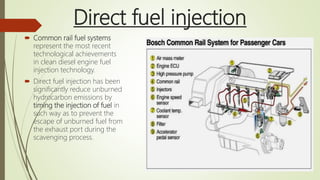

This document discusses electronic fuel injection systems and their advantages over conventional fuel systems. It notes that conventional systems have issues with fuel pressurization and atomization at low engine speeds as well as fixed timing and fuel rates. Electronic fuel injection systems address these issues by allowing variable timing and duration of fuel injection. Direct fuel injection systems in particular have been shown to significantly reduce unburned hydrocarbon emissions by carefully timing fuel injection to prevent unburned fuel from escaping during exhaust. The timing and duration of fuel injection is electronically controlled for optimal emissions, fuel efficiency, and noise reduction.