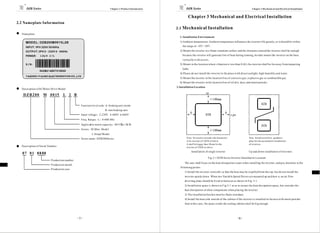

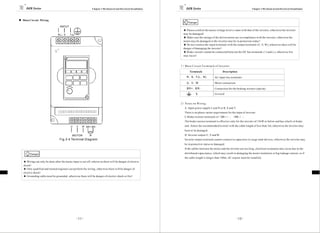

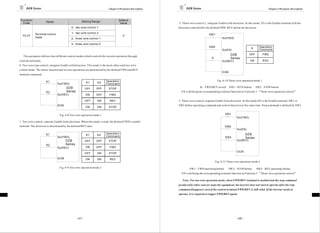

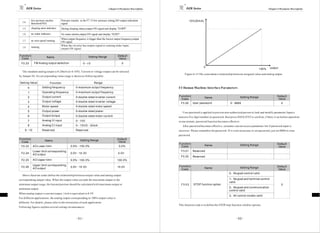

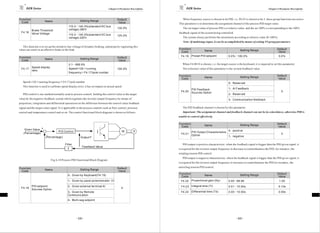

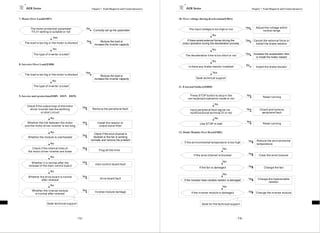

The document provides an overview of the DZB200 inverter covering receiving, storage, transportation, nameplate information, and safety cautions. It discusses the inverter's mechanical and electrical installation, operation, function parameters, fault diagnosis, and quality guarantees over multiple chapters.