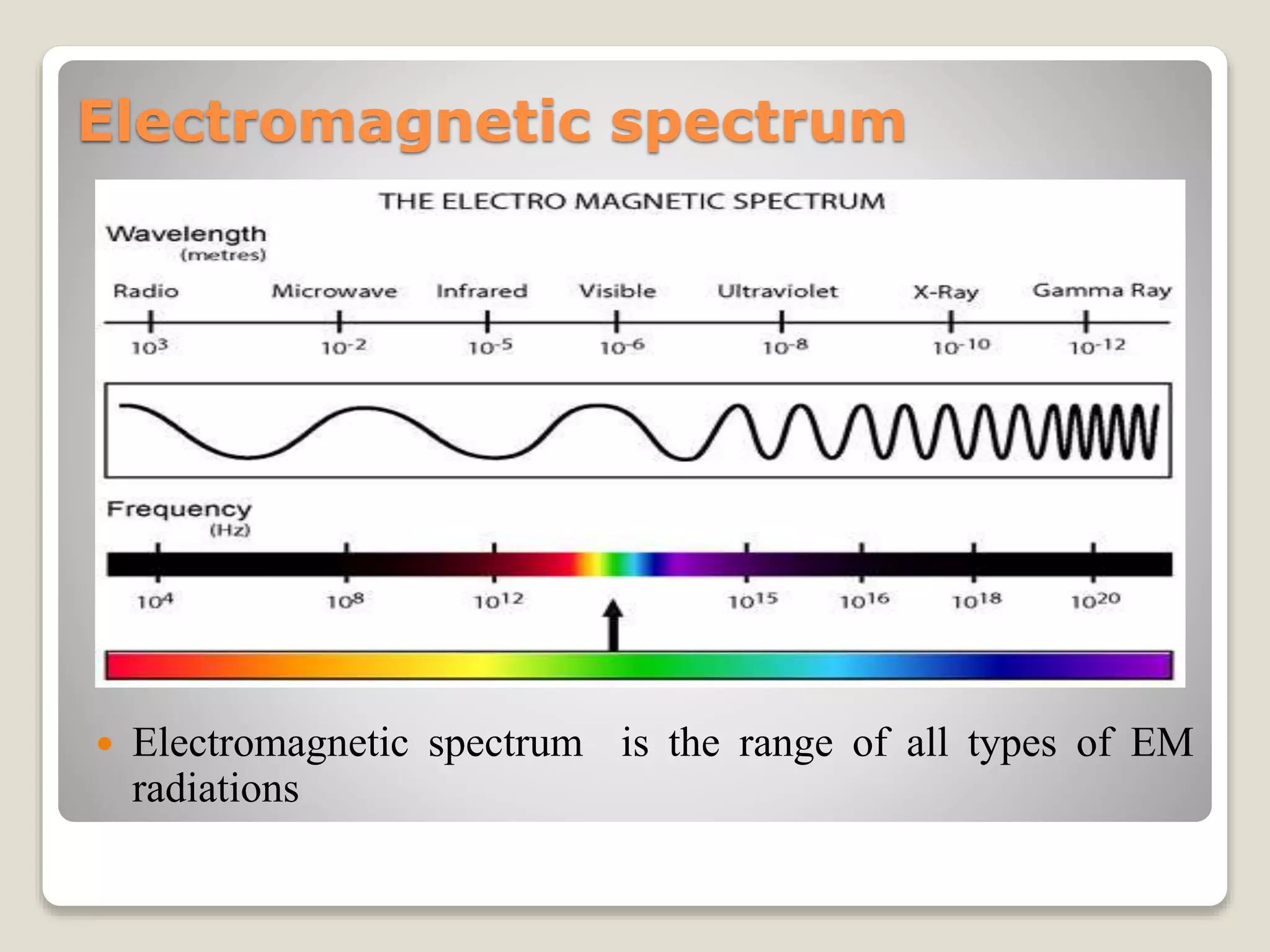

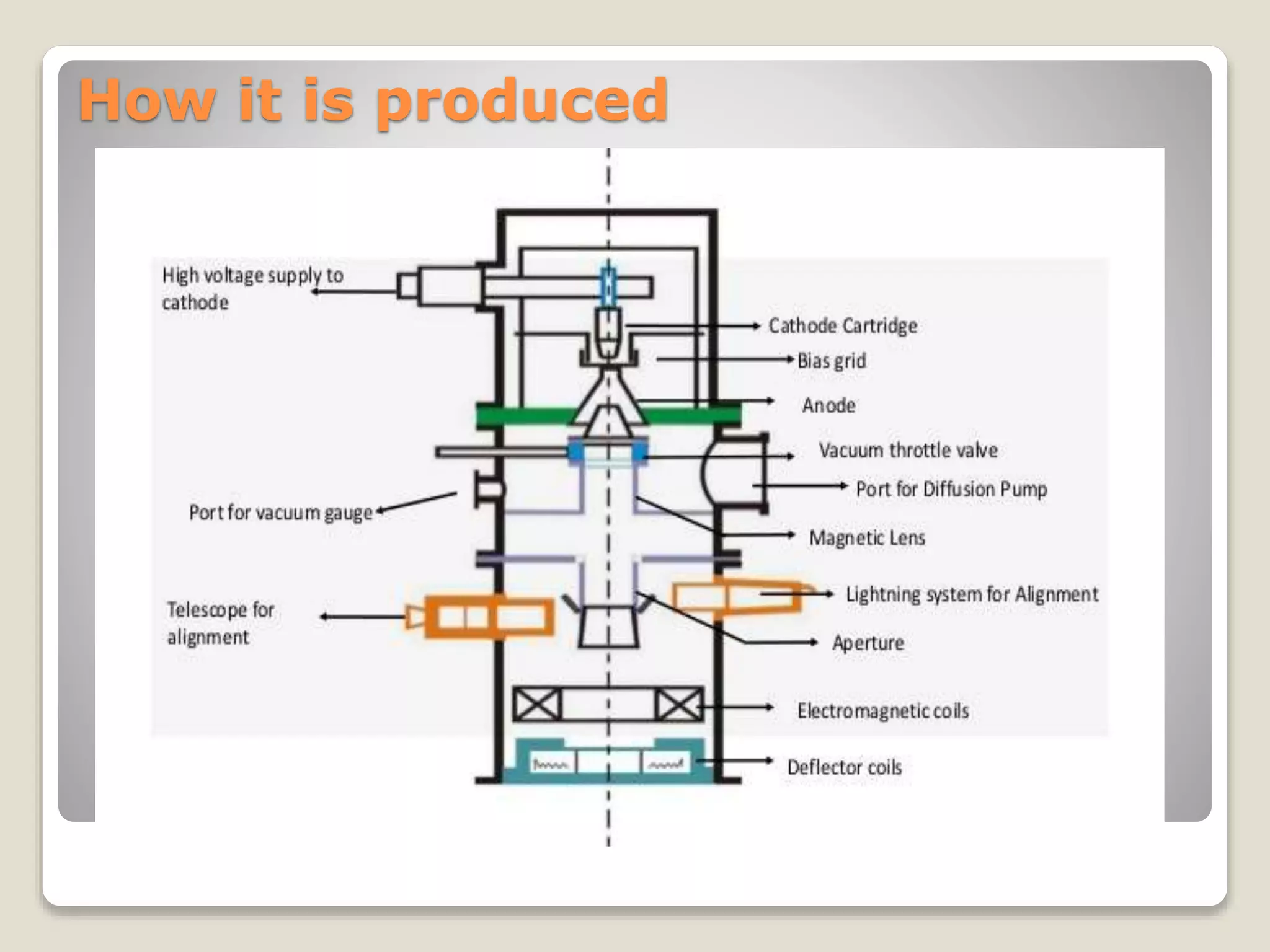

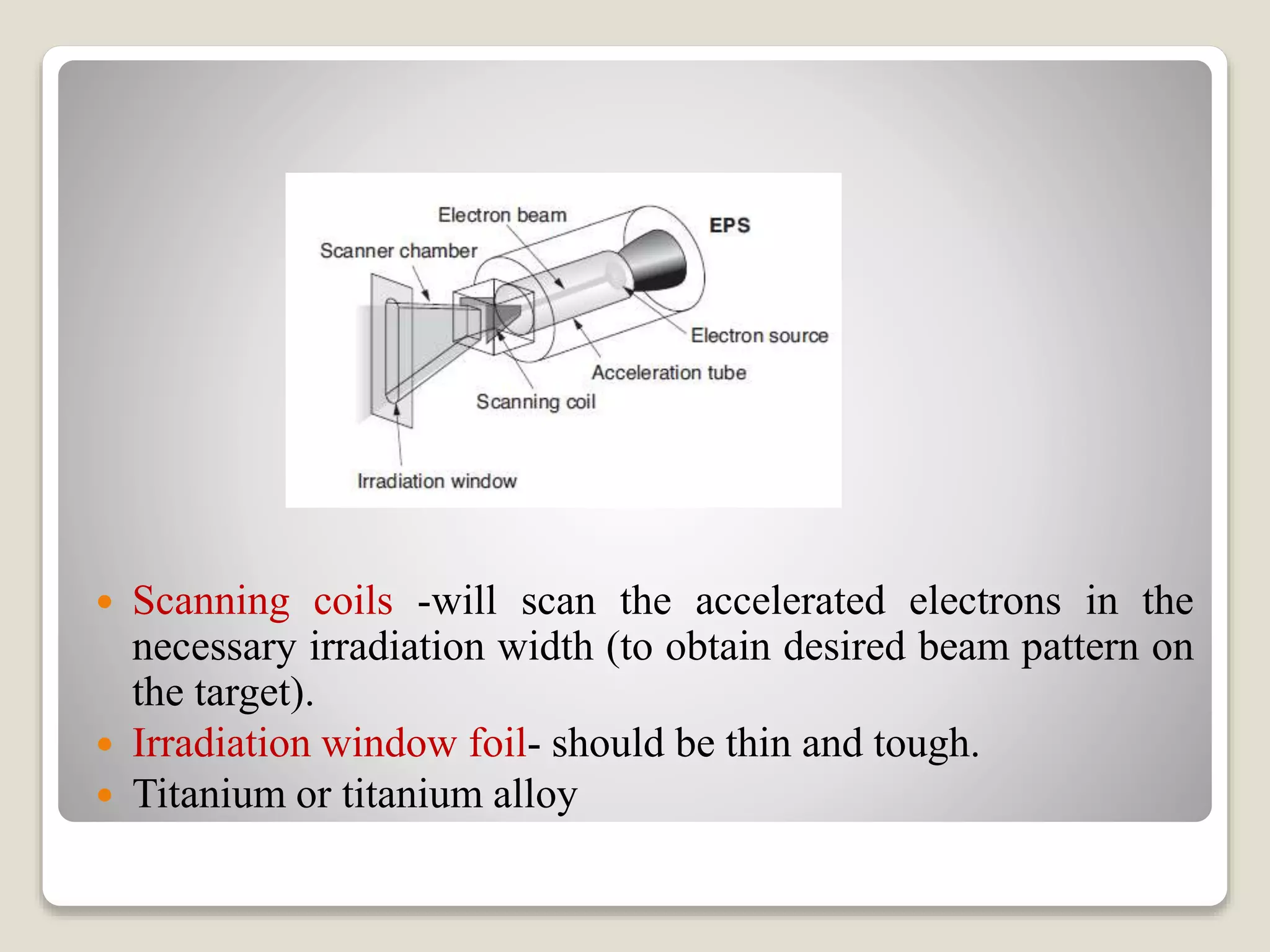

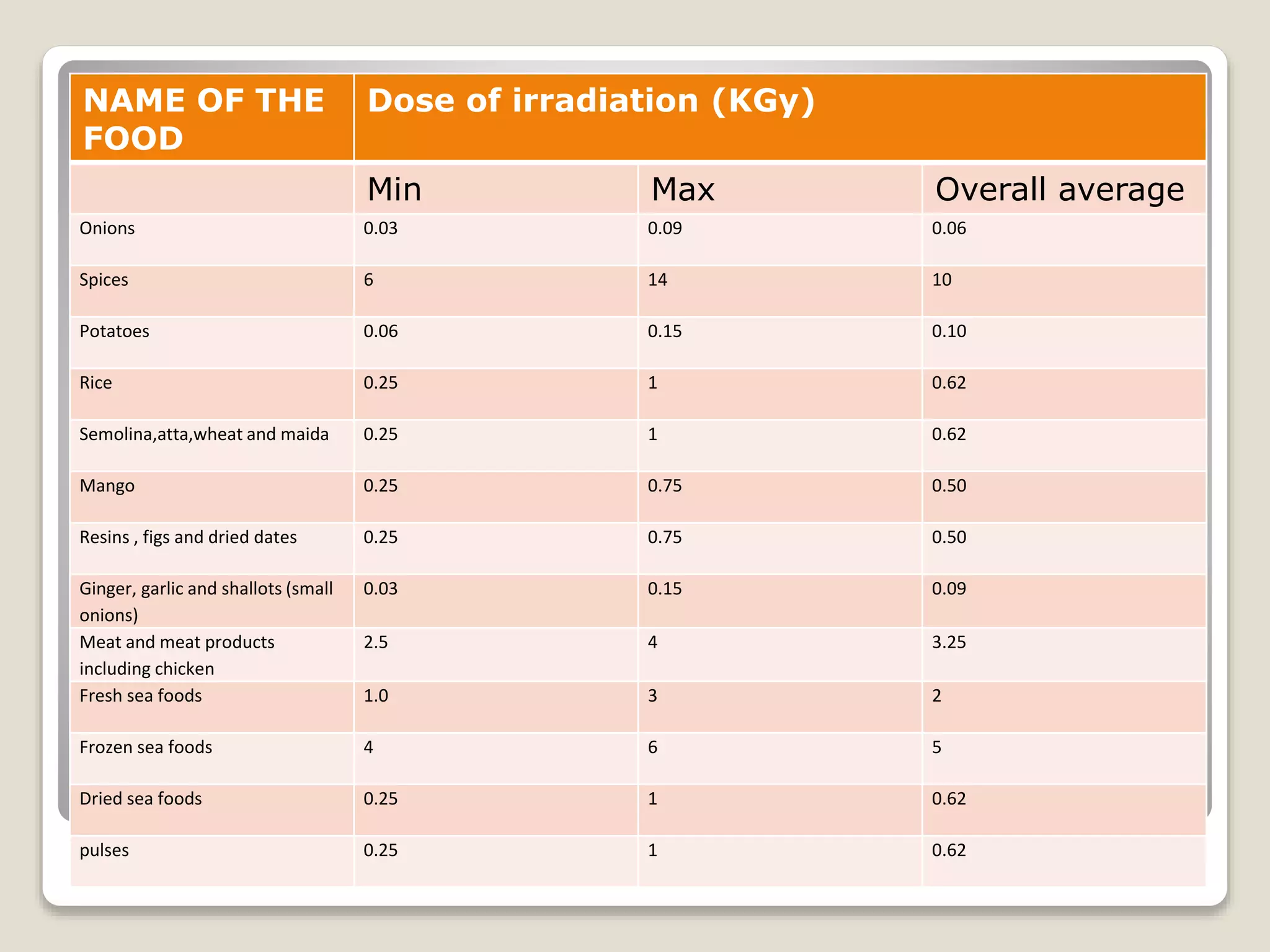

The document discusses electron beam (e-beam) technology, including its characteristics, applications in food irradiation, and the physics of ionizing radiation. It covers the history of irradiation, components of e-beam equipment, and its advantages over traditional gamma irradiation, such as the ability to process heat-sensitive materials at room temperature. Additionally, it highlights regulatory aspects, consumer acceptance, and potential applications in space food and waste management.