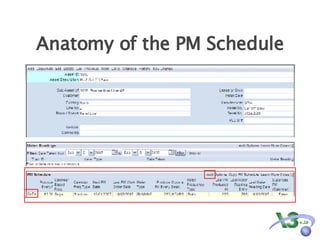

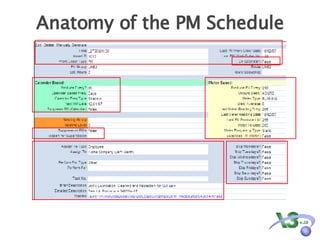

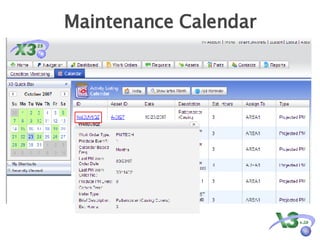

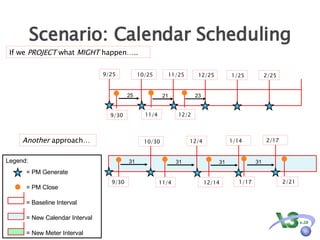

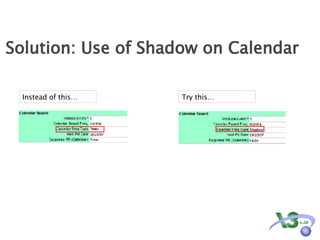

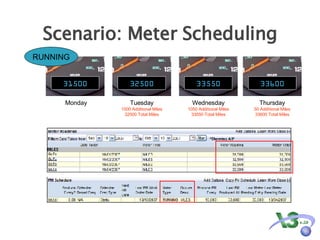

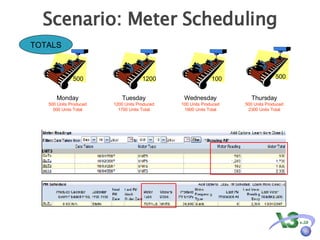

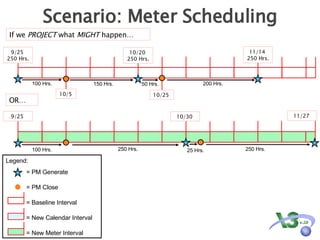

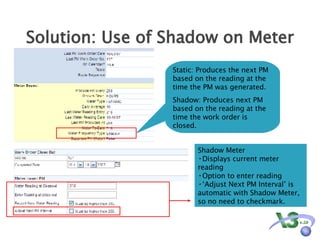

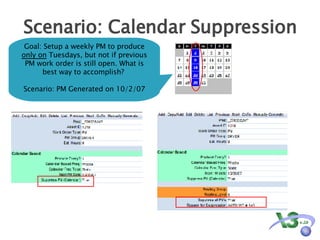

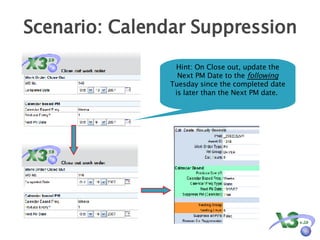

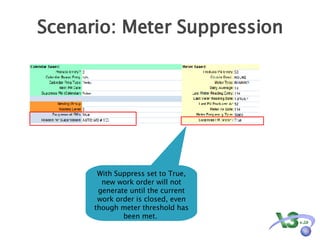

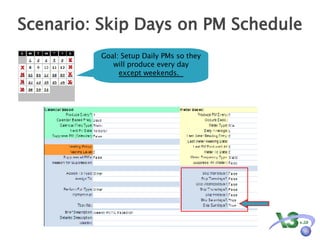

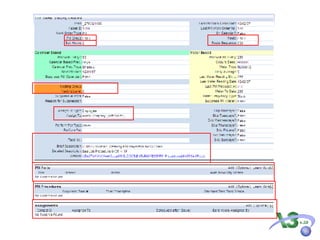

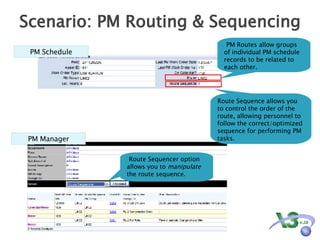

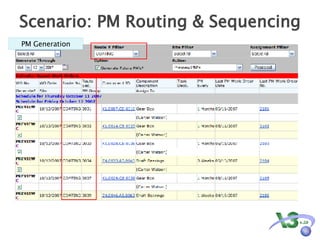

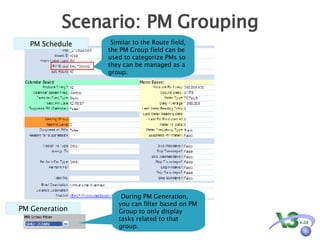

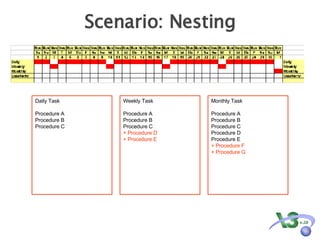

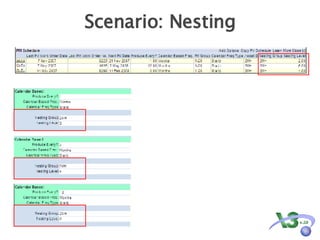

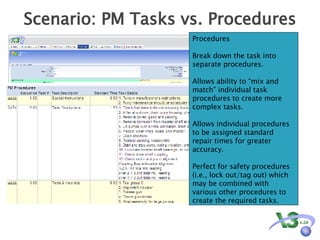

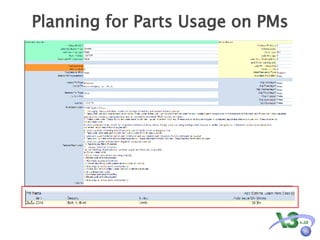

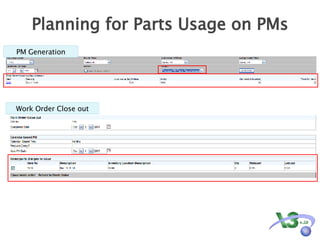

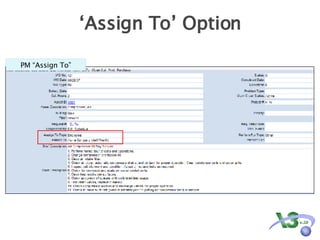

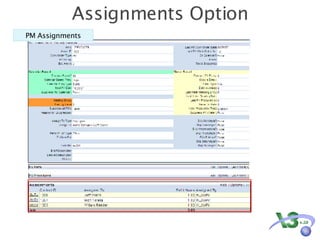

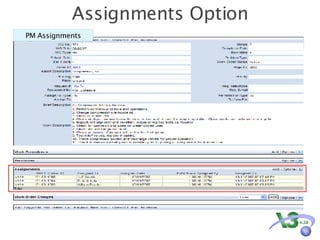

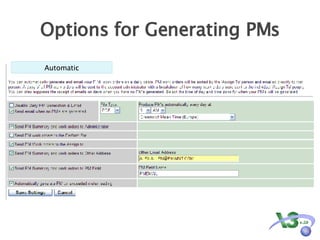

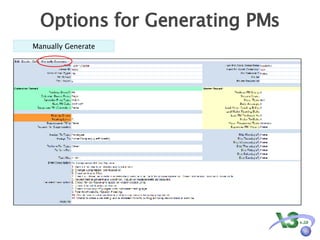

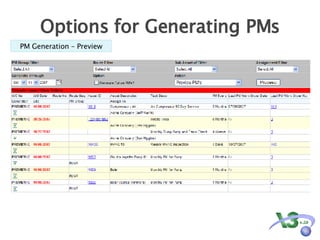

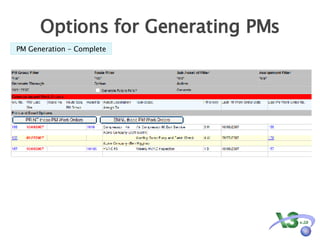

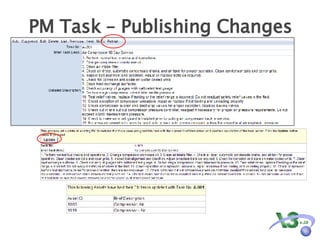

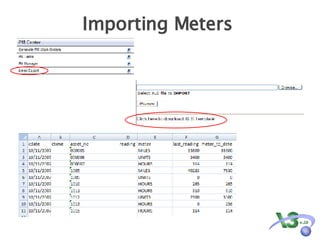

The document discusses effective preventive maintenance (PM) management using eMaint X3 software. It covers topics like PM schedule setup, generating and managing PMs, and tools for better PM planning. Specific areas covered include calendar vs. meter based scheduling, using shadow scheduling, grouping and routing PMs, nesting tasks and procedures, planning for parts usage, and generating PMs through automatic, manual, or imported methods.