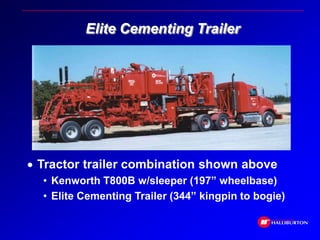

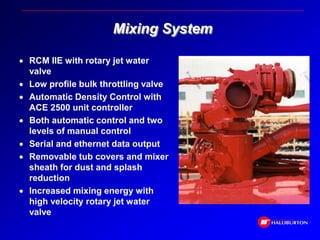

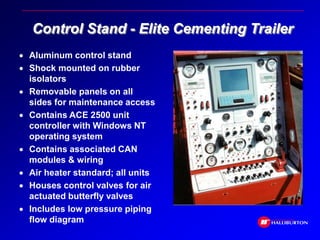

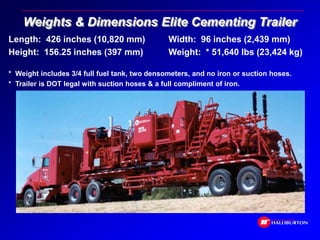

This document provides details on the Elite Cementing Trailer designed and built by Zonal Isolation Technology Exchange starting in November 1998. The trailer utilizes standardized components, improved cement mixing technology, and ergonomic operator features. It can be configured as a single or twin pump trailer. The example trailer shown is a twin pump unit pulled by a Kenworth truck with a 344 inch trailer. It includes two centrifugal pumps powered by Cat diesel engines with a total of 660 horsepower. The trailer also features a computerized cement mixing and monitoring system, aluminum mixing tub, measuring tank, and walkways for operator safety and accessibility.