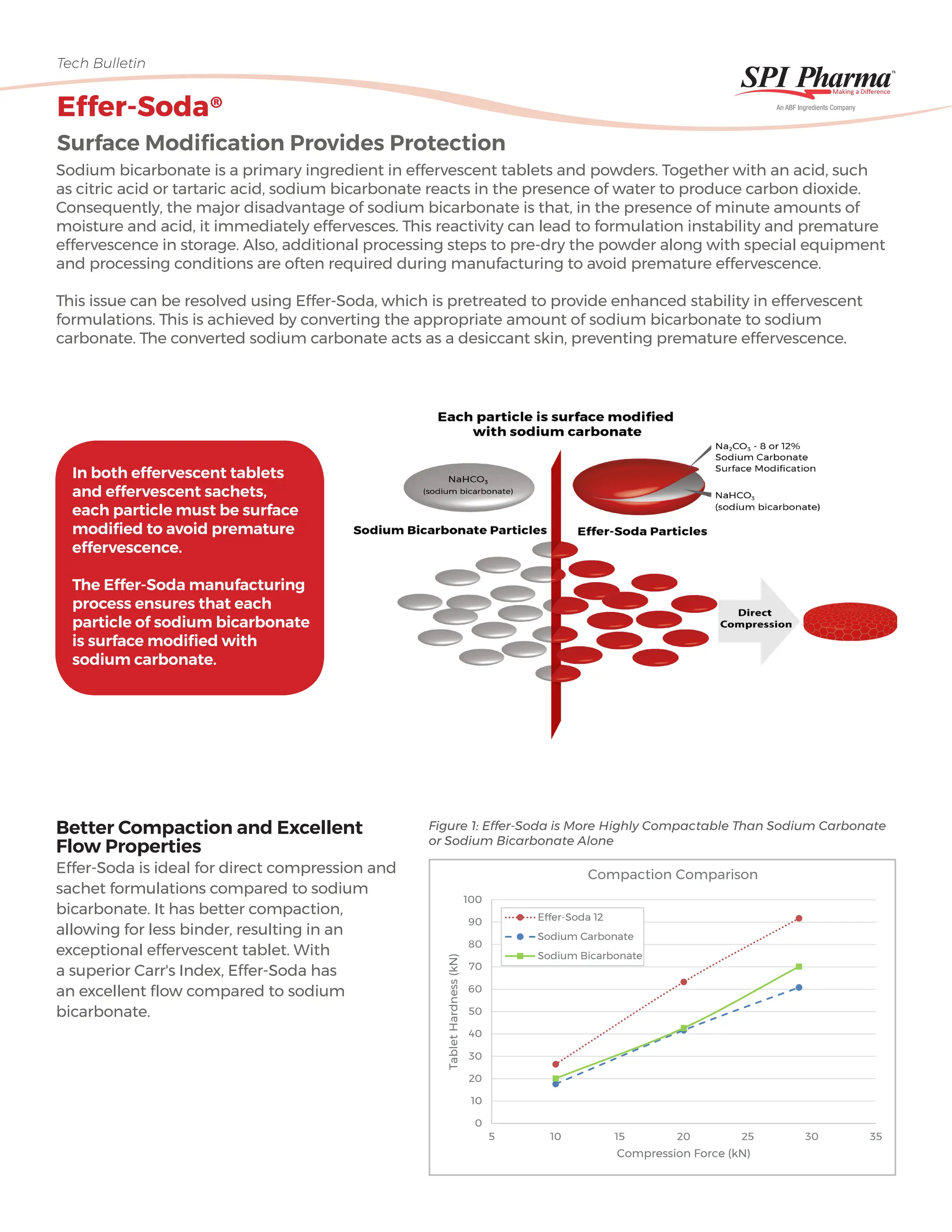

Effer-soda® surface modification enhances the stability of effervescent formulations by converting sodium bicarbonate to sodium carbonate, preventing premature effervescence. It offers improved compaction, excellent flow properties, and lower product failures compared to traditional sodium bicarbonate, making it suitable for direct compression and sachet formulations. Additionally, its manufacturing adheres to CGMP guidelines, supporting advanced pharmaceutical applications while reducing costs related to humidity control and protective packaging.