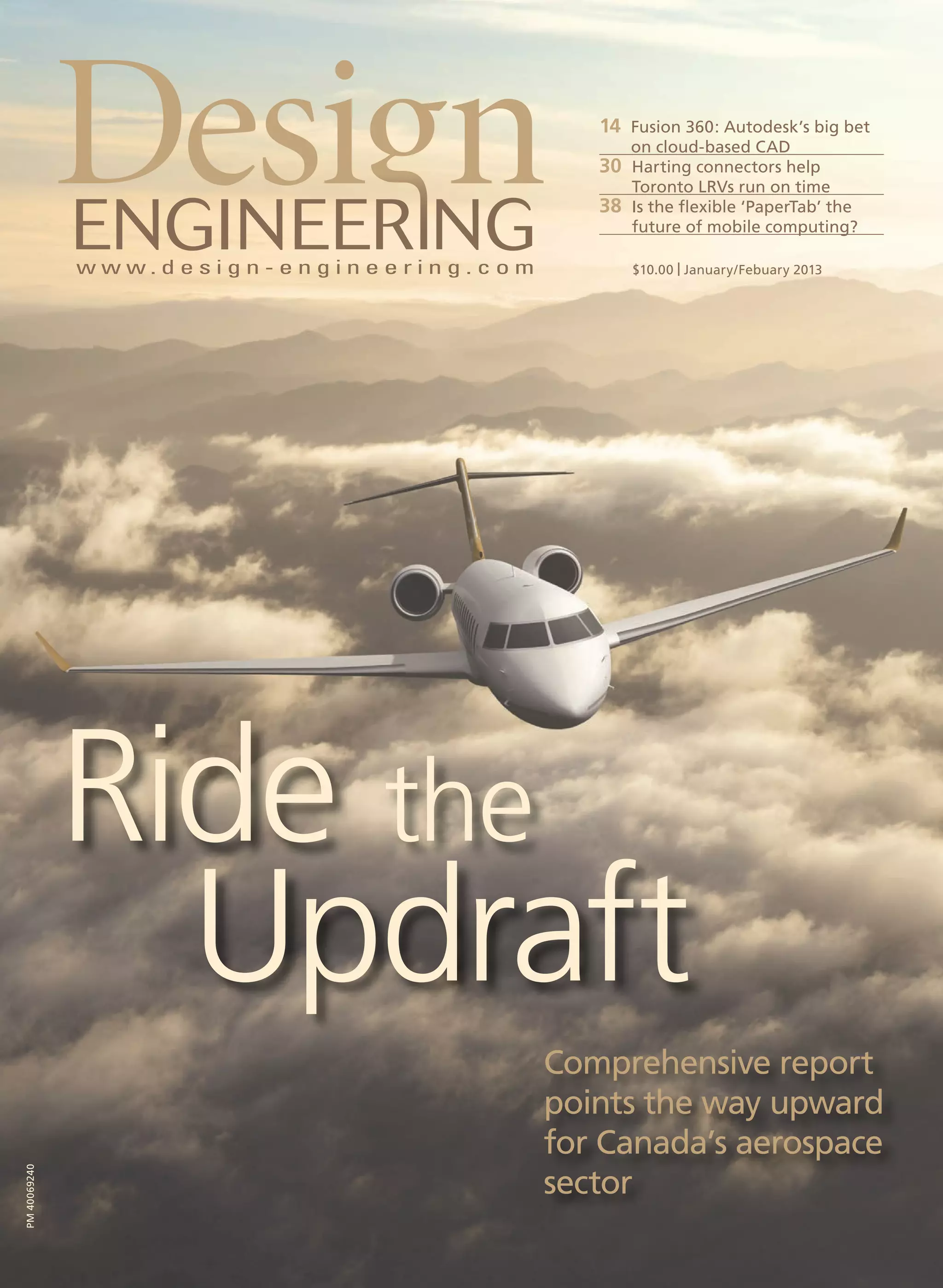

The document is an issue of Design Engineering magazine from January/February 2013. It includes articles on various topics in engineering design and manufacturing in Canada, such as Autodesk's new cloud-based CAD software Fusion 360, CFD analysis helping improve cycling helmet design, and a report outlining recommendations to support growth in Canada's aerospace sector. It also contains advertisements, including from Festo and Omega Engineering, and sections with industry news briefs.