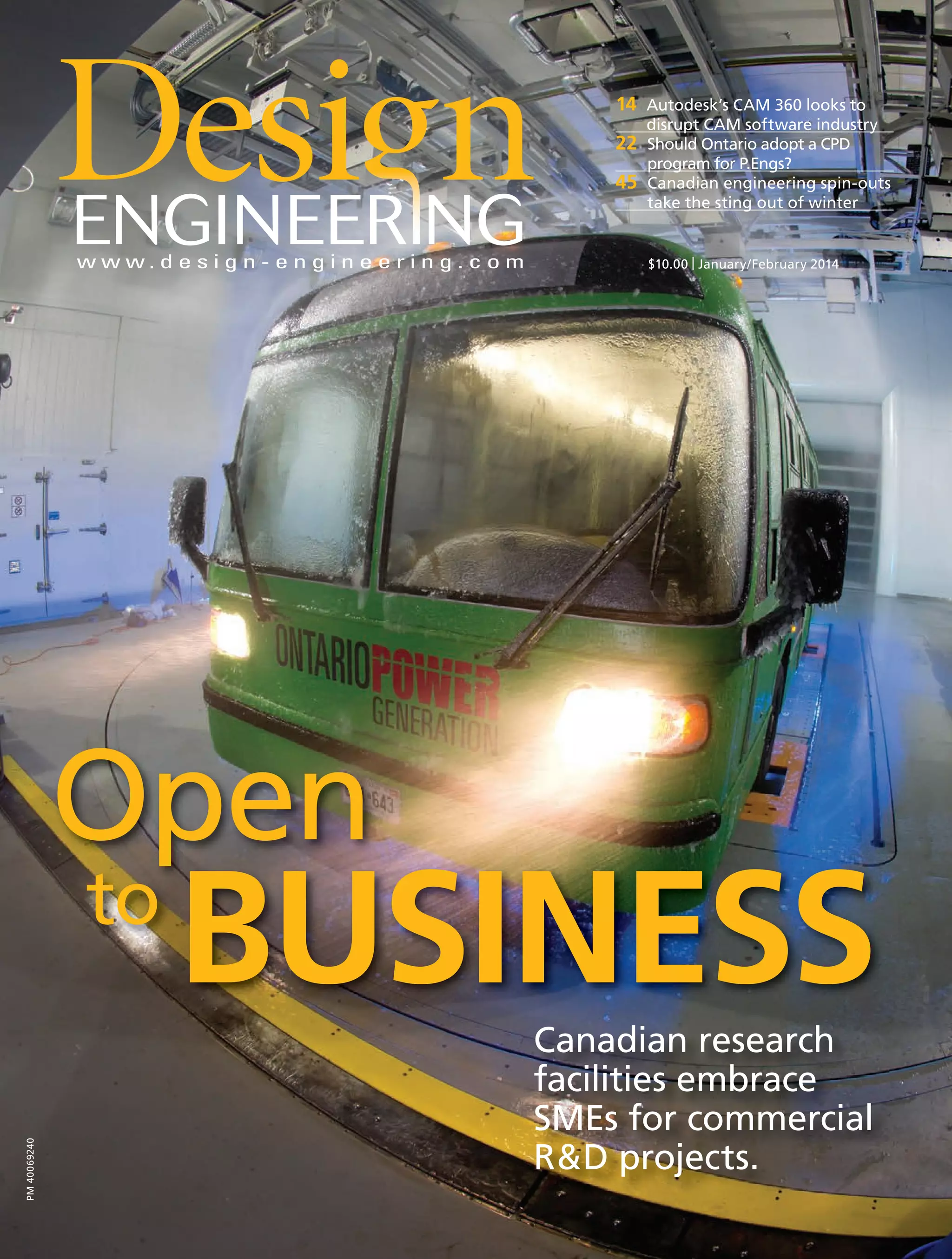

The document is an issue of Design Engineering magazine from January/February 2014. It includes articles on various engineering topics such as additive manufacturing, motion control, automation, and Canadian engineering startups. It also contains advertisements and information on upcoming events. The cover story discusses how Canadian university research facilities partner with small and medium enterprises for commercial research and development projects.