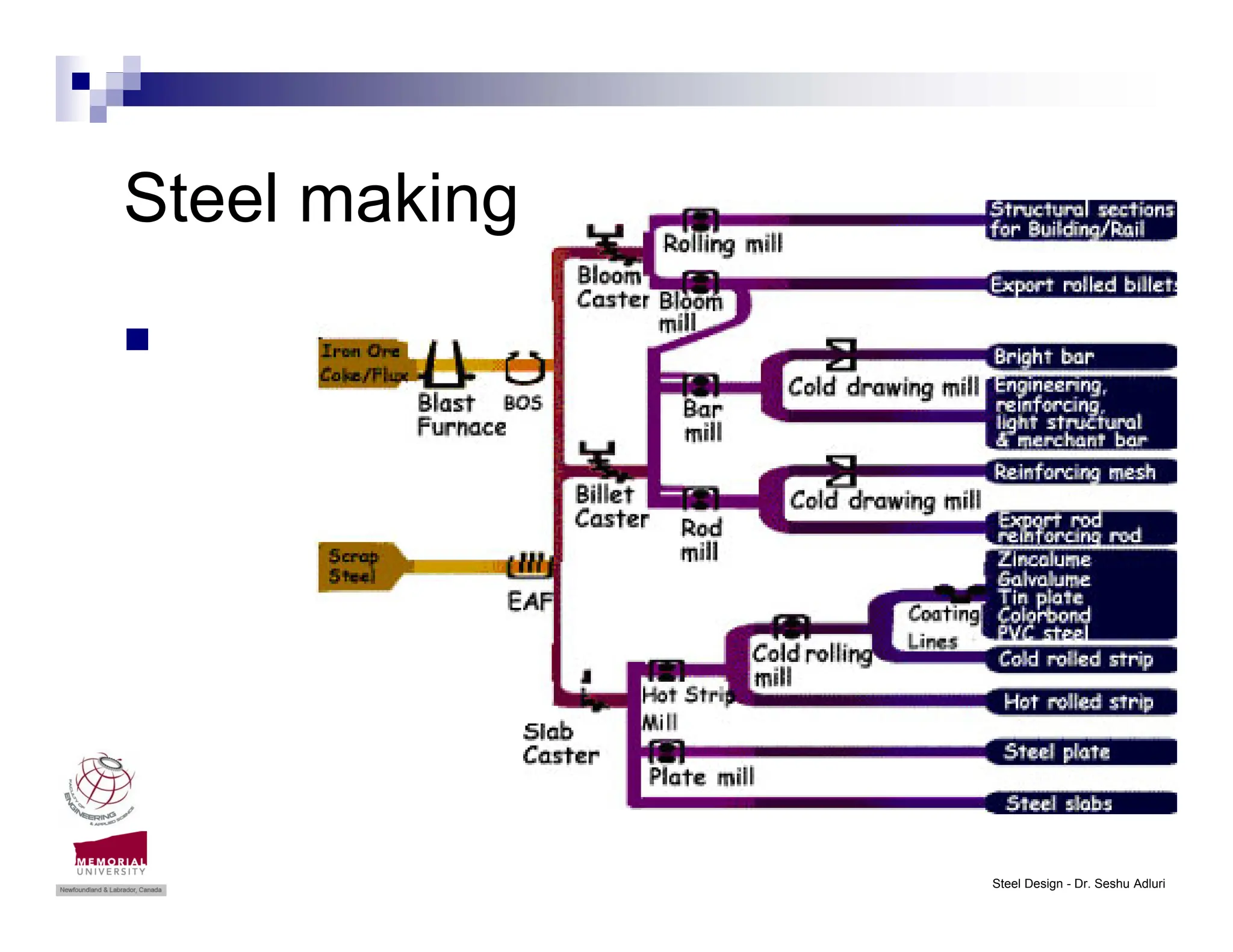

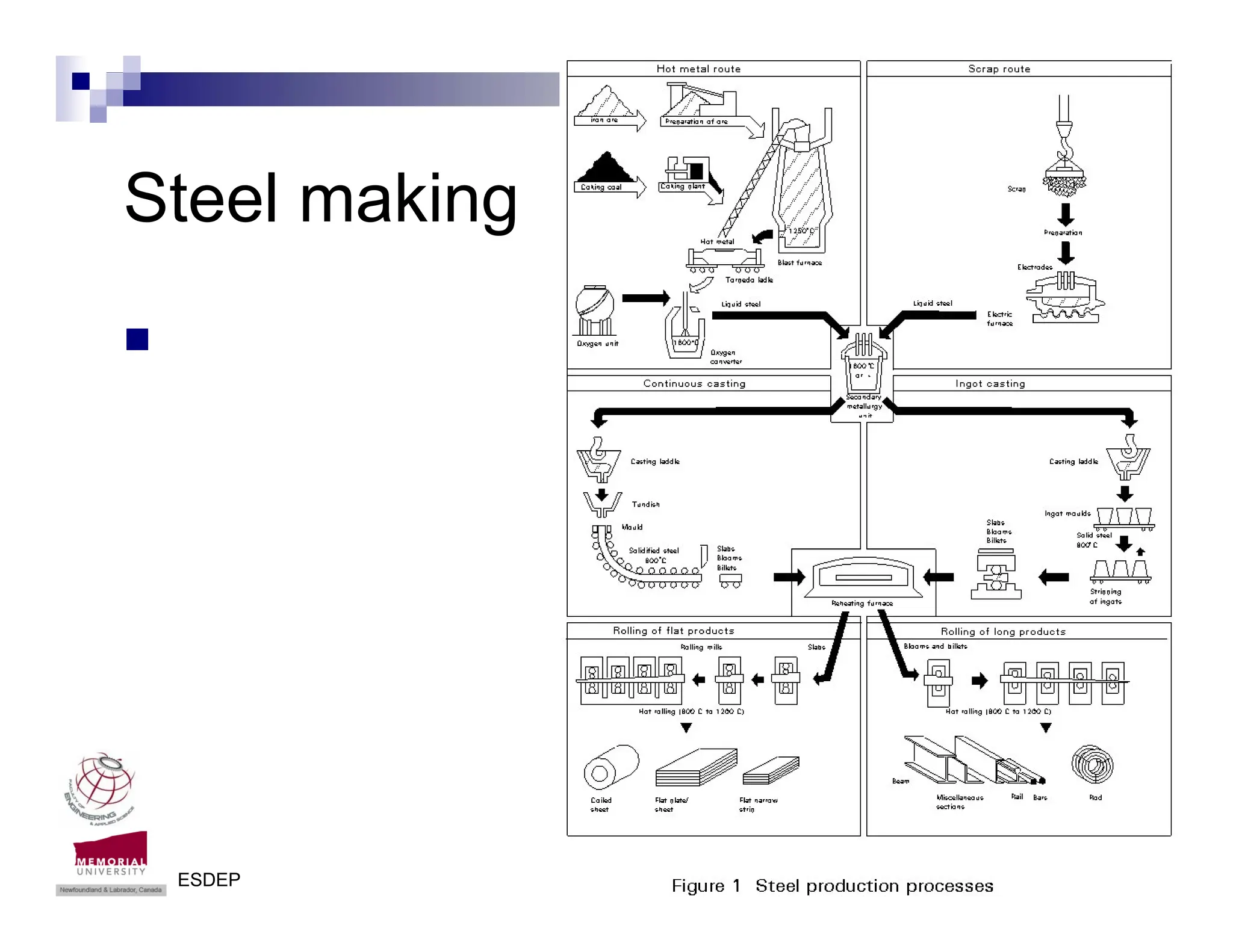

The document outlines the course structure and content for ENG 7704 Structural Steel Design, focusing on aspects such as the evolving capabilities of structural steel and its importance in modern construction. It emphasizes the material's advantages including strength, flexibility, and recyclability, while detailing key topics ranging from design principles to advanced fabrication techniques. Additionally, it covers historical contexts and future perspectives on steel usage in construction and its global impact.