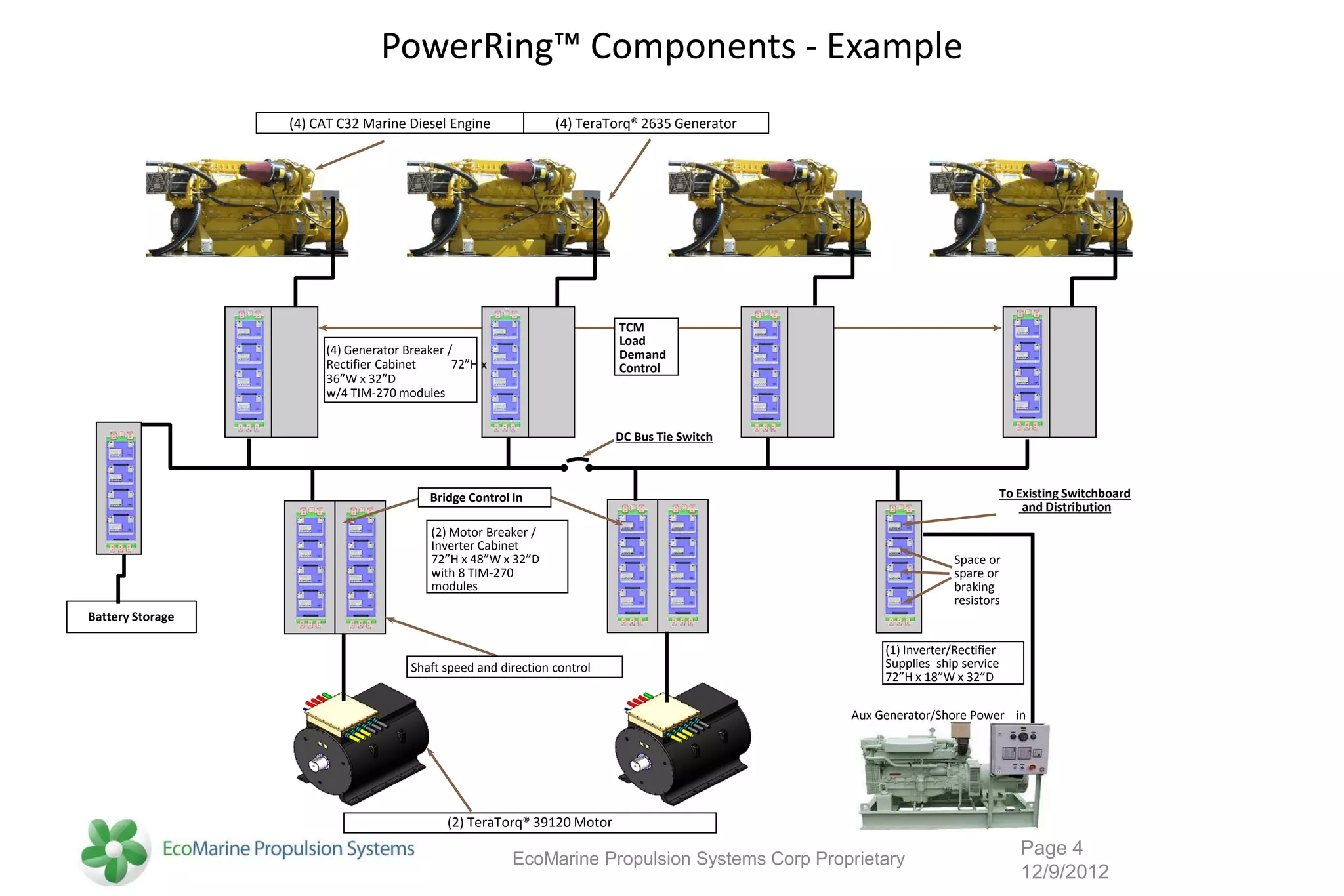

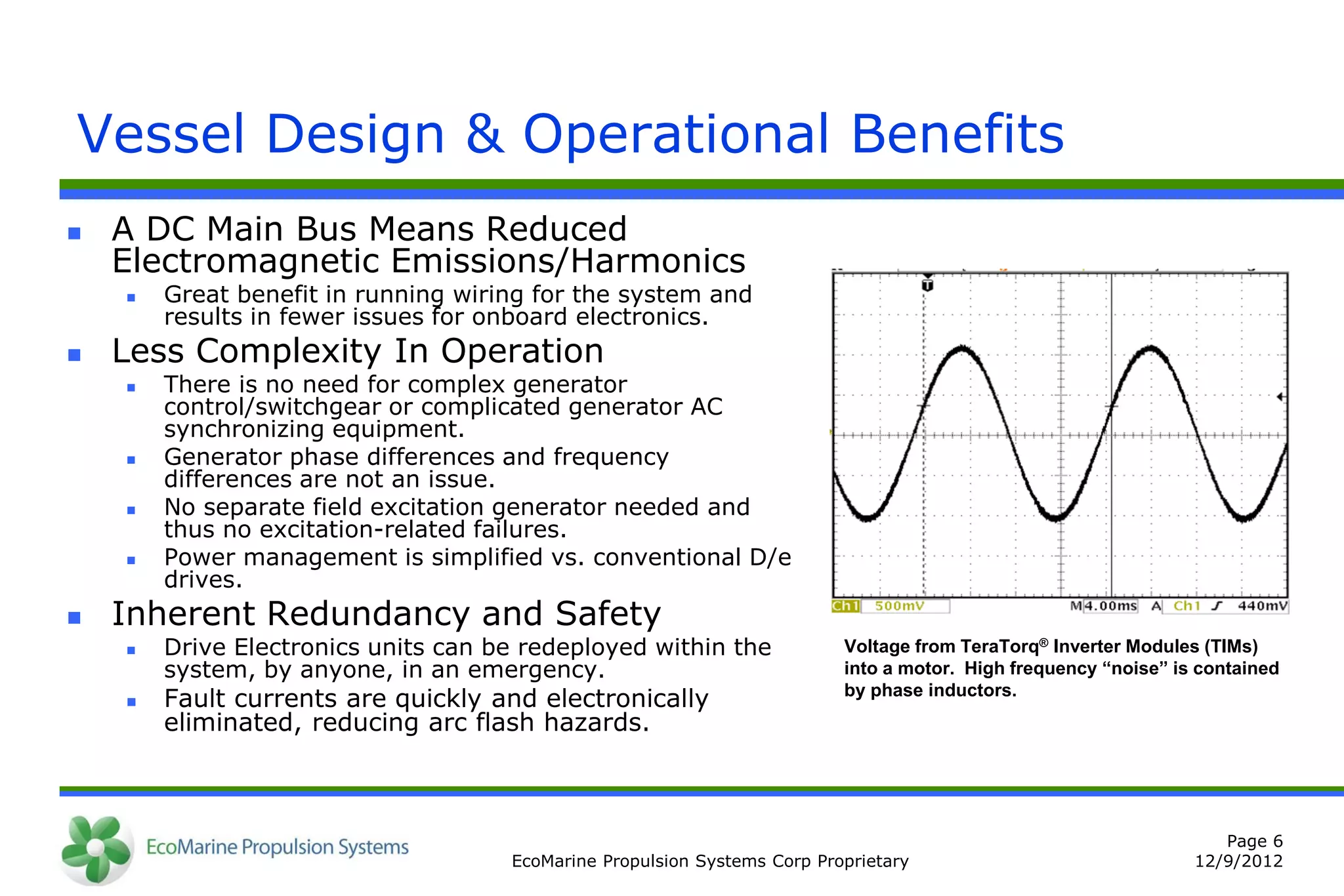

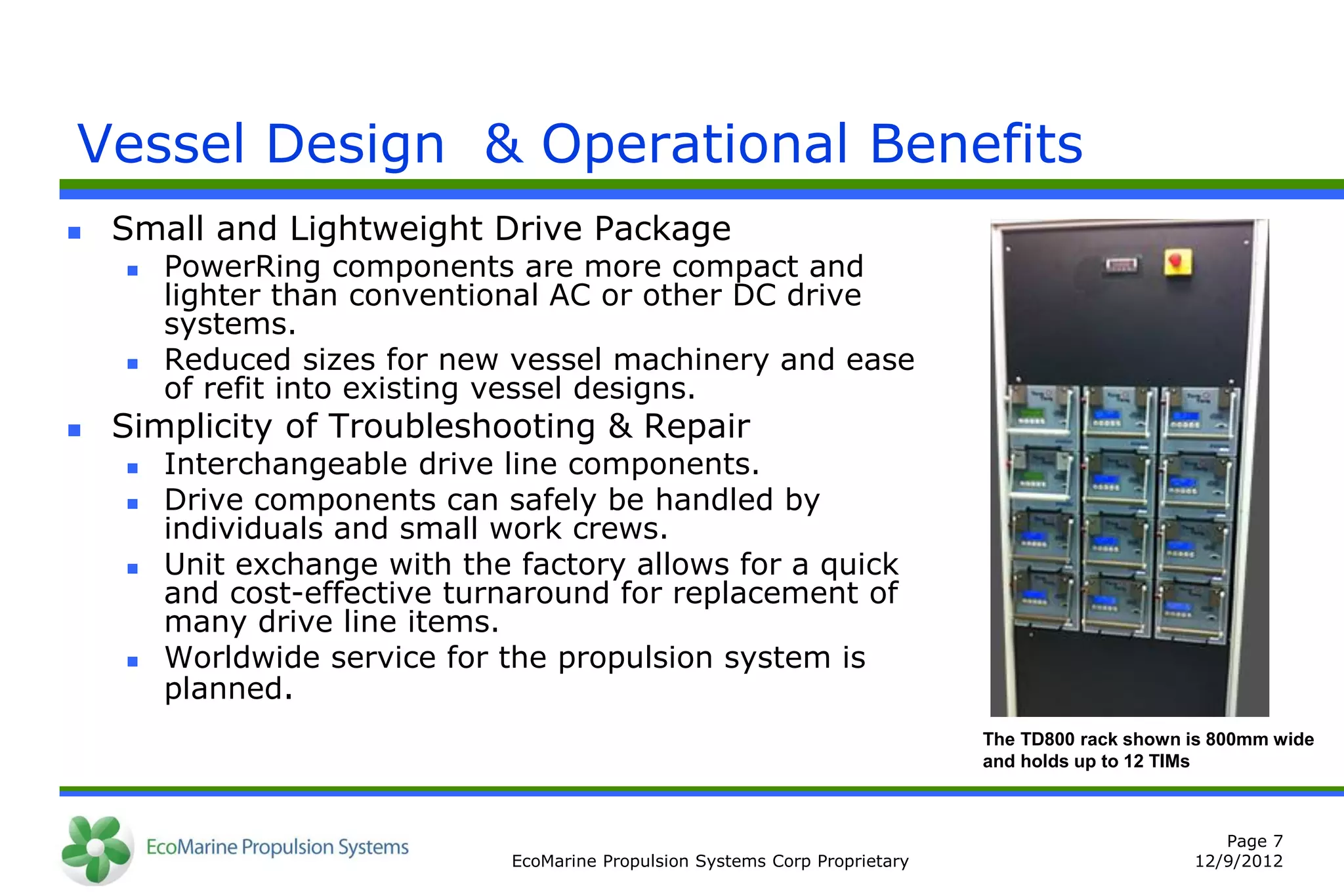

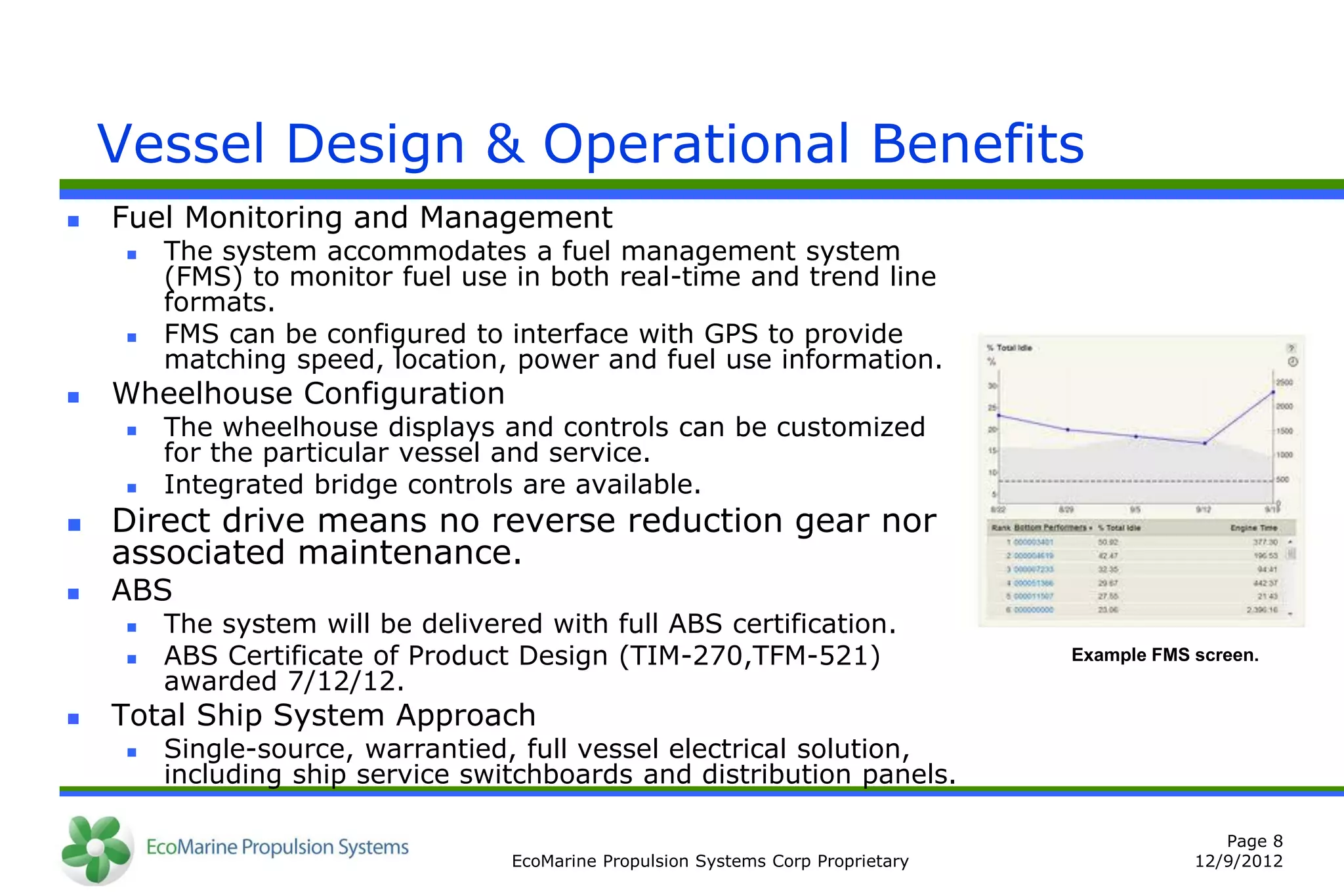

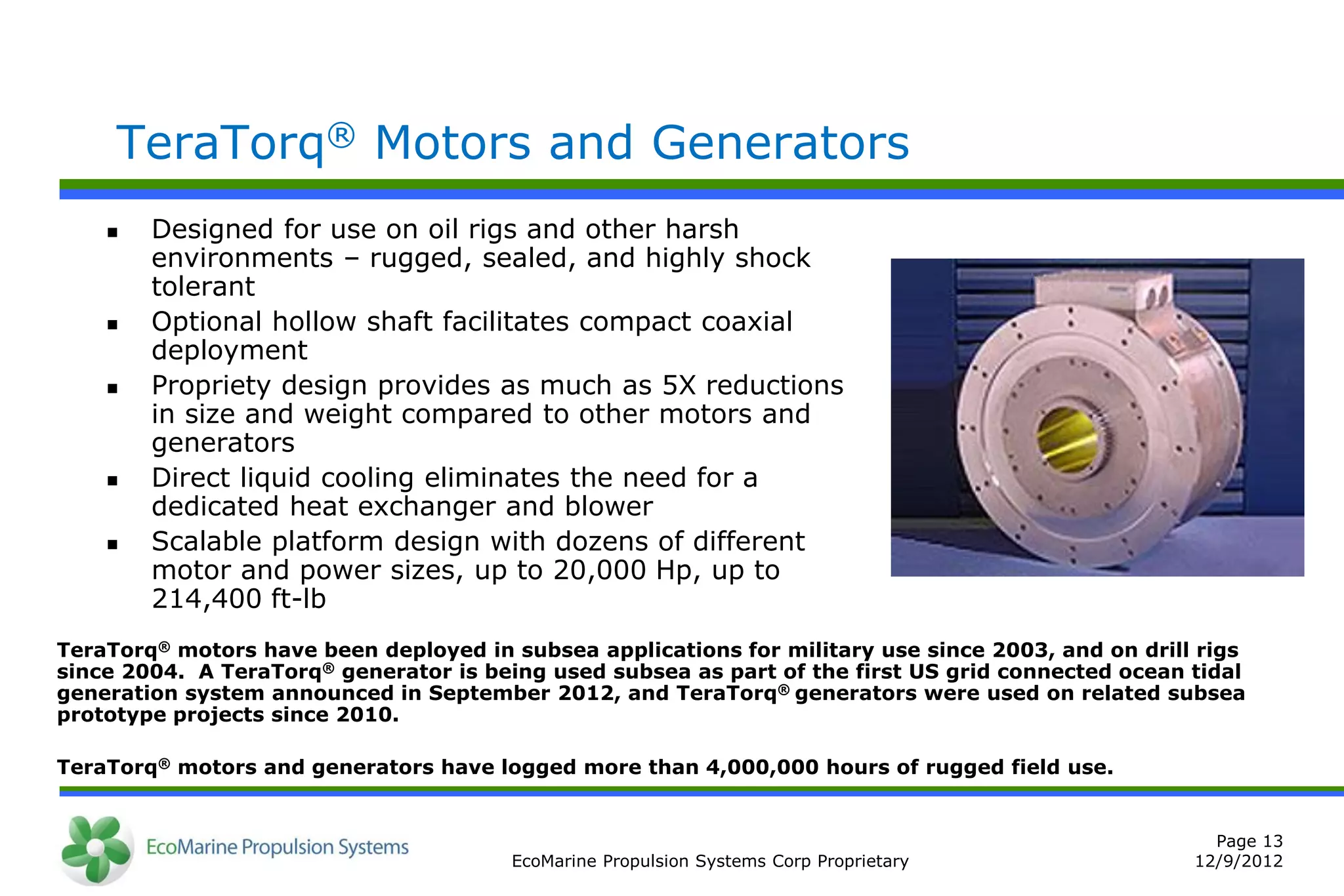

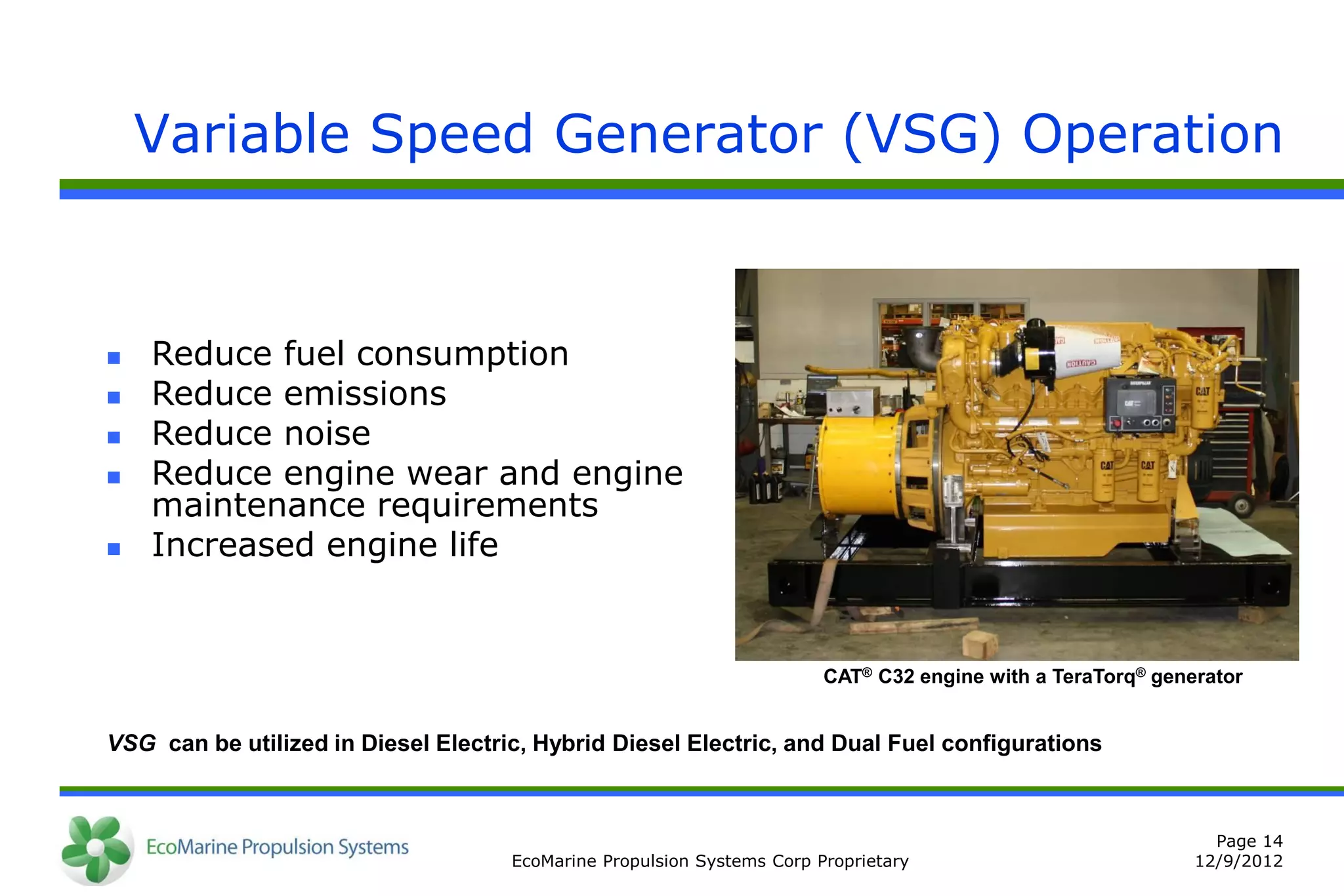

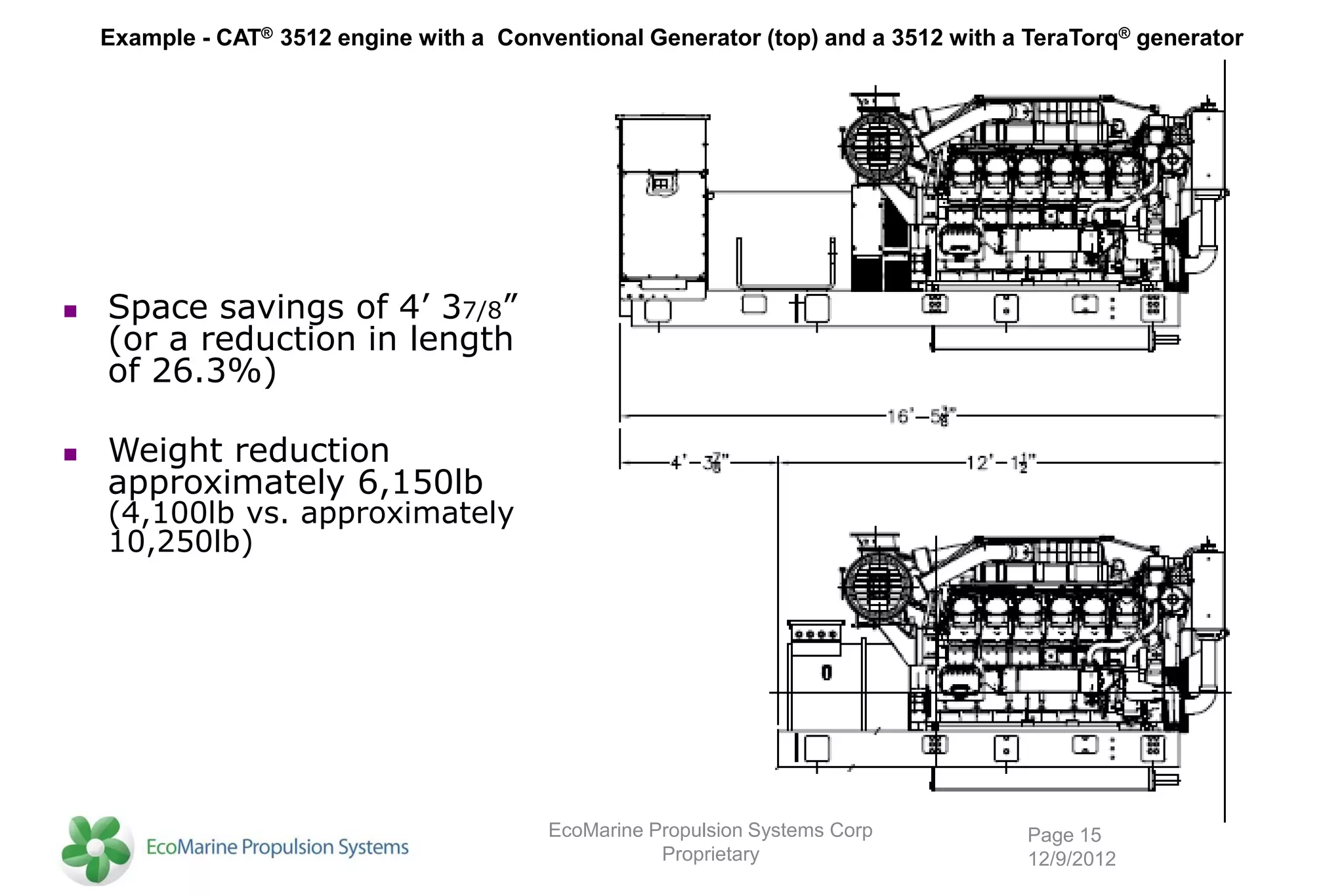

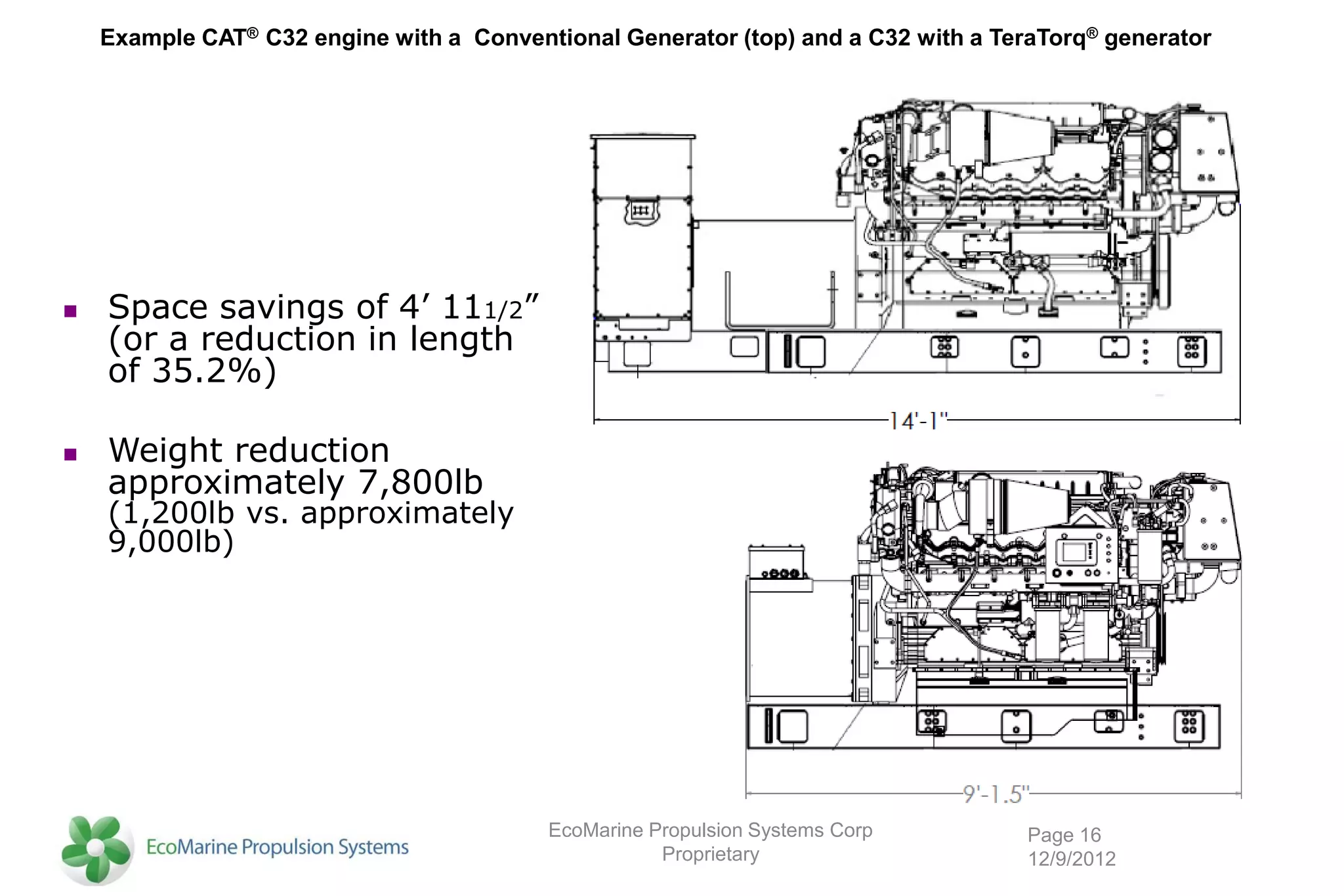

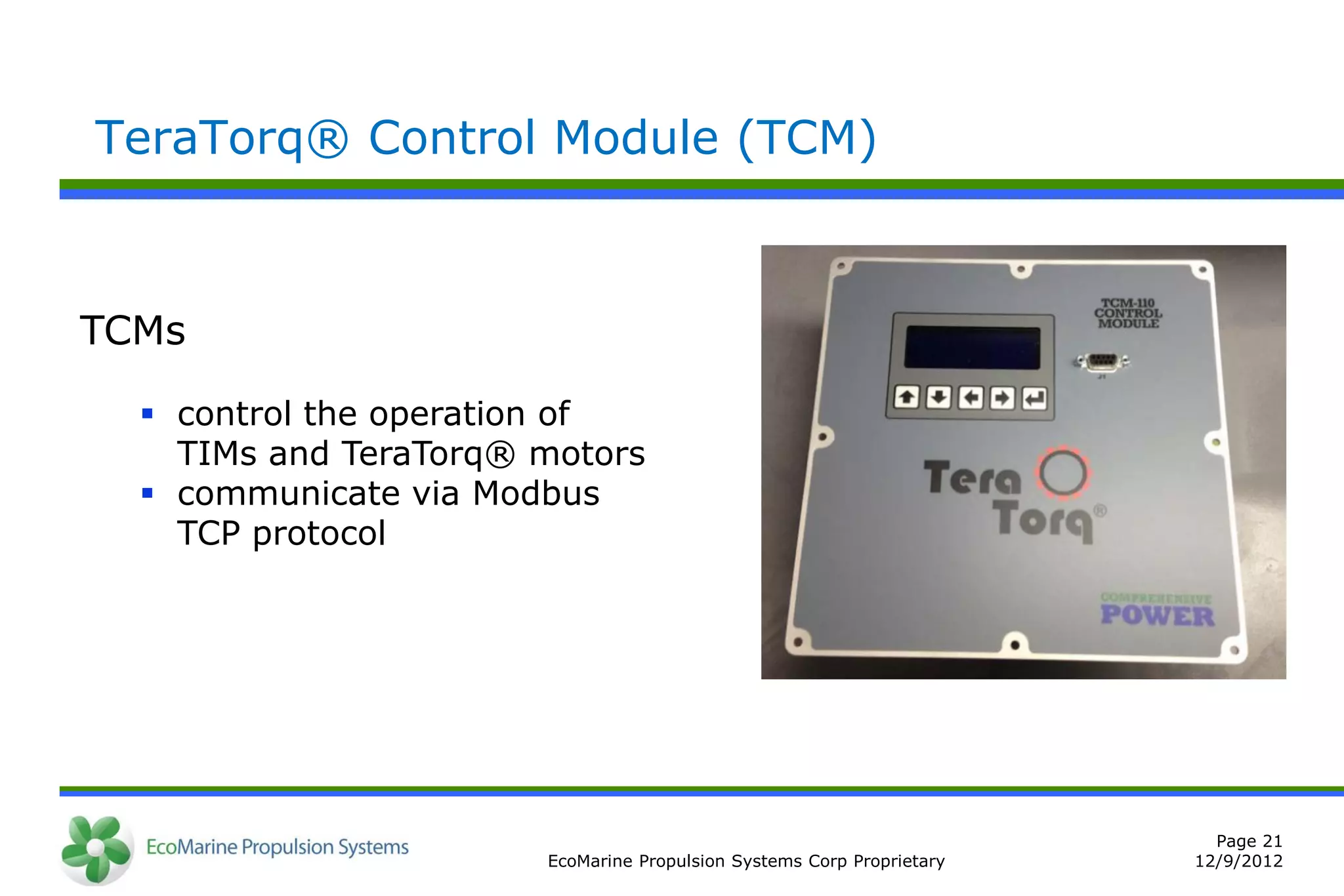

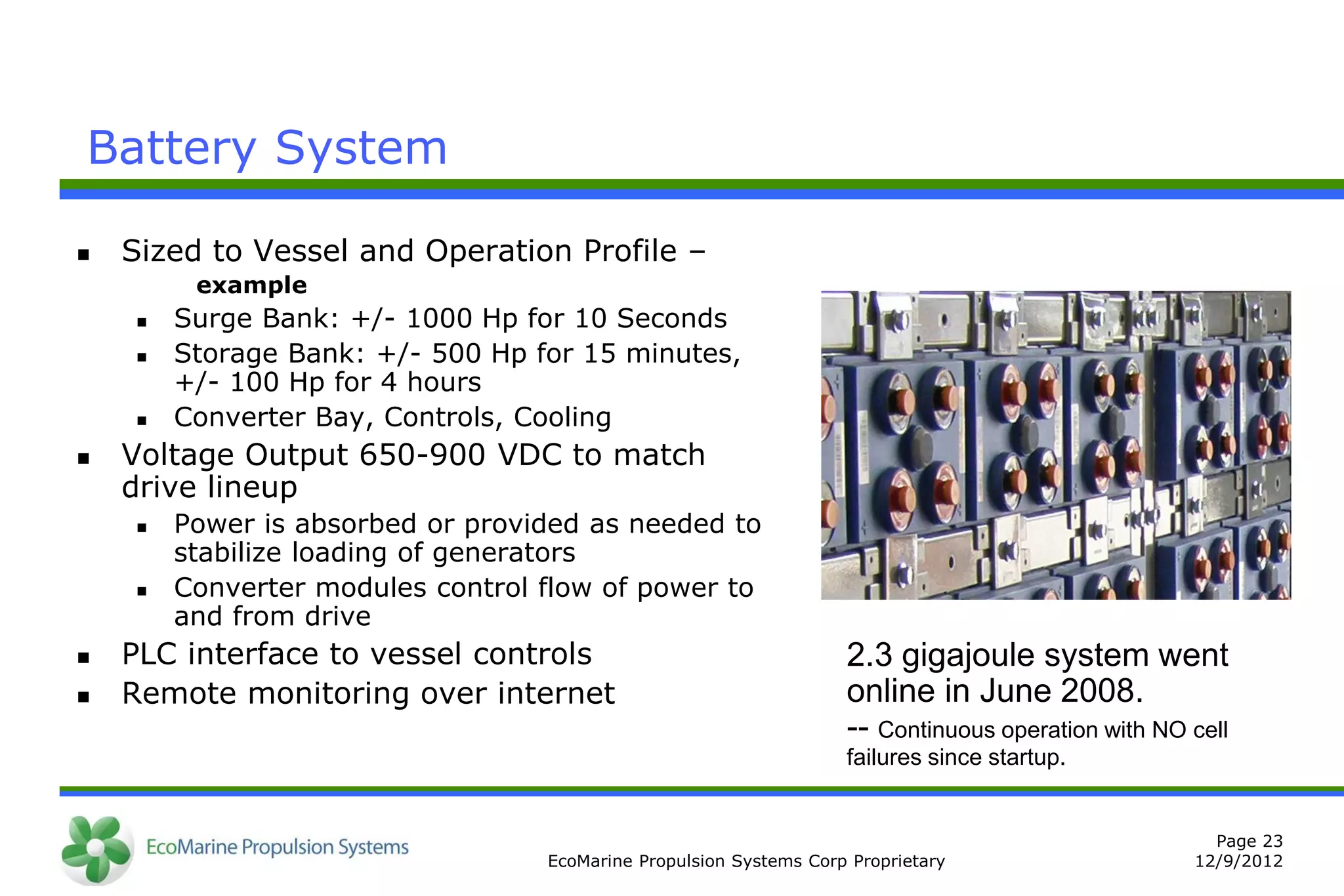

Ecomarine Propulsion Systems Corporation is a joint venture specializing in marine electric propulsion and the development of alternative green power sources for the tug/barge industry. They offer cost-effective propulsion systems that reduce emissions, fuel consumption, maintenance costs, and noise while enhancing operational efficiency. The company's technology includes innovative components such as Teratorq motors and generators, enabling advanced control and performance in various marine applications worldwide.