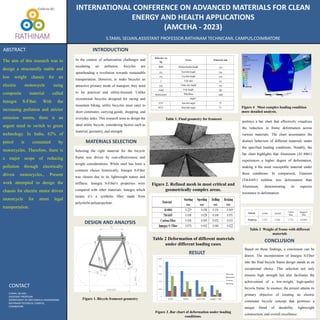

The document discusses the design of an electric motorcycle chassis using composite material called Innegra S-Fiber. It aims to reduce pollution by switching to electric vehicles since motorcycles account for 62% of petrol consumption in India. The design process analyzed different materials like aluminum, titanium, and Innegra S-Fiber for the chassis to find the optimal lightweight yet stiff material. Innegra S-Fiber was selected as it exhibited the least deformation under loading conditions compared to other materials, allowing for a strong but lightweight chassis. This helps achieve the goal of an electric motorcycle suitable for street use with reduced weight and pollution.