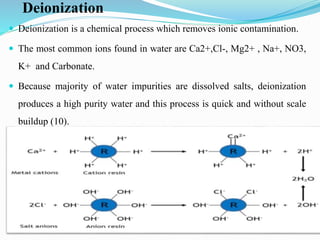

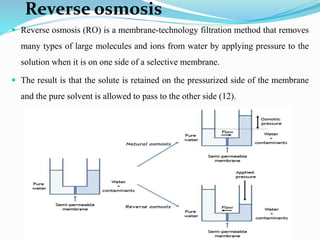

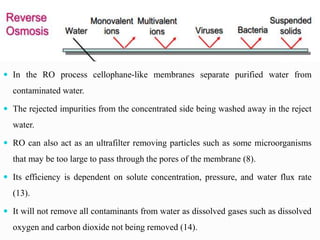

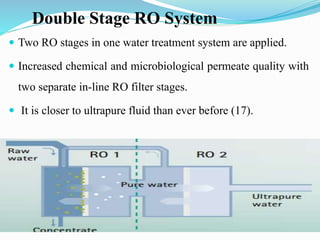

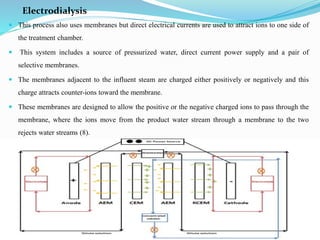

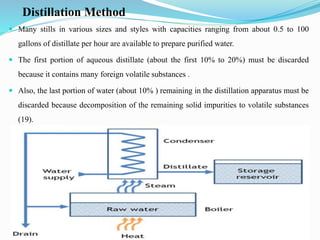

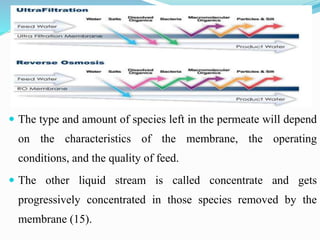

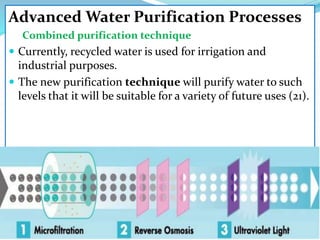

This document summarizes various water purification methods used in pharmaceutical applications. It discusses different types and grades of water including drinking water, purified water, highly purified water, and water for injection. Key water purification techniques described include deionization, reverse osmosis, distillation, ultrafiltration, and combinations thereof. Advanced processes like microfiltration and double pass reverse osmosis systems are also outlined to produce higher purity water suitable for various future uses.