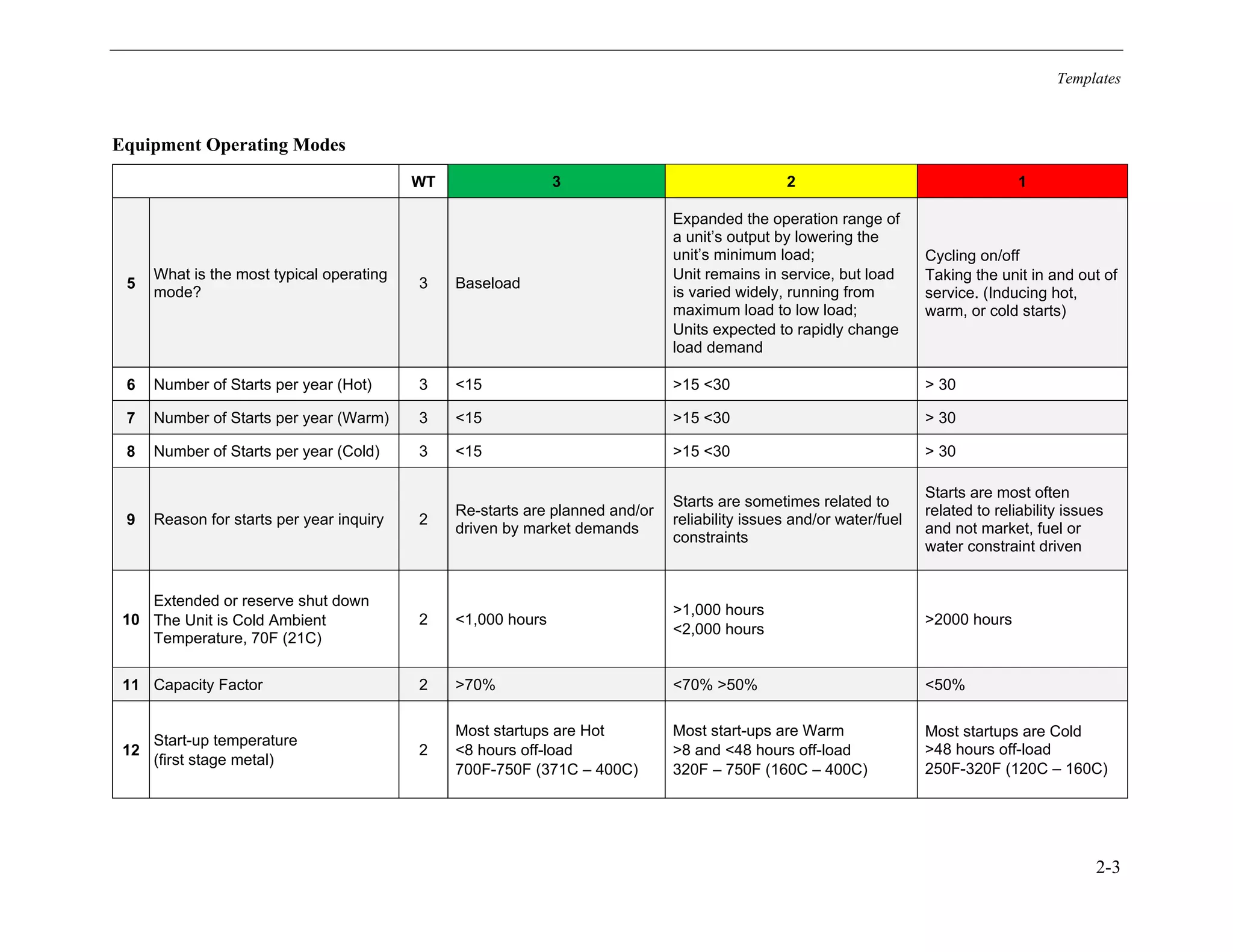

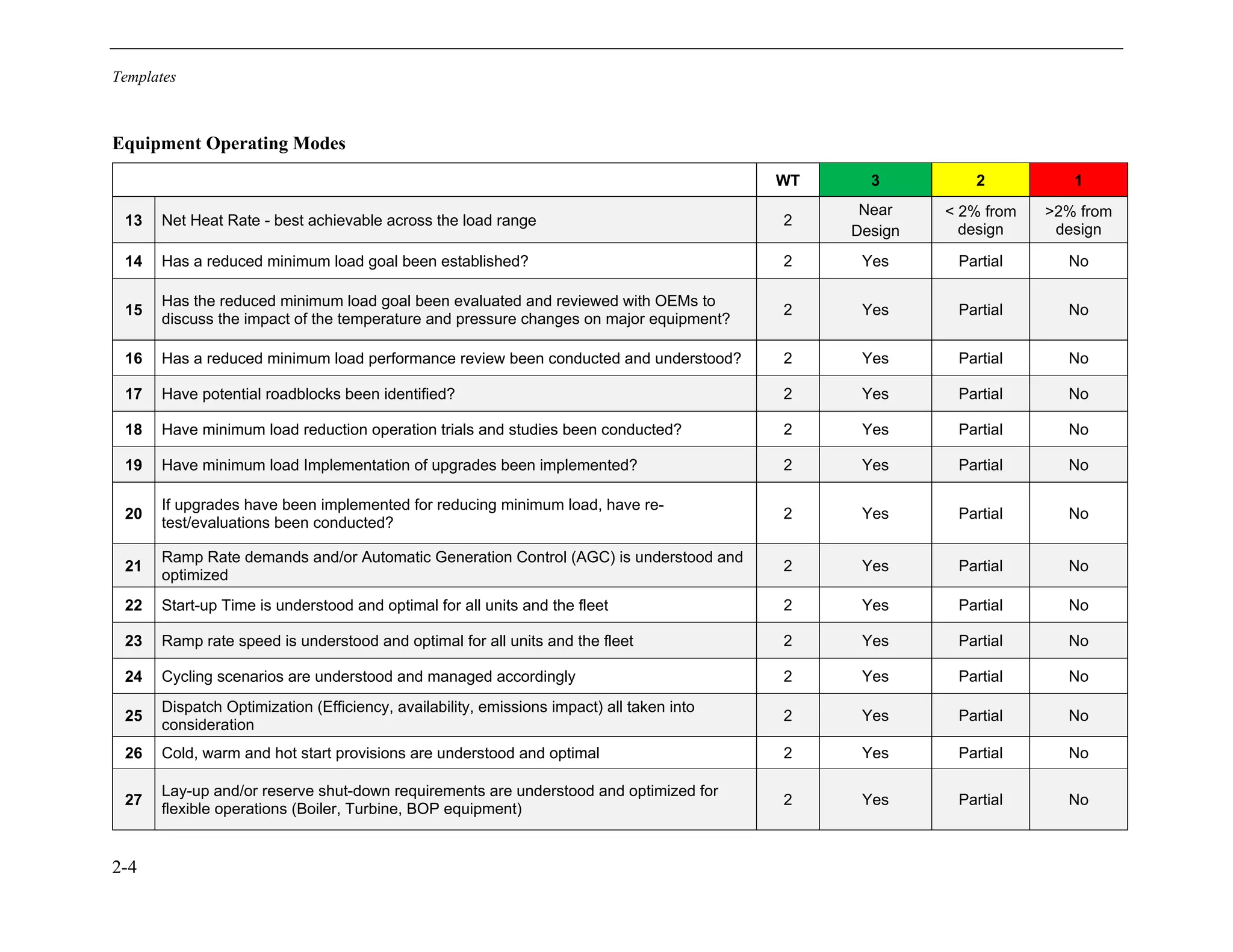

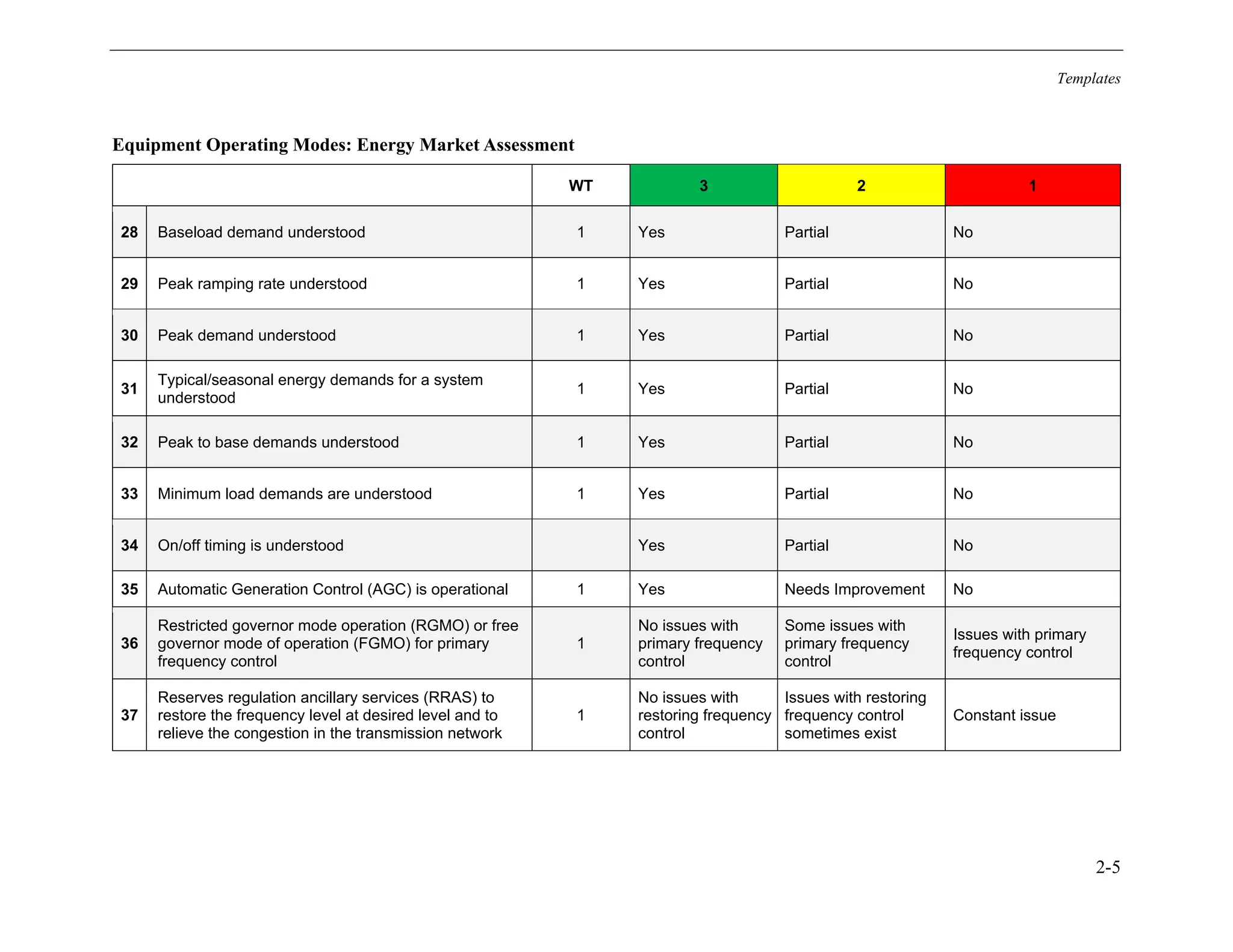

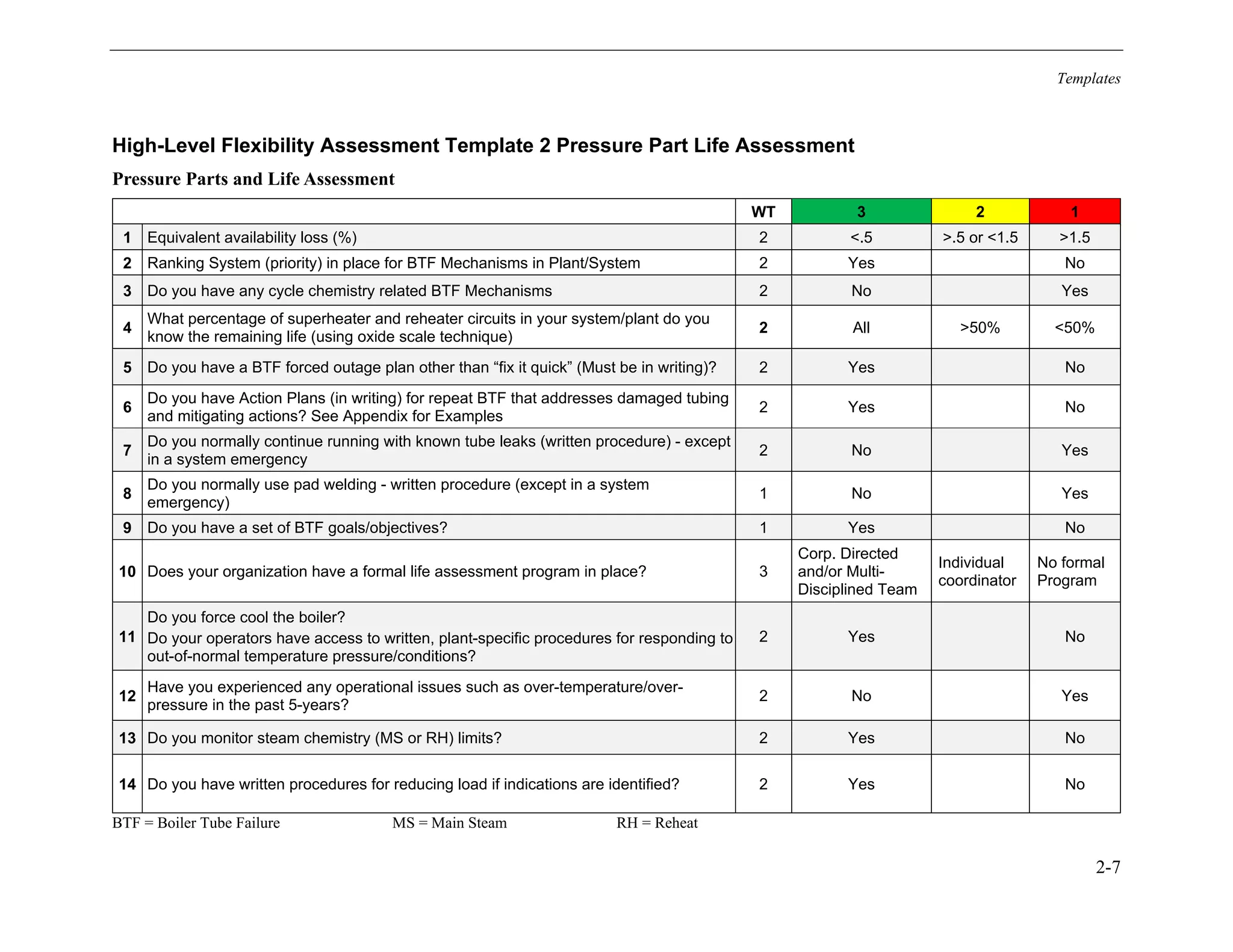

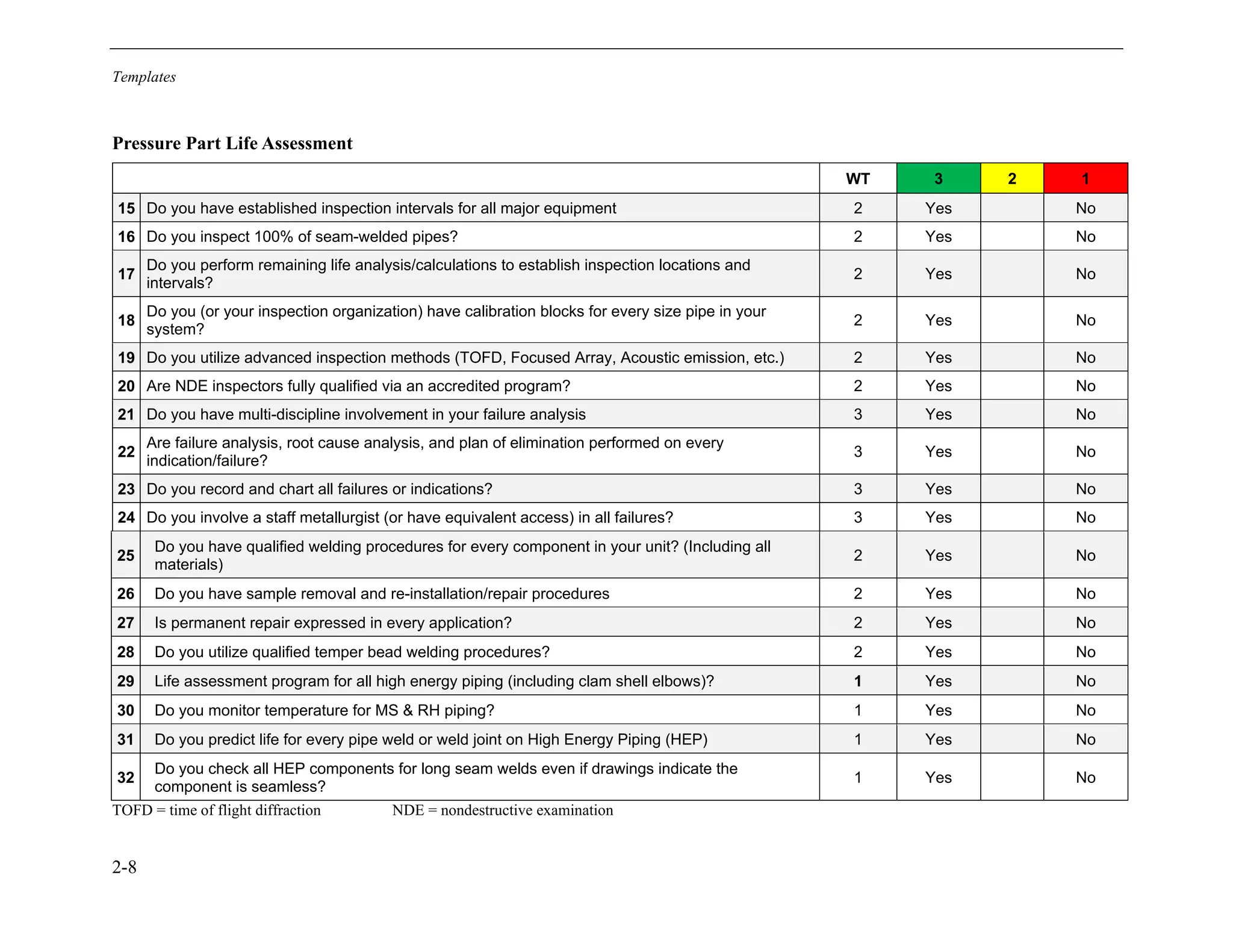

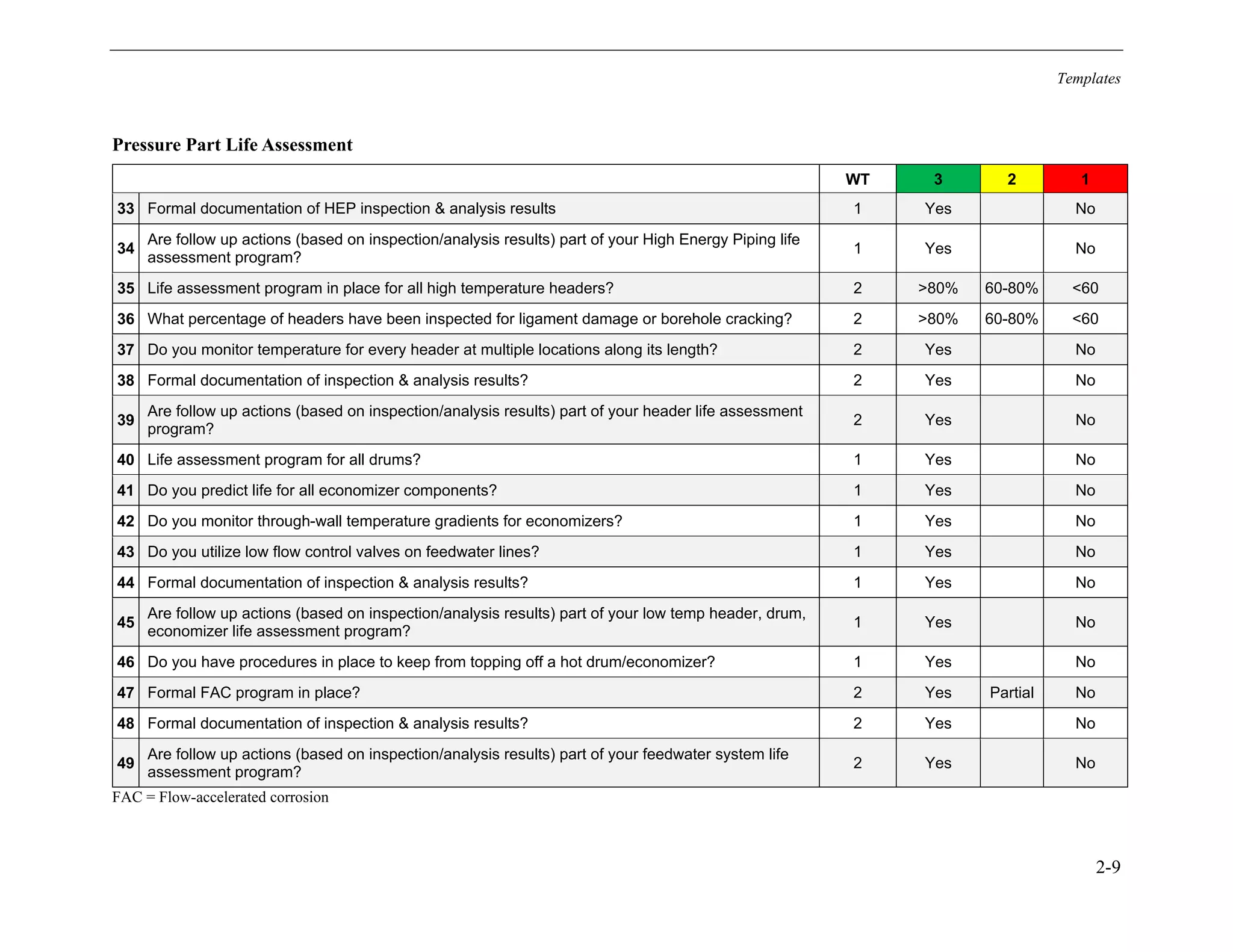

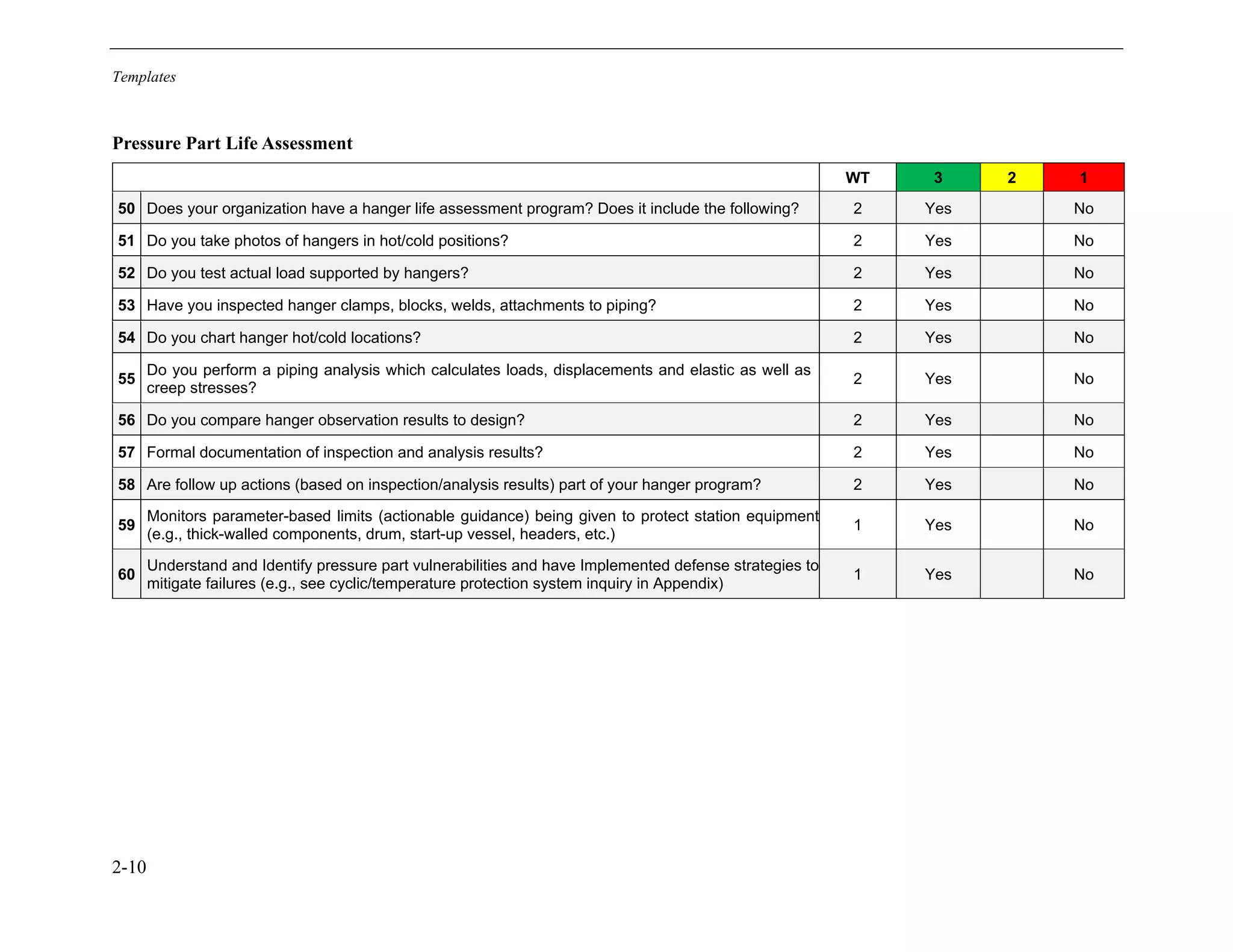

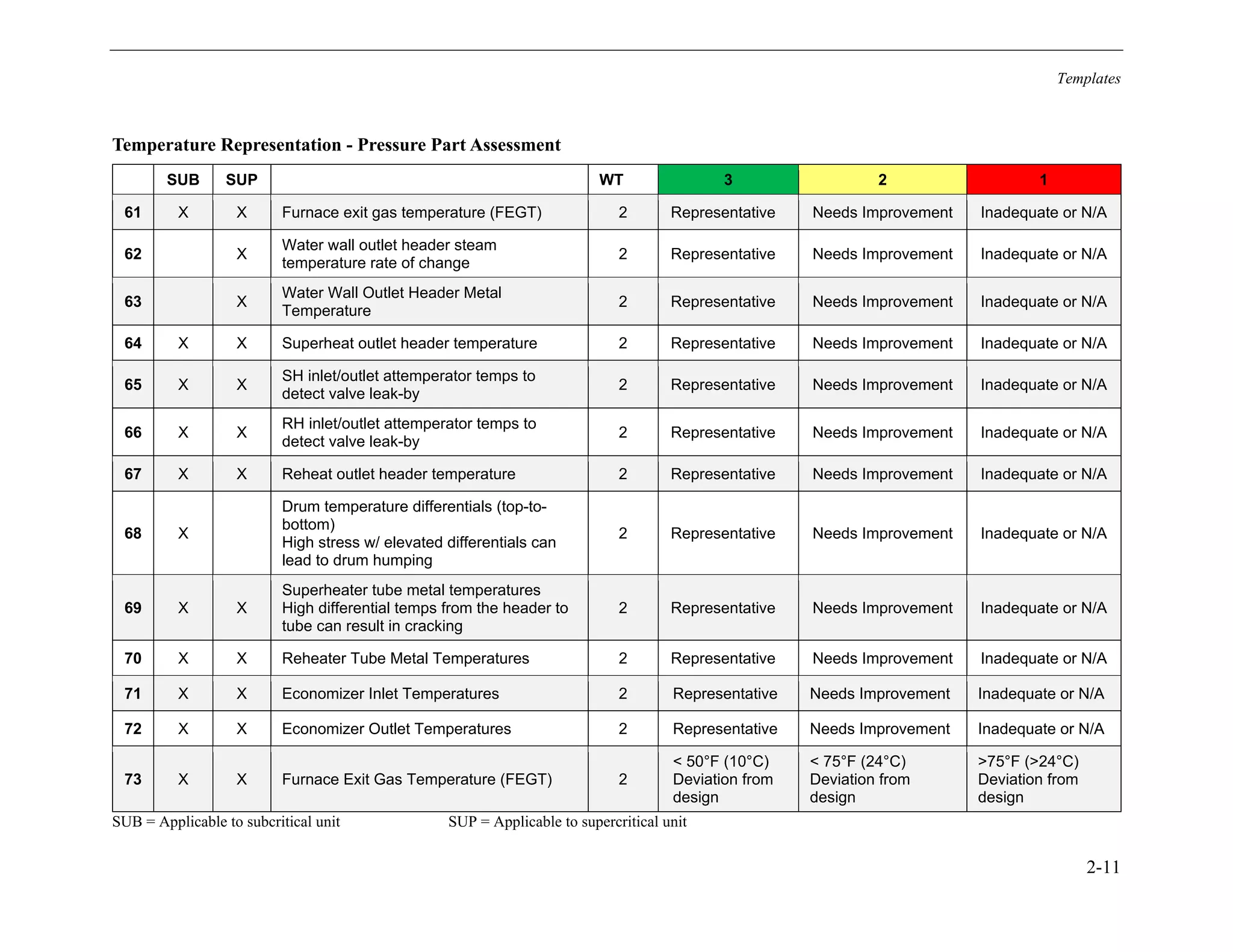

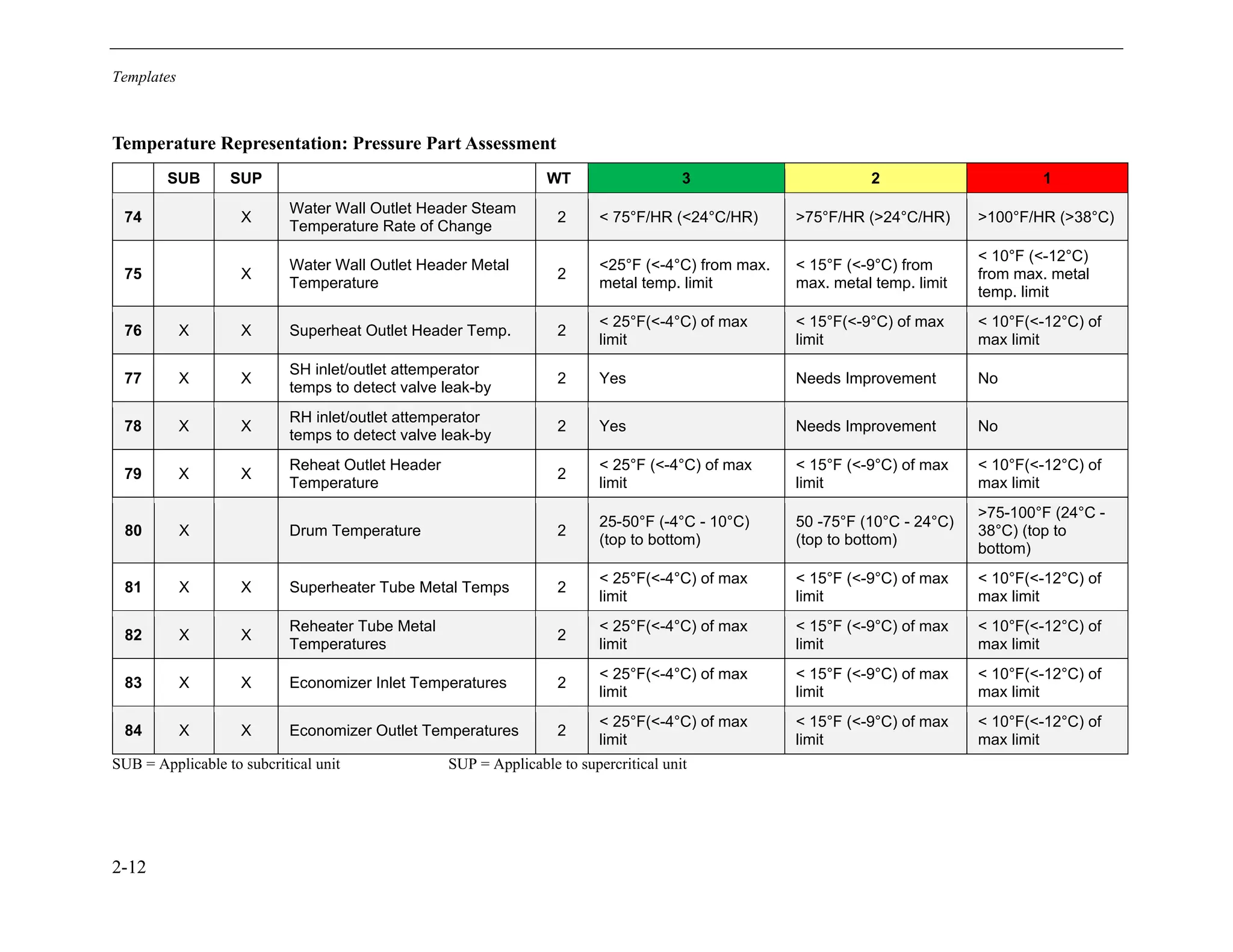

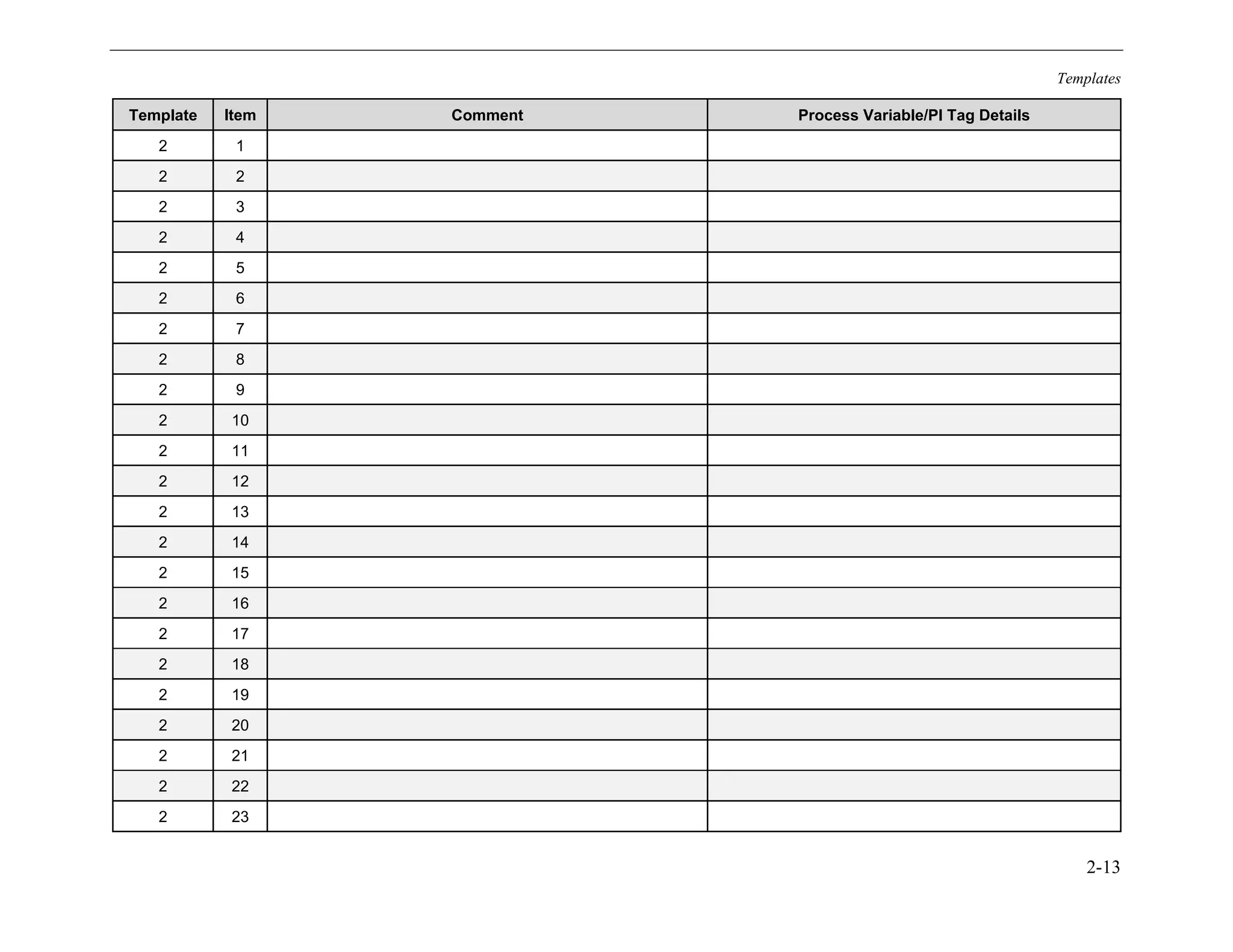

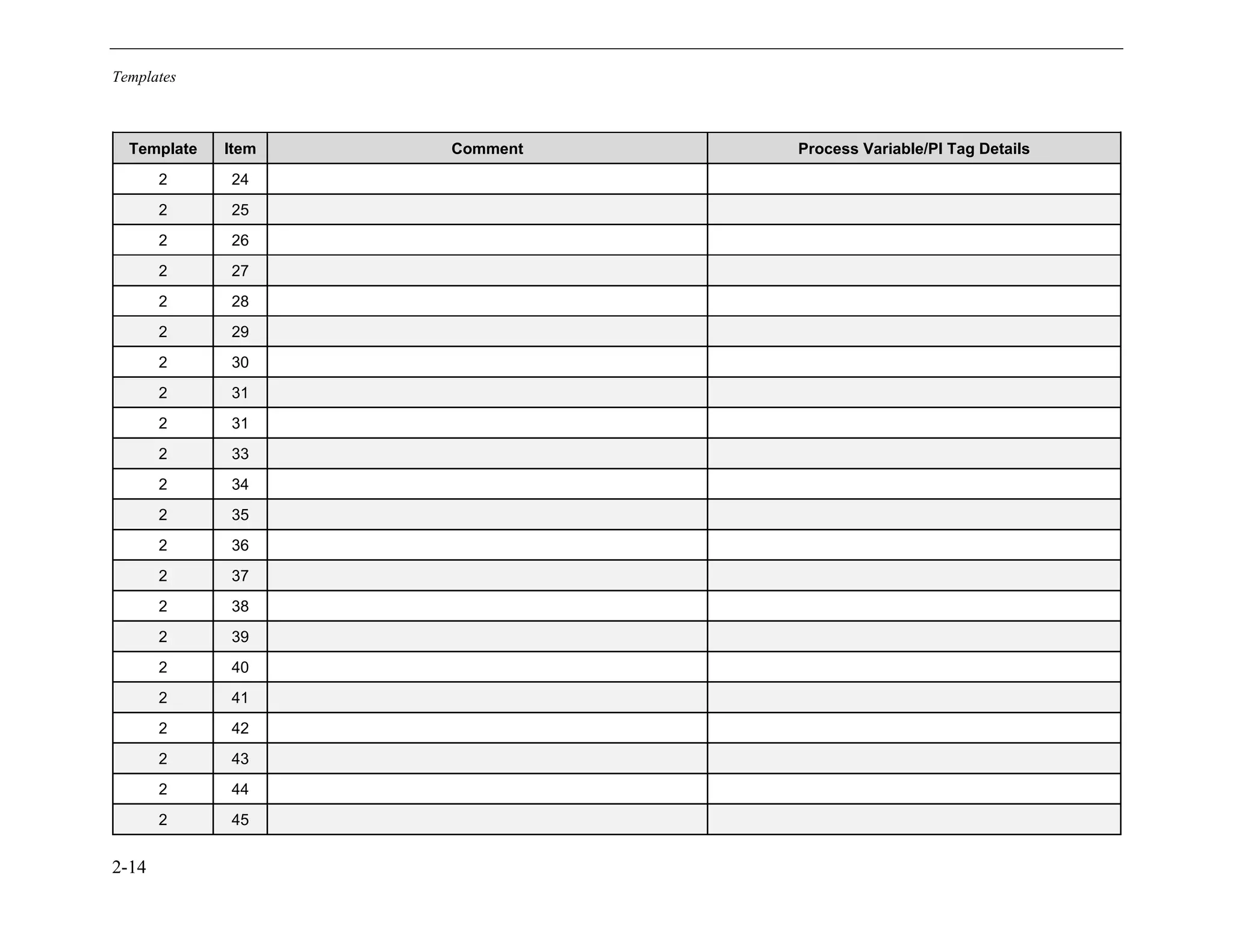

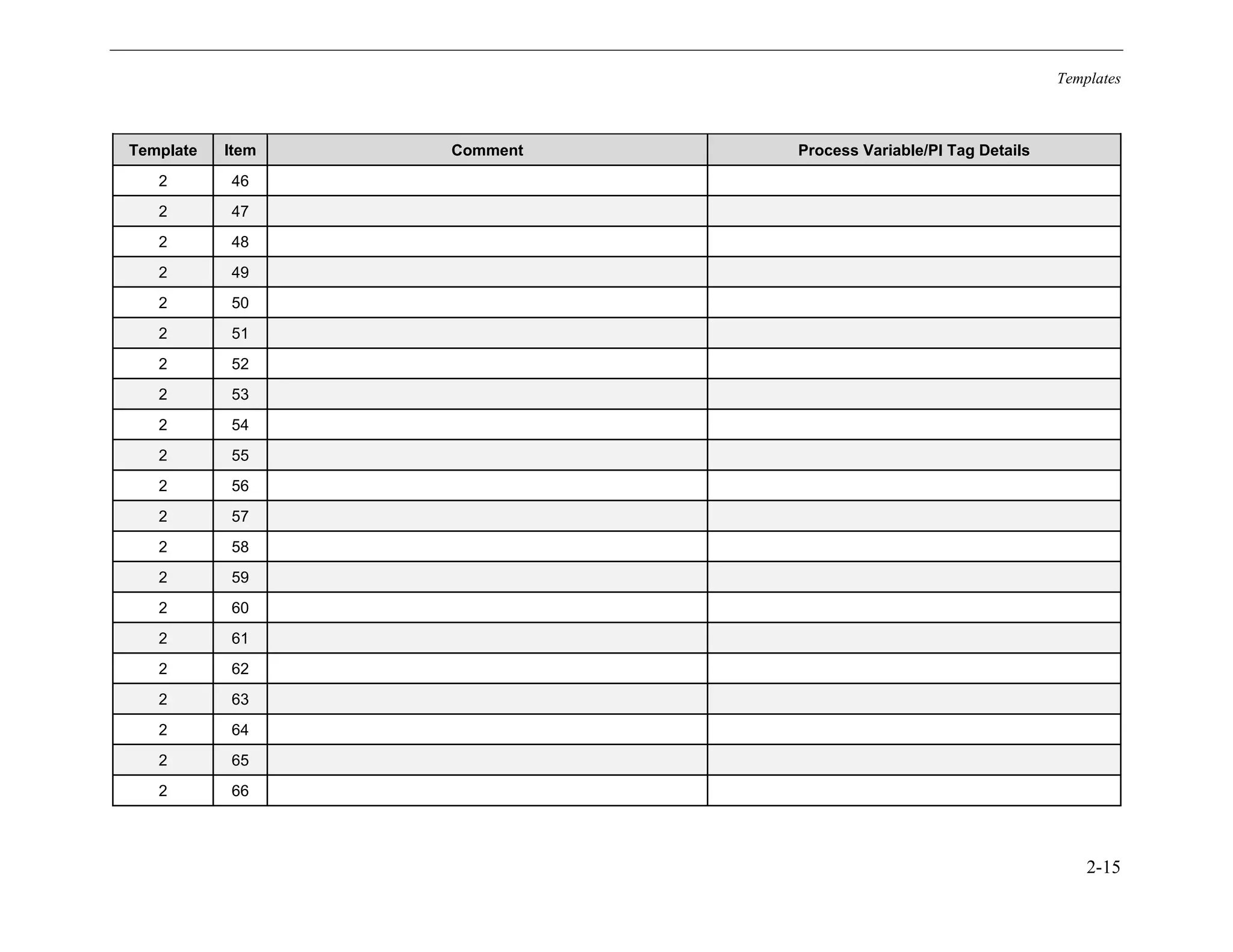

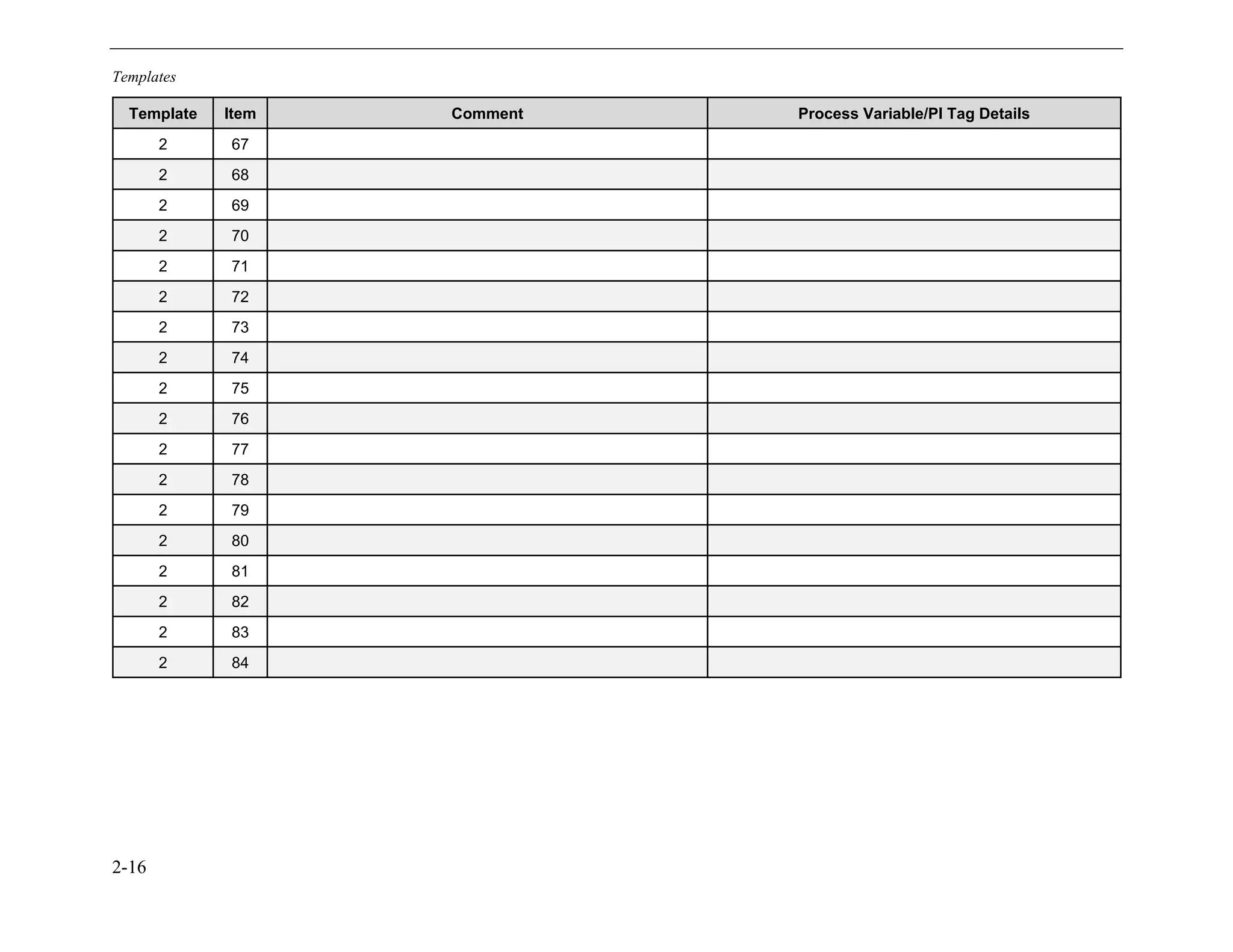

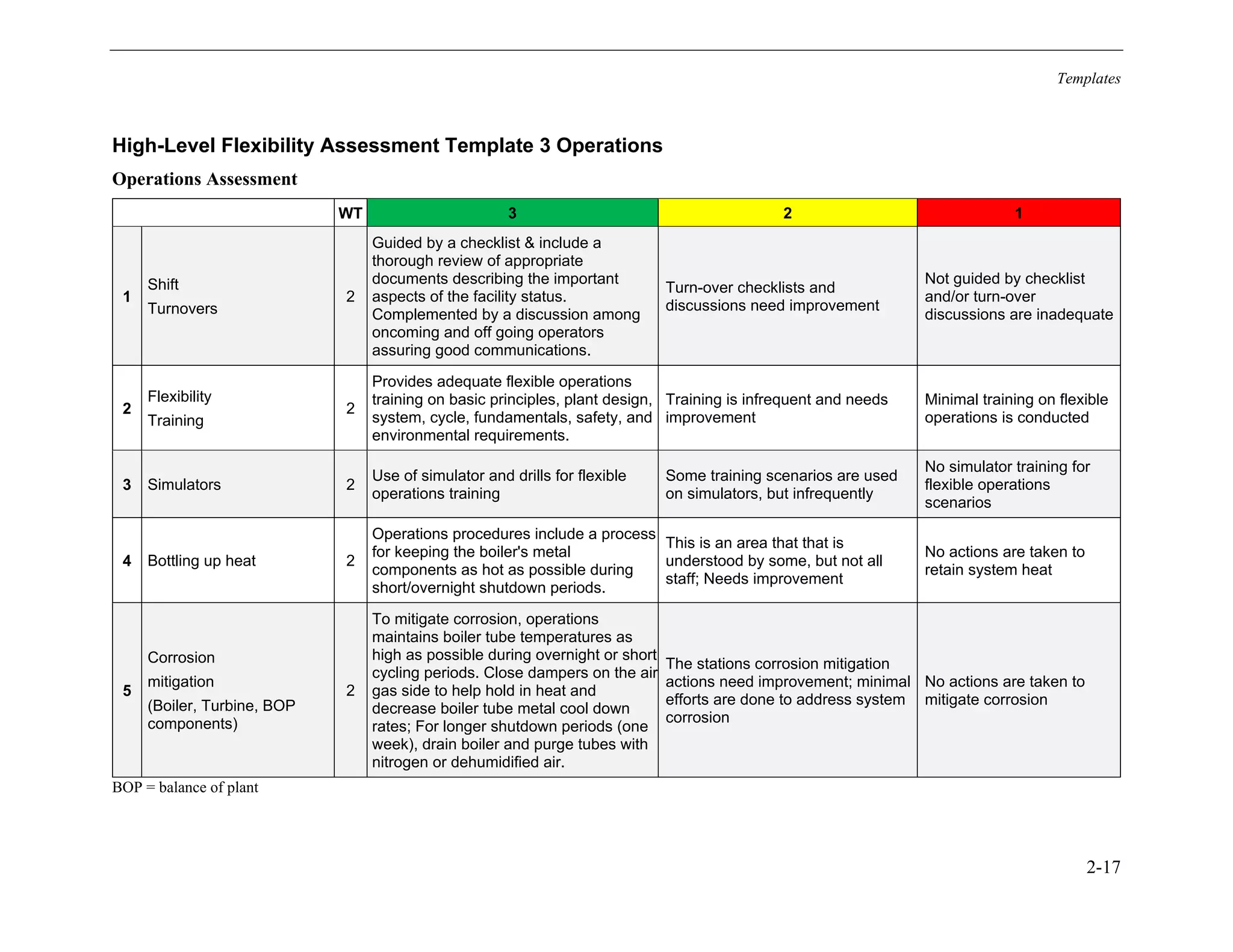

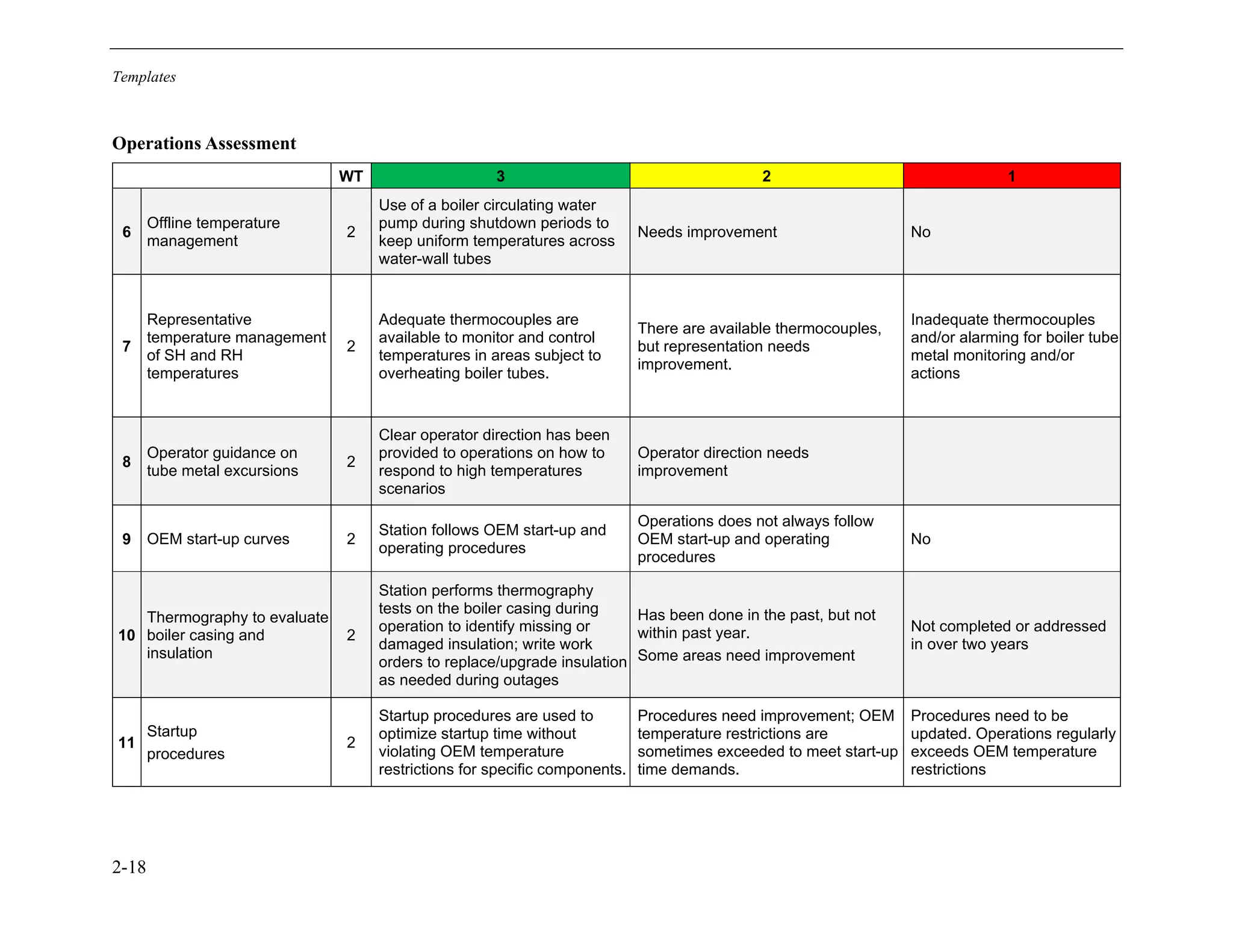

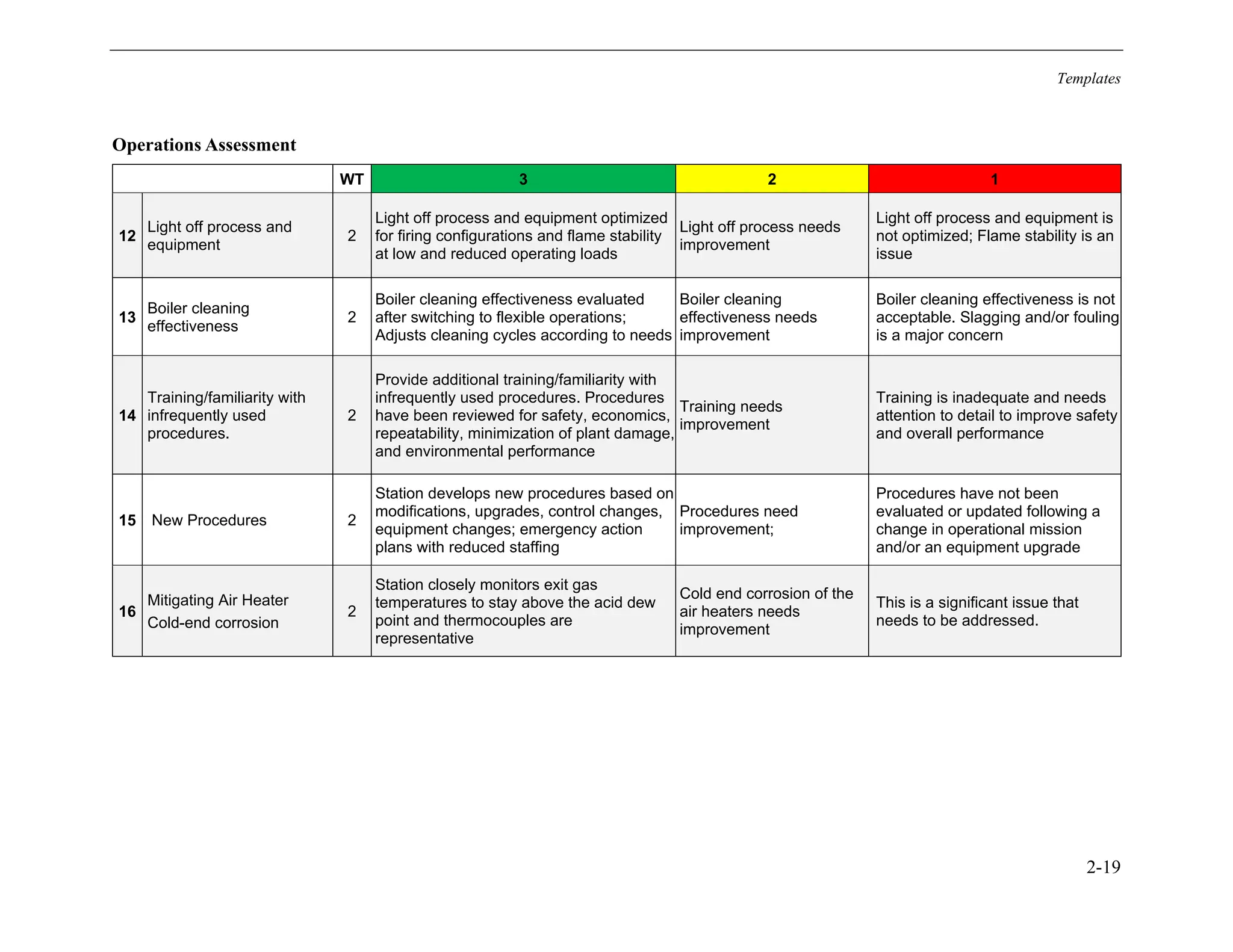

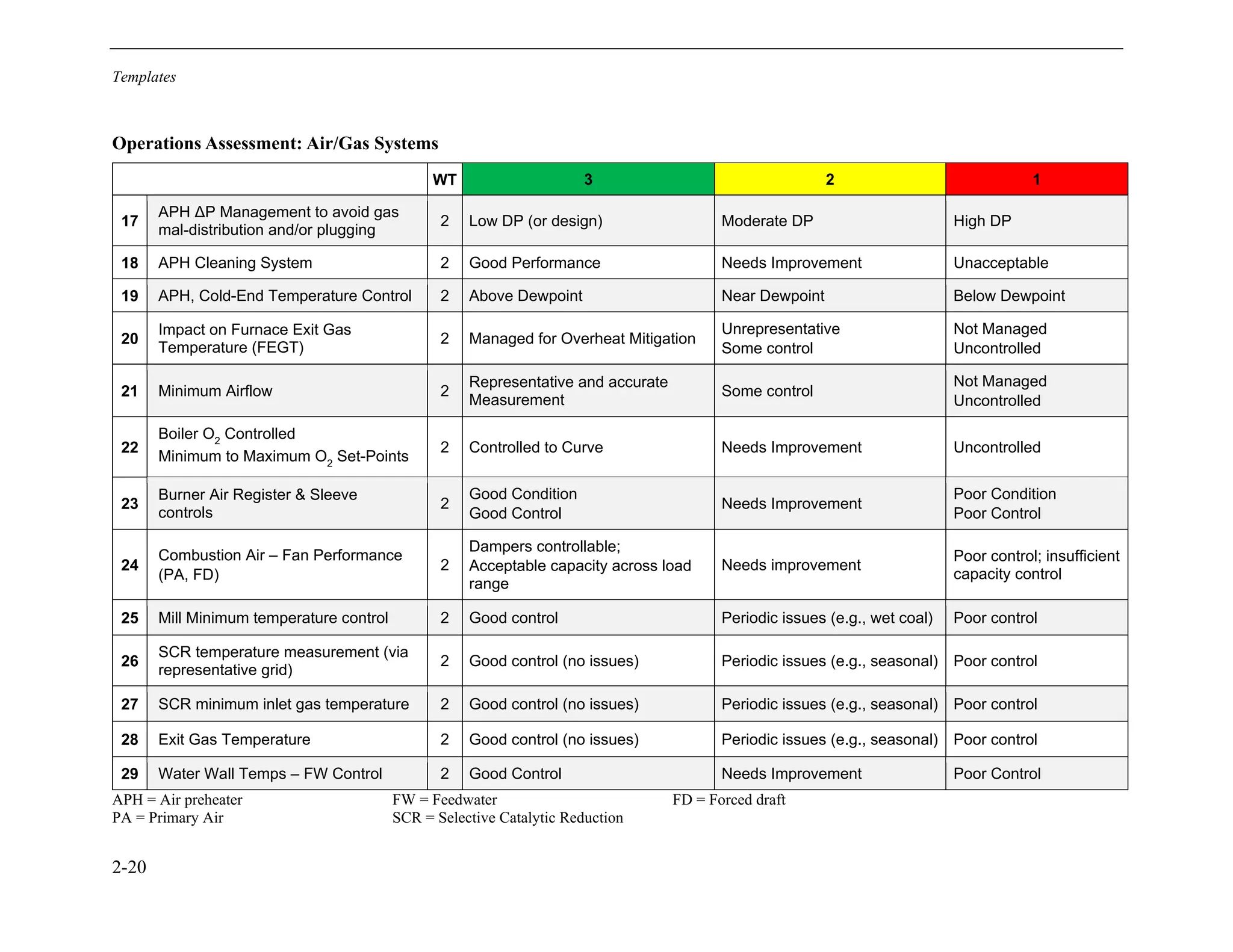

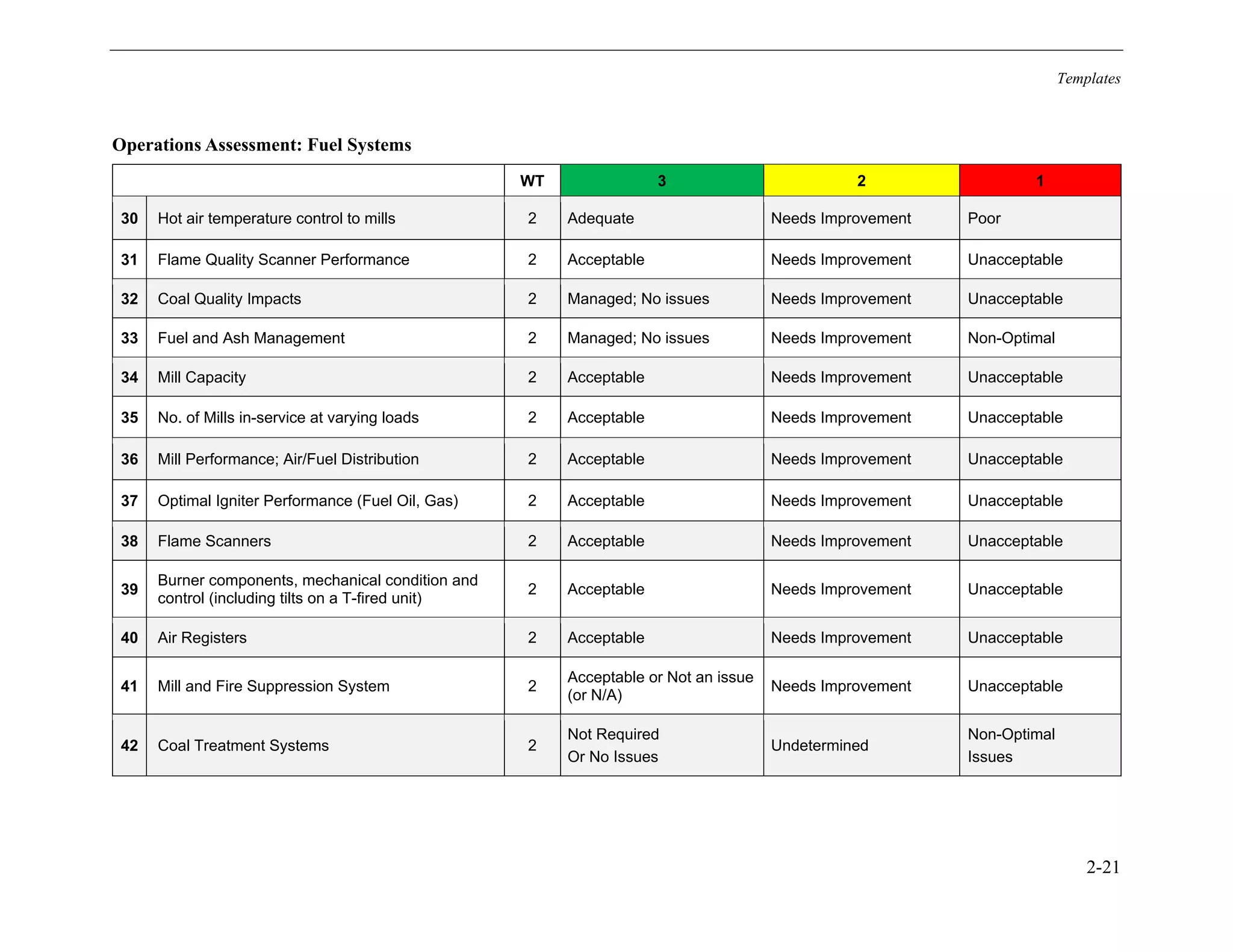

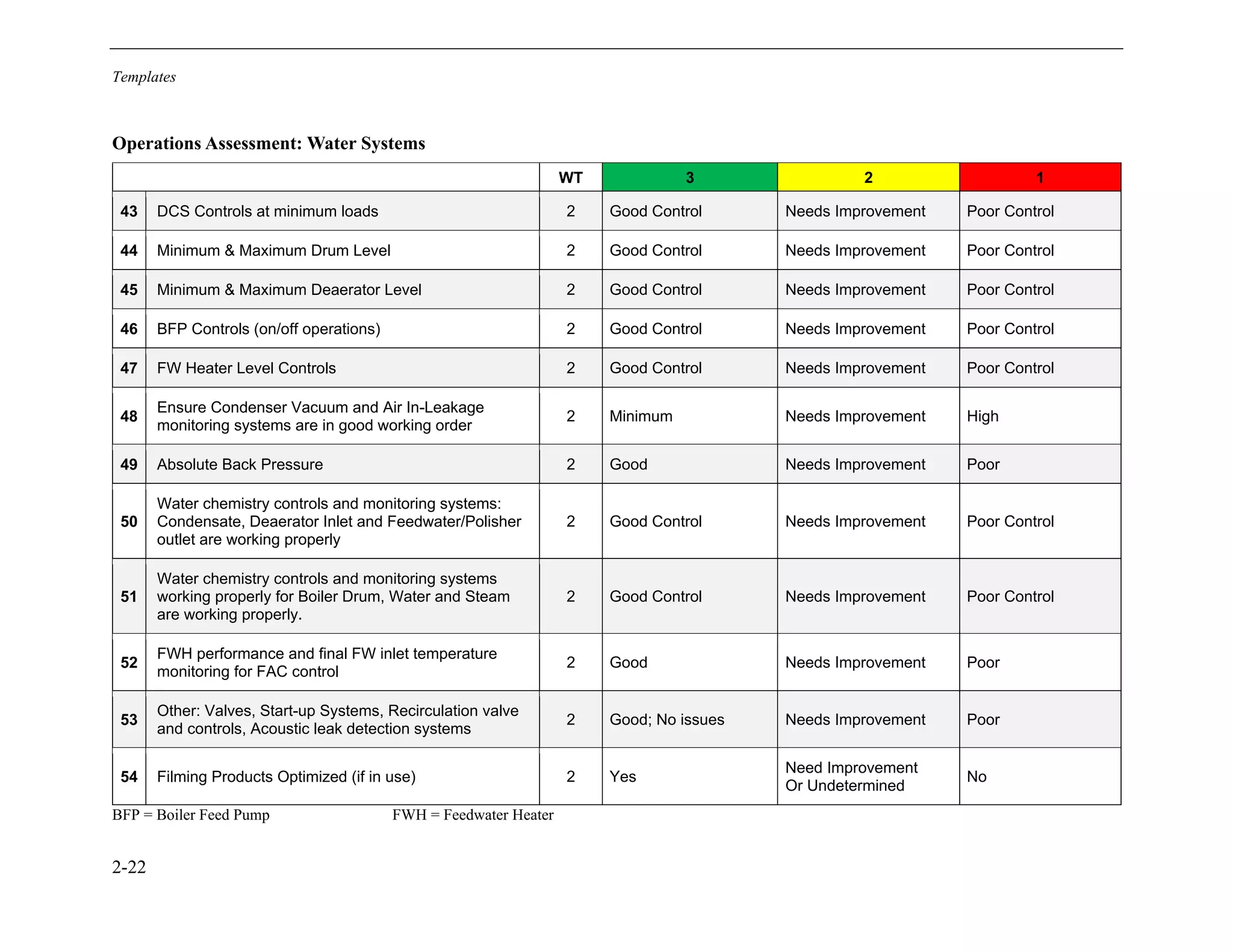

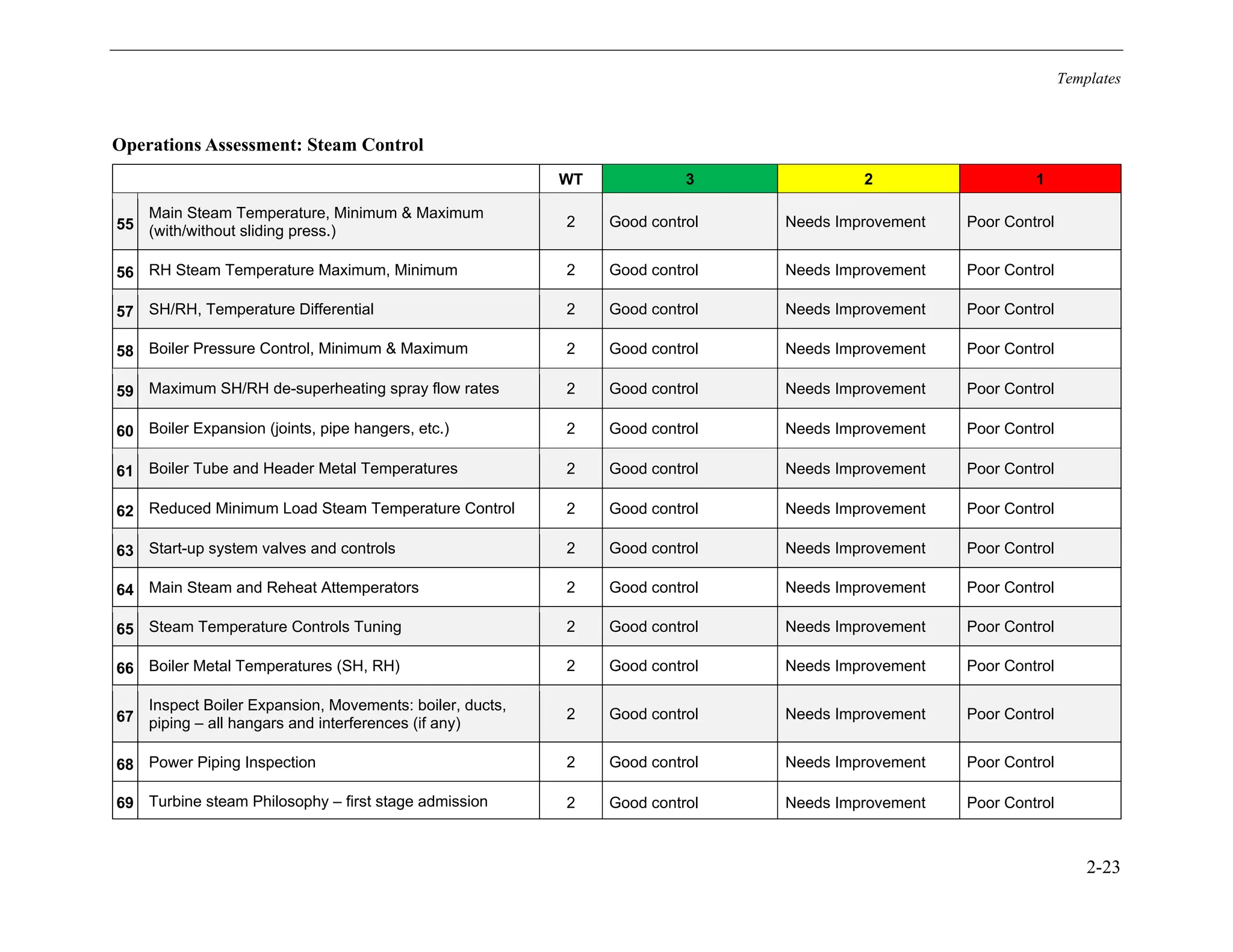

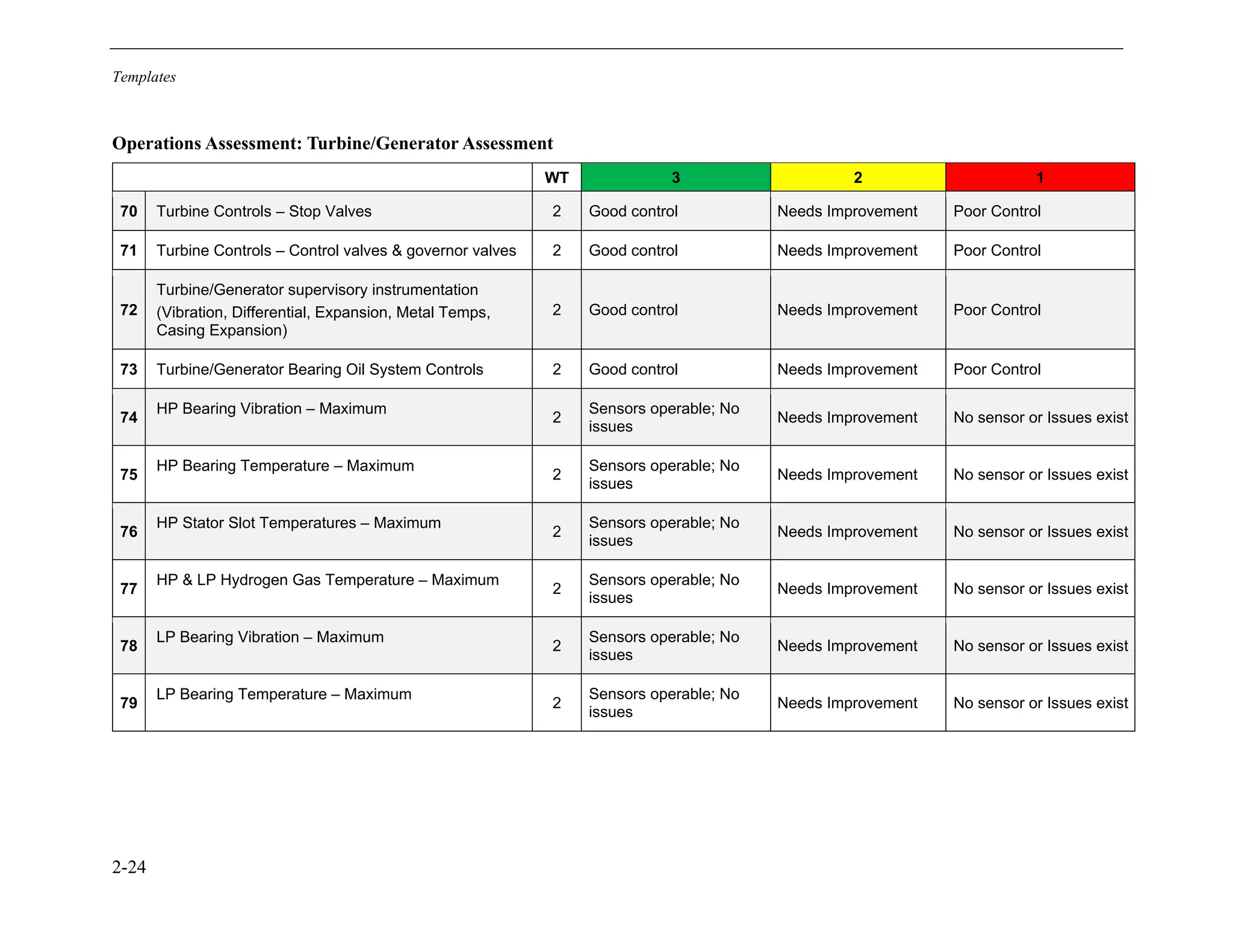

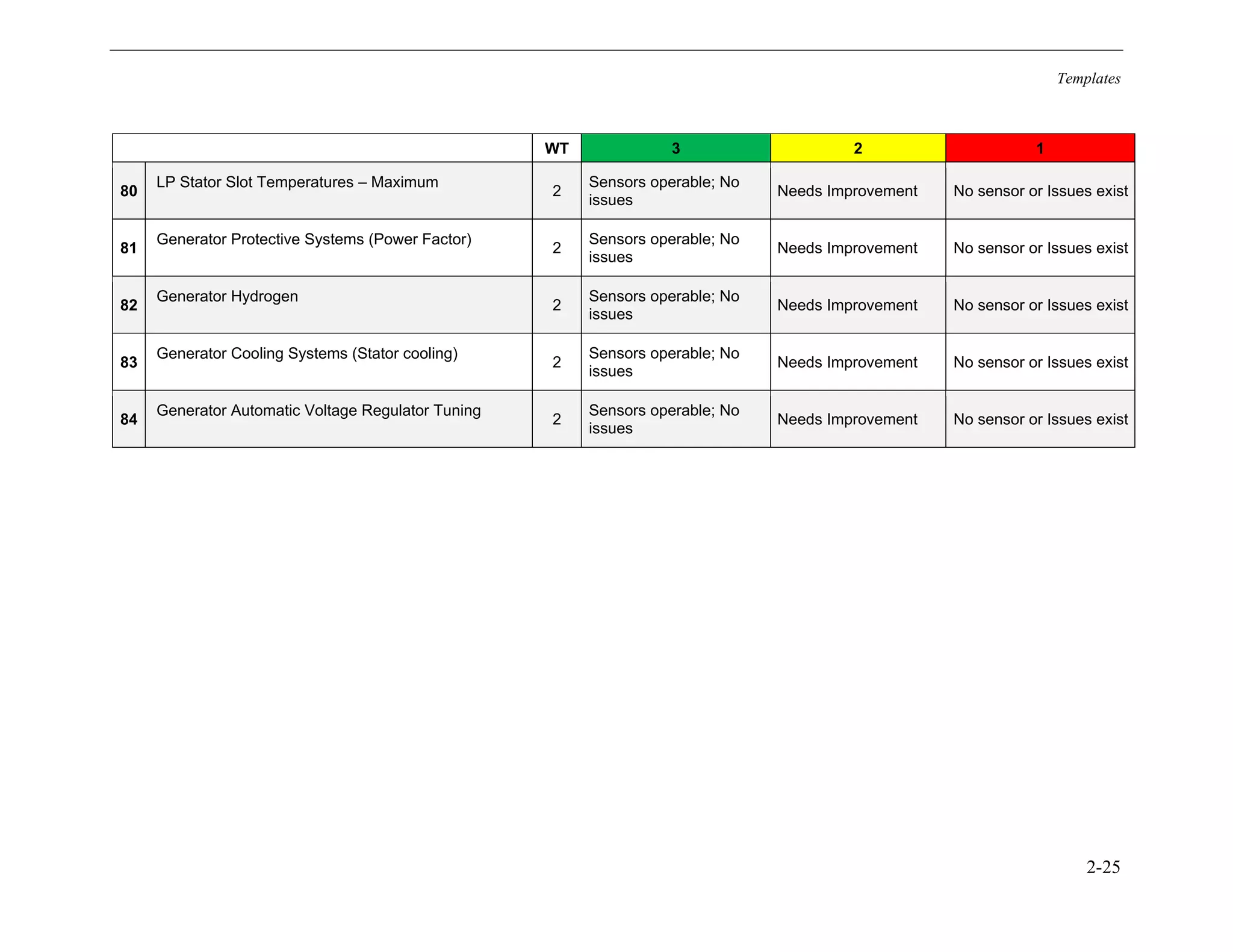

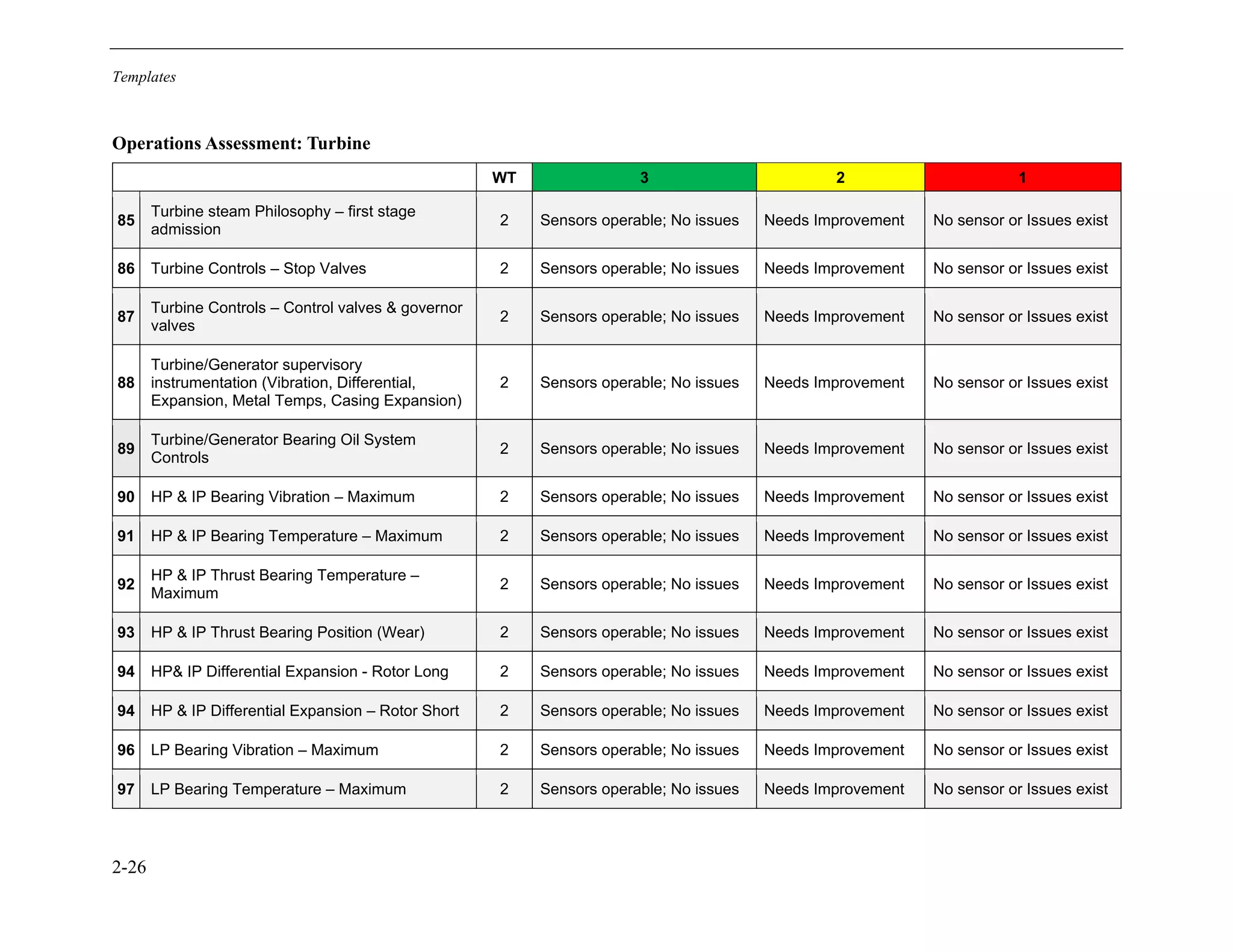

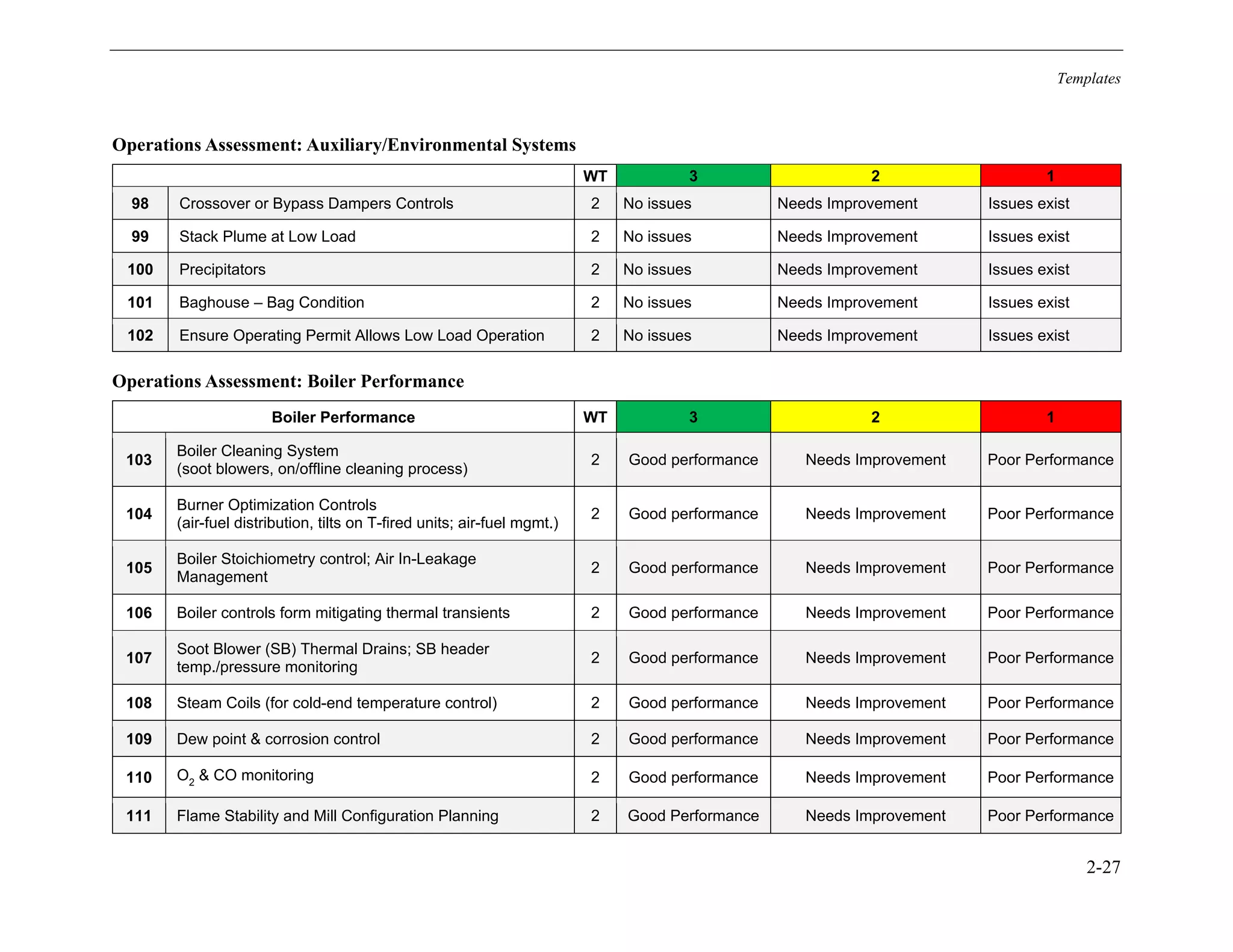

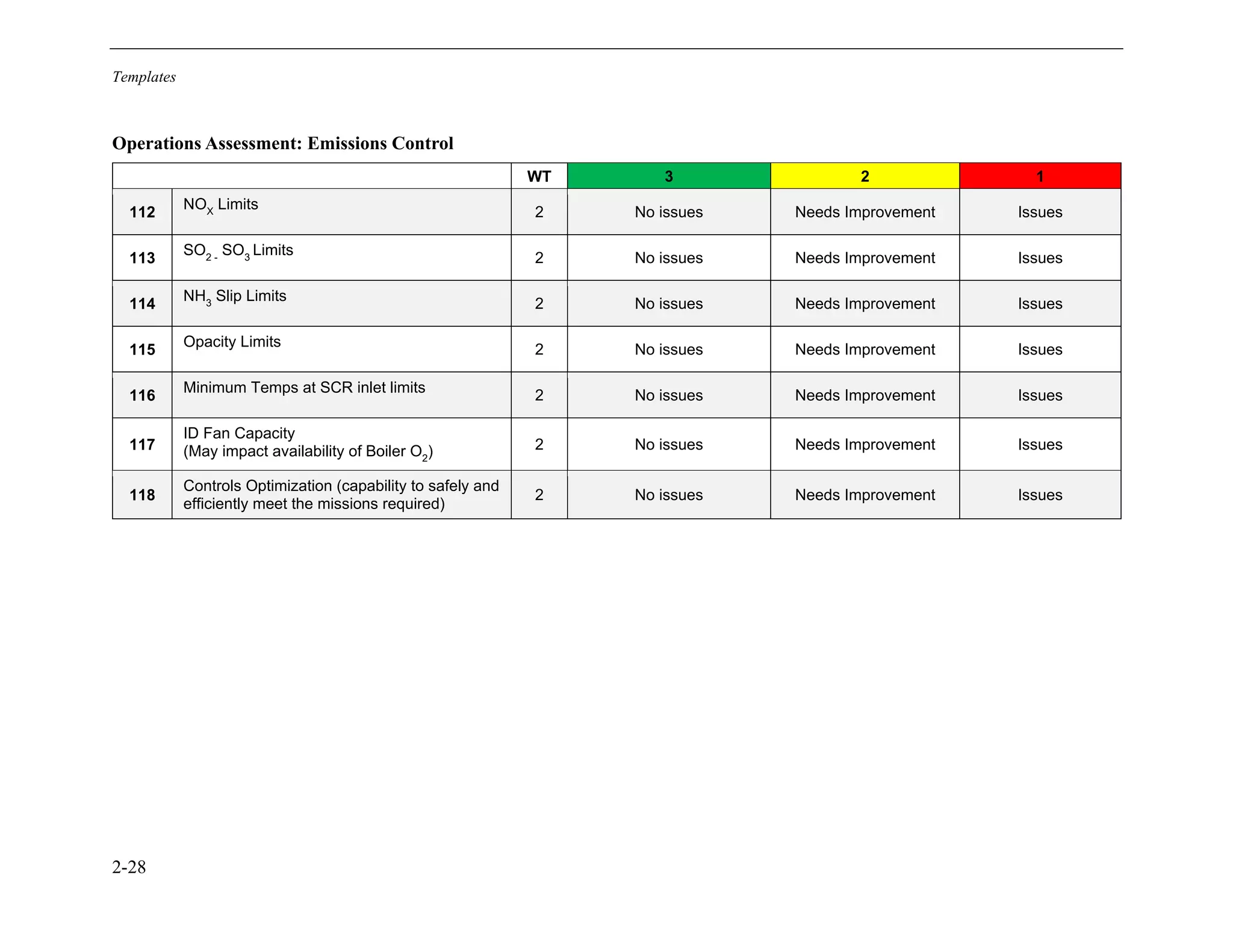

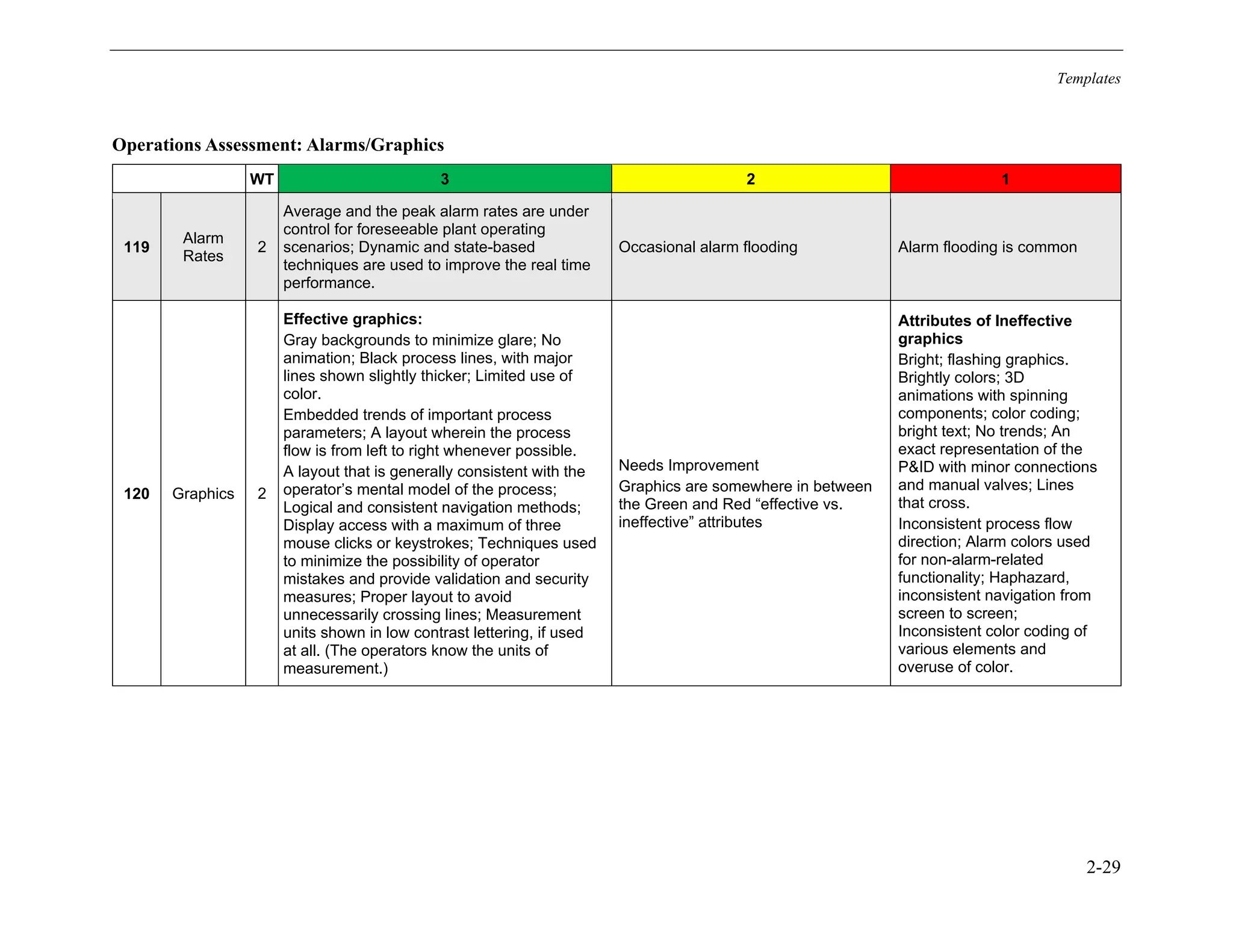

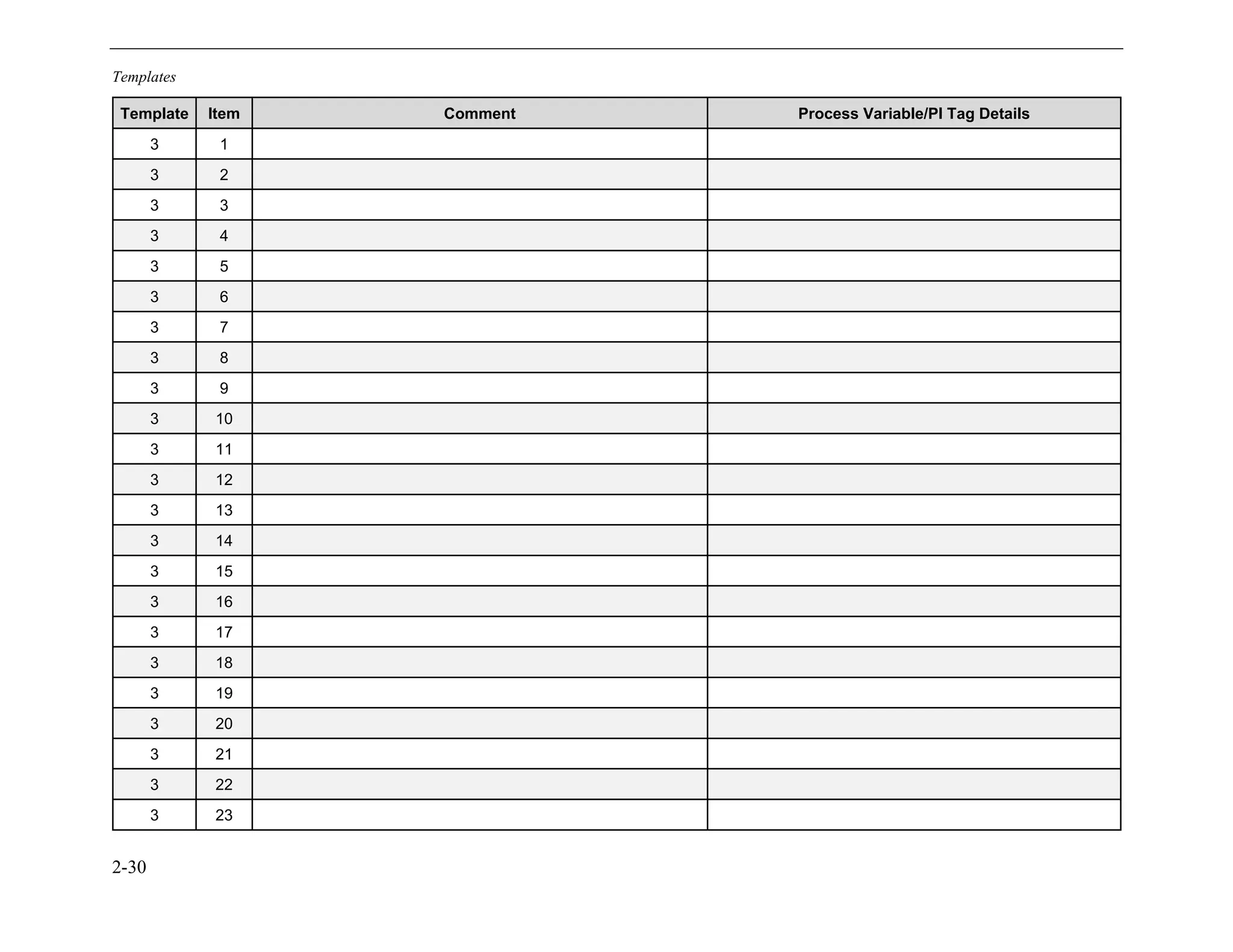

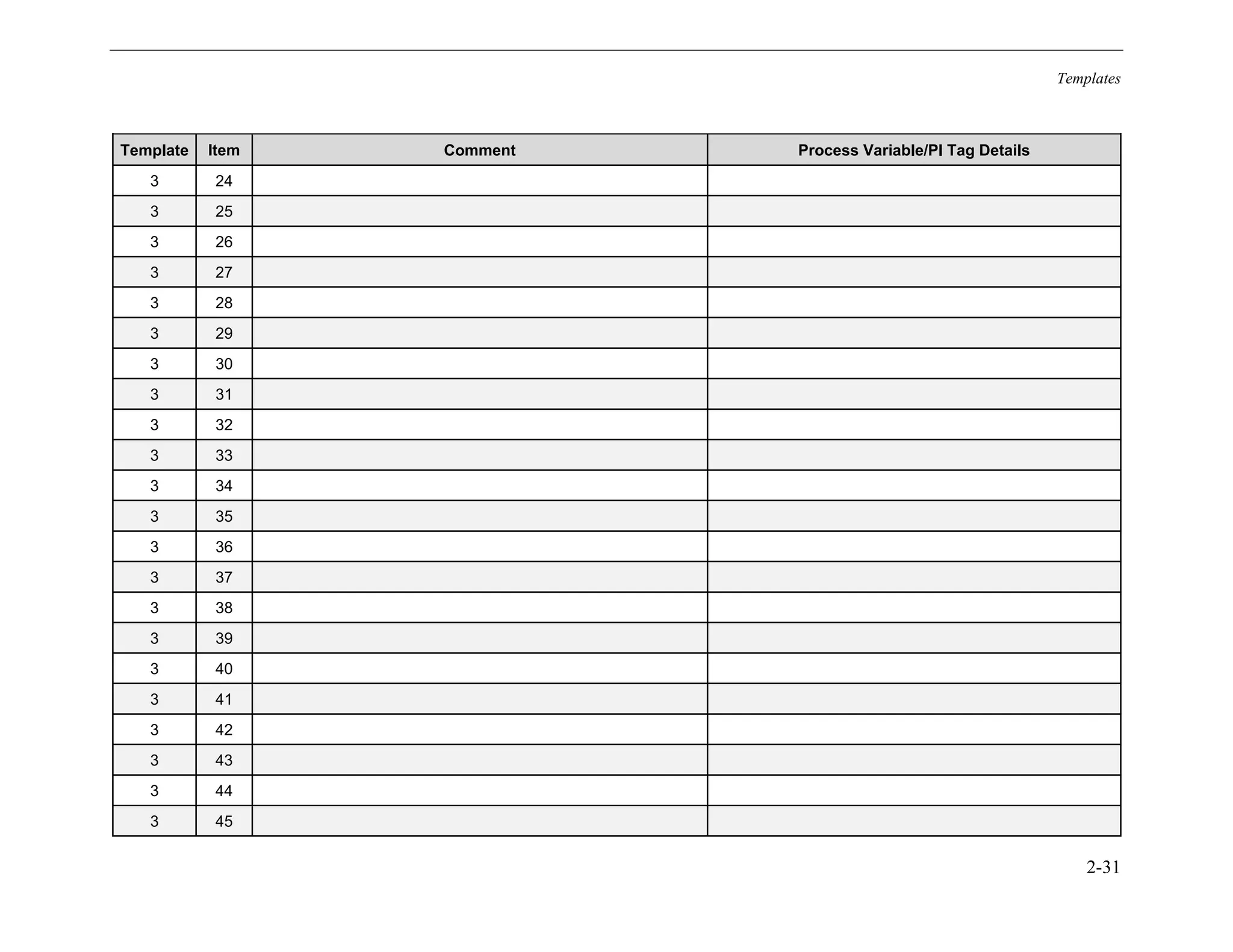

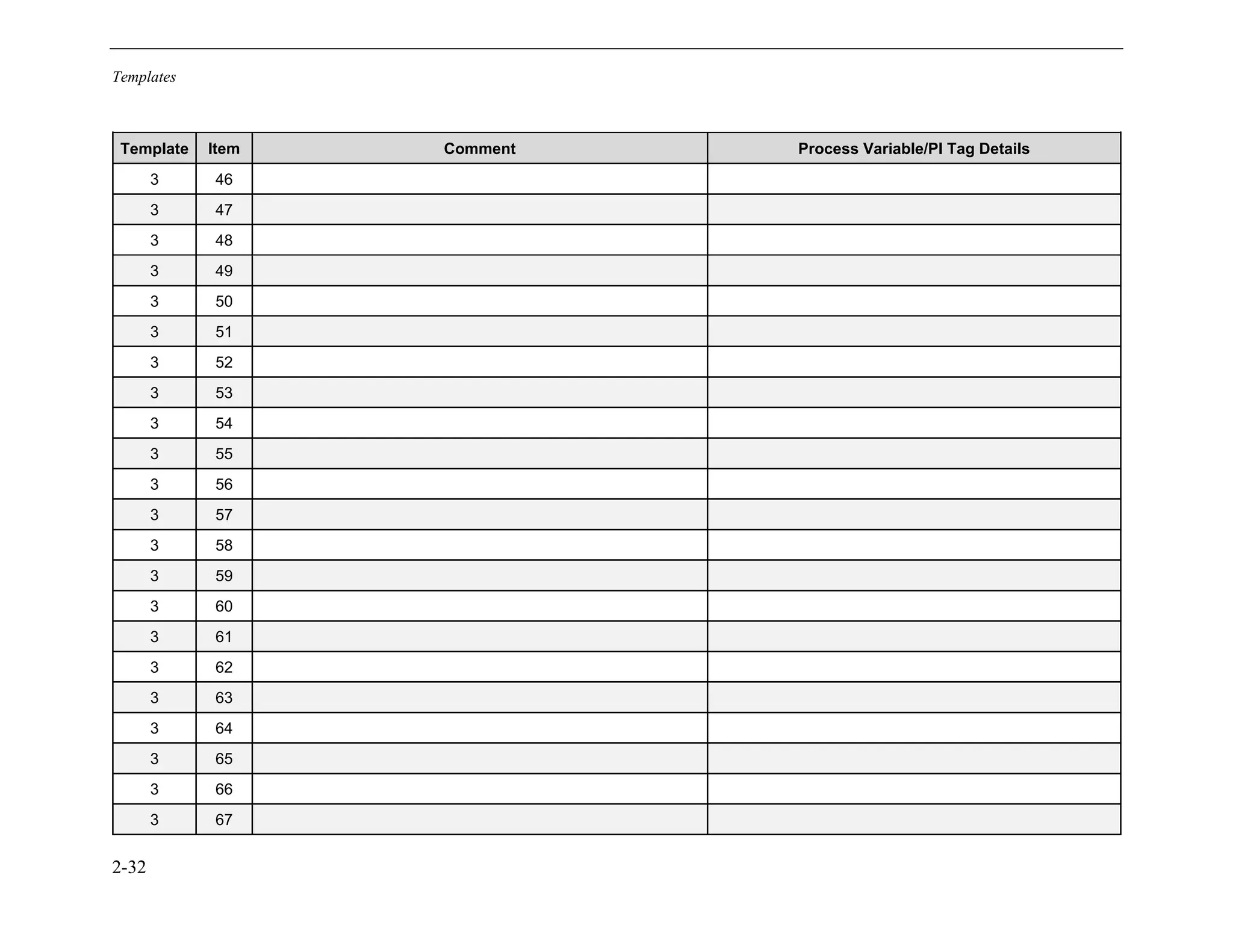

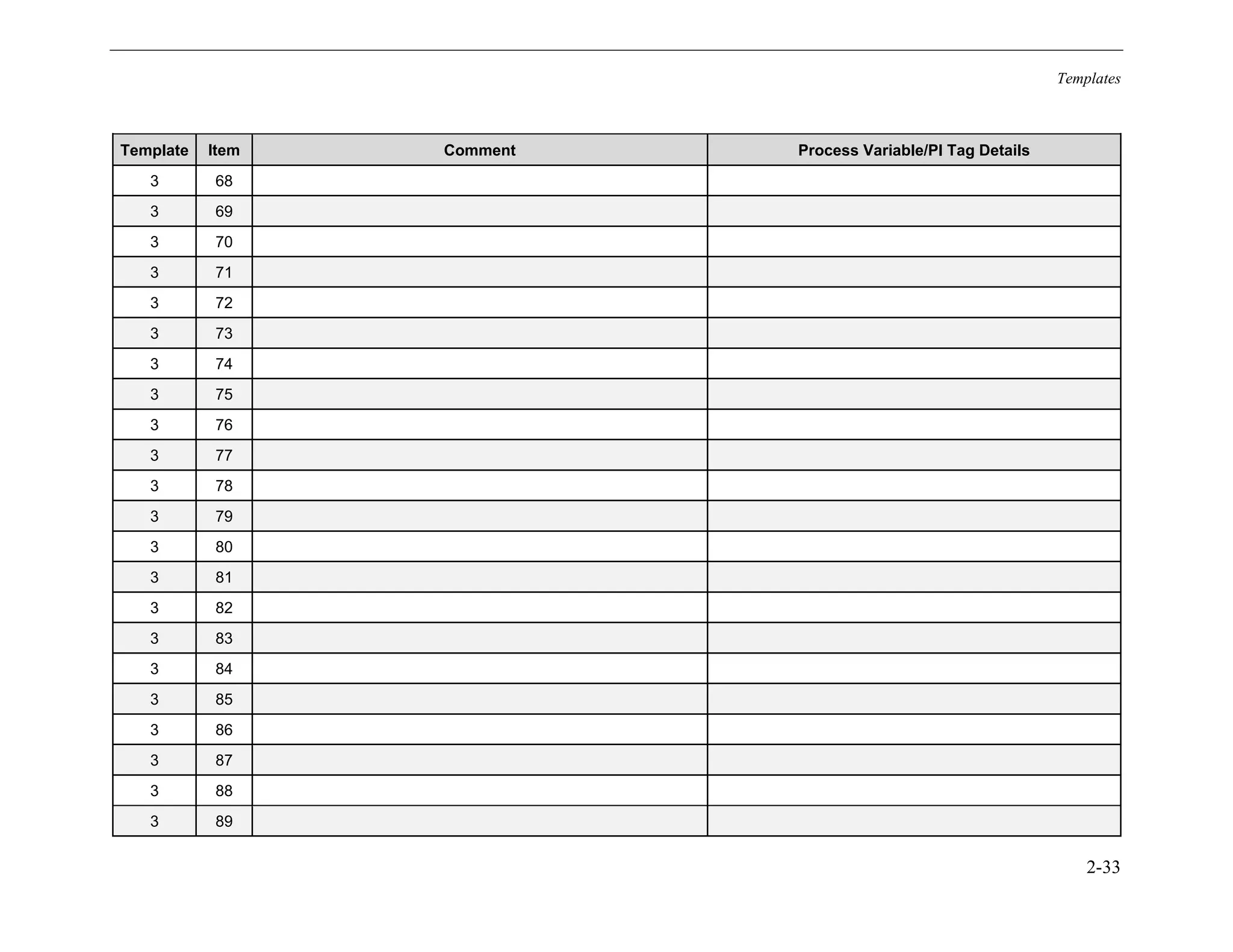

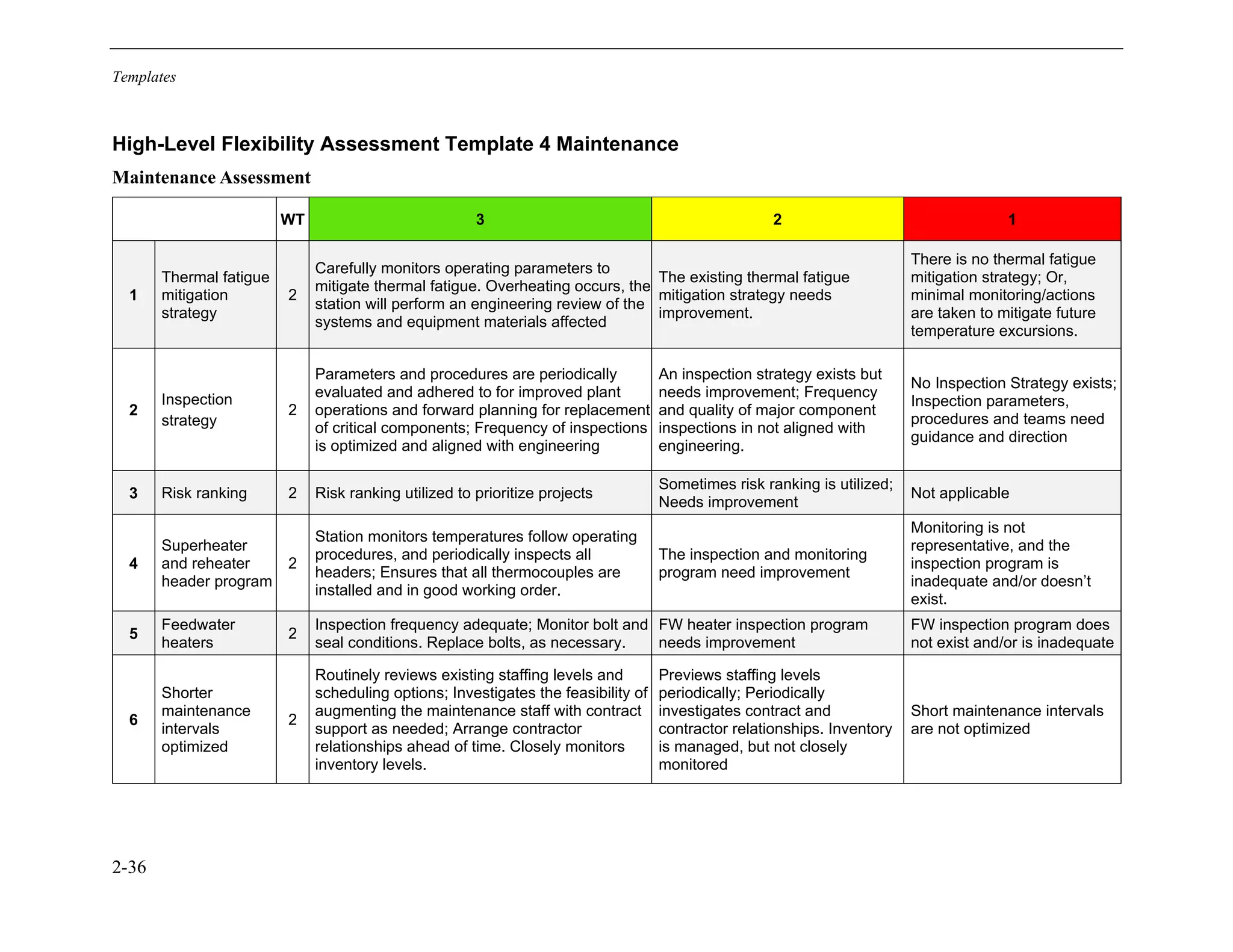

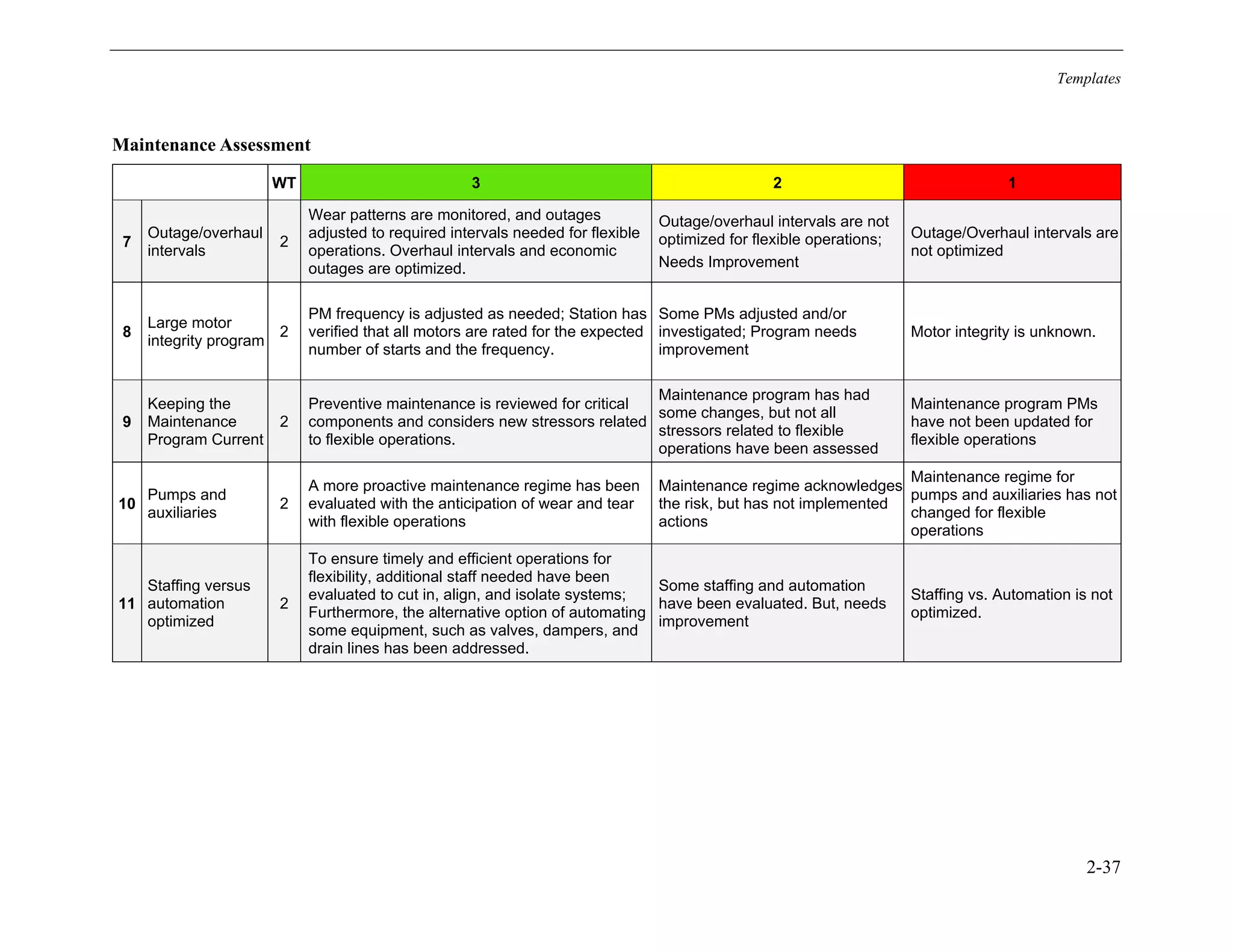

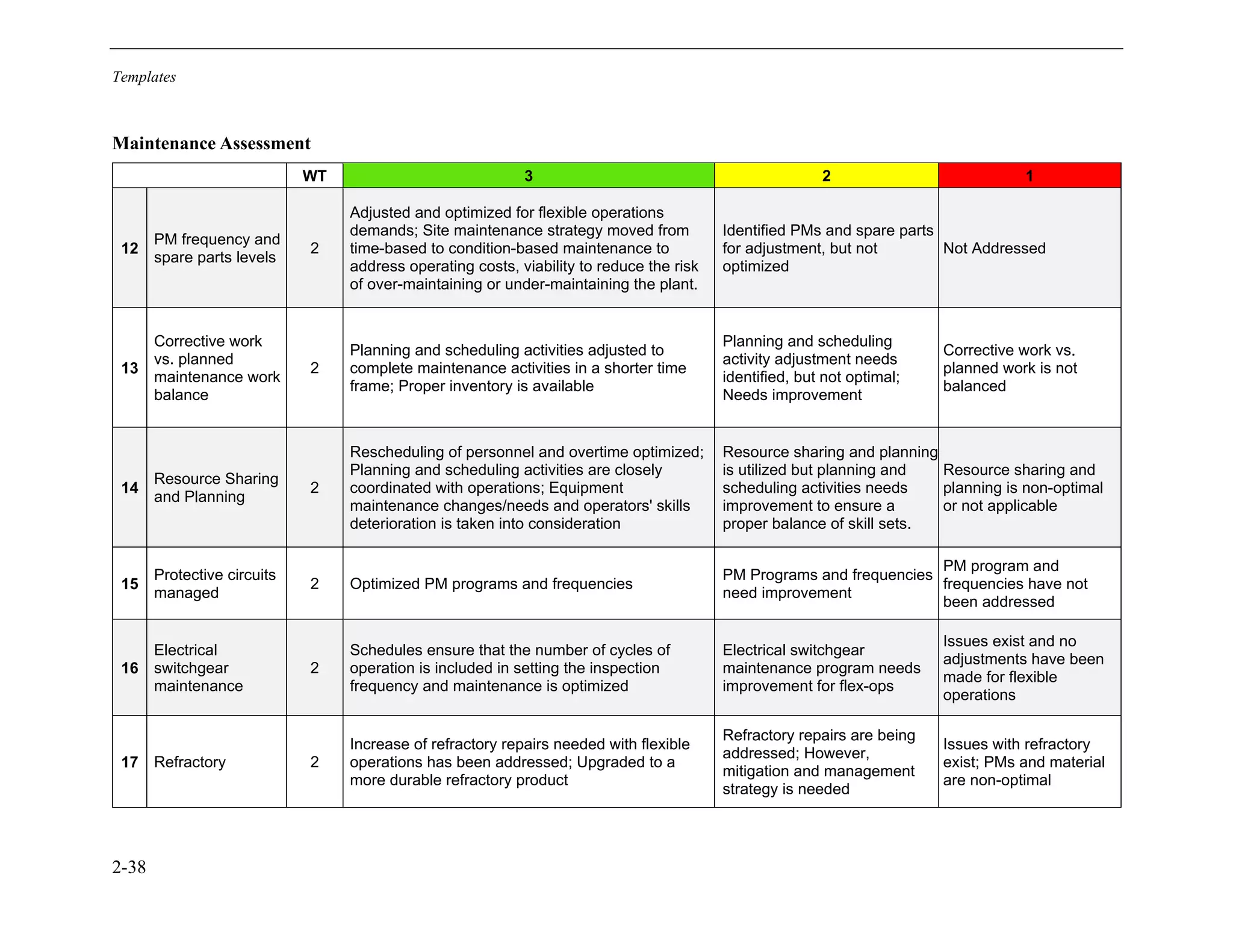

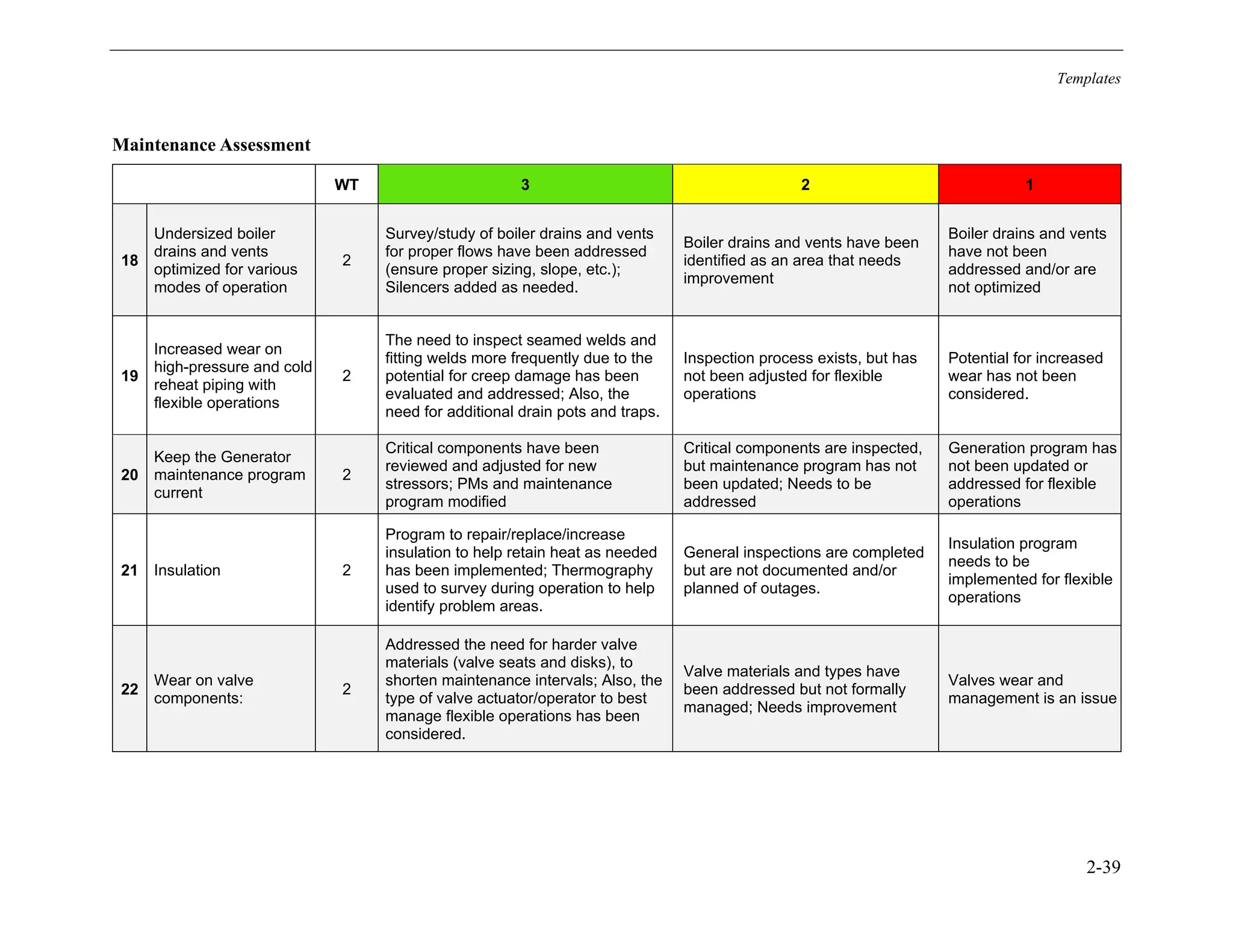

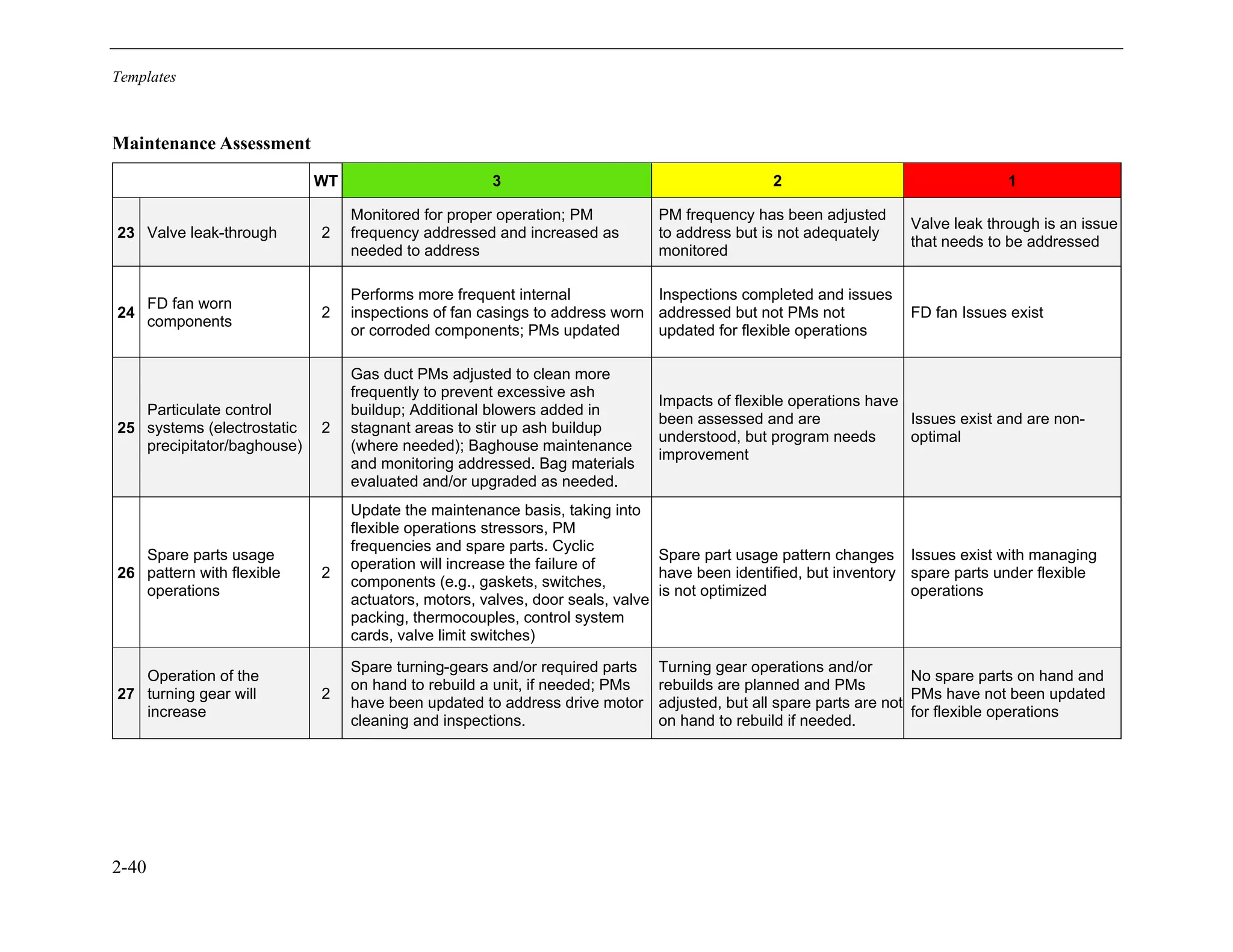

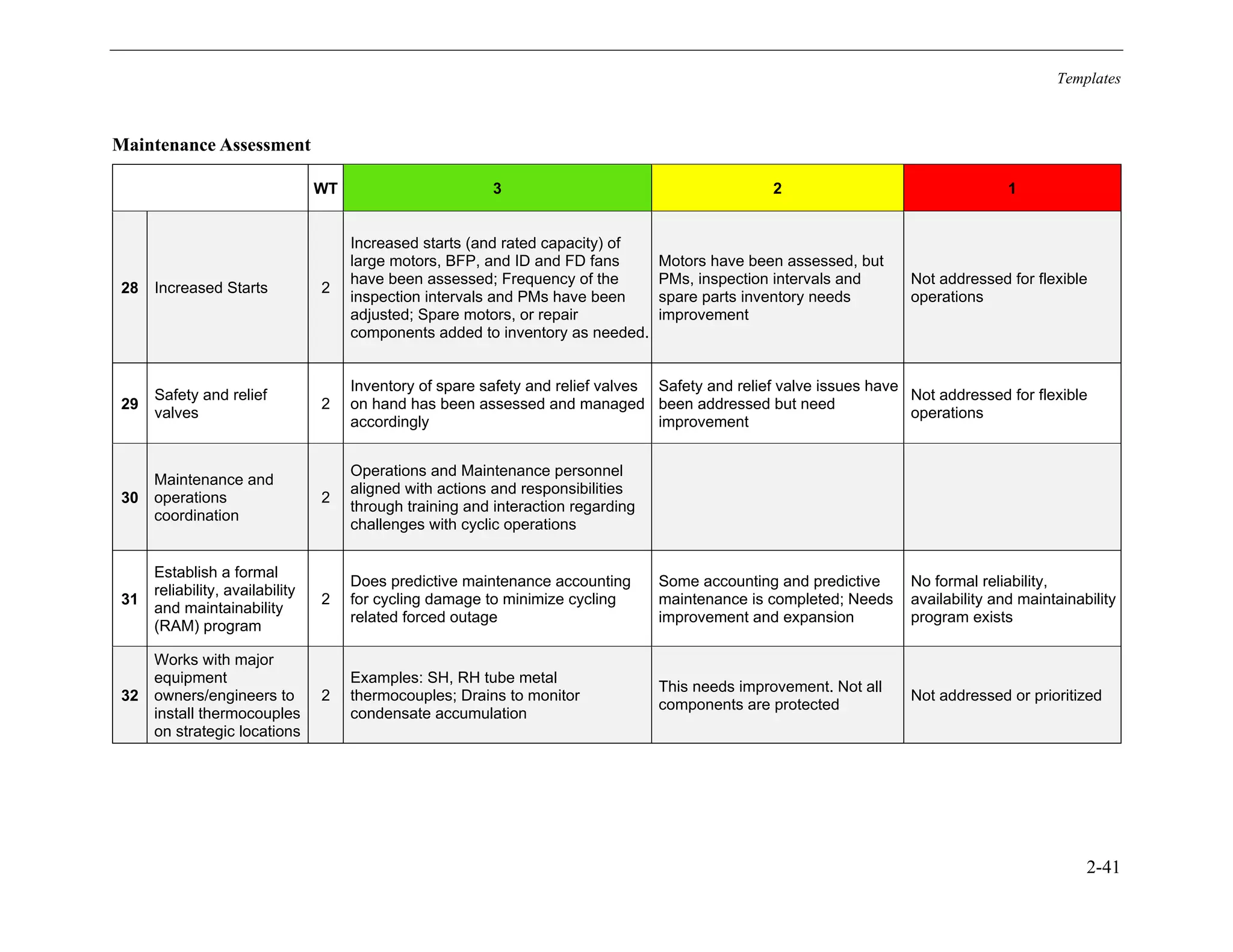

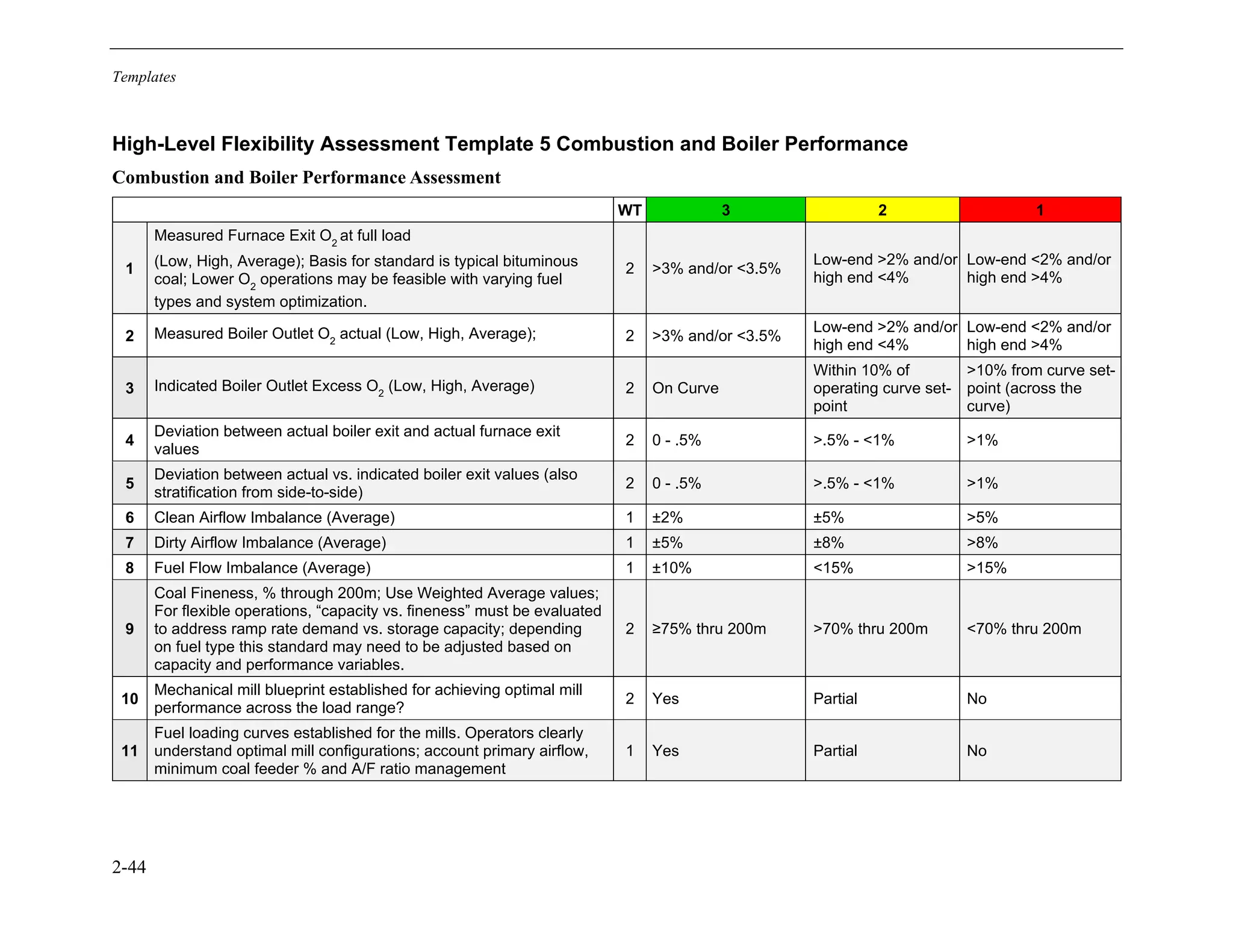

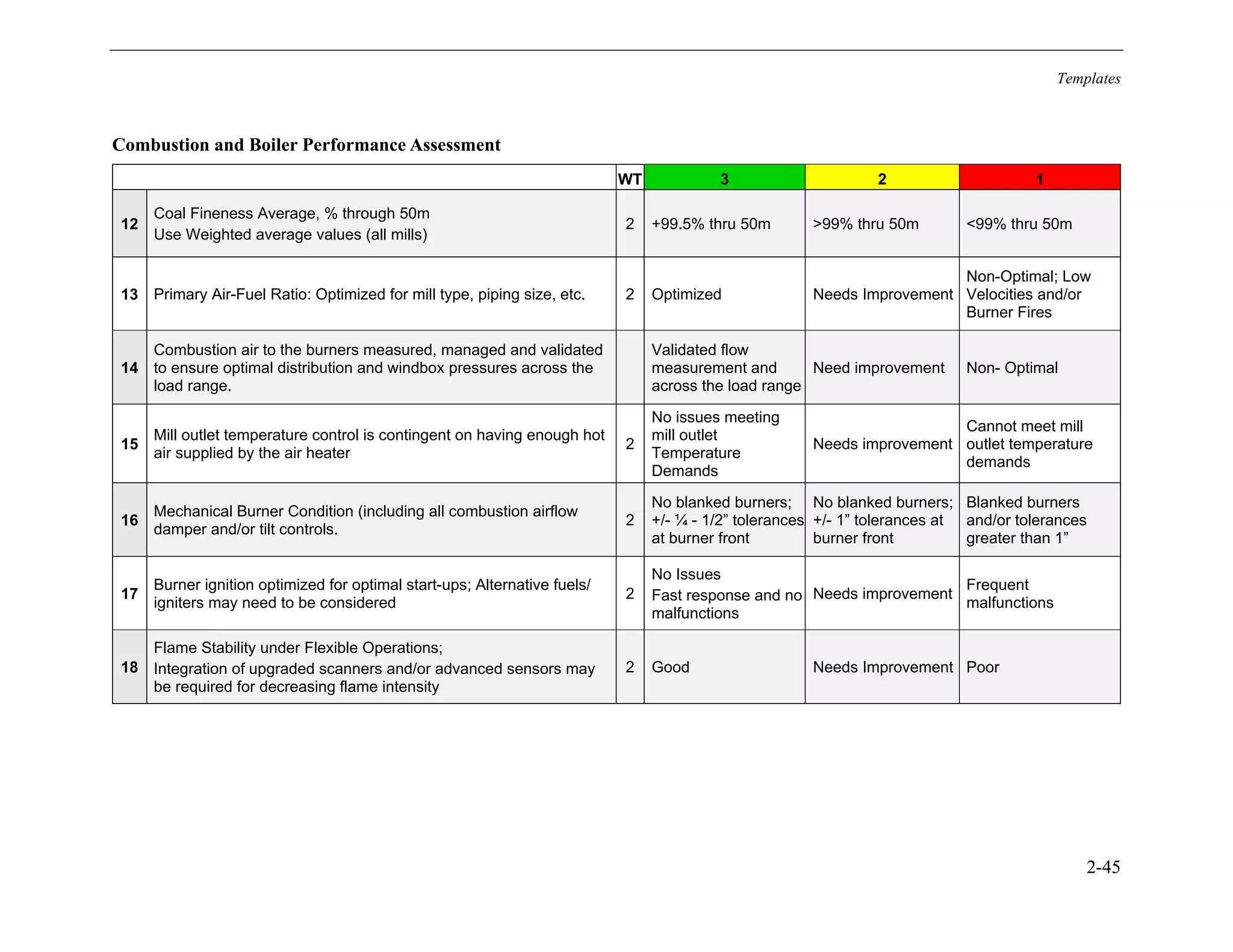

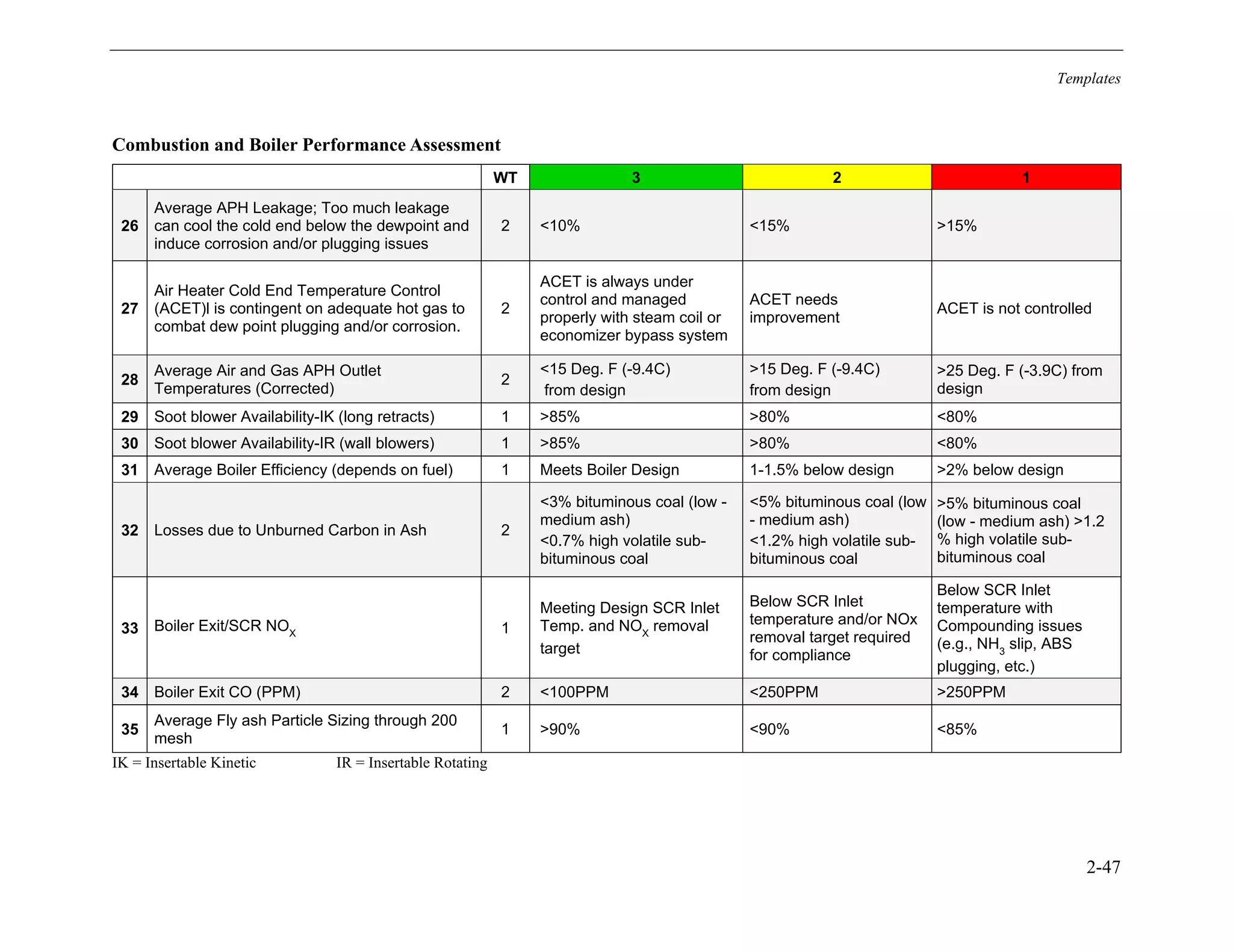

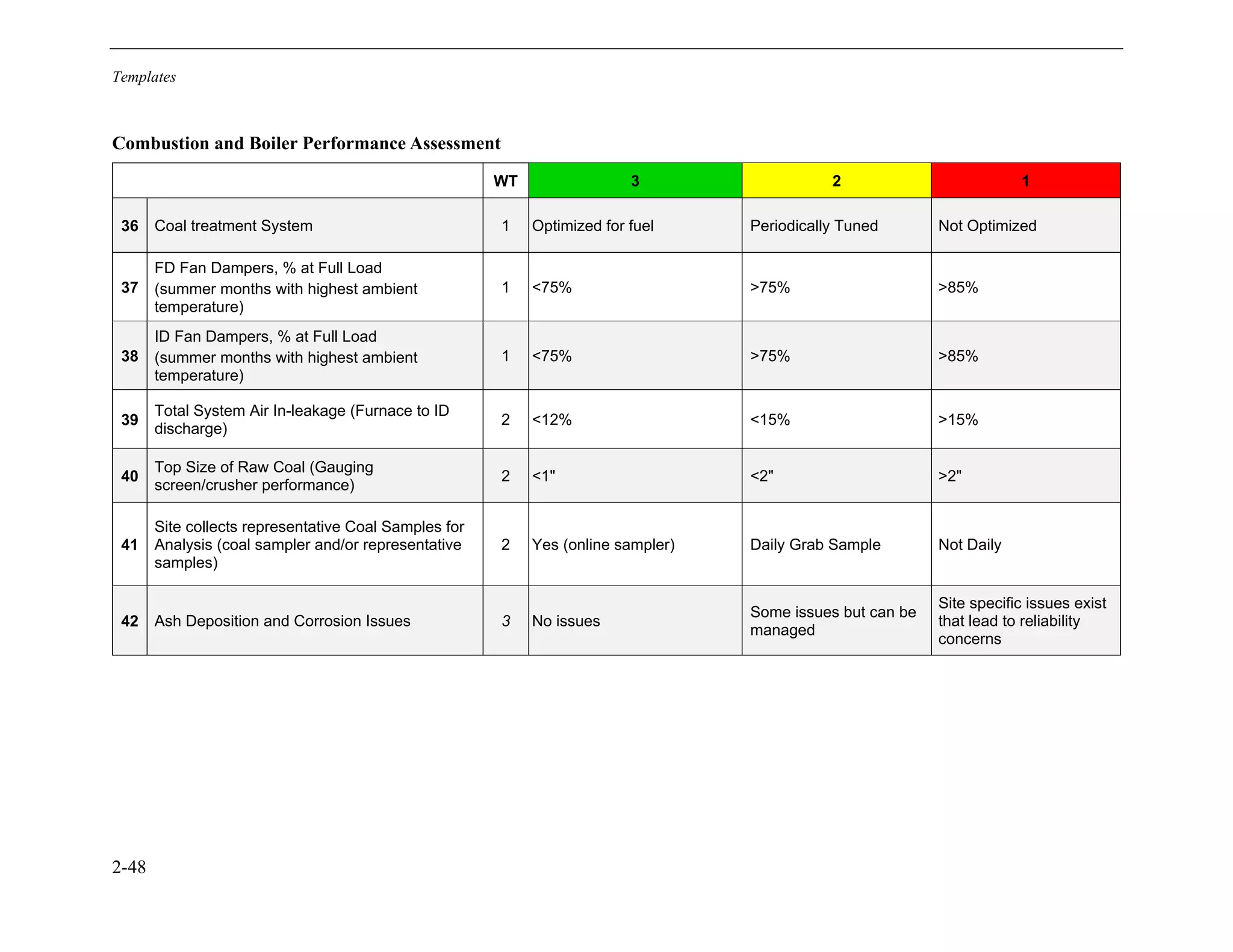

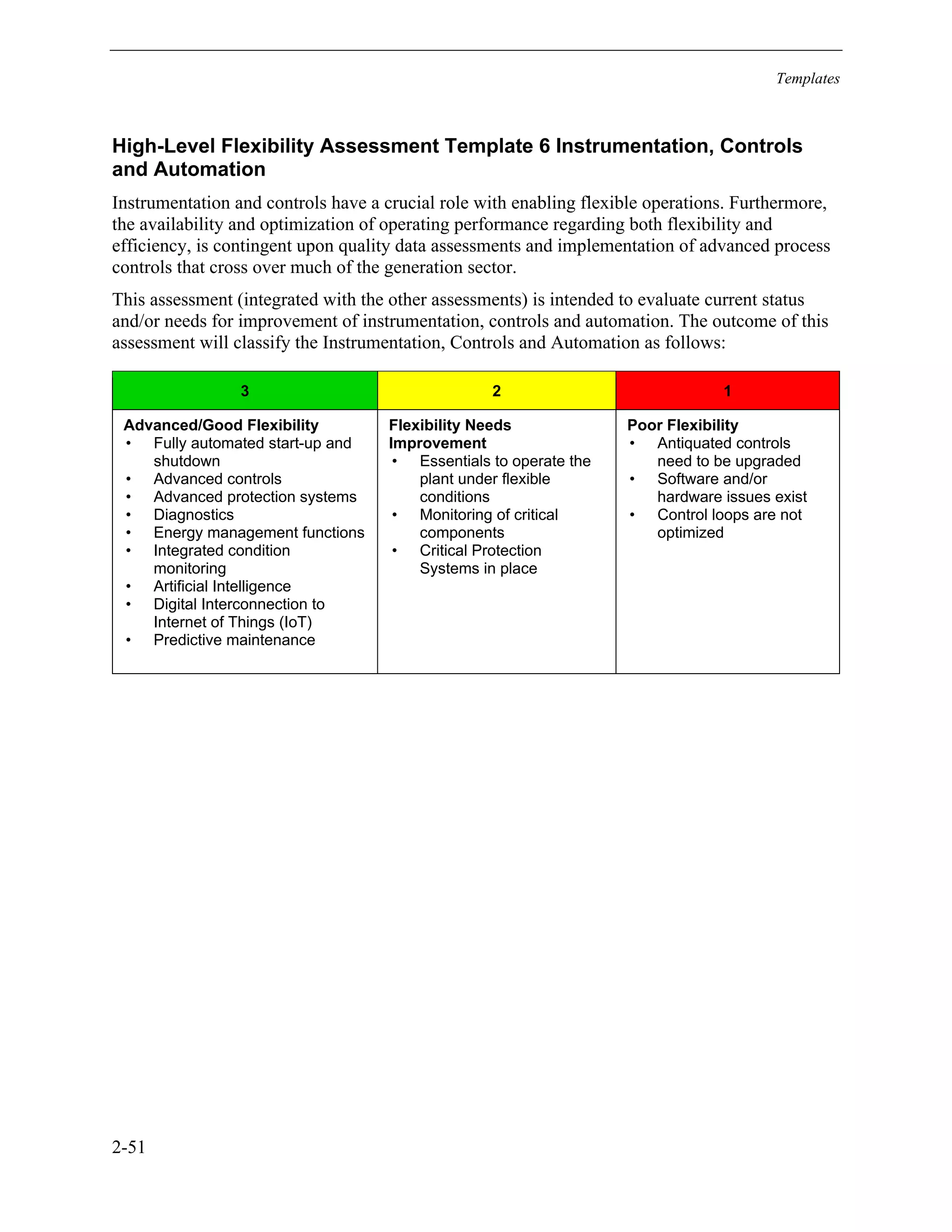

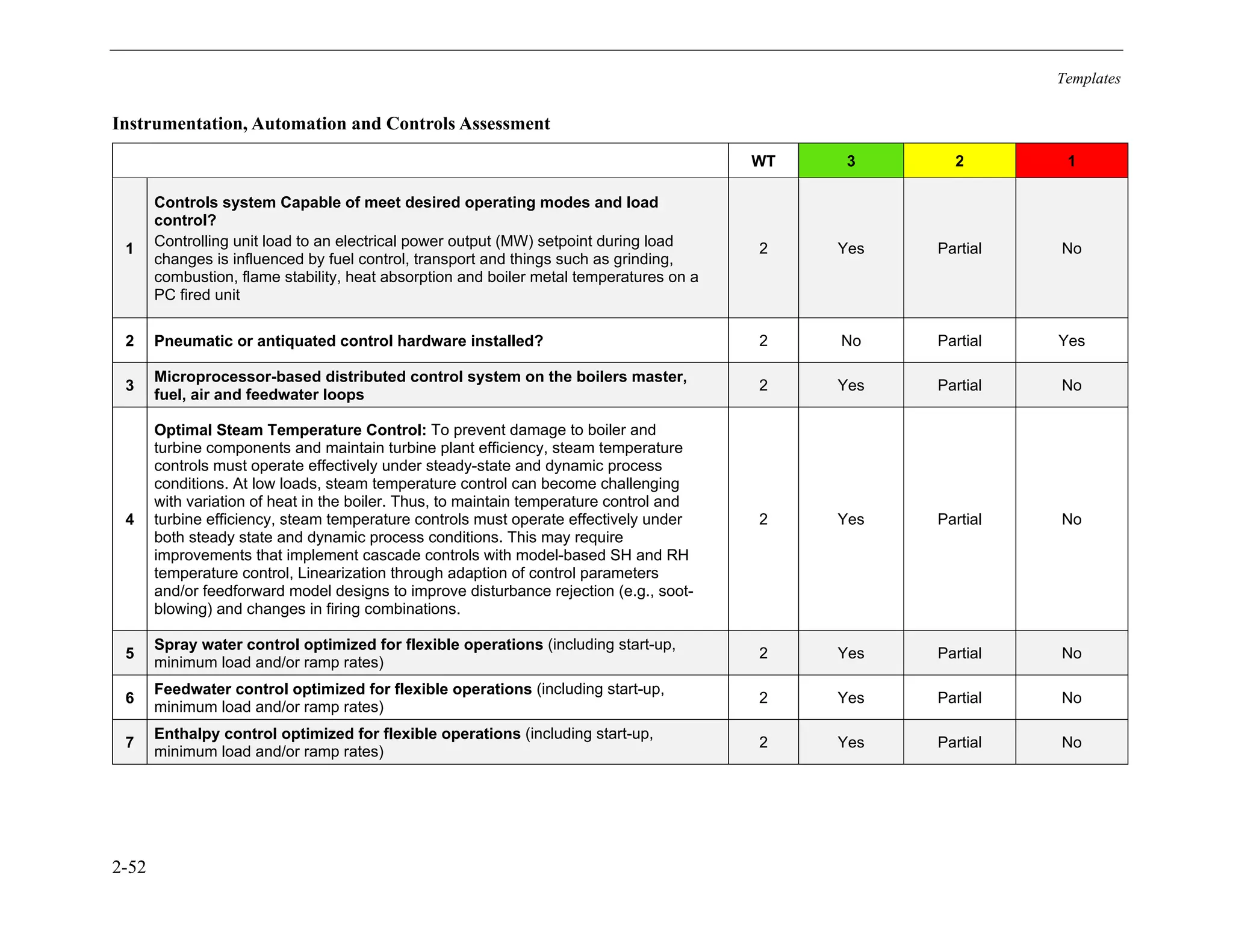

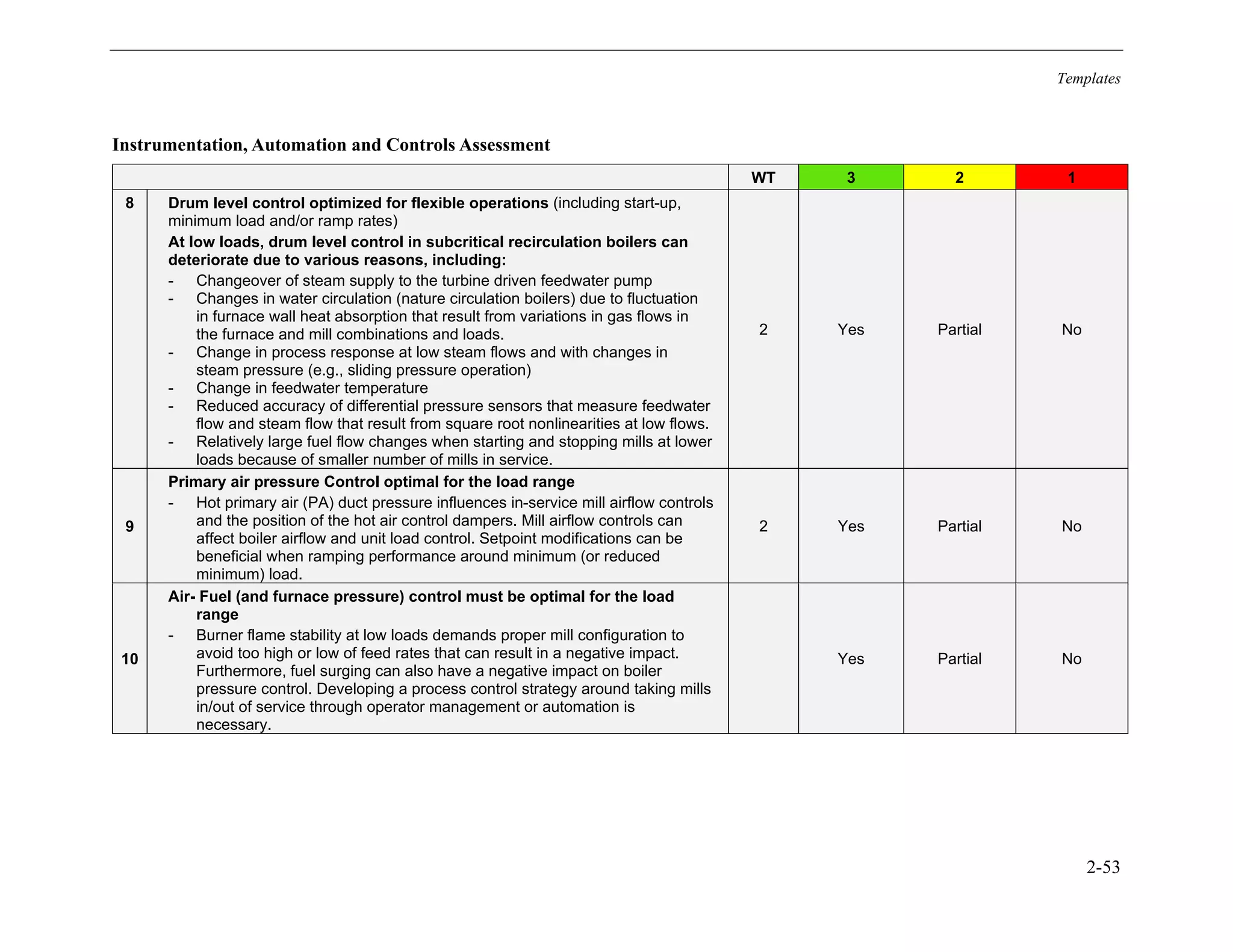

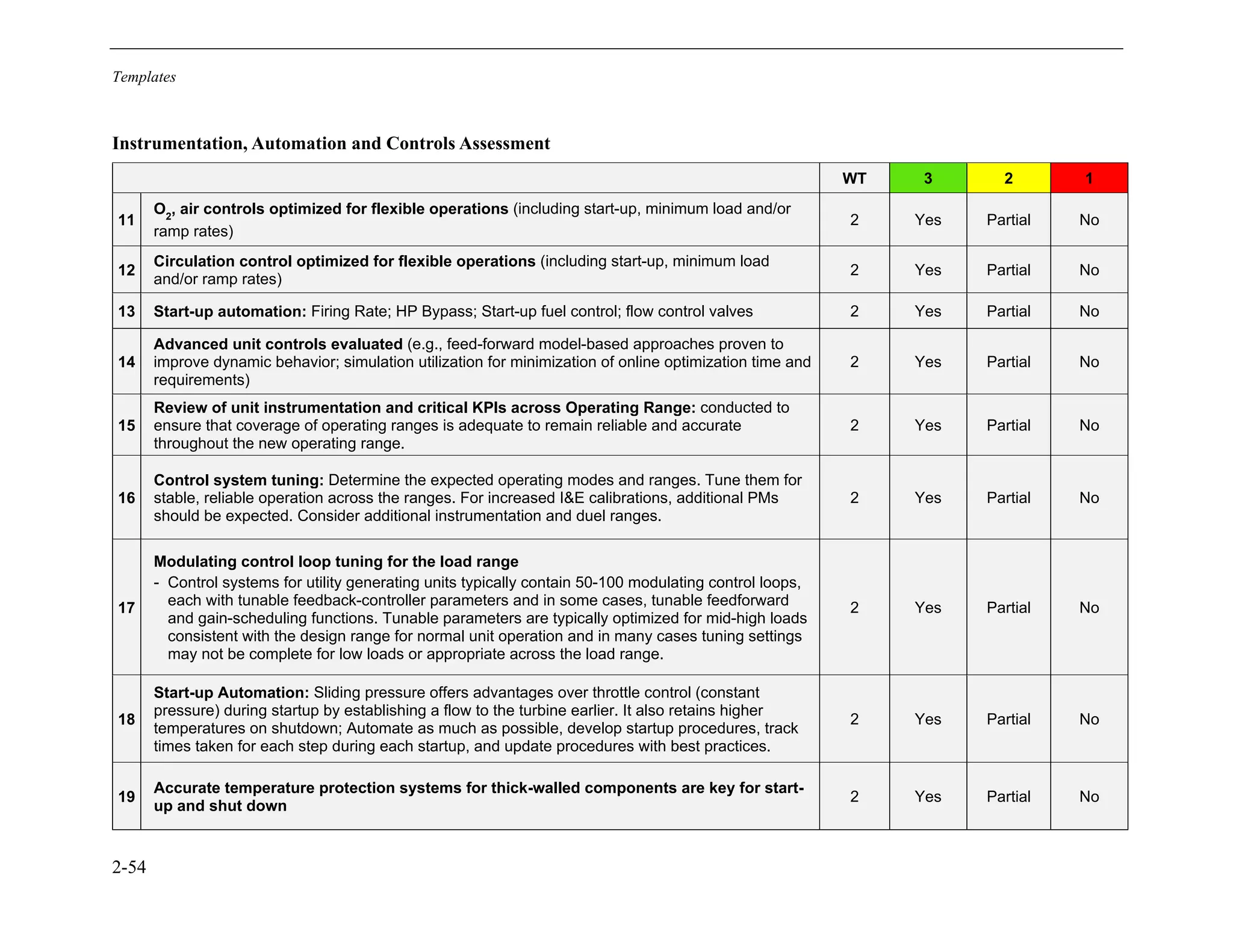

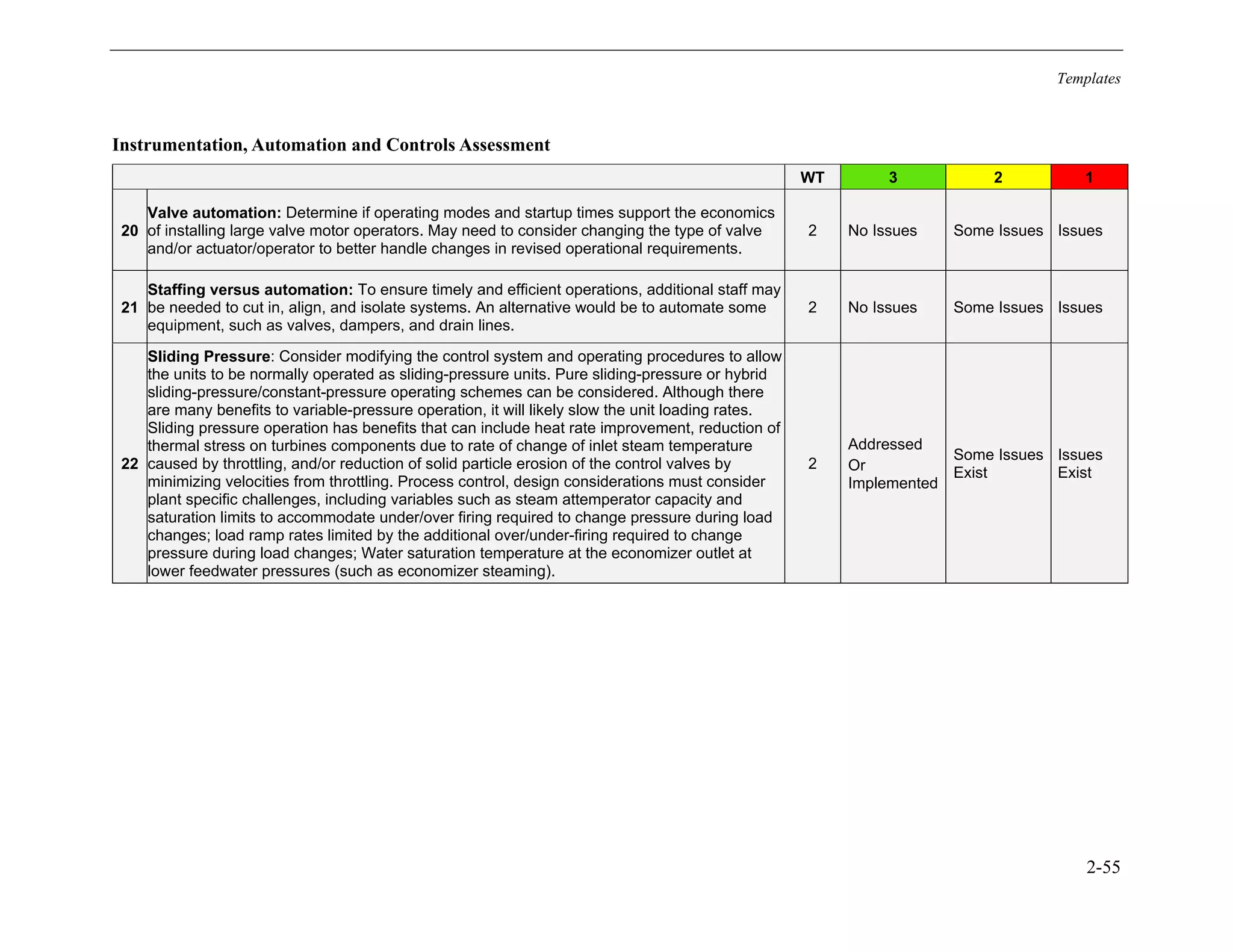

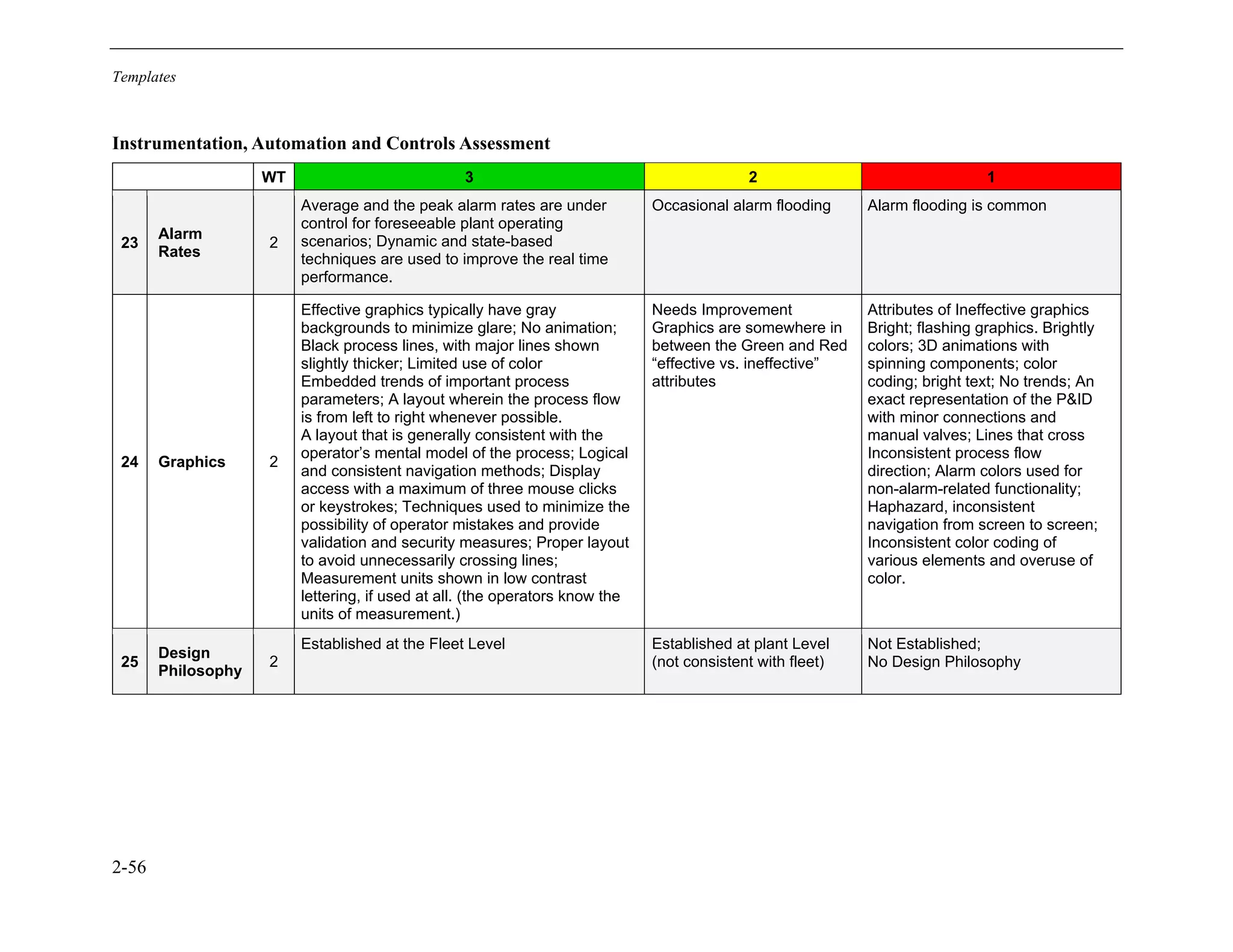

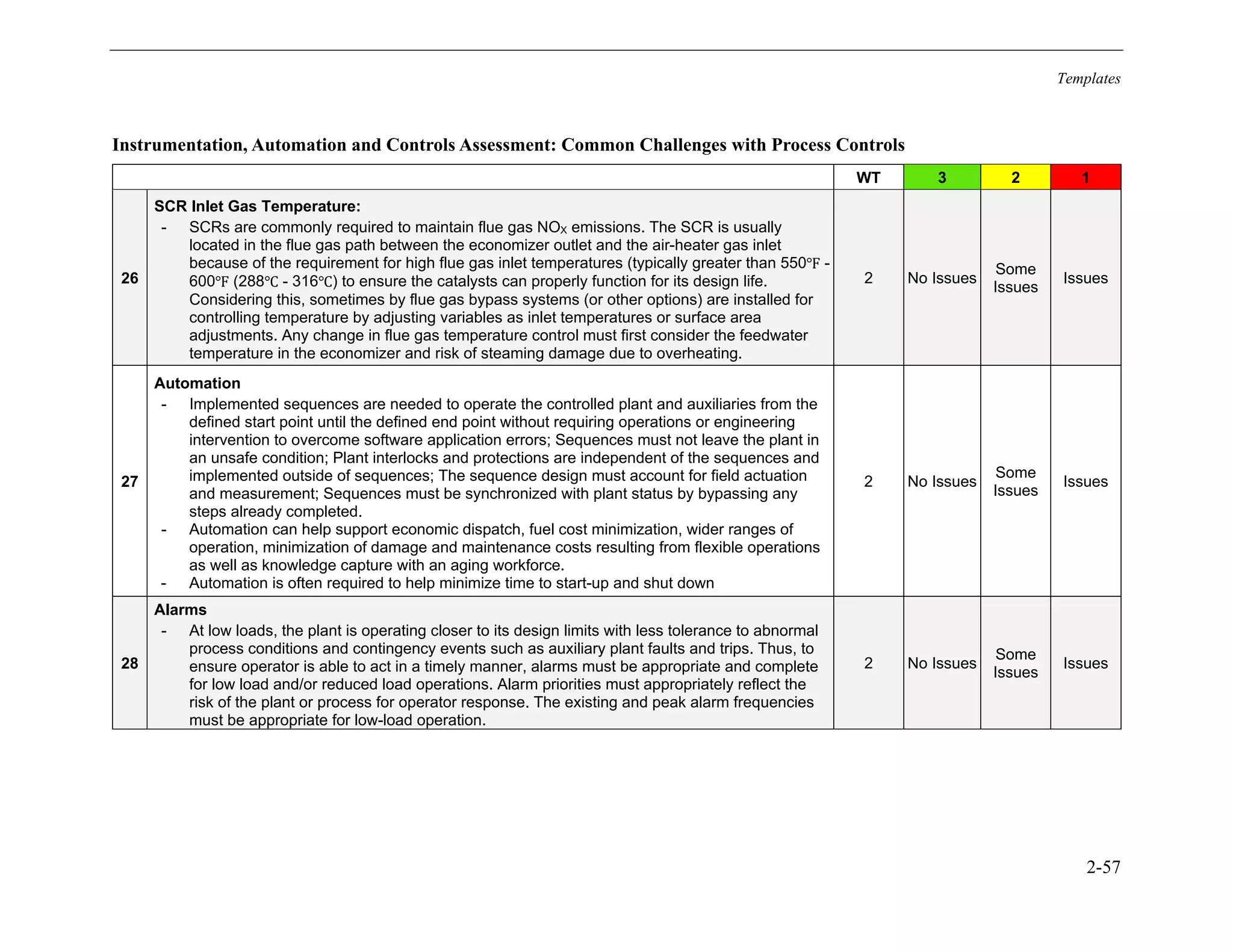

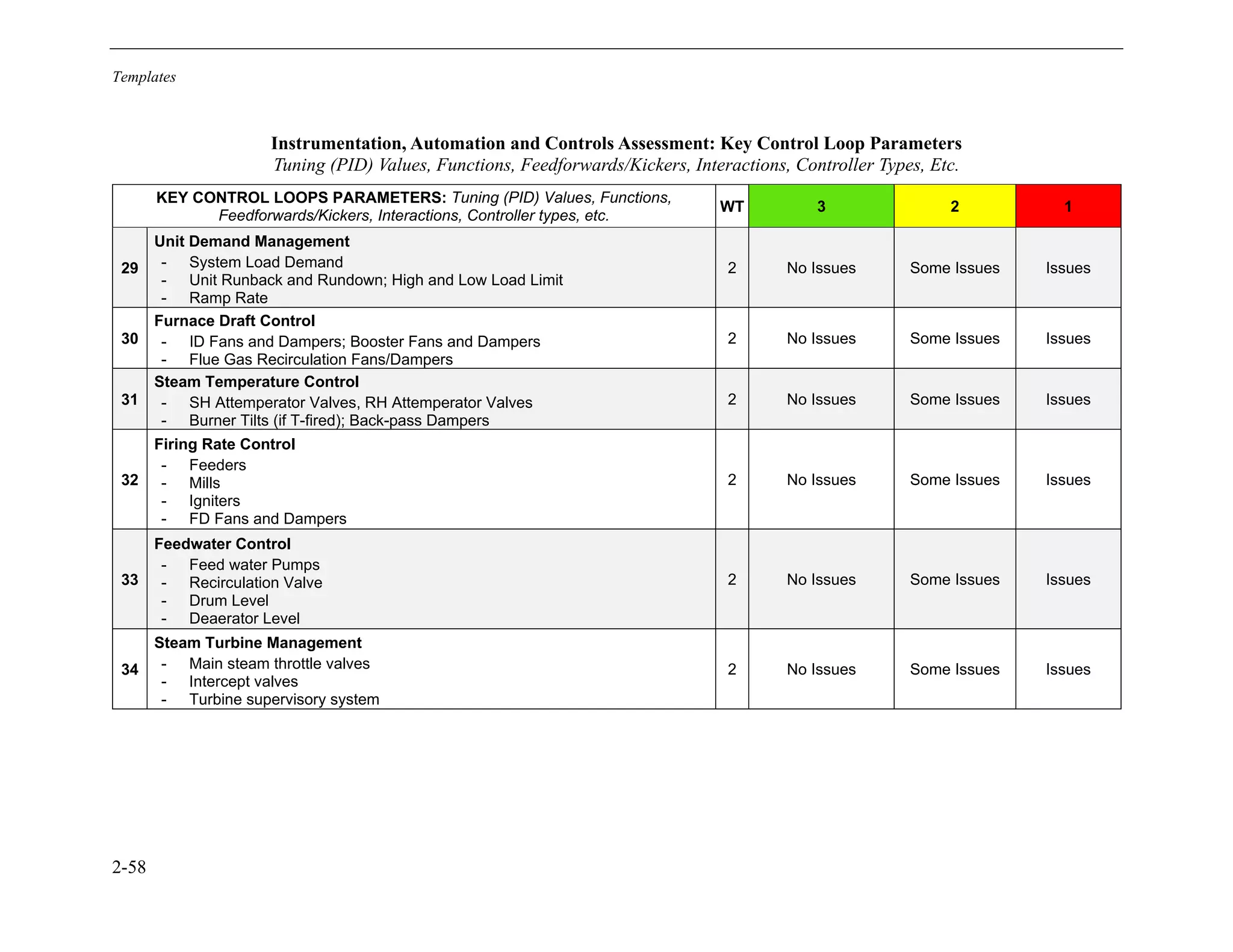

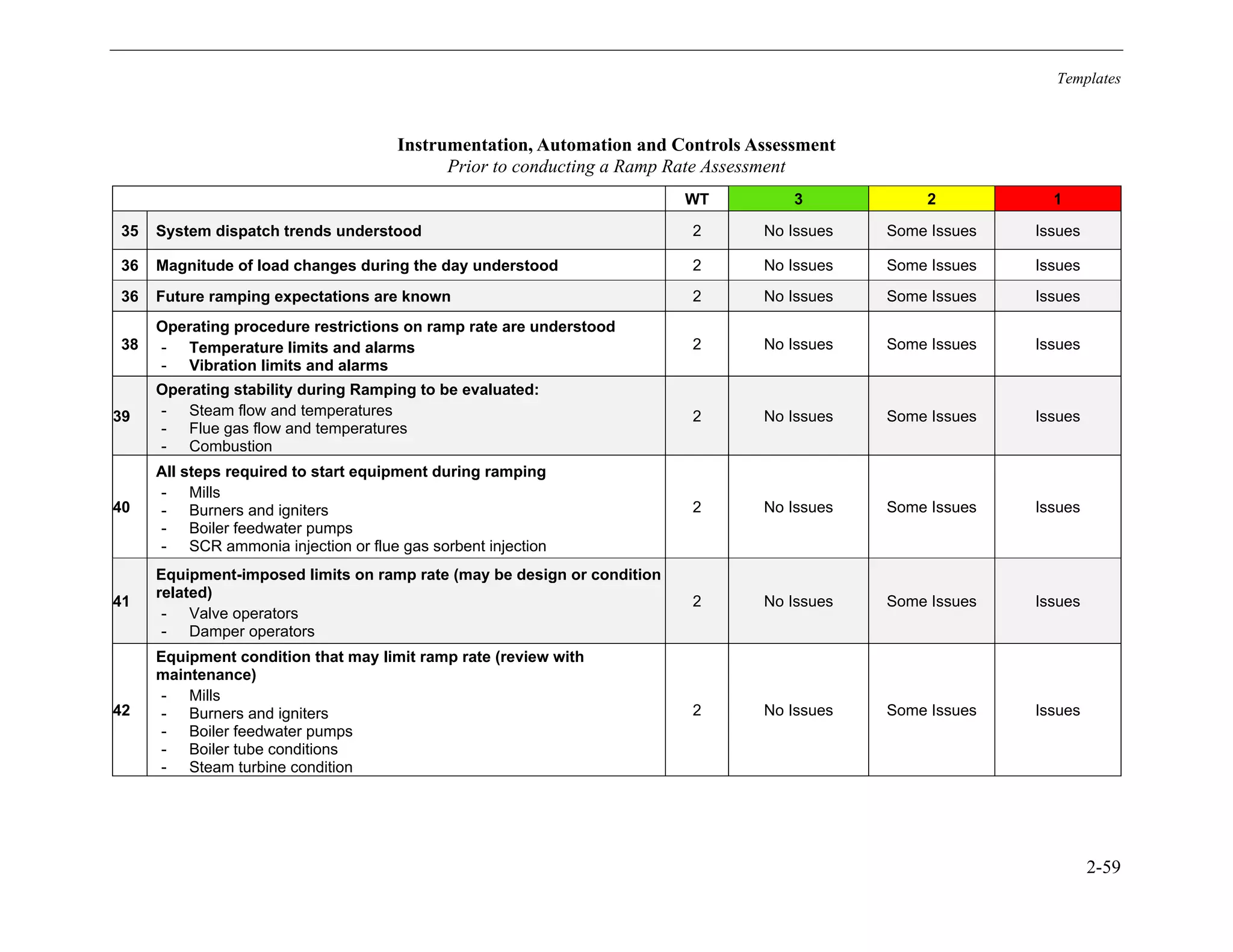

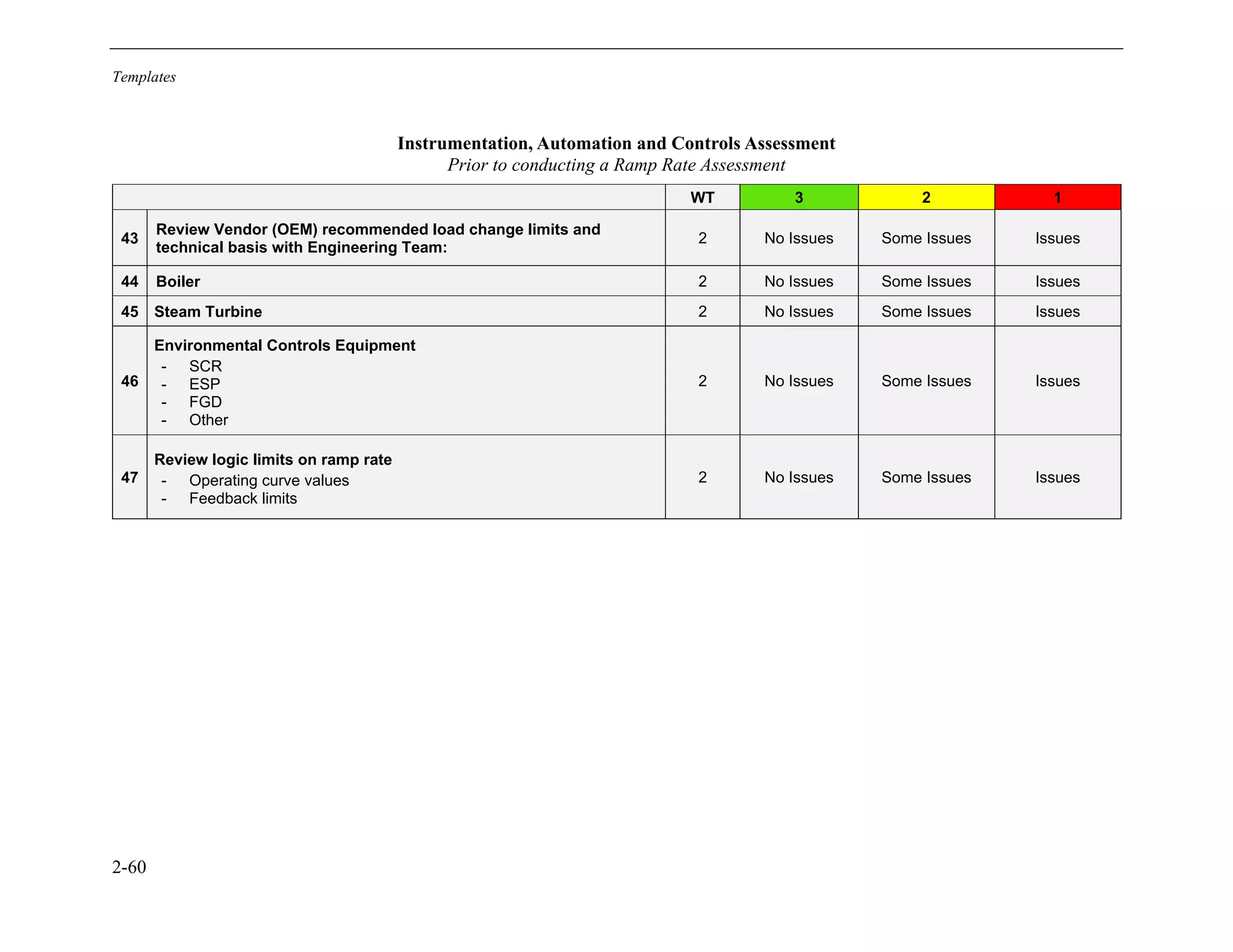

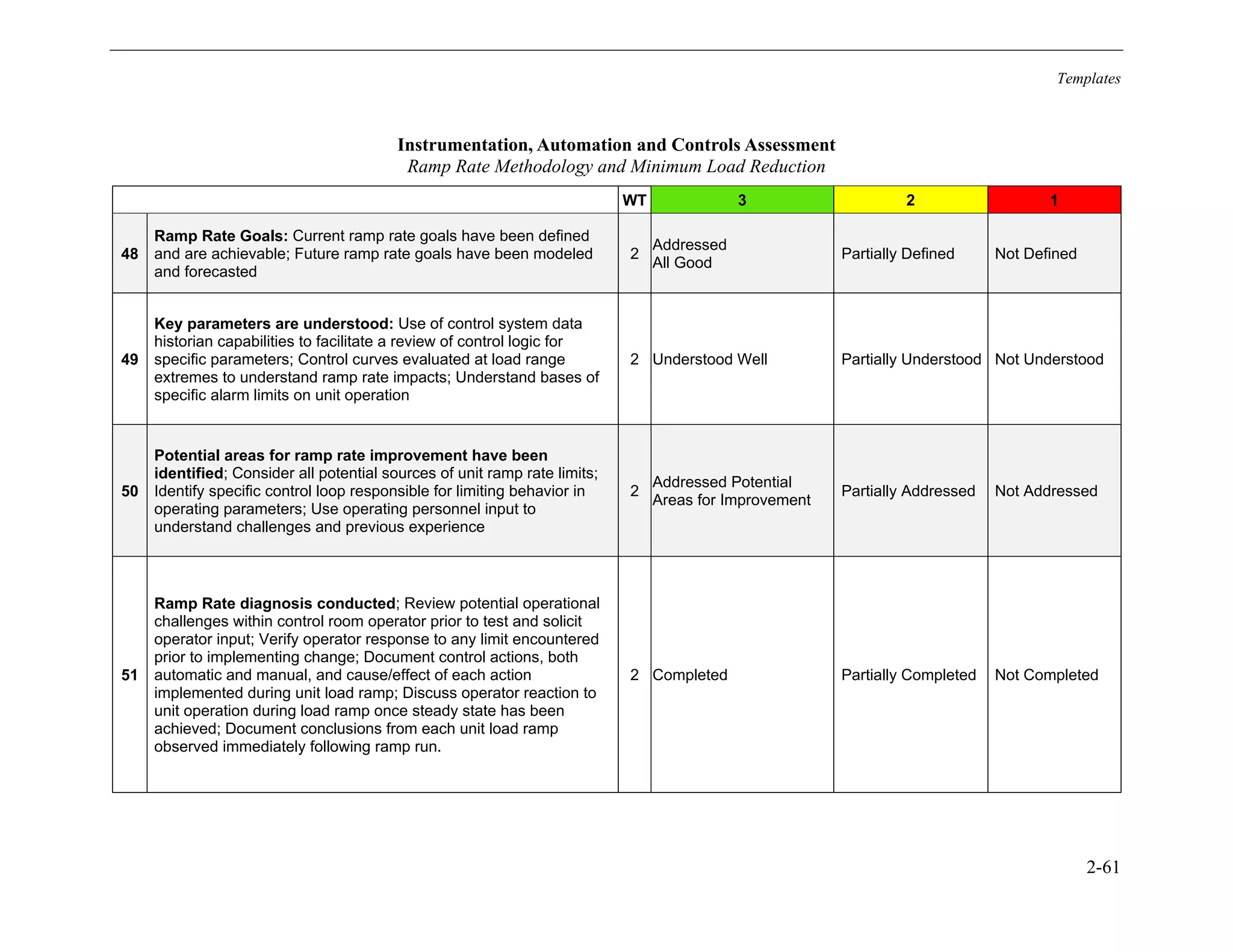

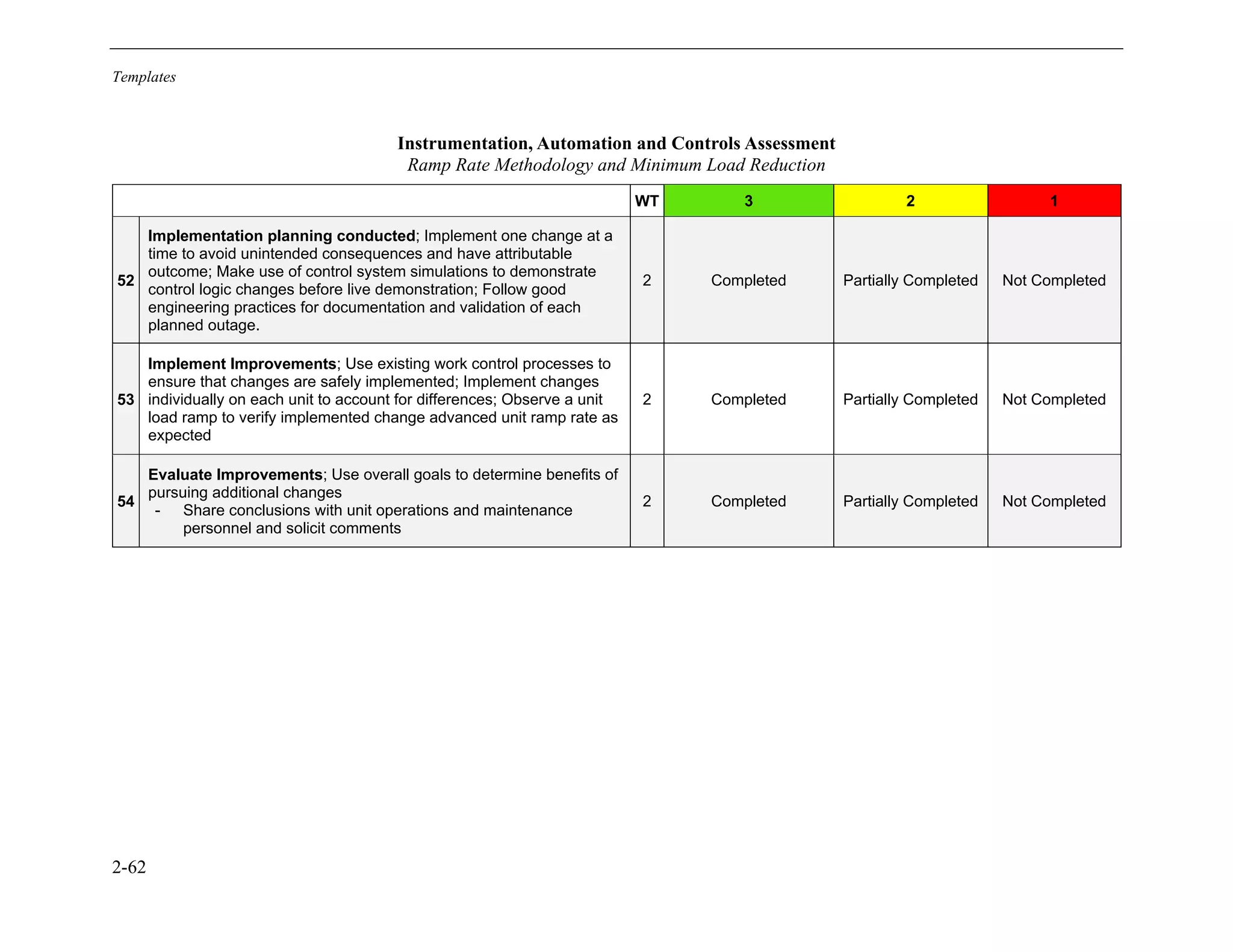

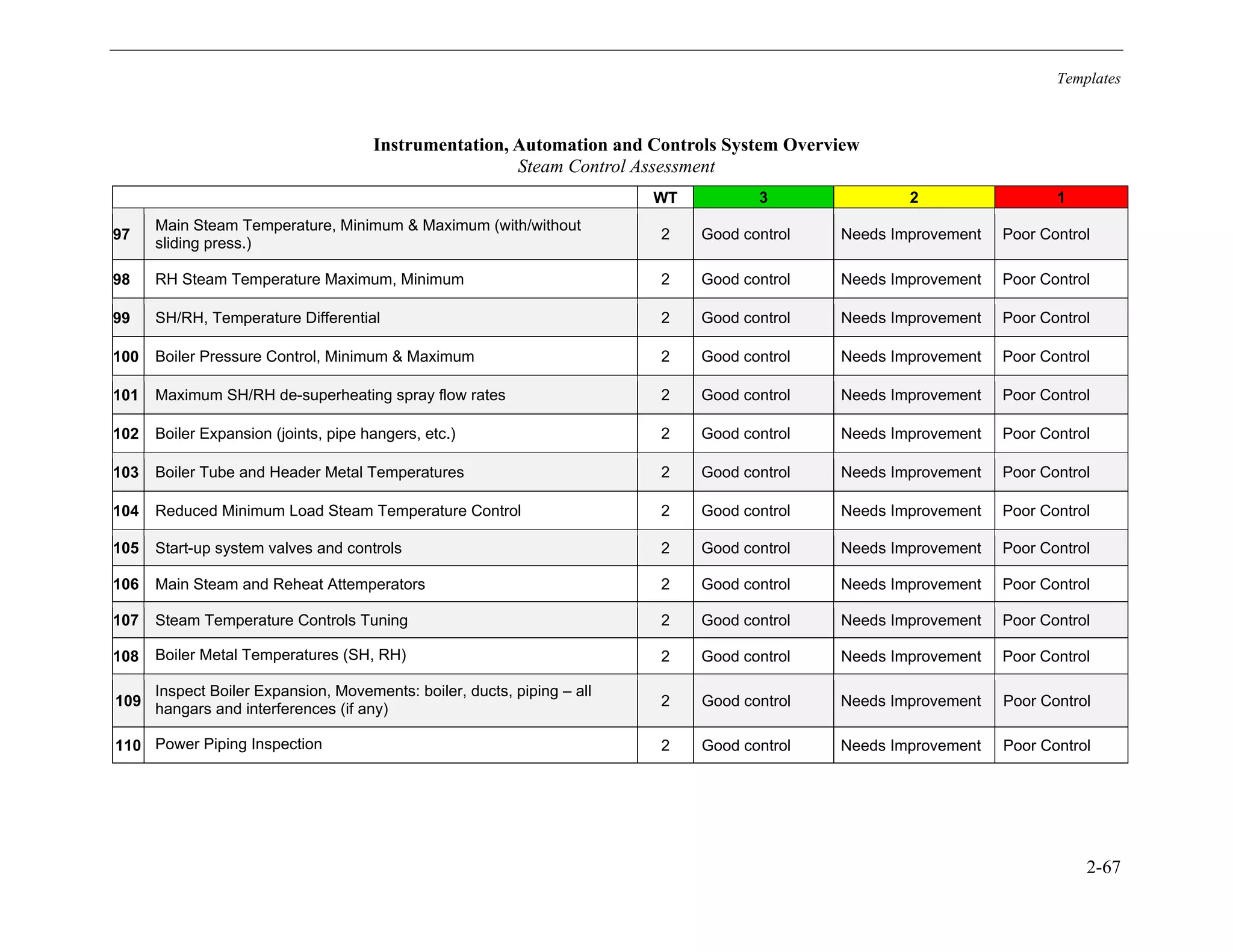

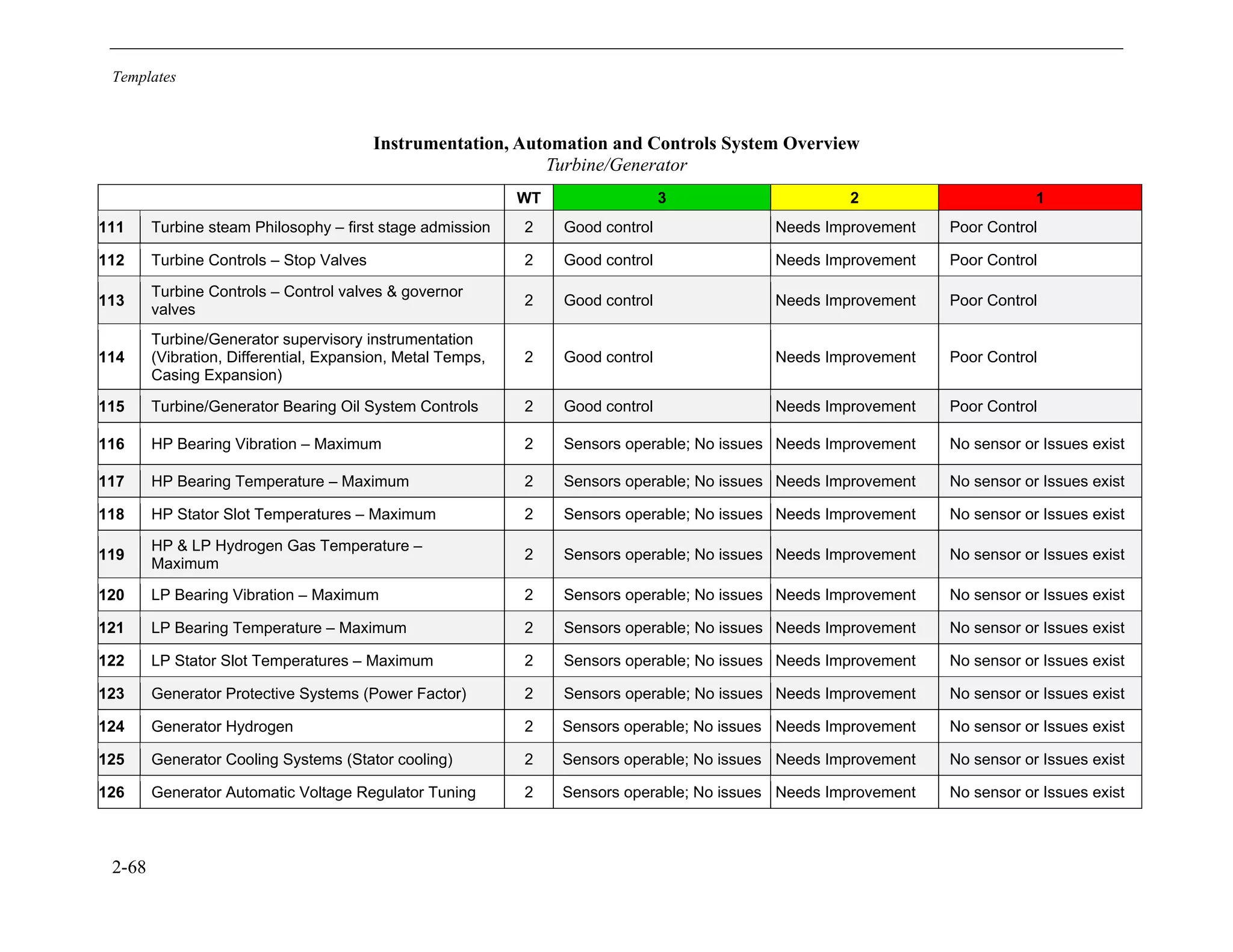

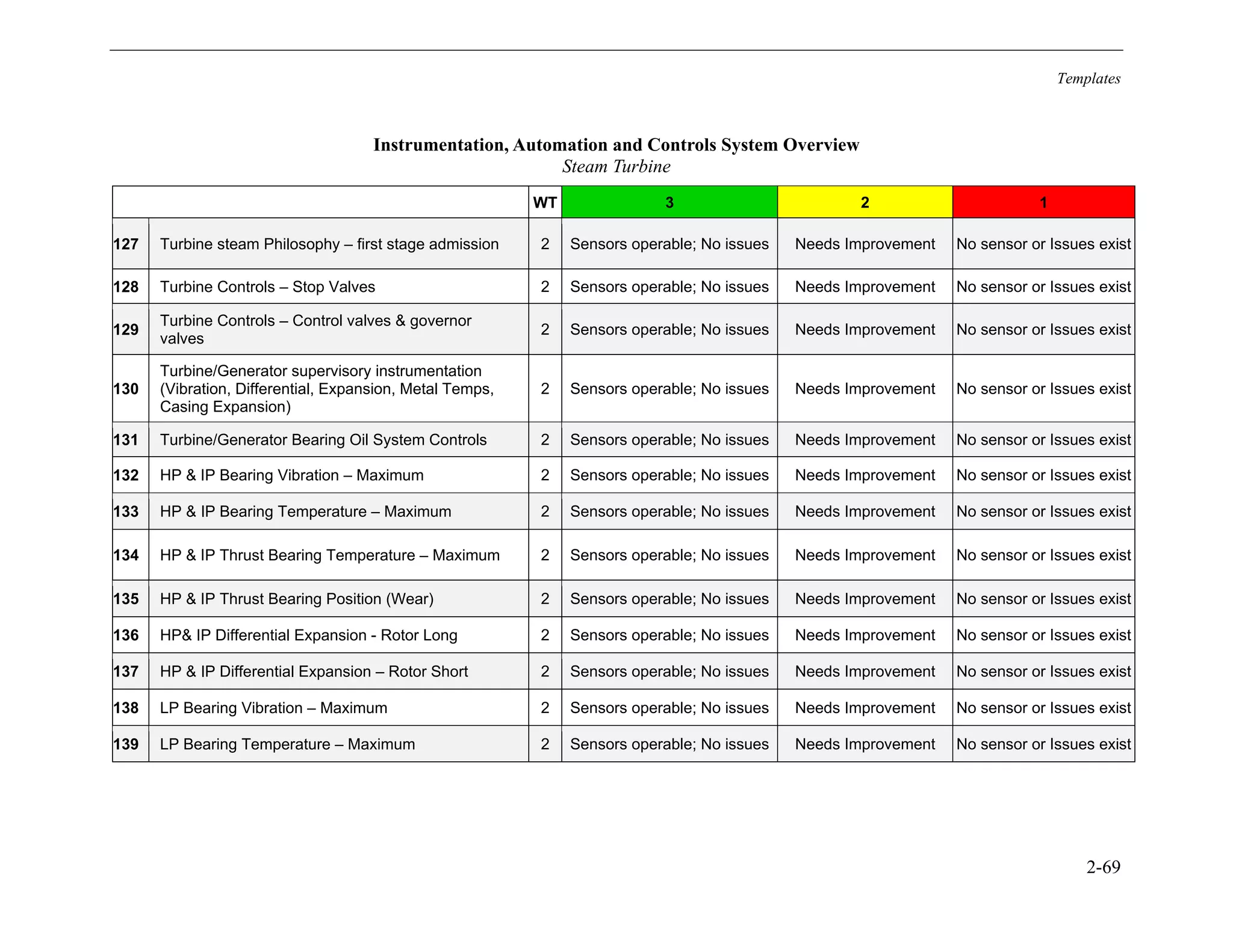

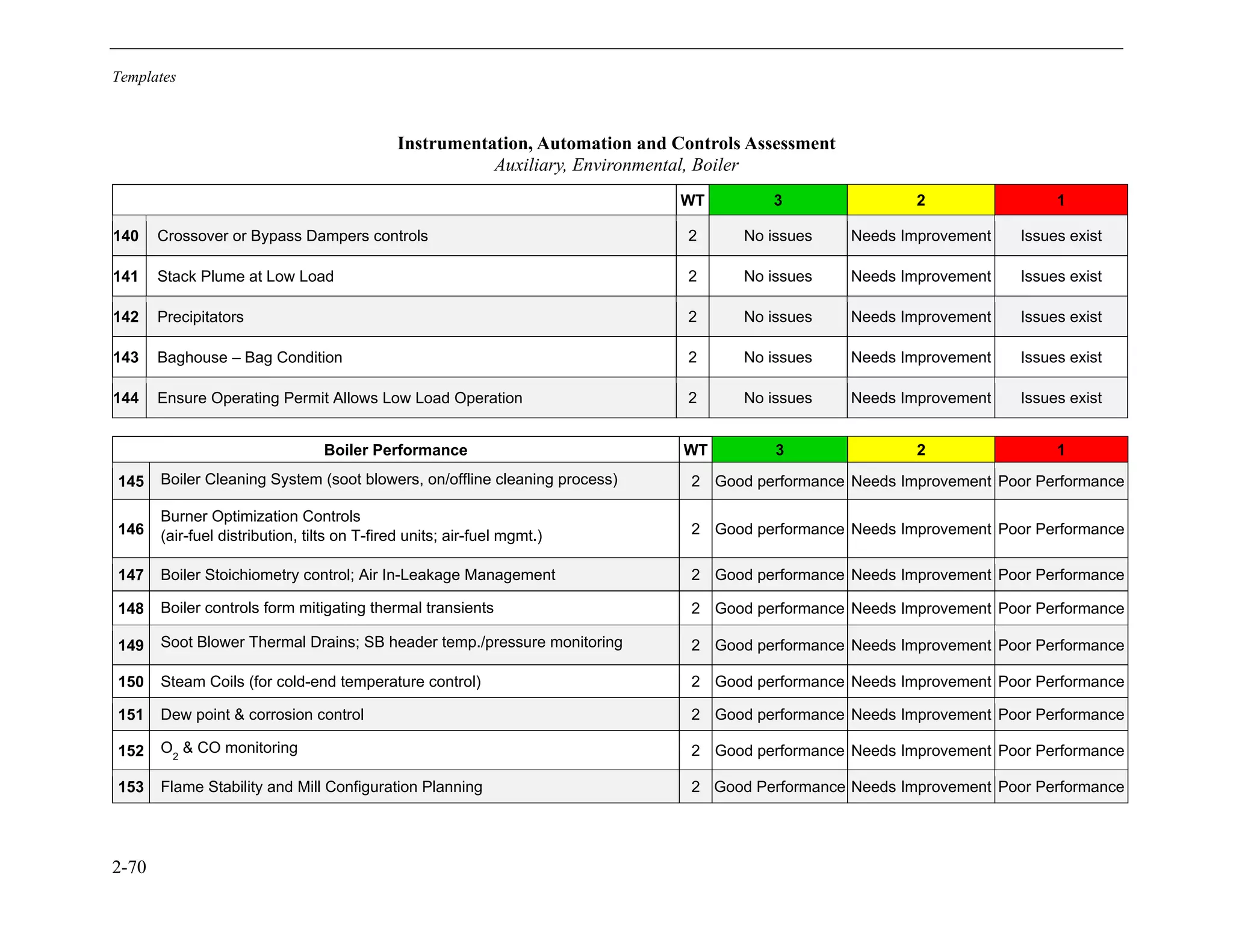

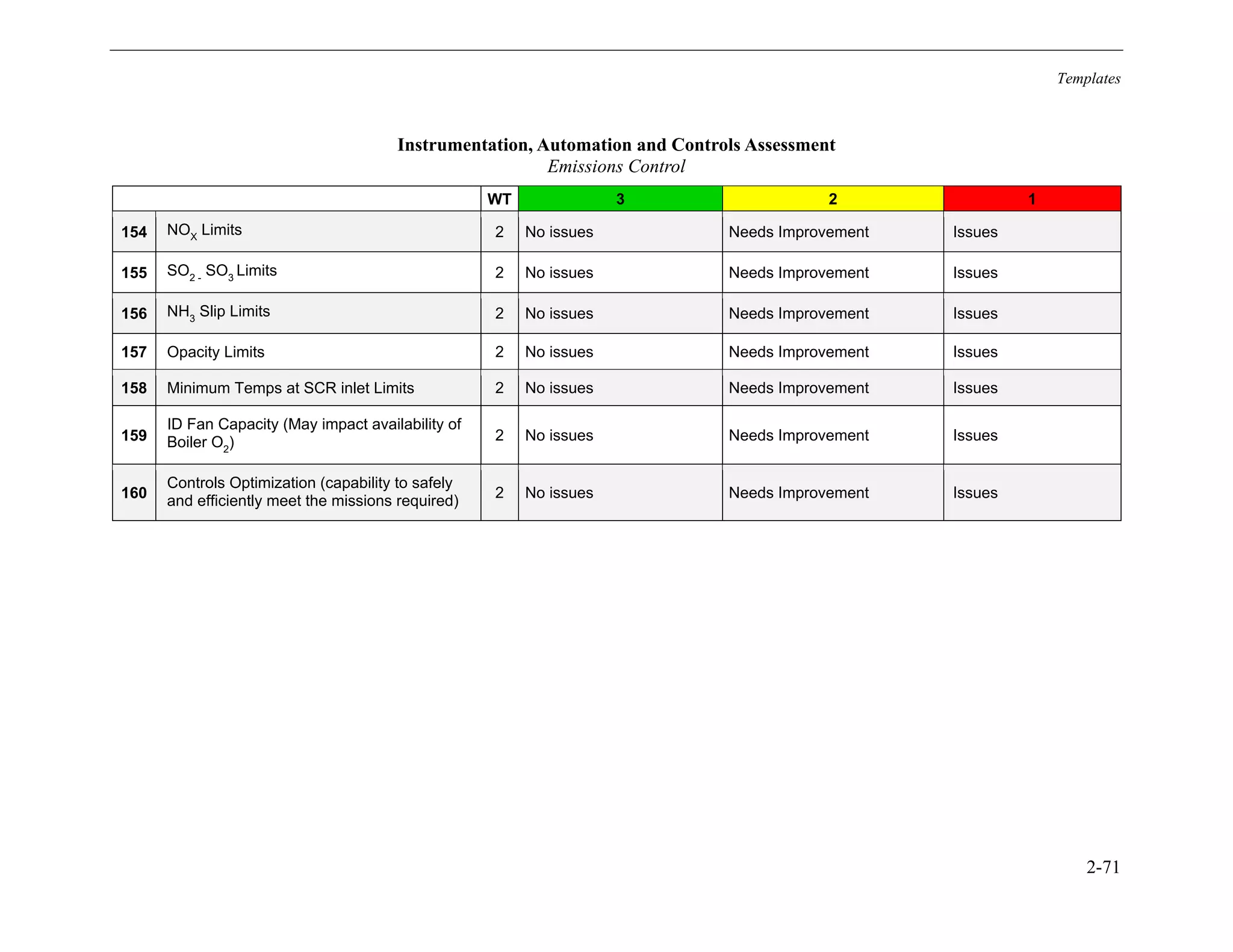

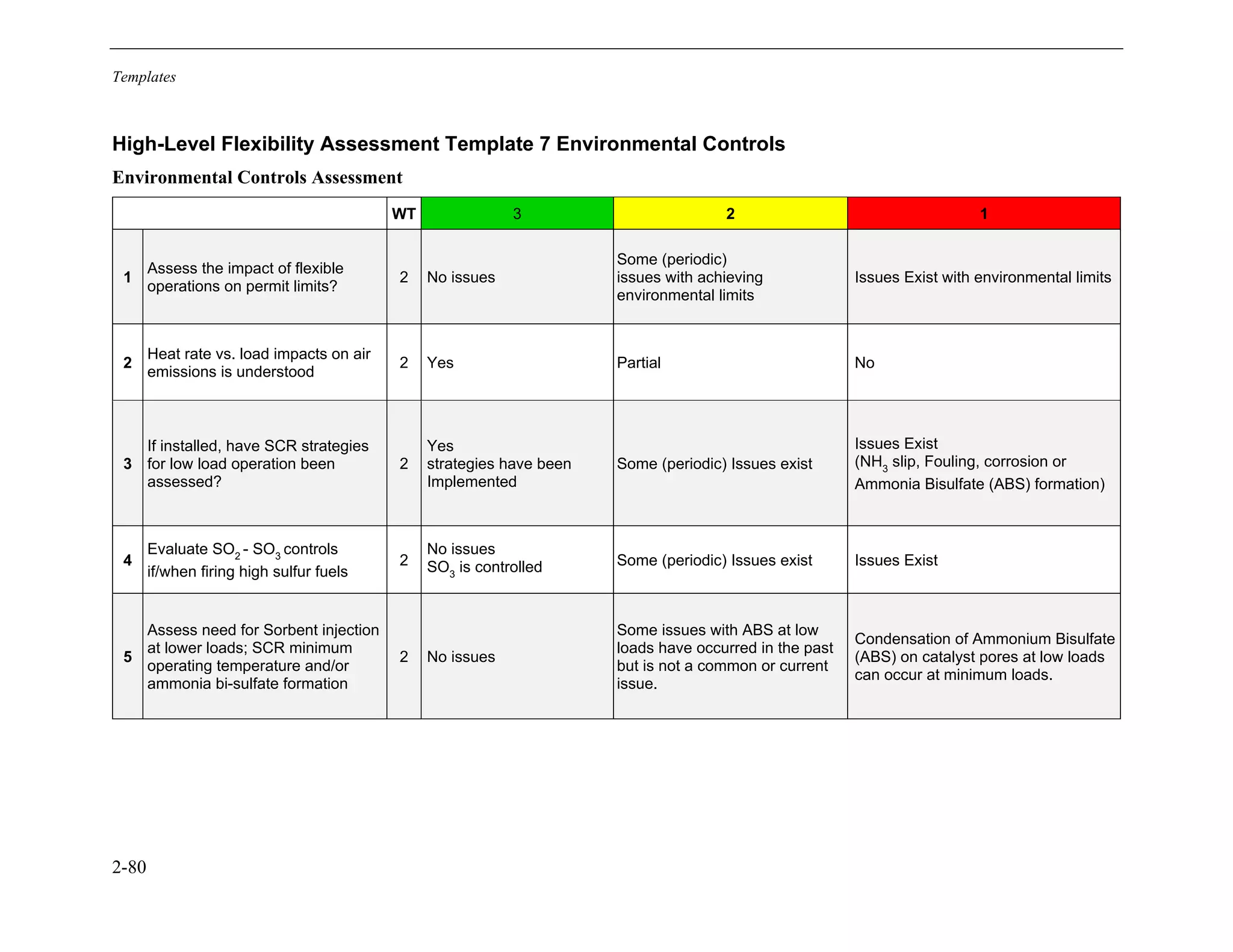

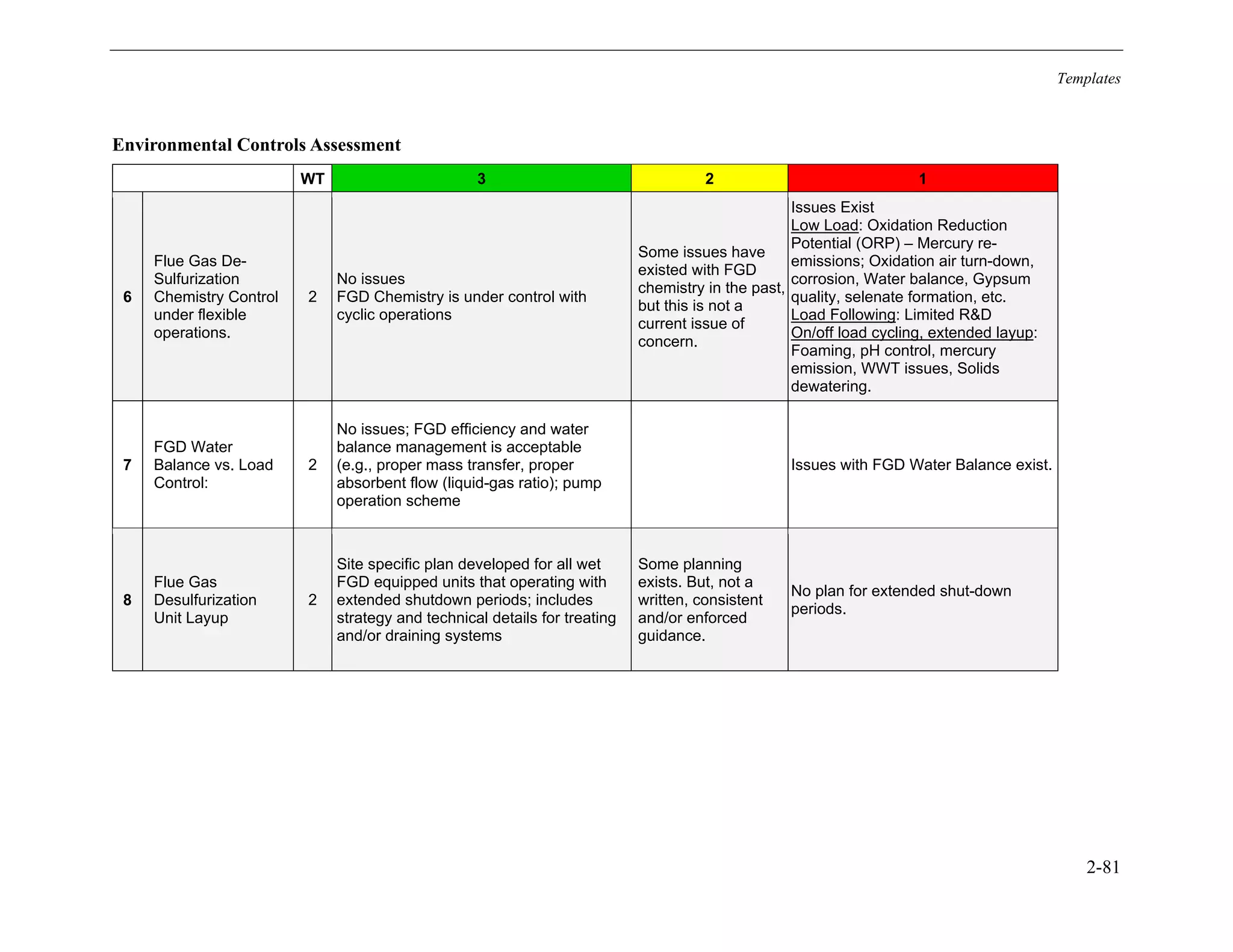

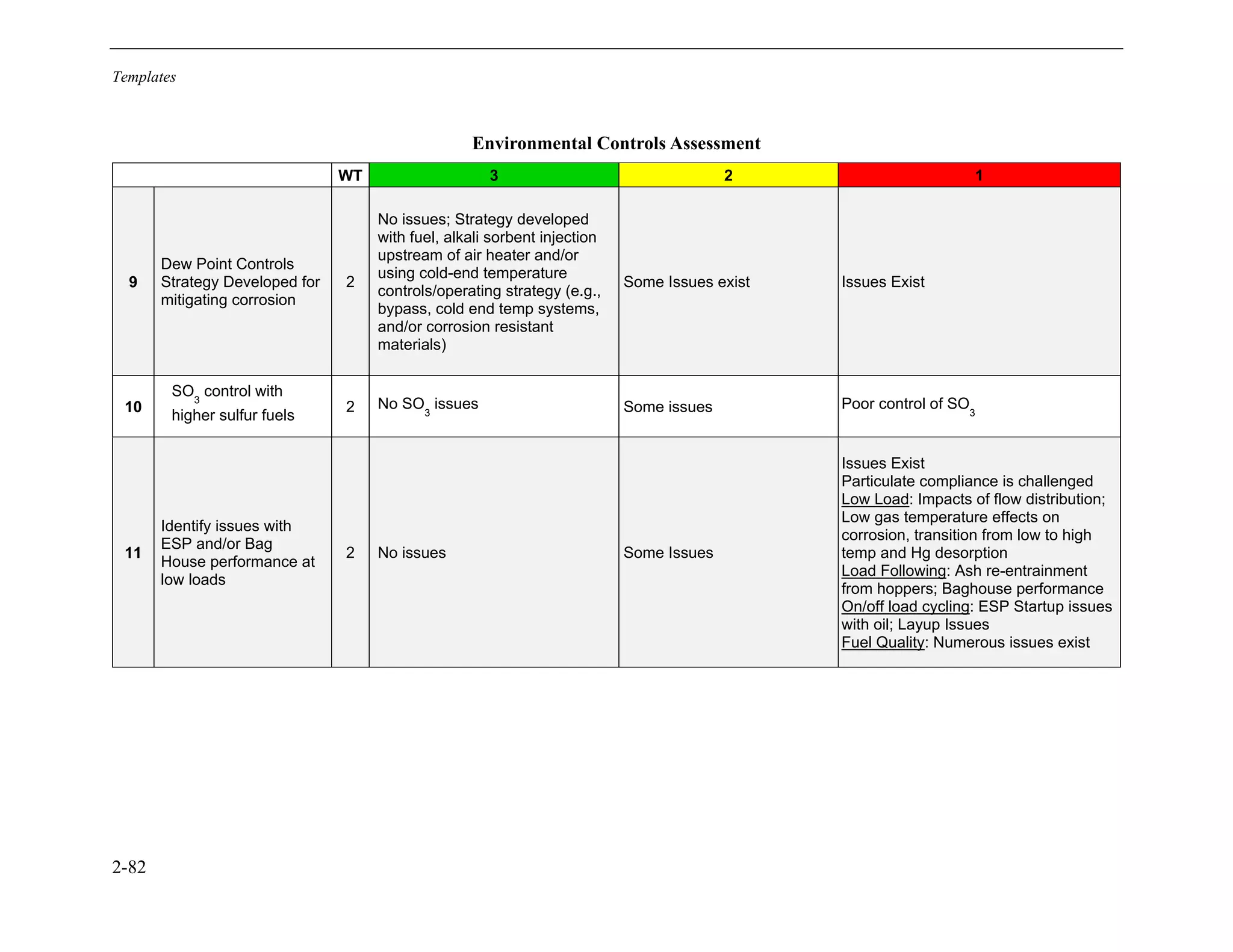

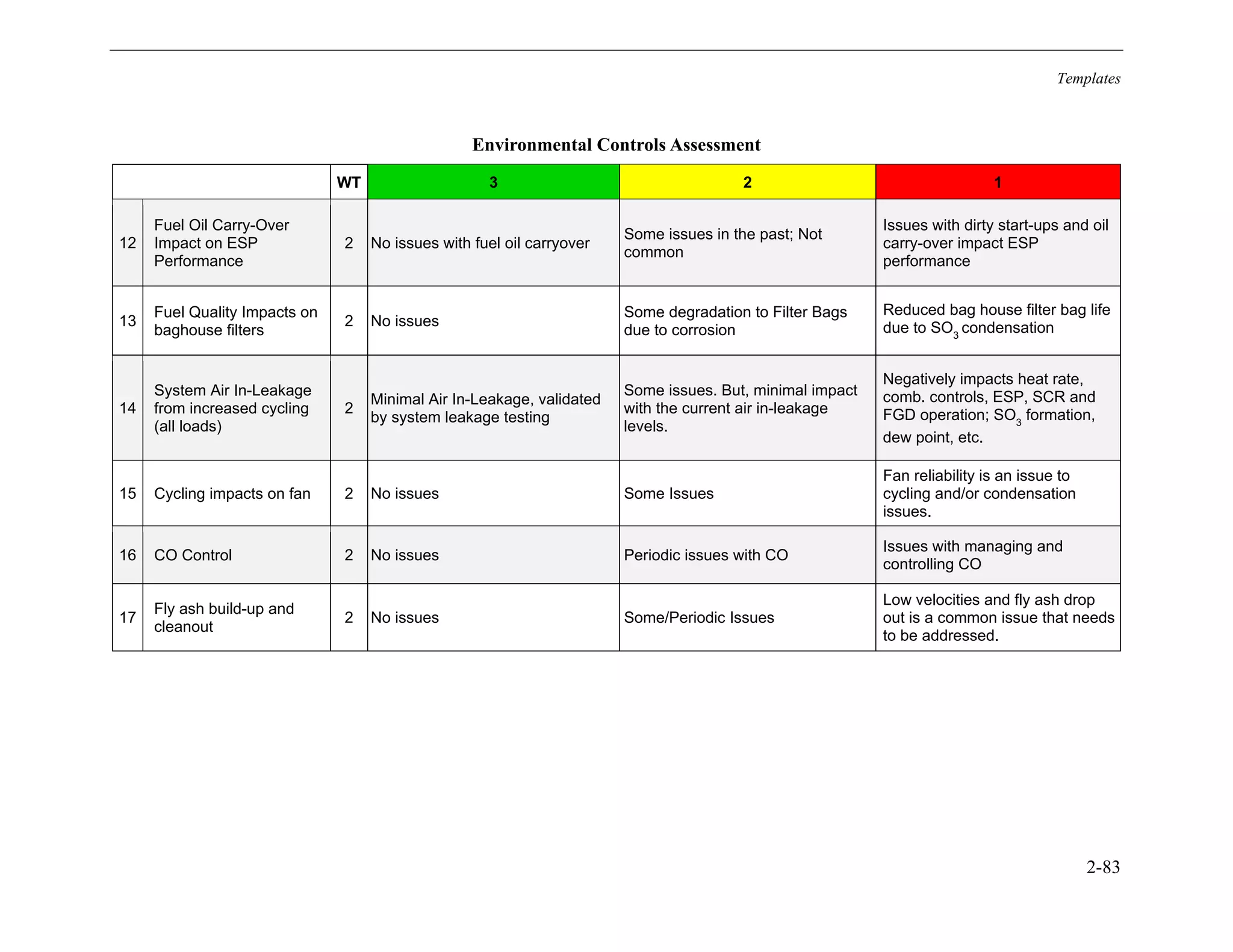

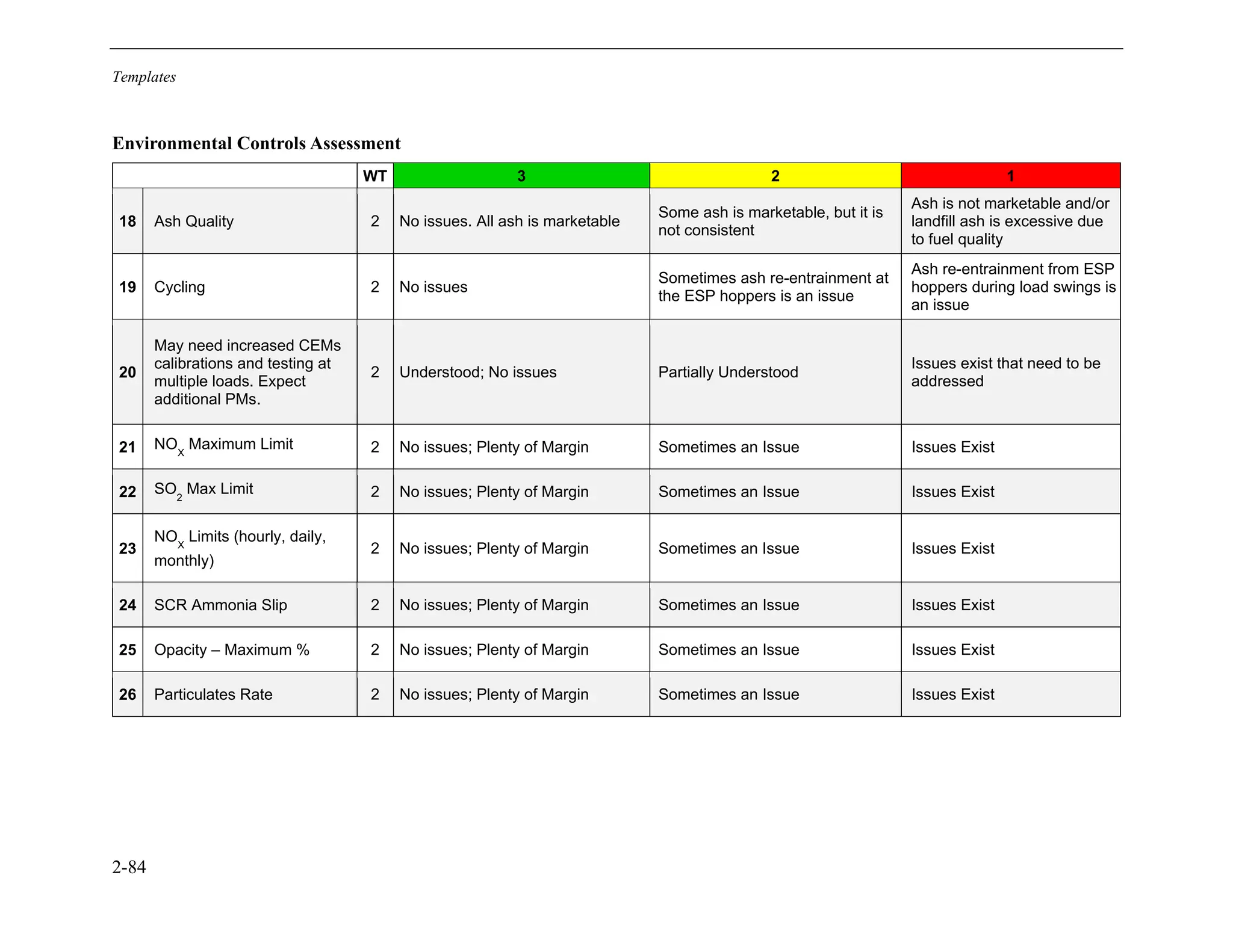

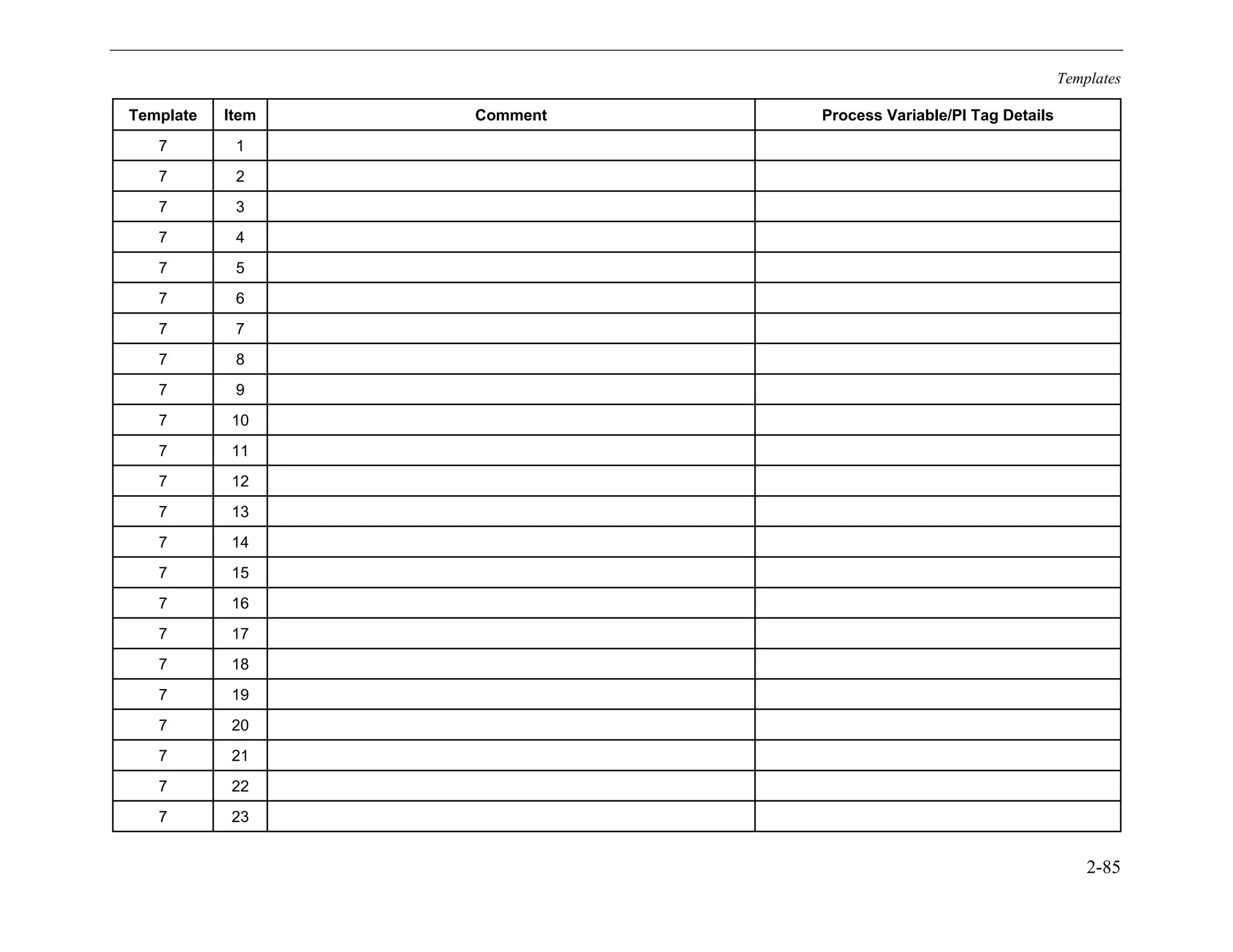

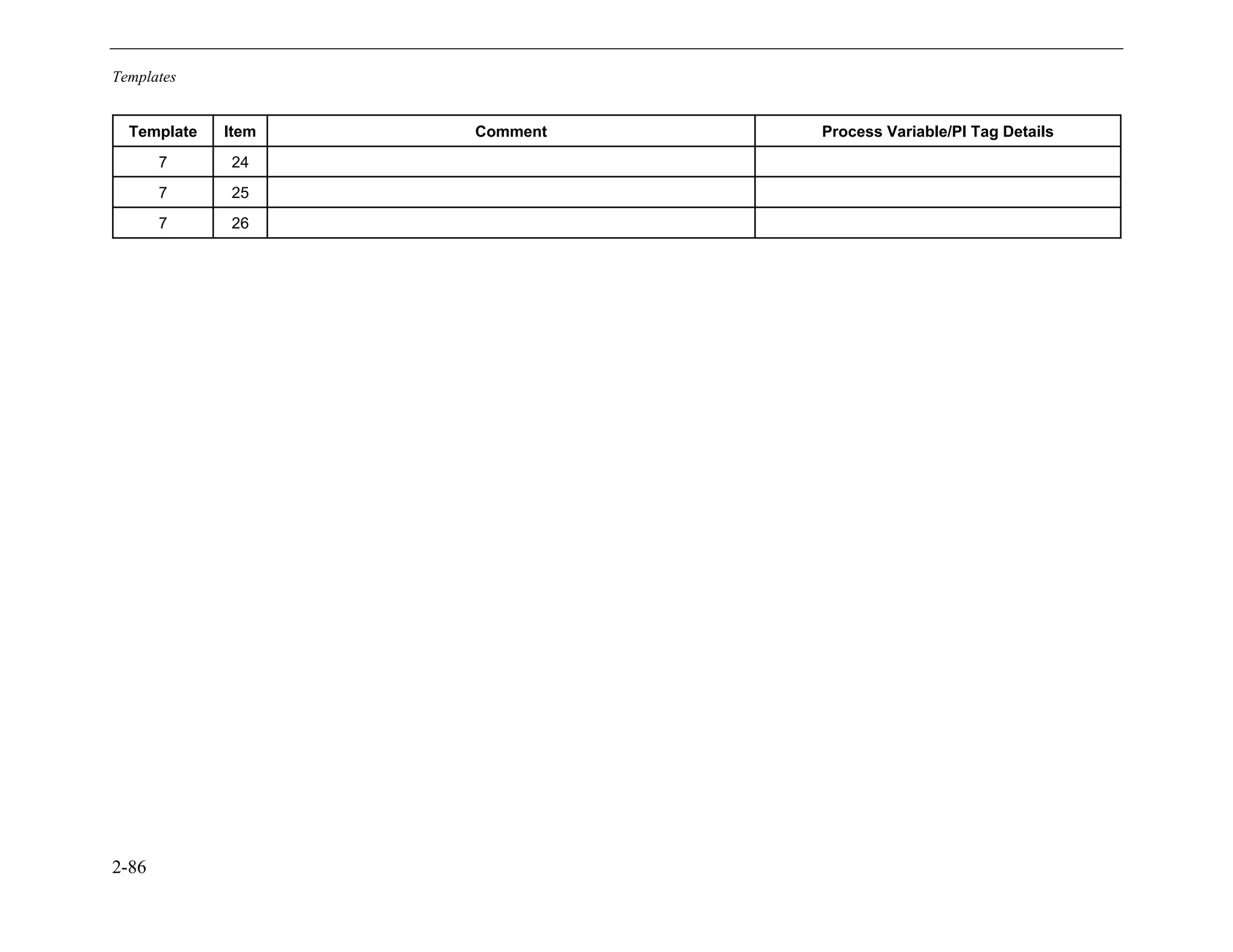

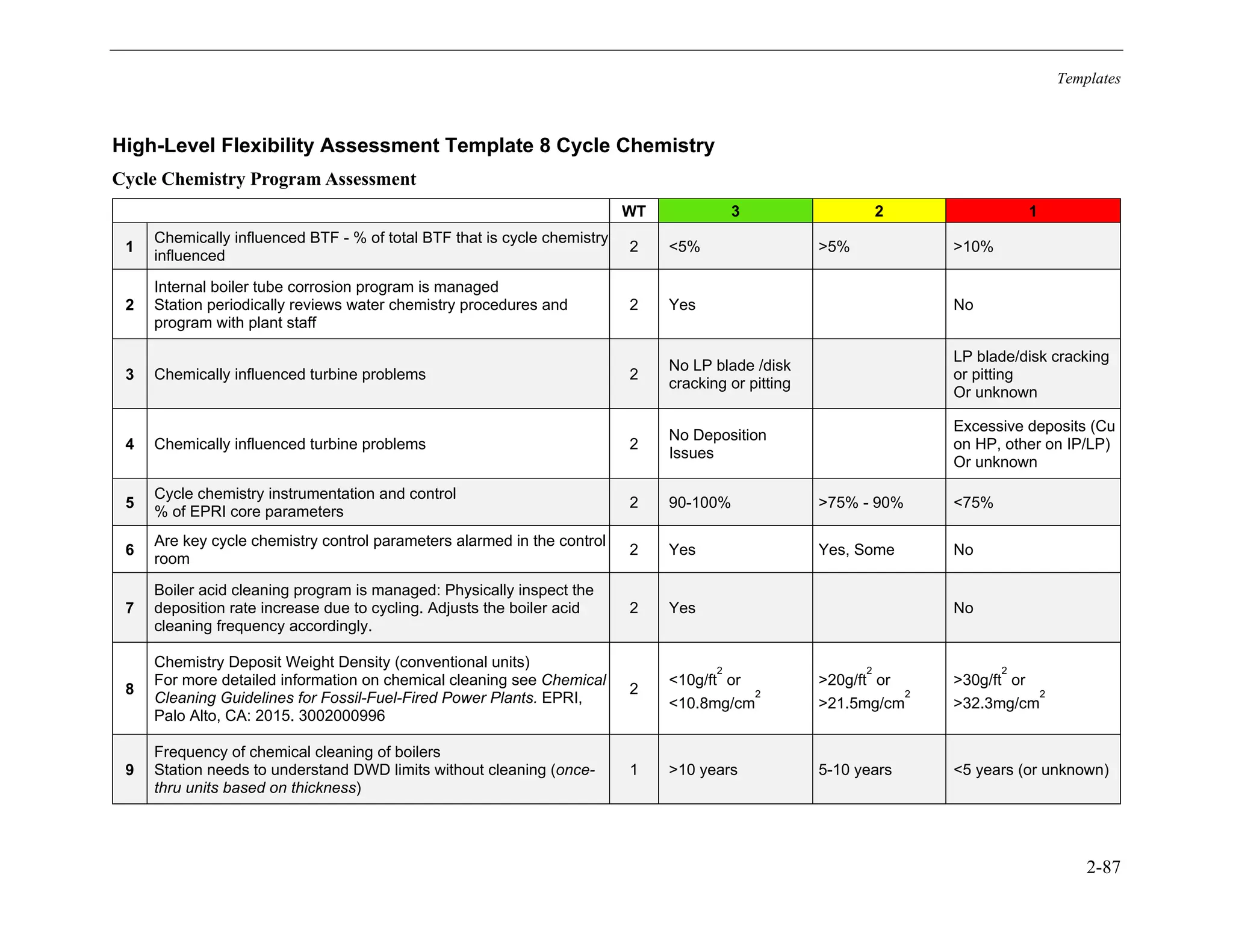

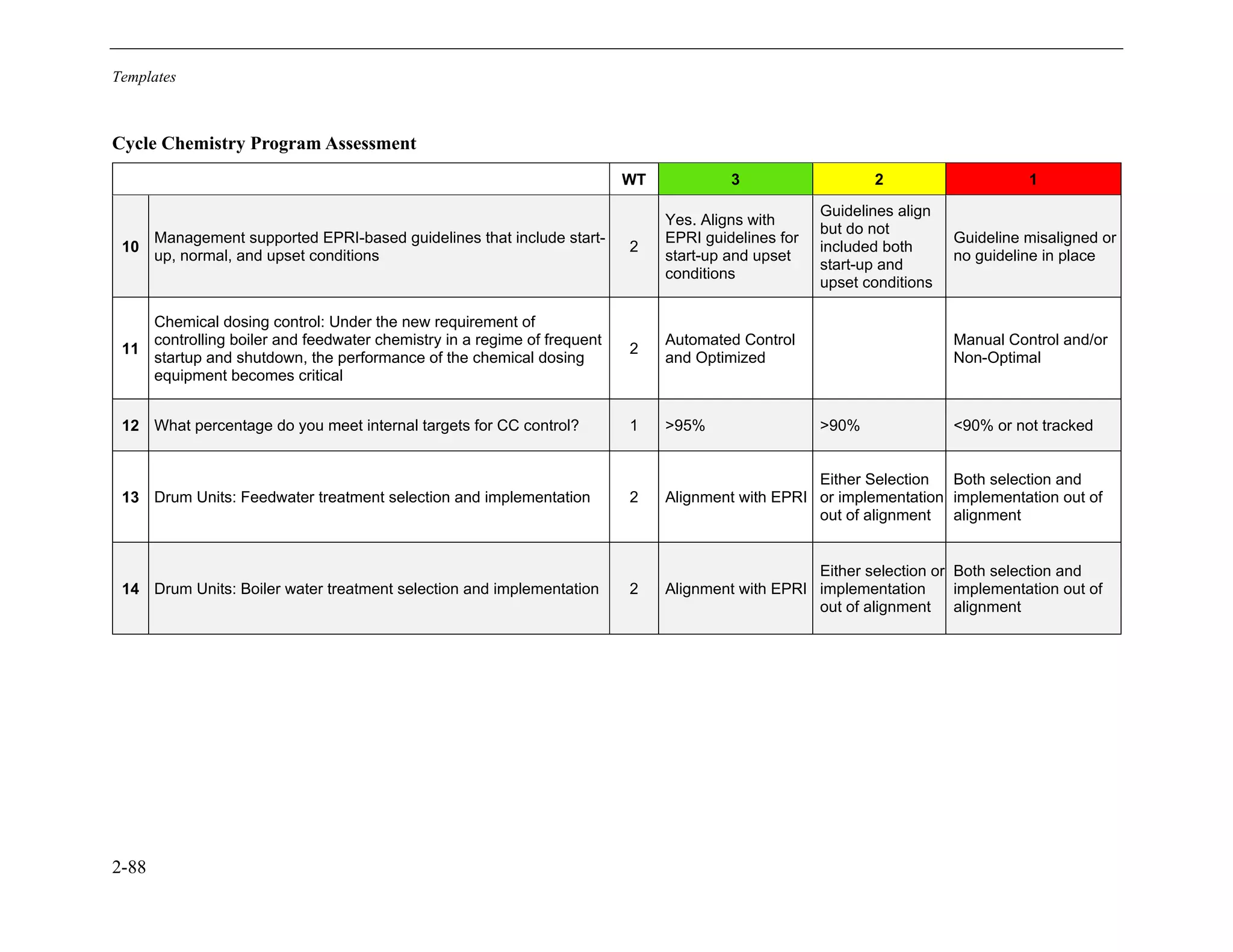

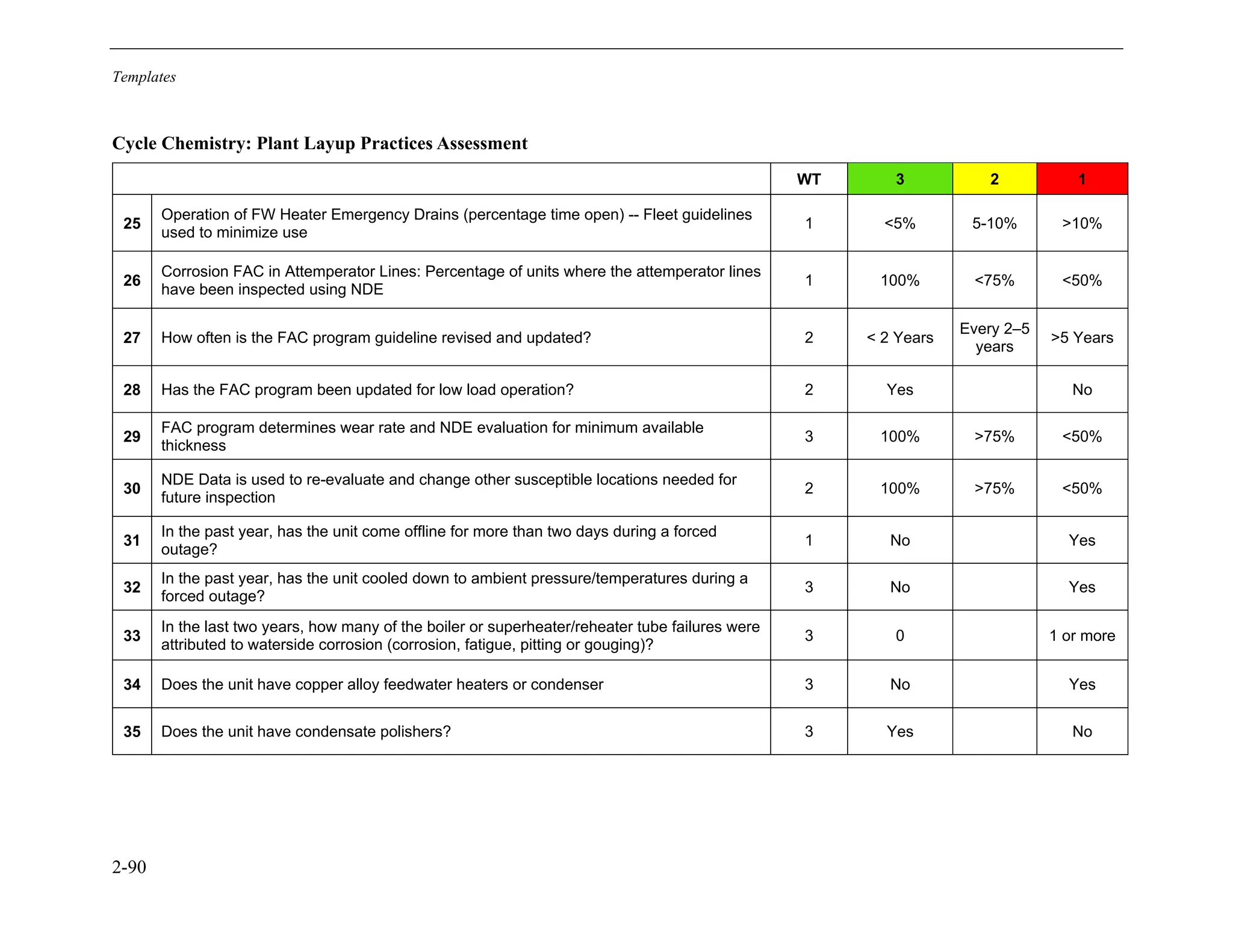

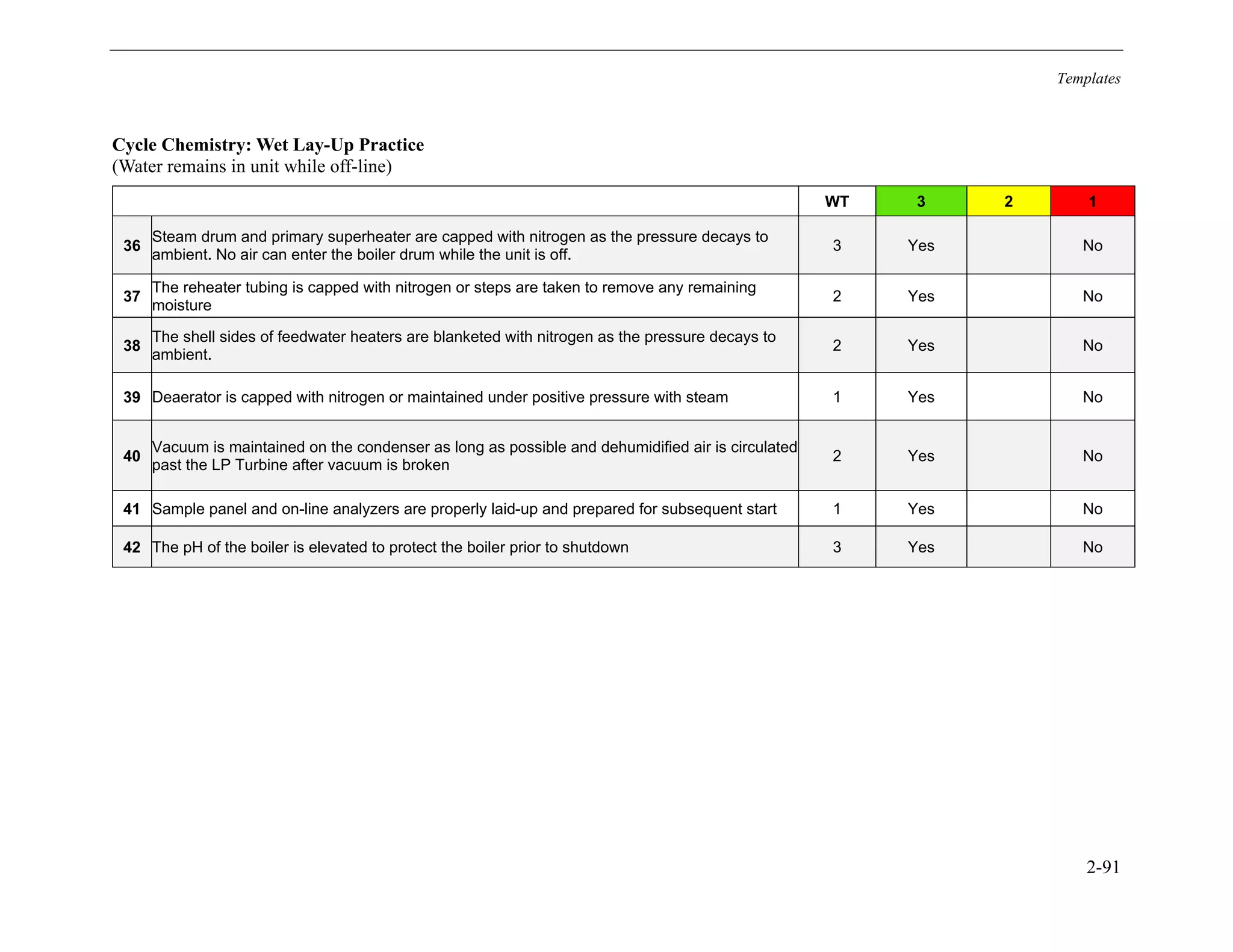

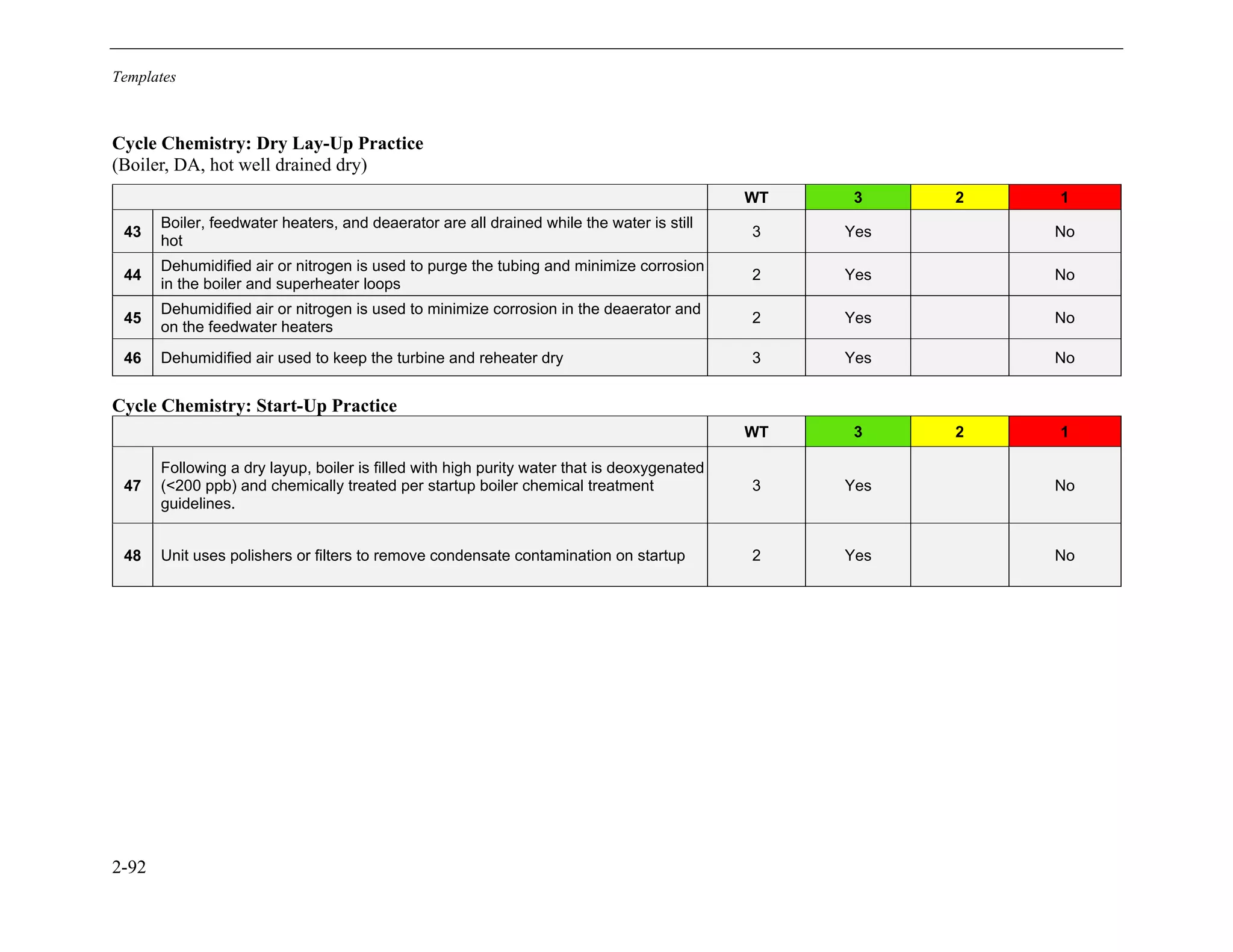

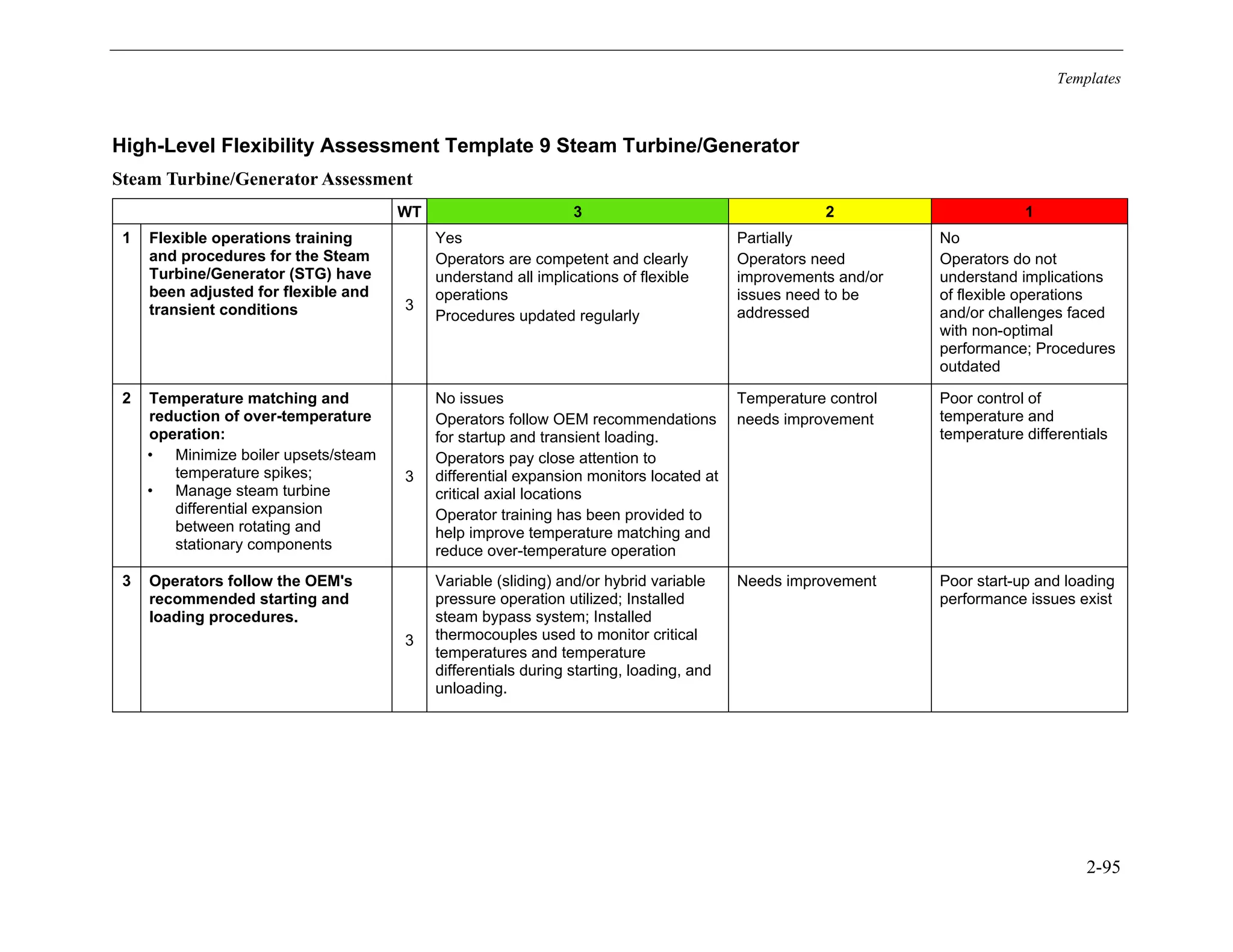

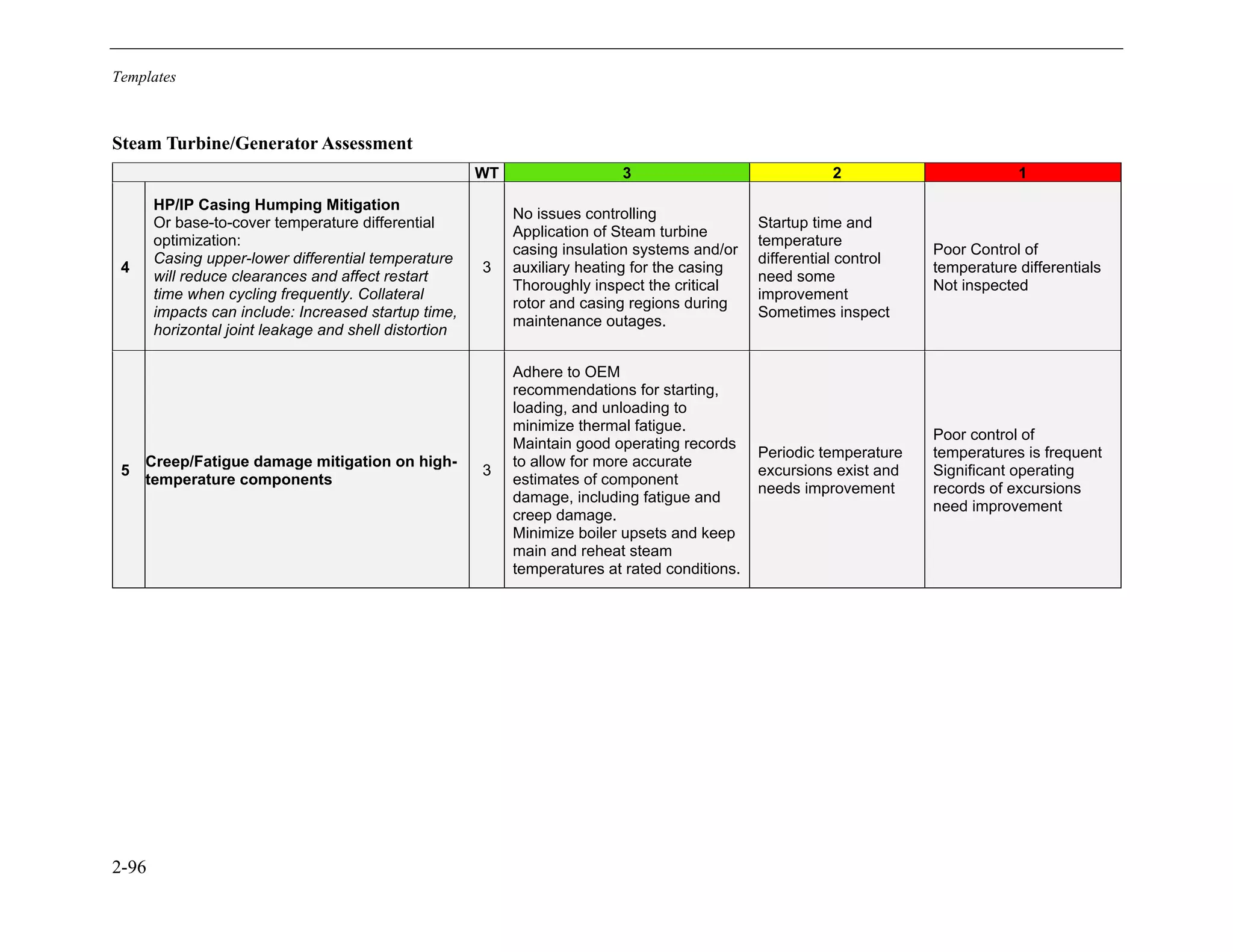

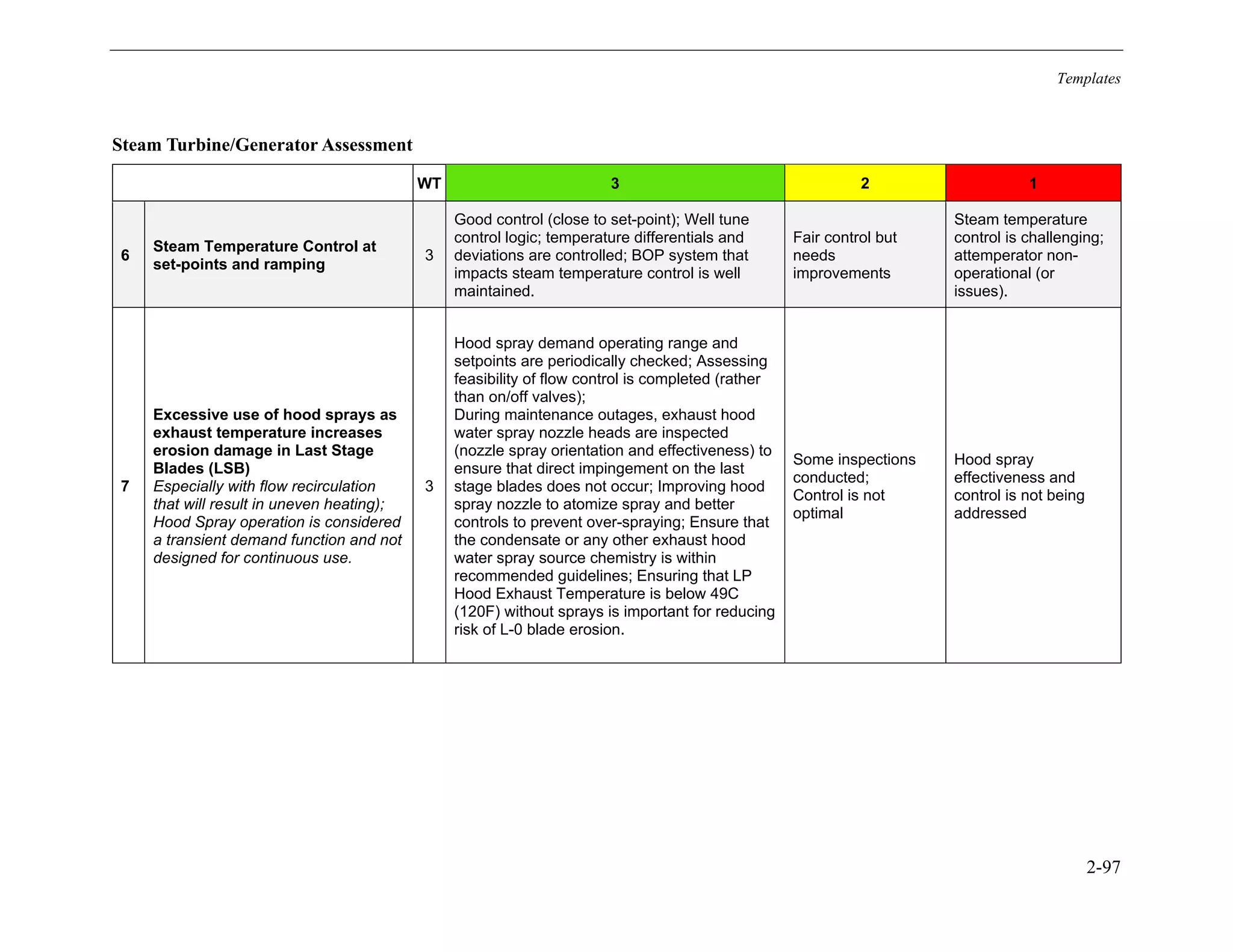

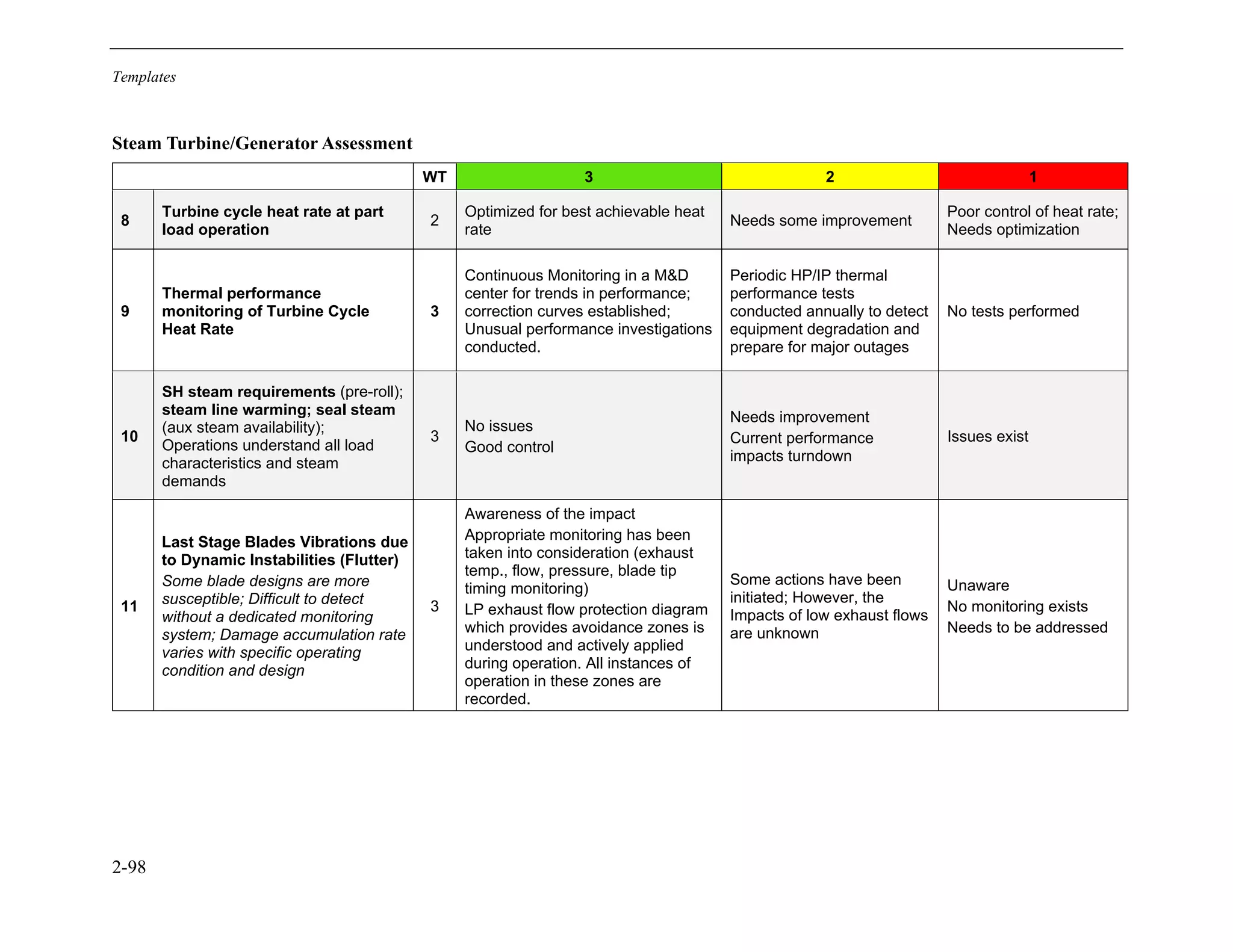

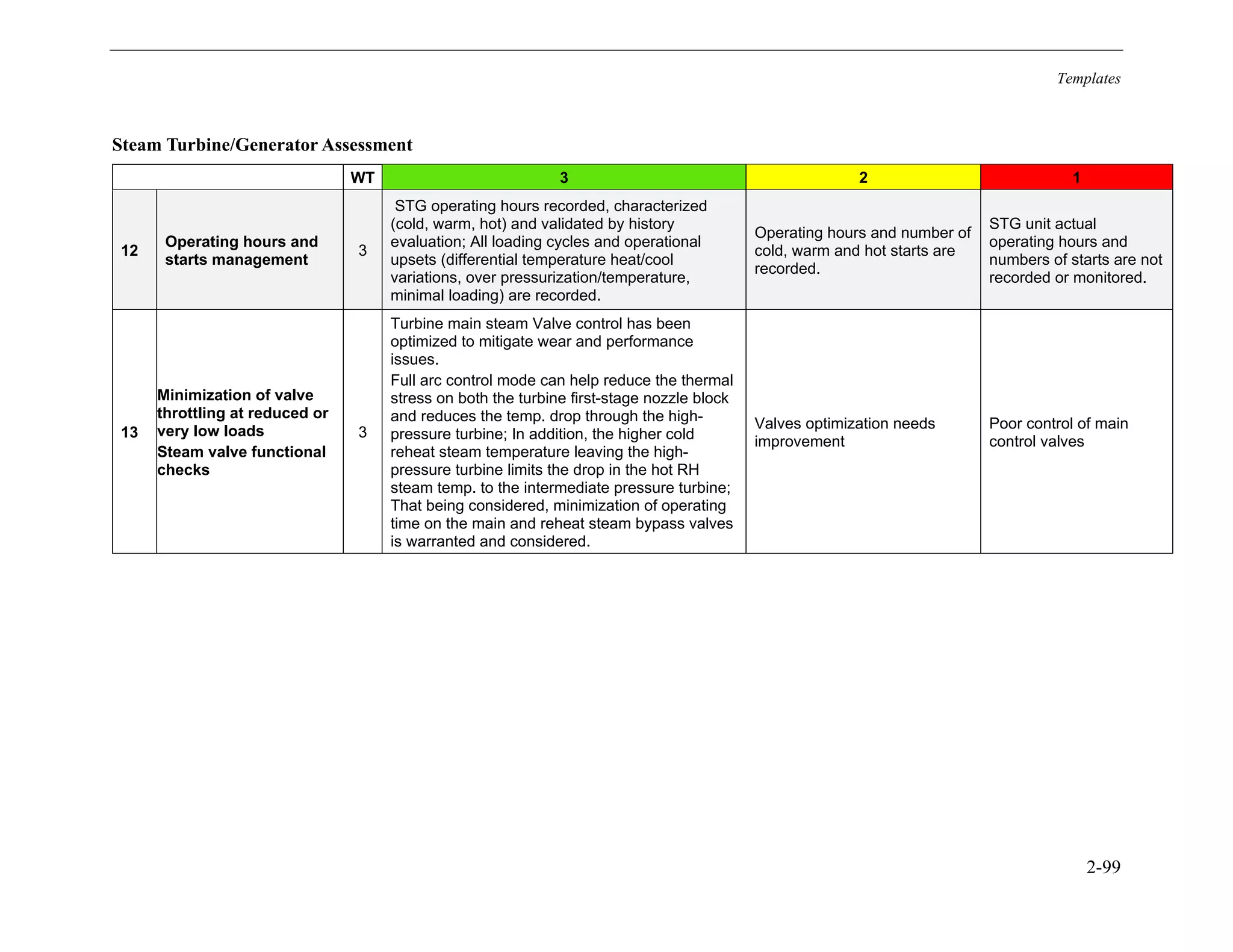

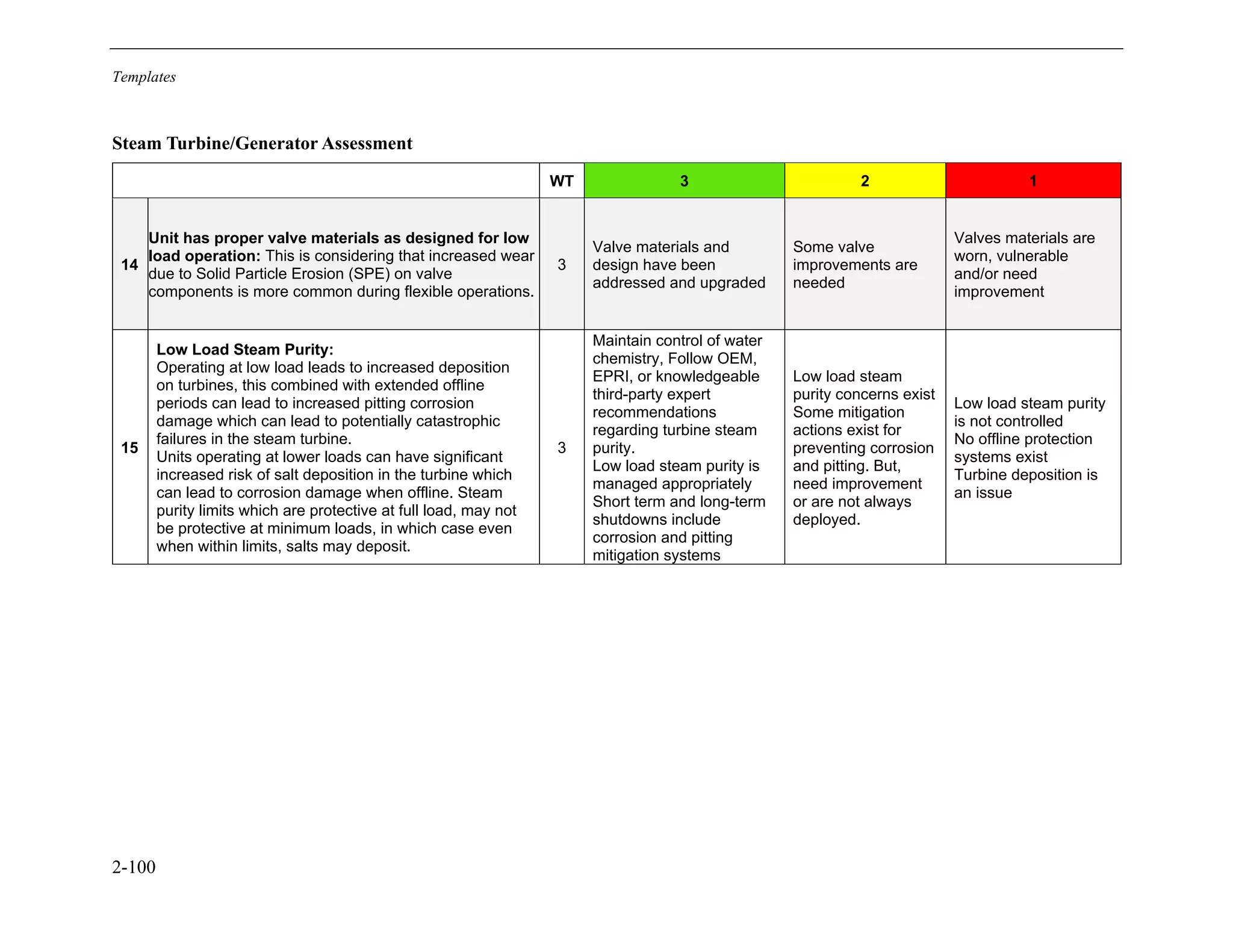

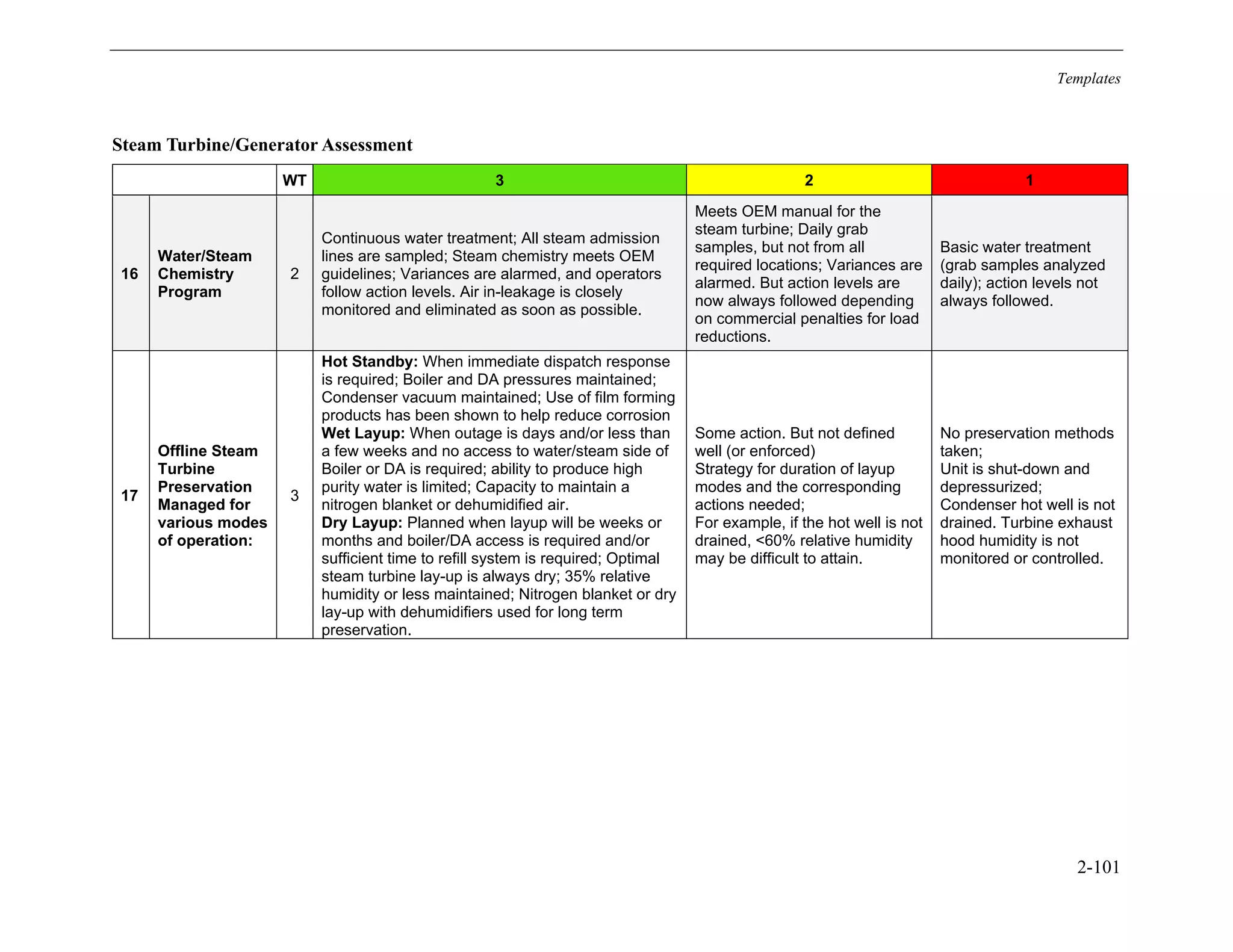

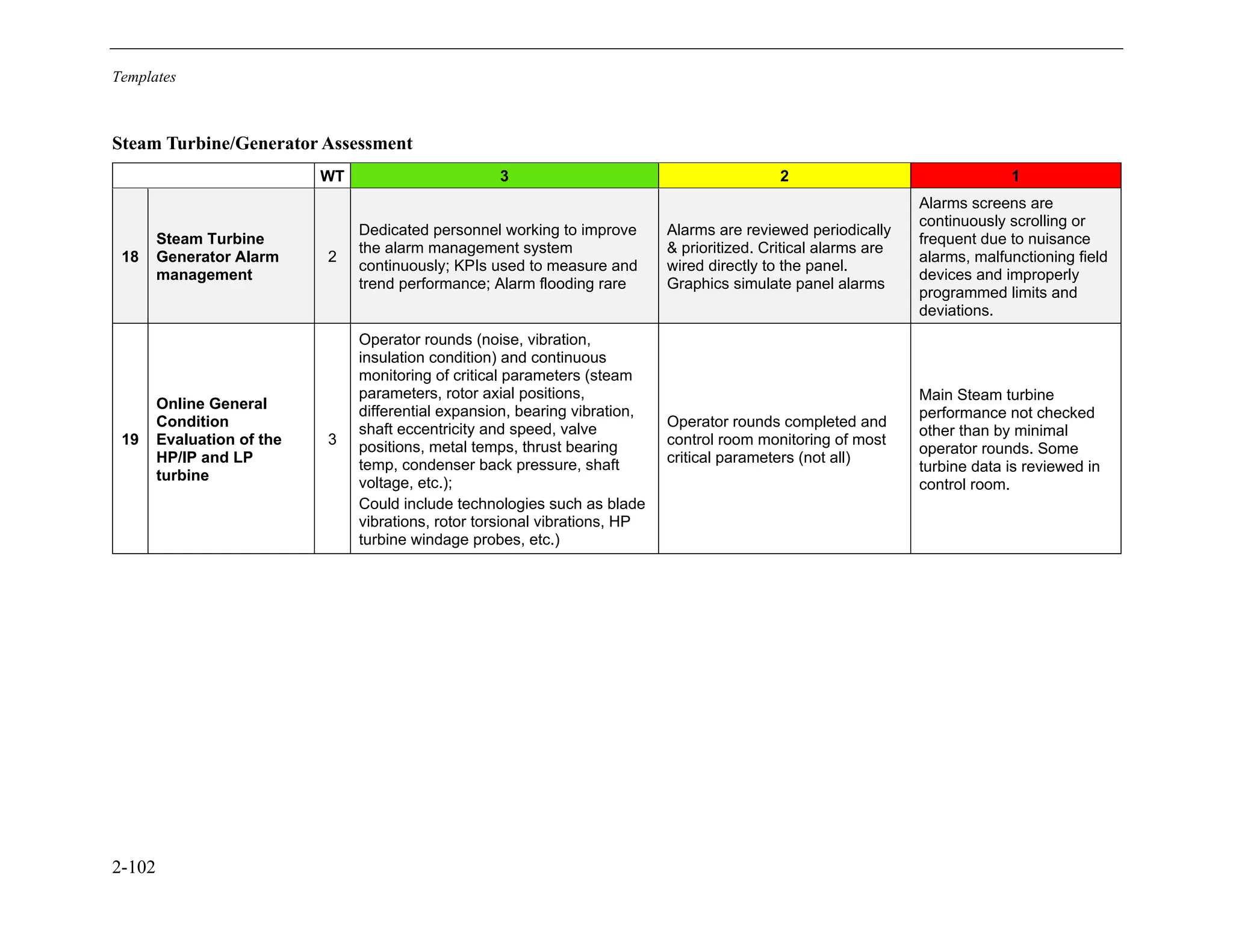

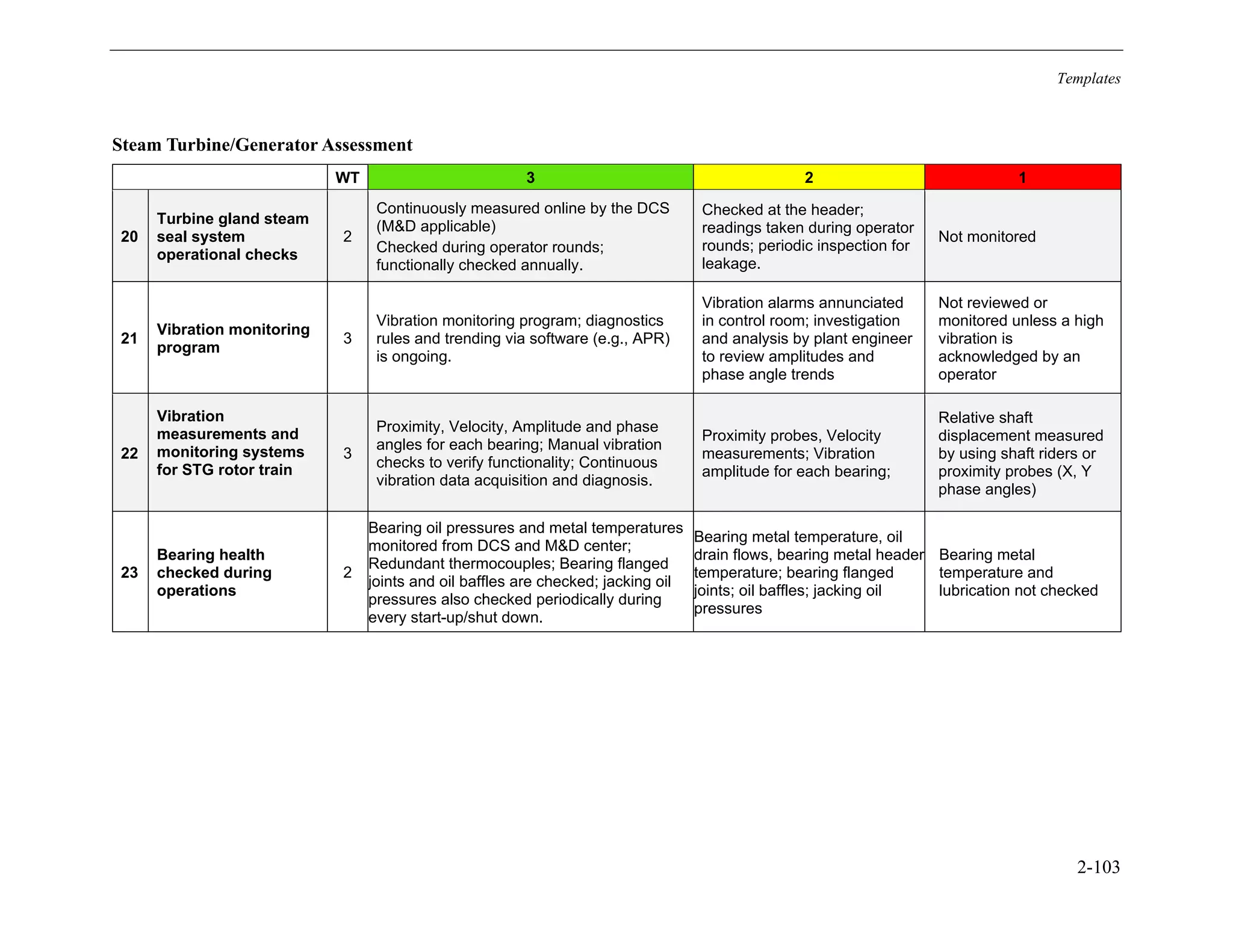

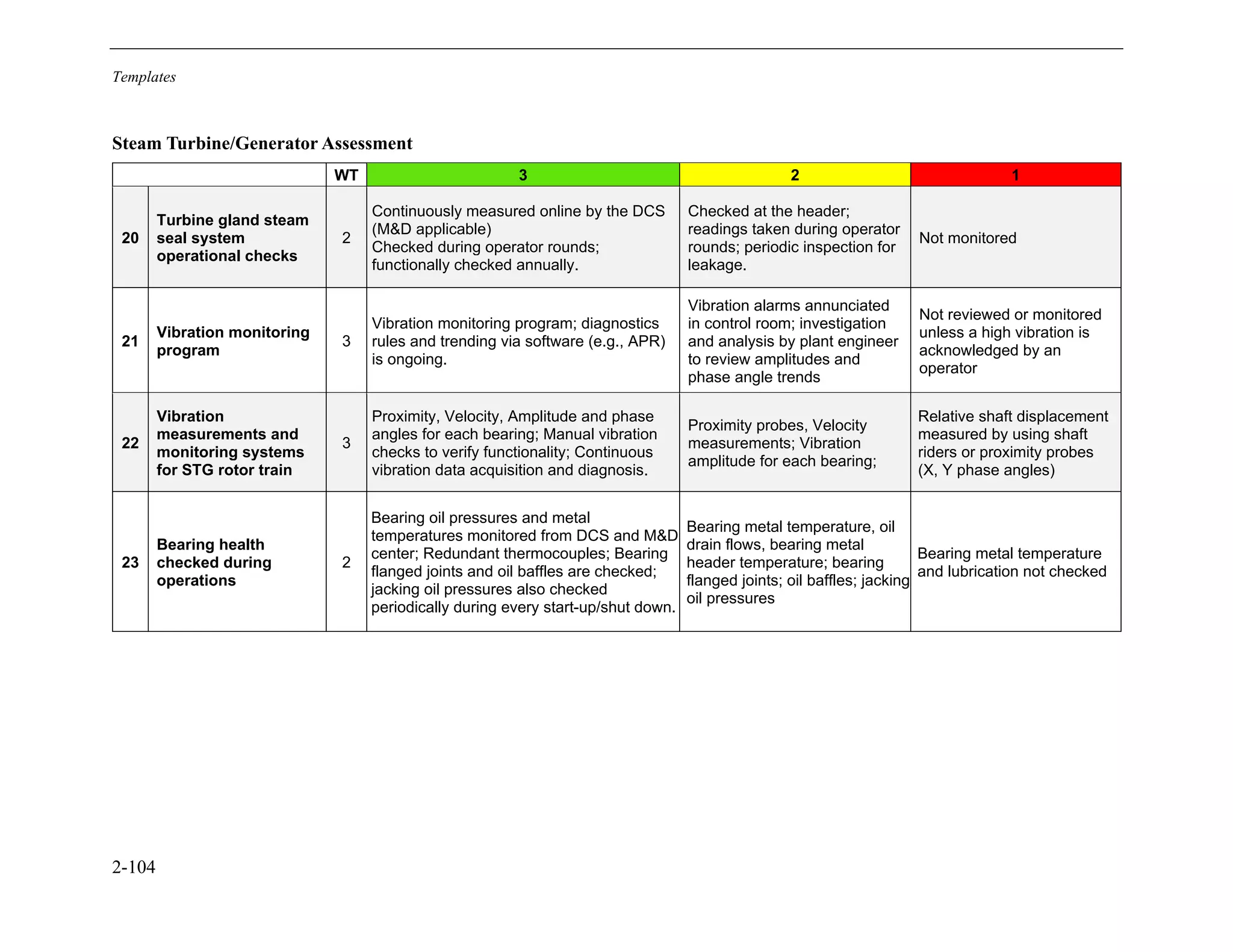

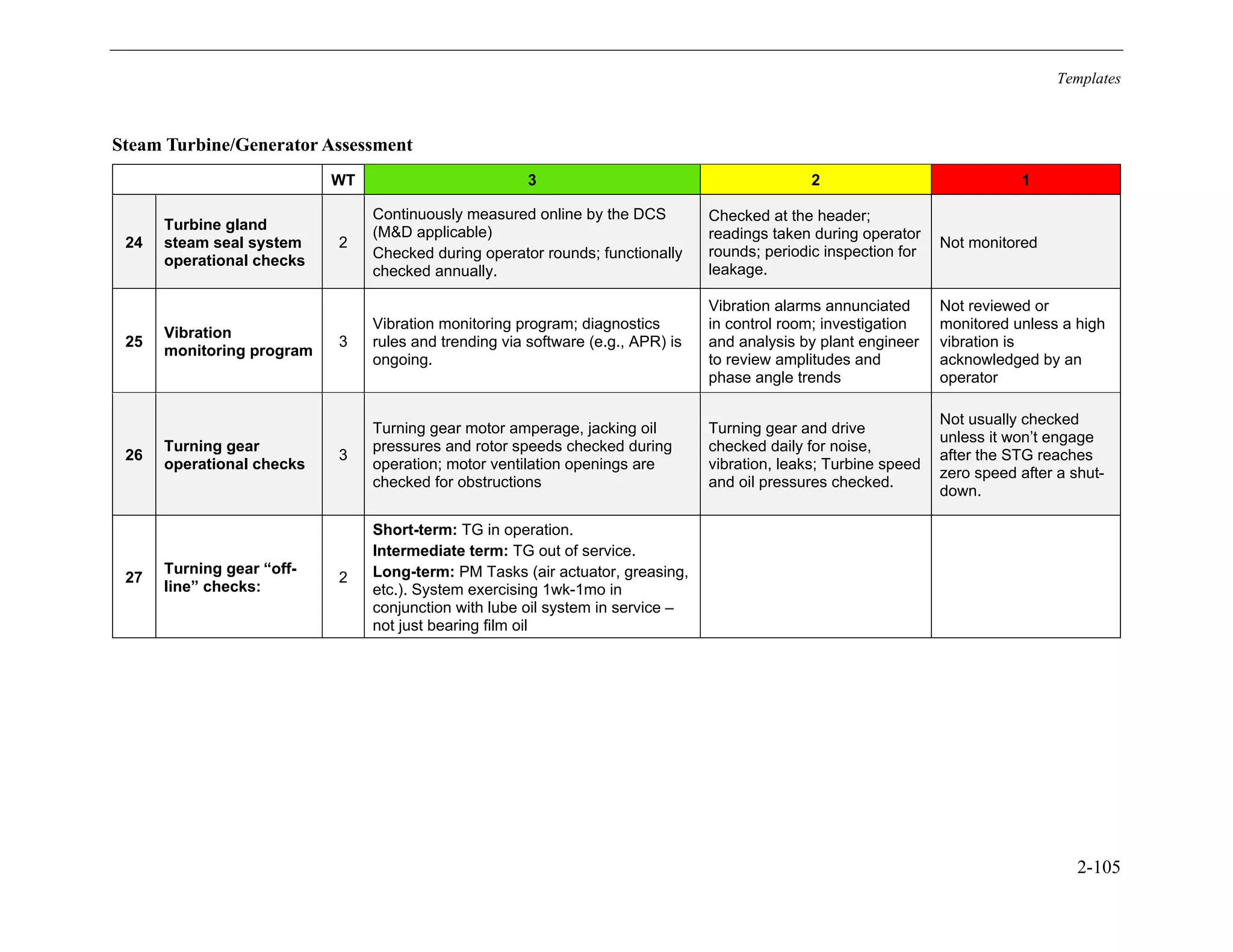

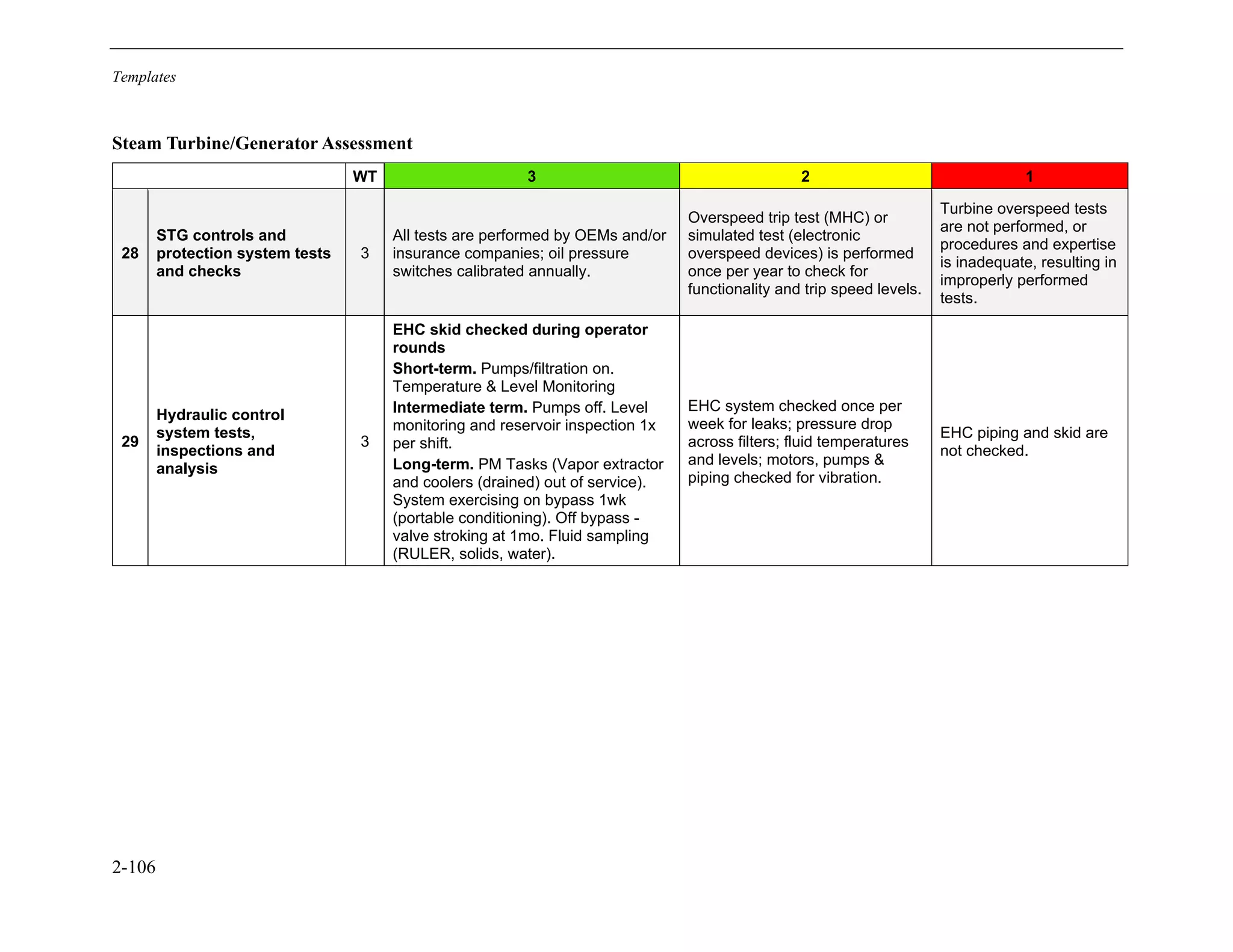

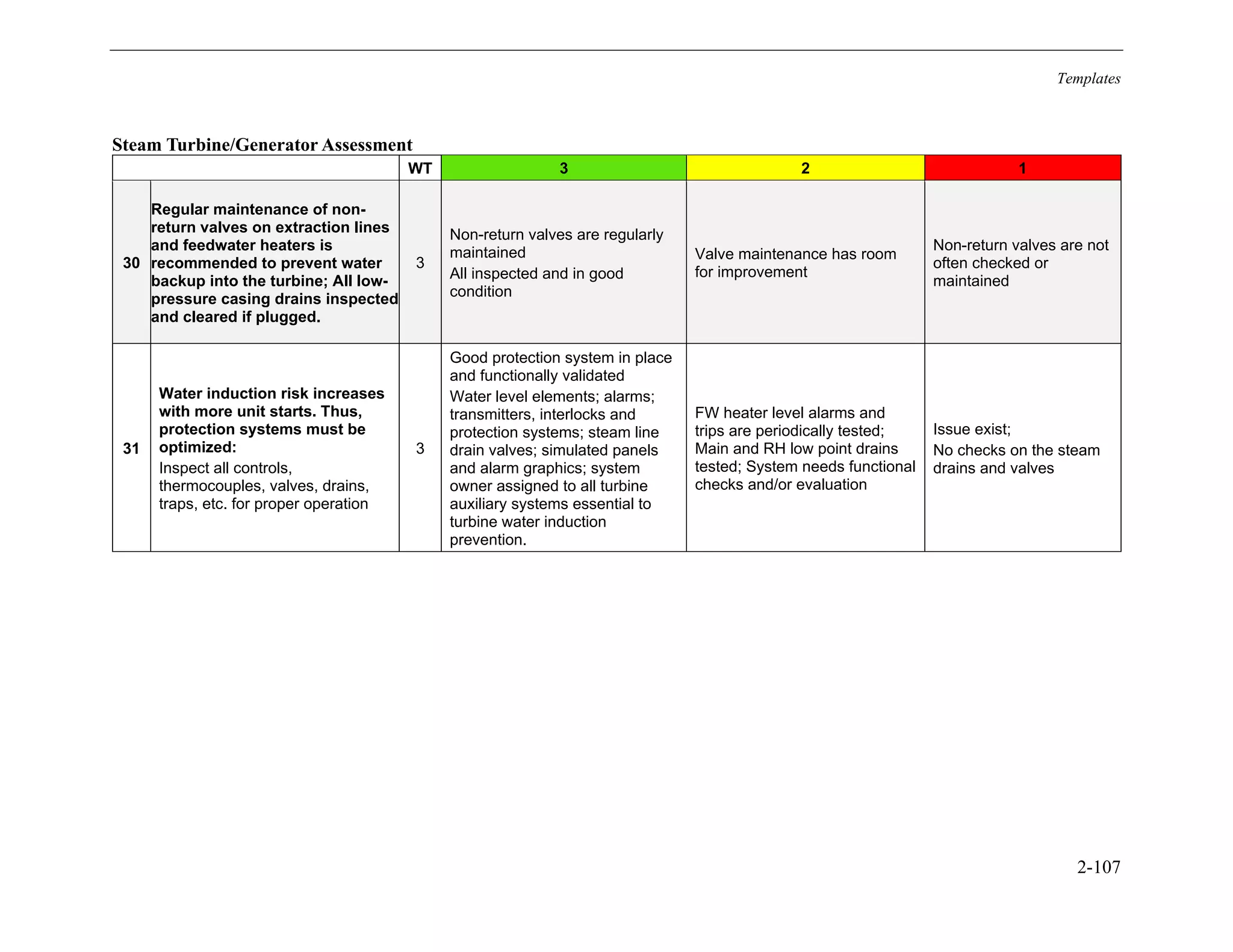

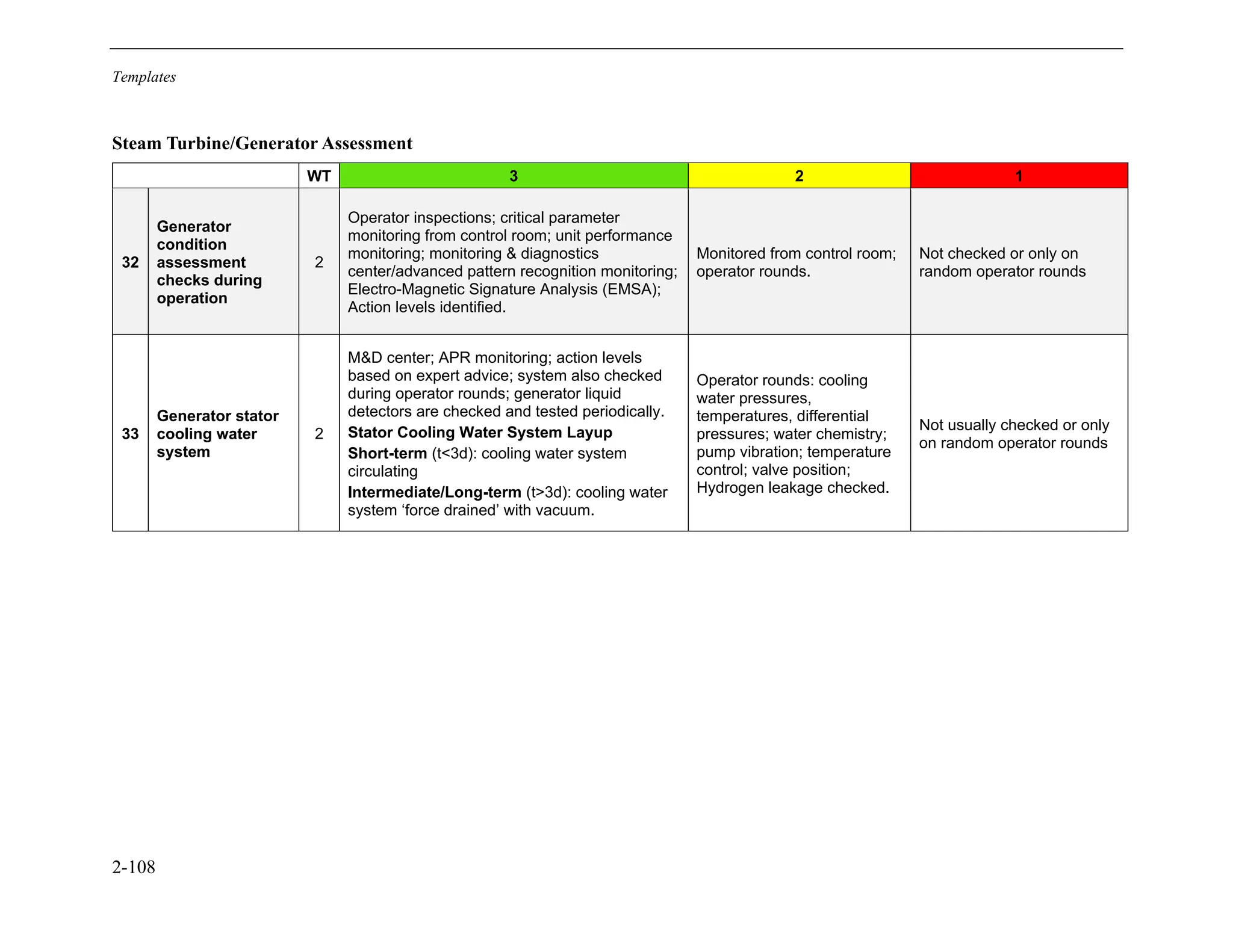

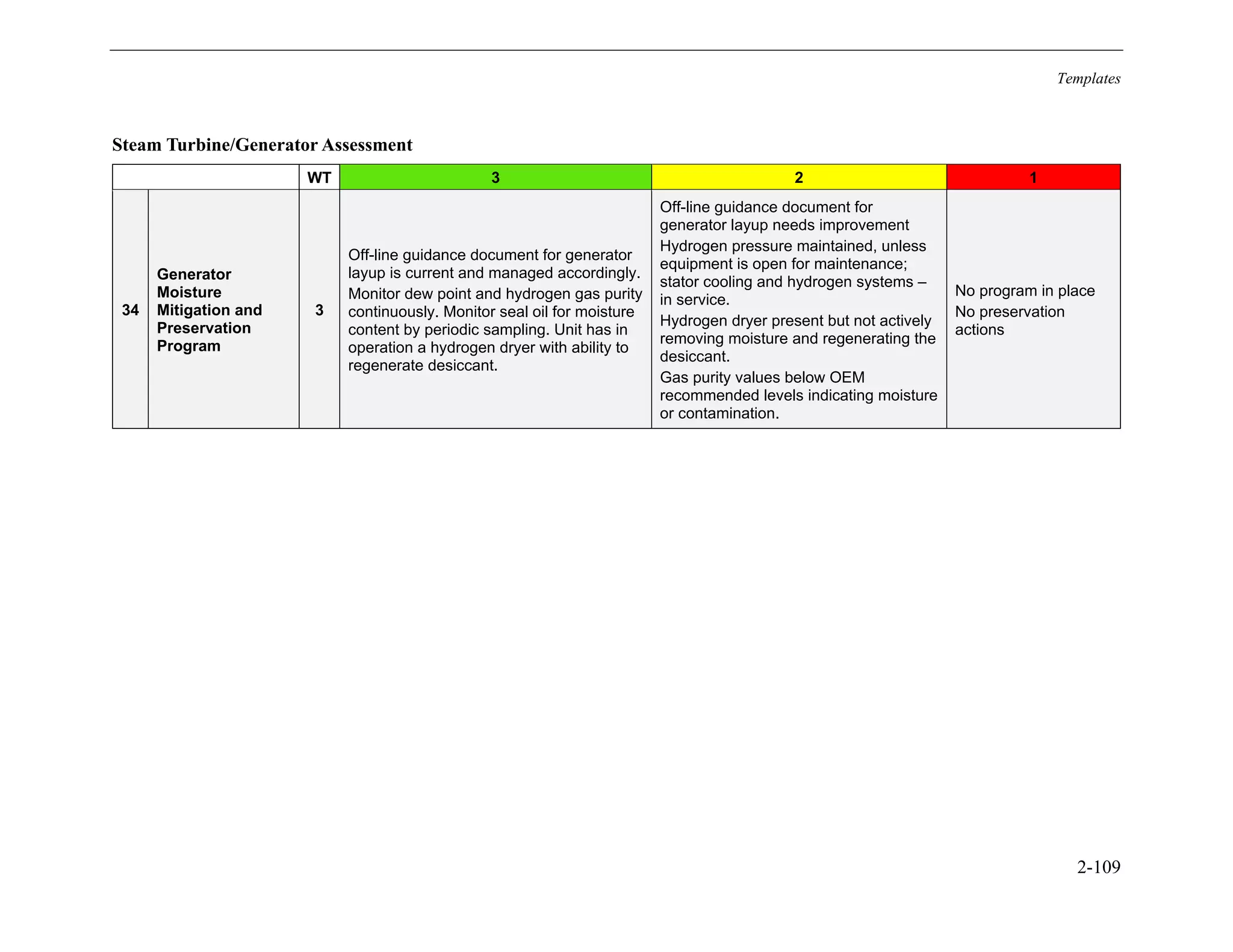

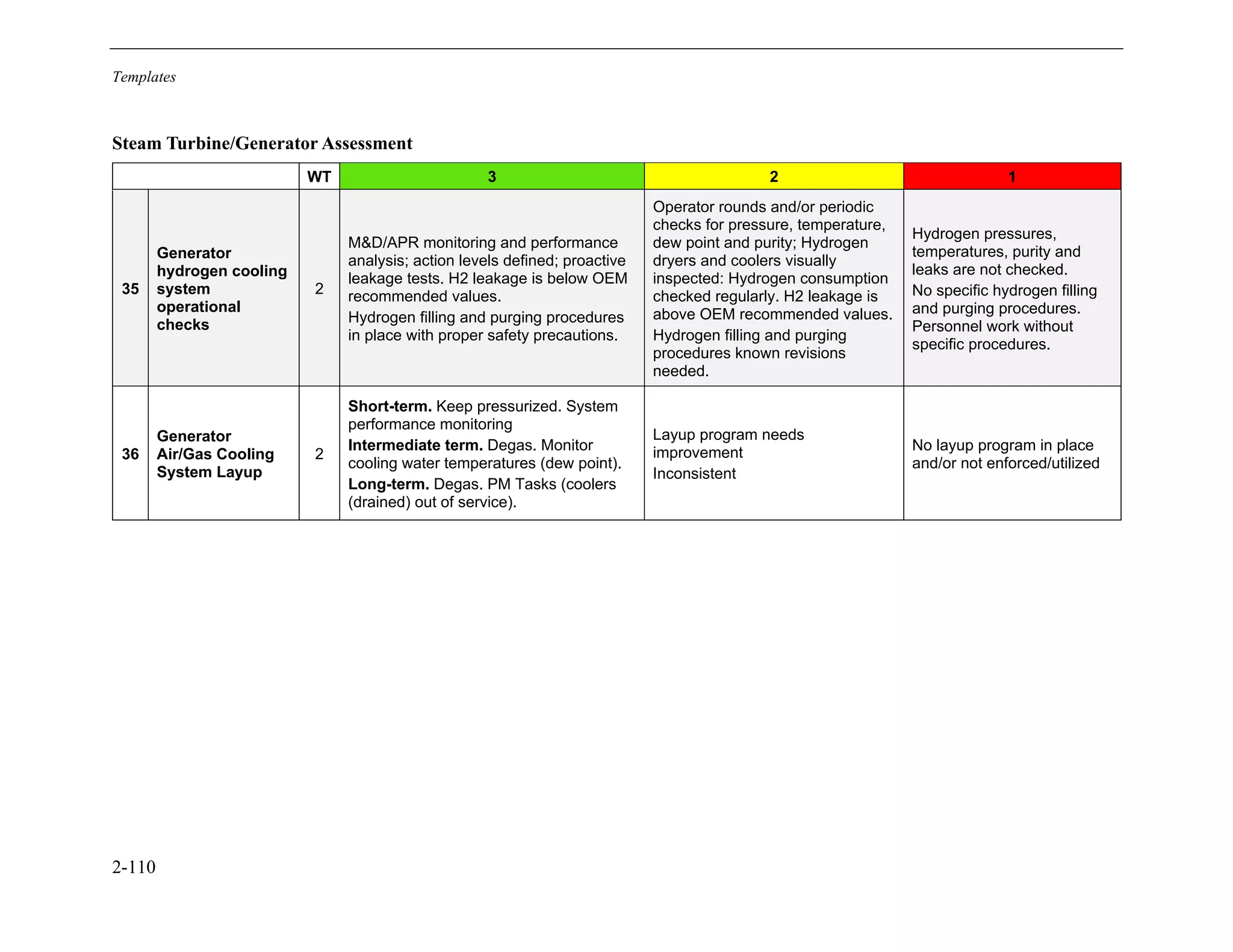

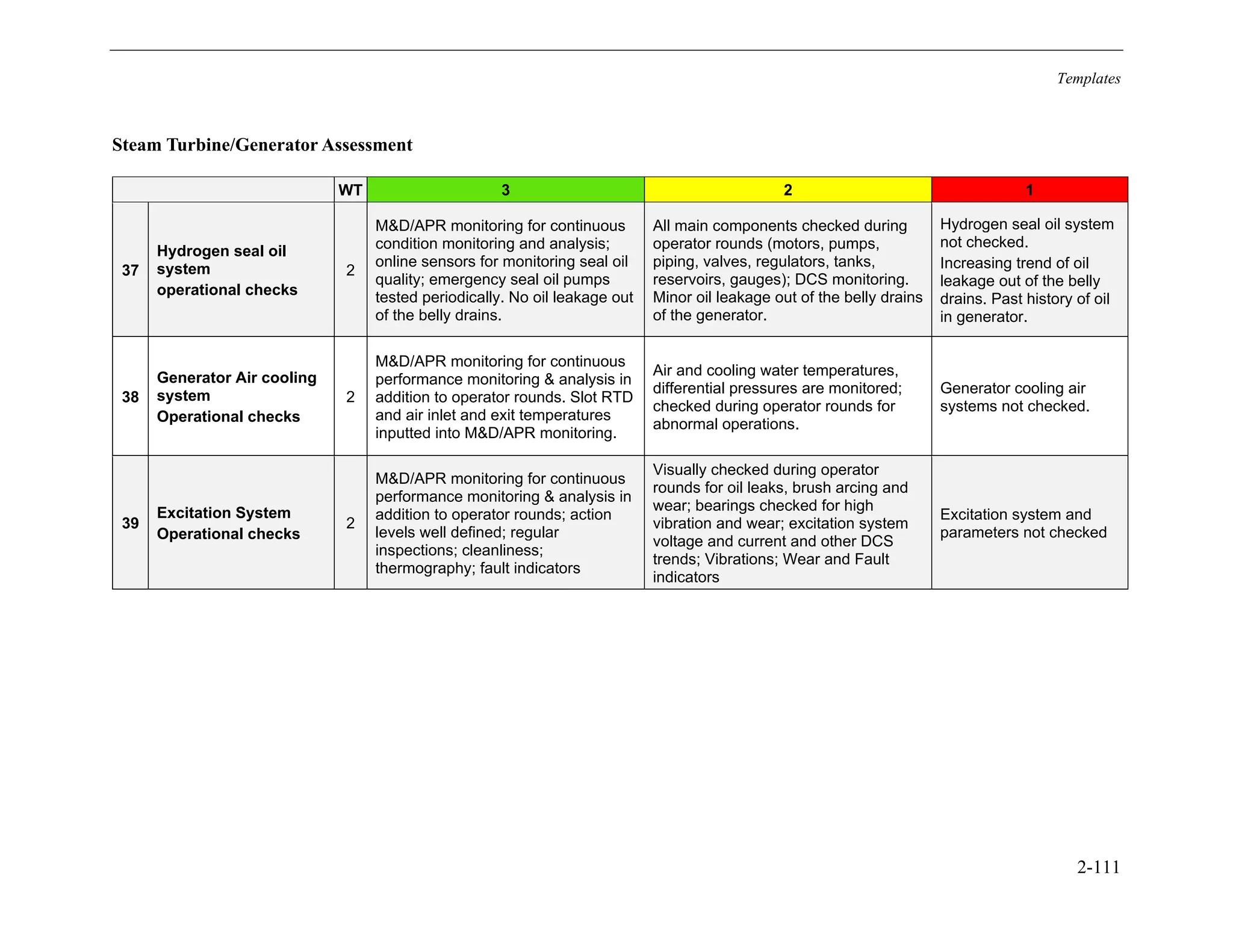

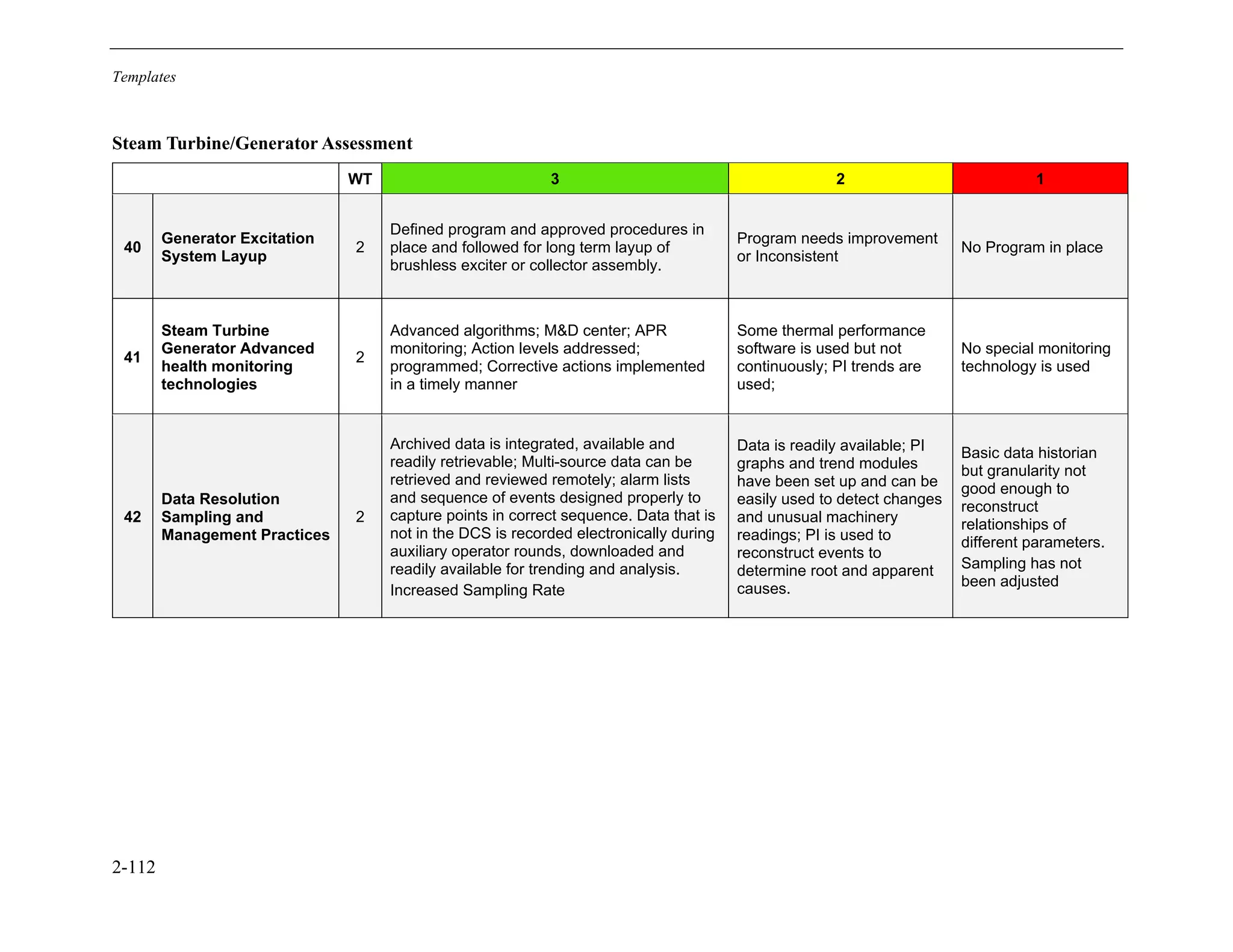

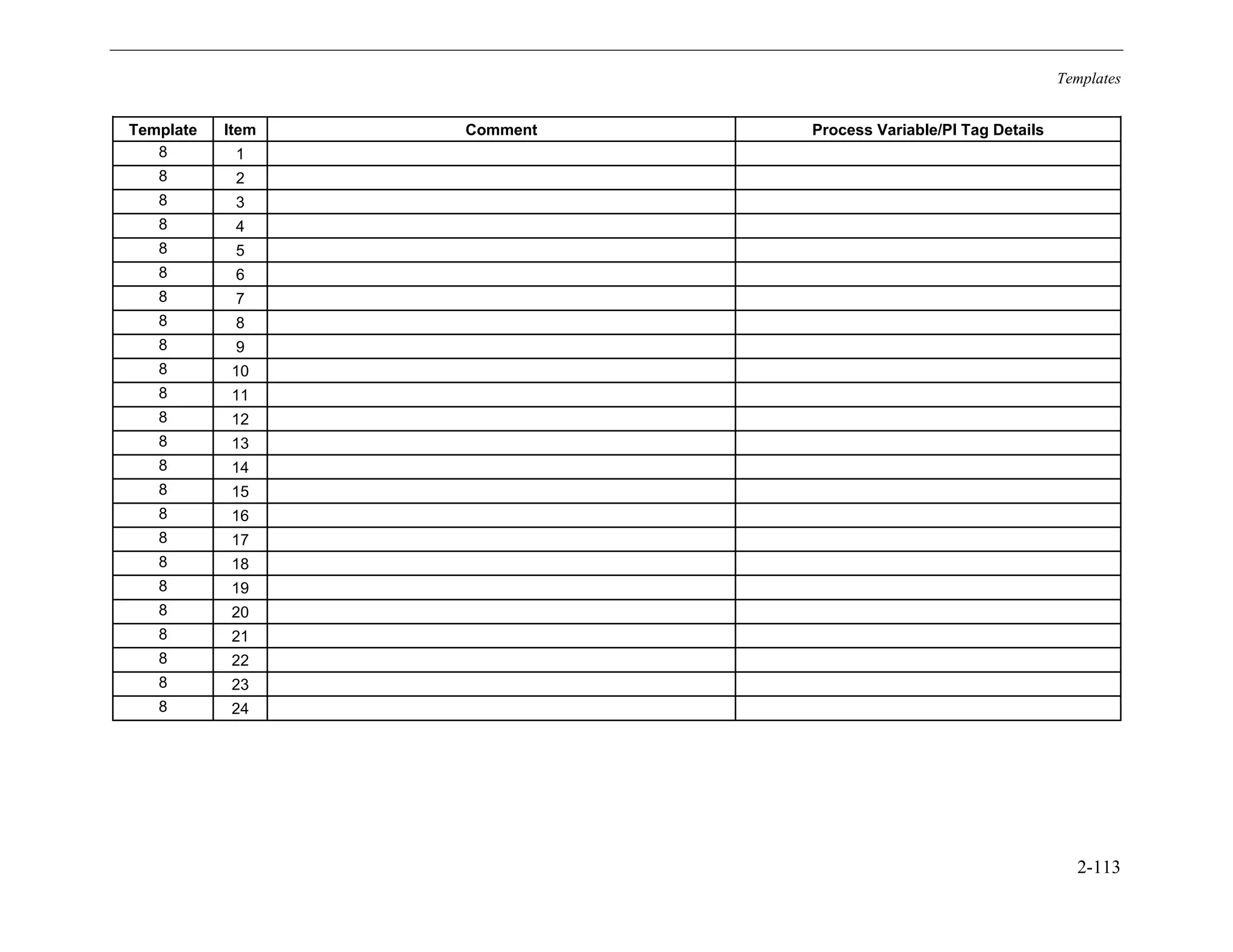

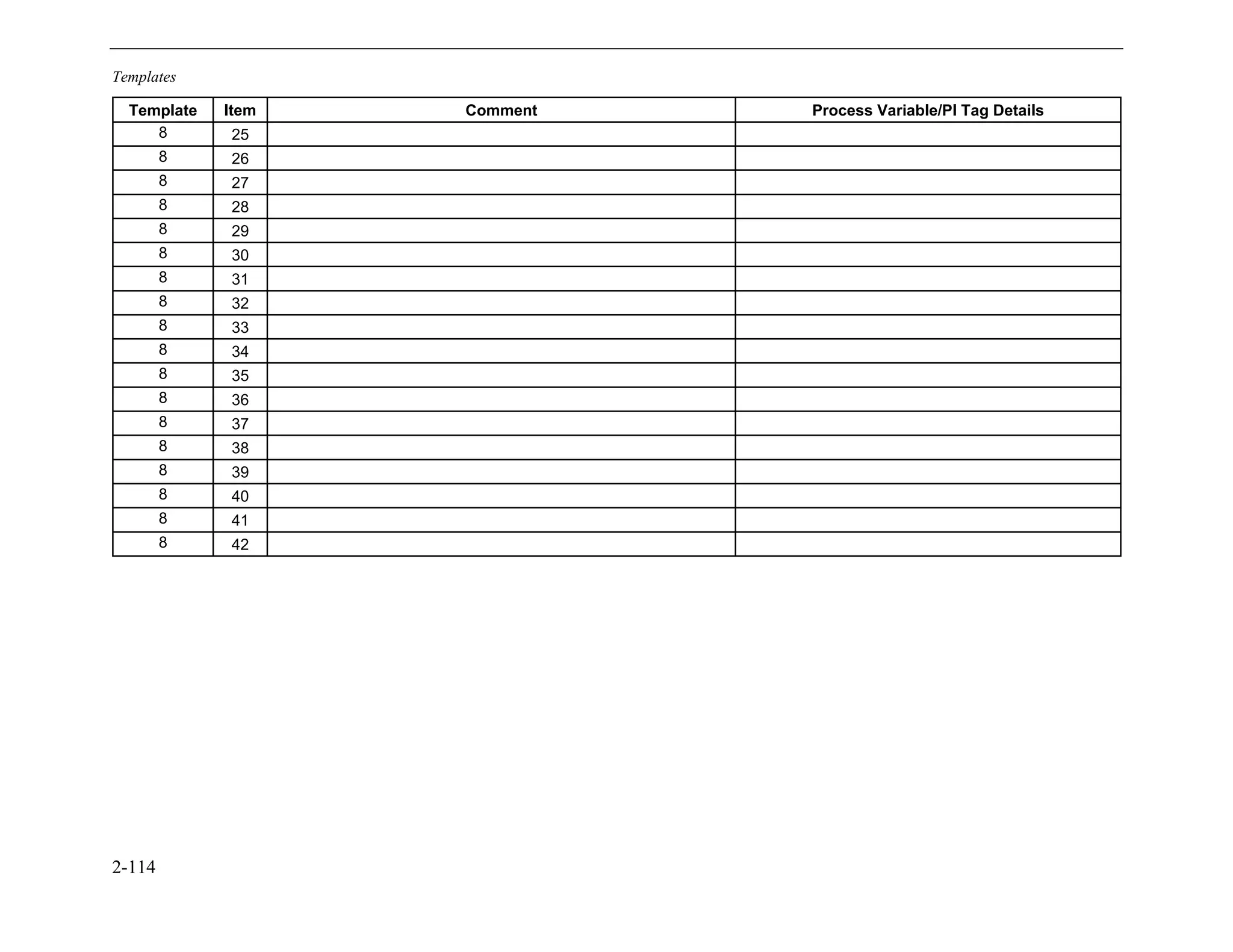

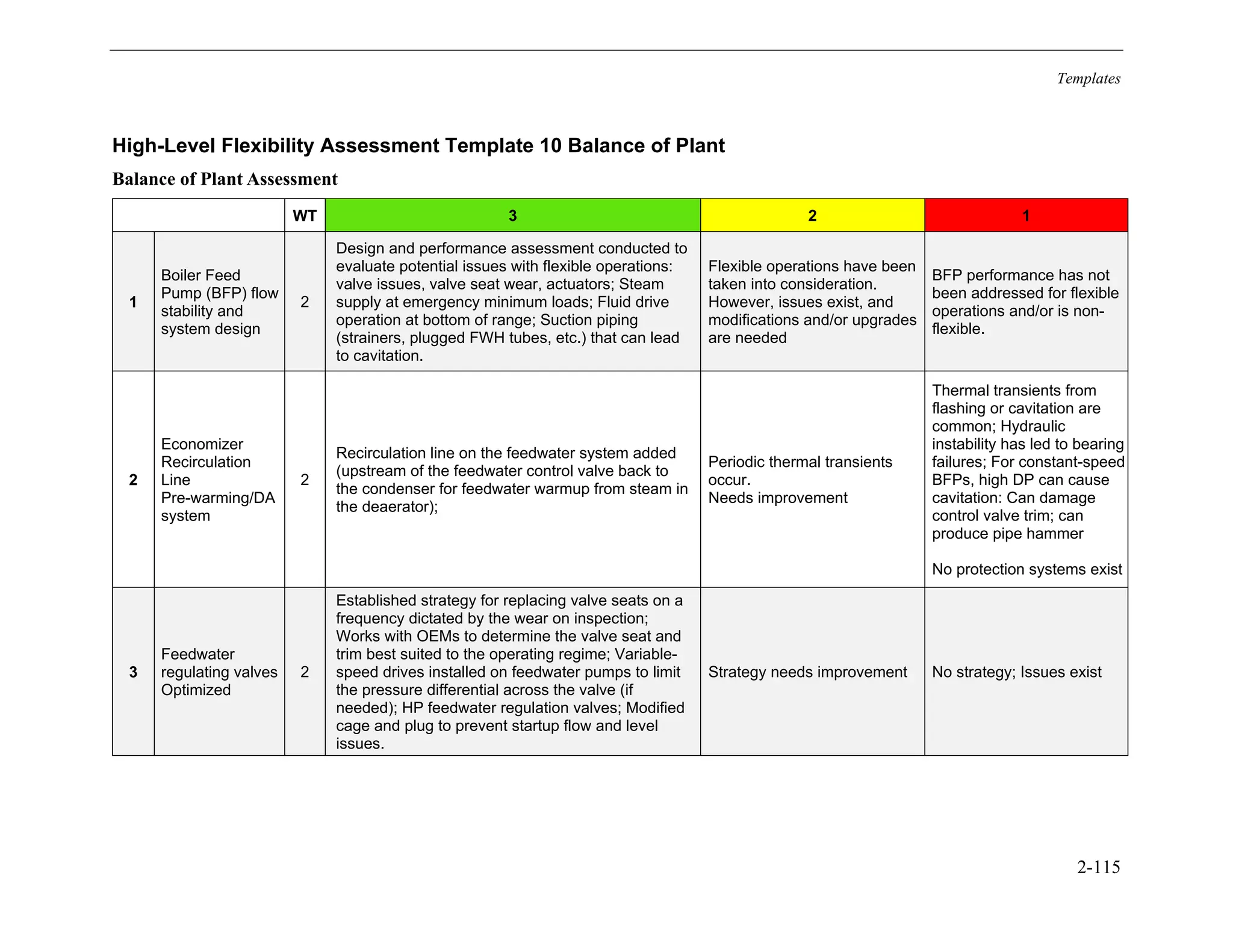

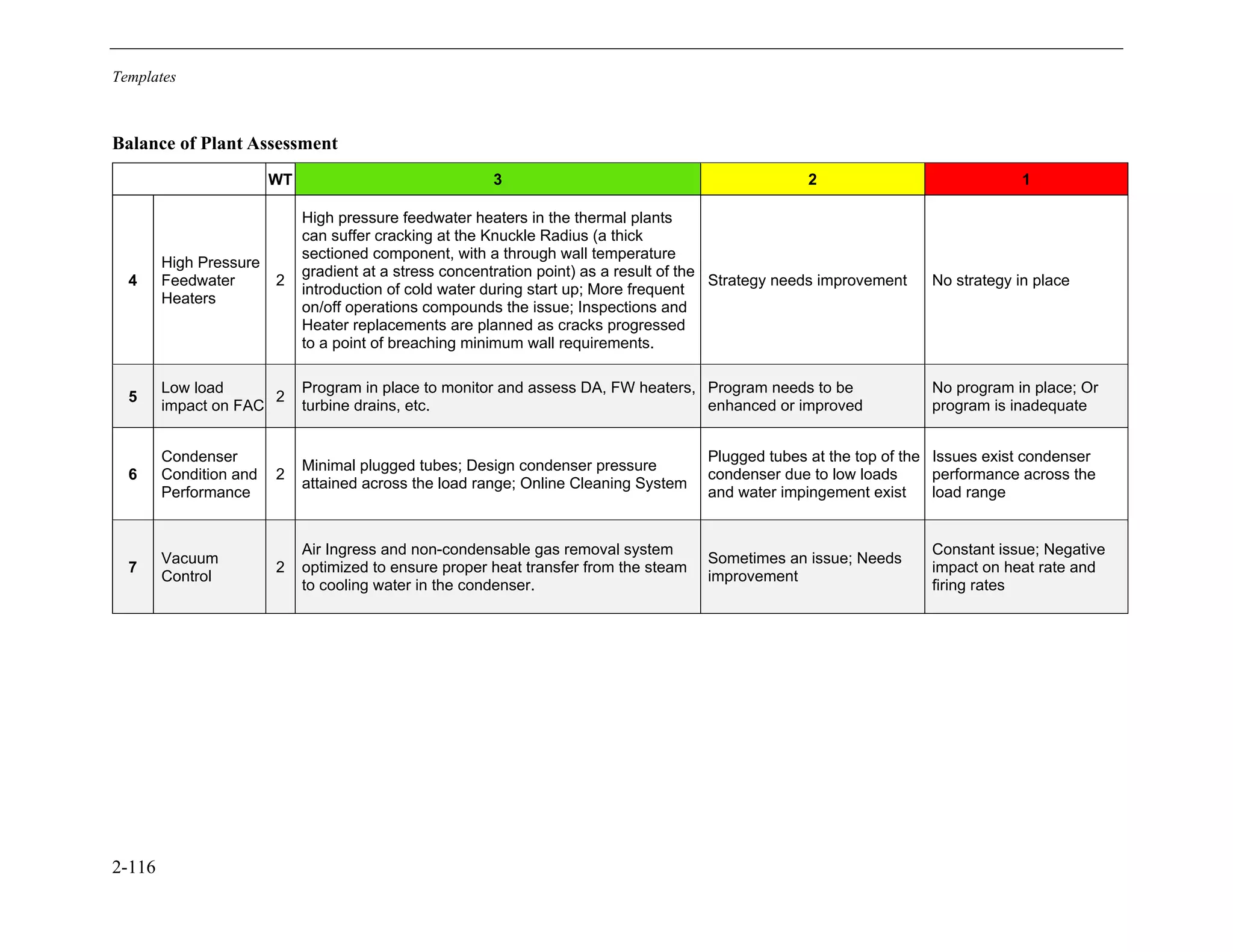

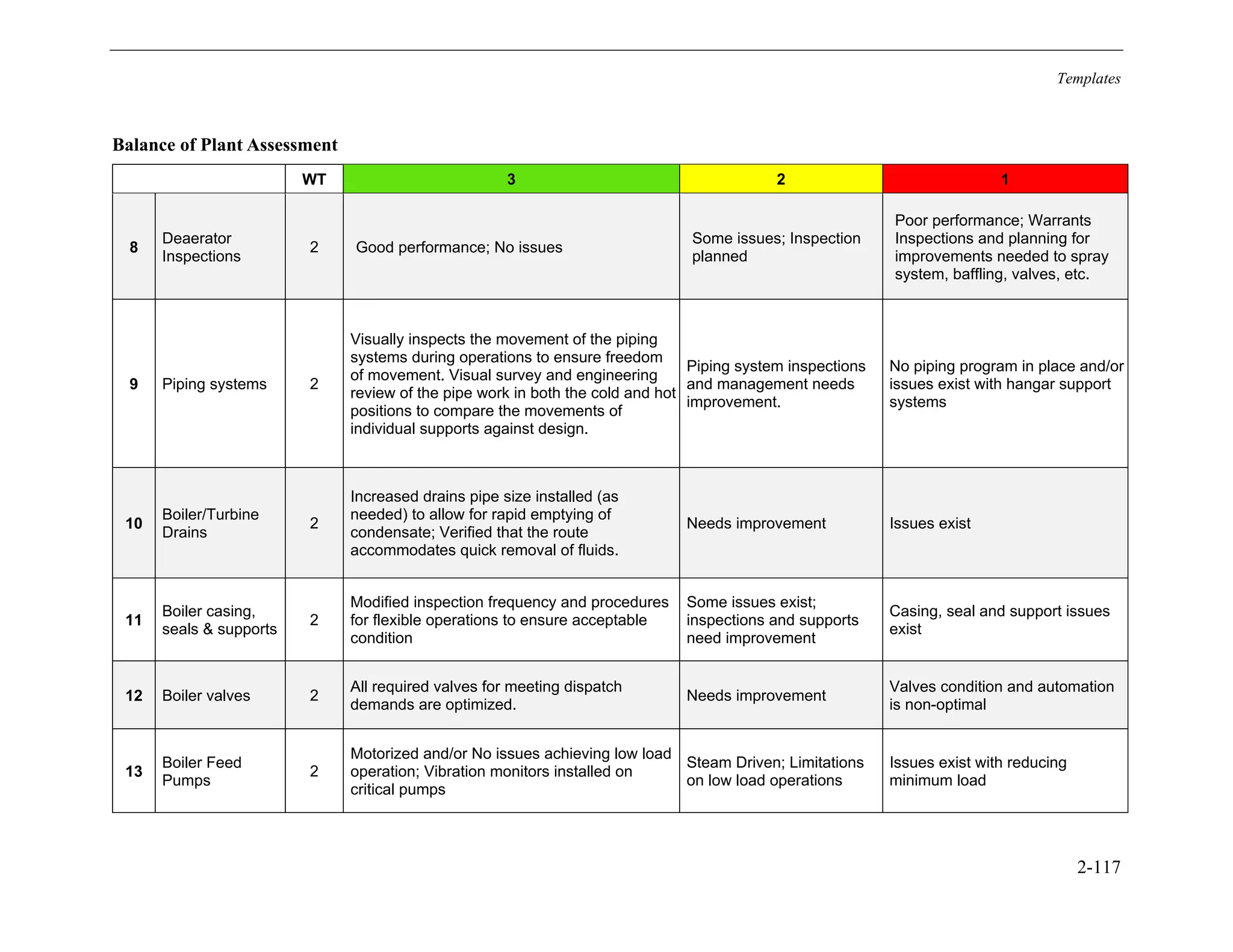

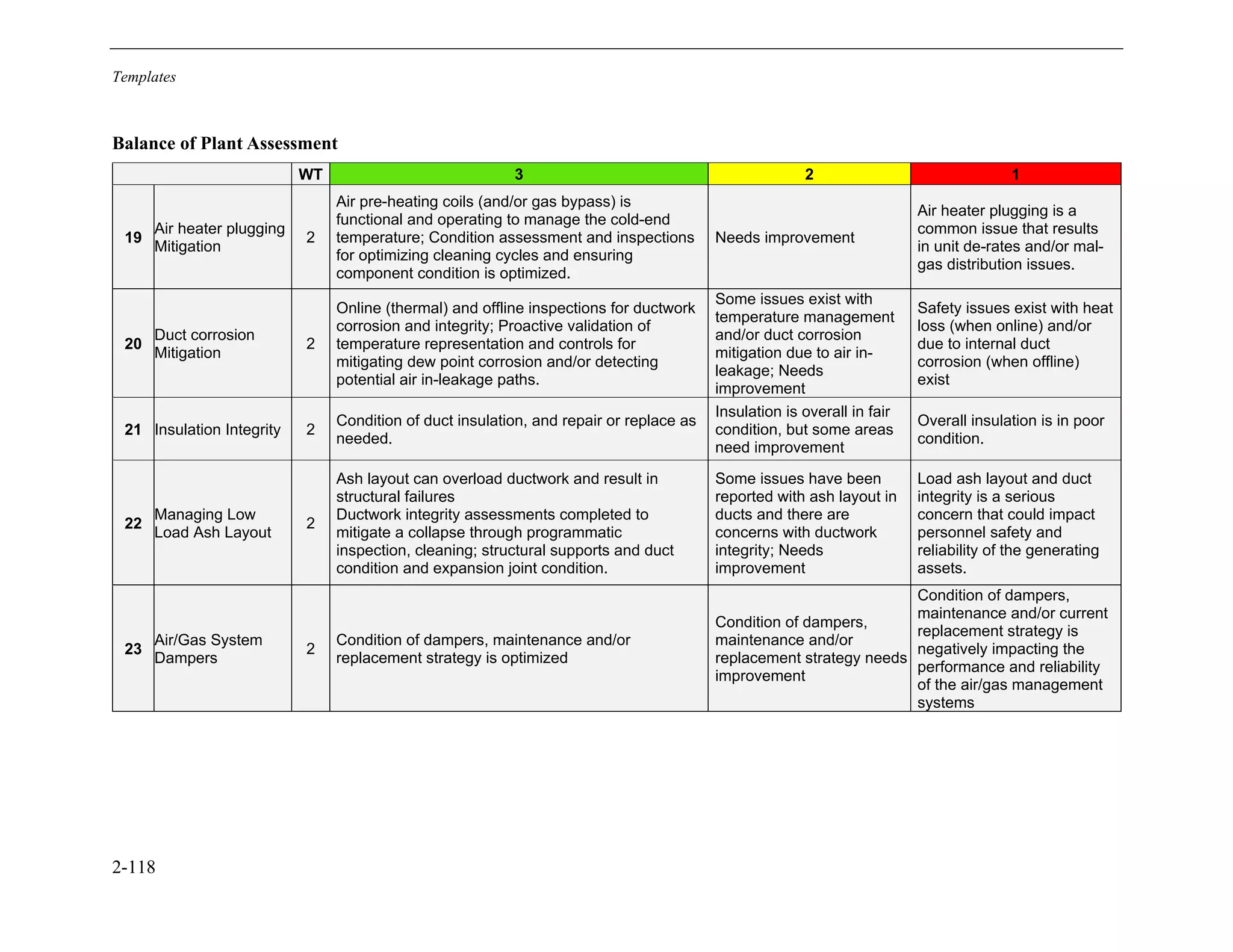

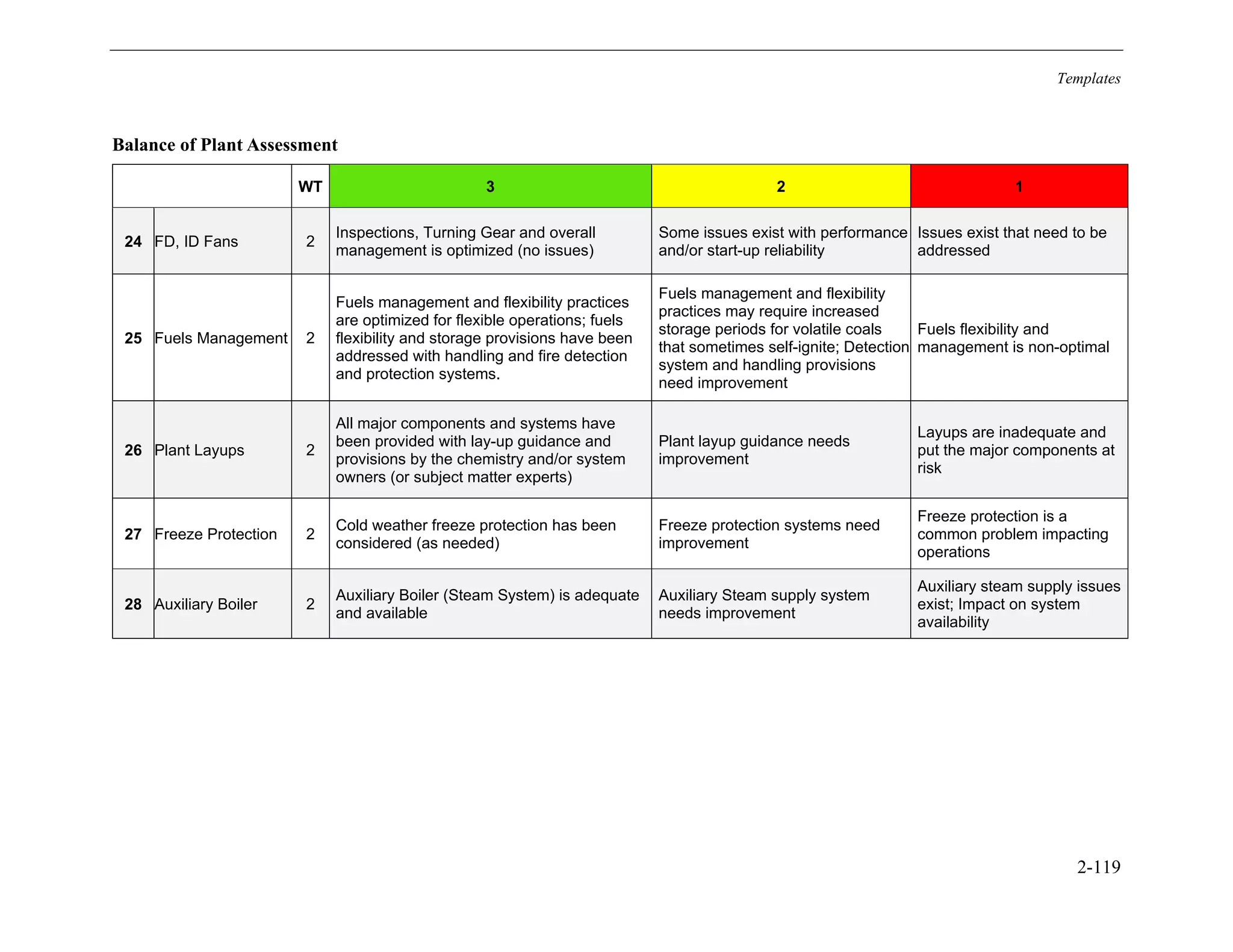

This technical report provides templates to help operators of conventional steam generators assess flexibility performance. The templates cover 10 key areas and are intended to identify gaps and improvement opportunities related to operating flexible units. As renewable energy increases on grids, coal plants are often required to operate more flexibly by load following or operating at lower minimum loads, which can impact reliability if not properly managed. The templates provide guidance to help plants evaluate systems and optimize for flexible operations while minimizing negative impacts on equipment.