This document provides information about a textbook on Computer Aided Design and Manufacturing.

It begins with the title, authors, subject code and other publishing details. The textbook covers key topics on CAD and CAM across 5 chapters. It provides fundamental concepts and step-by-step explanations of important topics with illustrations and examples. The textbook is intended to help students understand the basic concepts of CAD/CAM. It will be useful for both students and subject teachers.

![(ii)

AU 17

9 [1]

788194382515

ã Copyright with Authors

All publishing rights reserved with . No part of this book

should be reproduced in any form, Electronic, Mechanical, Photocopy or any information storage and

retrieval system without prior permission in writing, from Technical Publications, Pune.

(printed and ebook version) Technical Publications

Printer :

Yogiraj Printers & Binders

Sr.No. 10/1A,

Ghule Industrial Estate, Nanded Village Road,

Tal. - Haveli, Dist. - Pune - 411041.

Published by :

Amit Residency, Office No.1, 412, Shaniwar Peth, Pune - 411030, M.S. INDIA

Ph.: +91-020-24495496/97, Telefax : +91-020-24495497

Email : sales@technicalpublications.org Website : www.technicalpublications.org

PUBLICATIONS

TECHNICAL

An Up-Thrust for Knowledge

®

SINCE 1993

ISBN 978-81-943825-1-5

Price : 395/-

`

9 7 8 8 1 9 4 3 8 2 5 1 5

Semester - VI (Mechanical Engineering)

Subject Code : ME8691

Computer Aided Design

& Manufacturing

First Edition : January 2020](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-2-2048.jpg)

![Syllabus

Computer Aided Design and Manufacturing

[ME8691]

Unit I Introduction

Product cycle- Design process- sequential and concurrent engineering - Computer aided design

- CAD system architecture- Computer graphics - co-ordinate systems - 2D and 3D

transformations- homogeneous coordinates - Line drawing - Clipping - viewing

transformation-Brief introduction to CAD and CAM - Manufacturing Planning, Manufacturing

control- Introduction to CAD/CAM - CAD/CAM concepts - Types of production - Manufacturing

models and Metrics - Mathematical models of Production Performance. (Chapter - 1)

Unit II Geometric Modeling

Representation of curves - Hermite curve- Bezier curve - B-spline curves-rational

curves-Techniques for surface modeling - surface patch- Coons and bicubic patches - Bezier

and B-spline surfaces. Solid modeling techniques - CSG and B-rep. (Chapter - 2)

Unit III CAD Standards

Standards for computer graphics - Graphical Kernel System (GKS) - standards for exchange

images - Open Graphics Library (OpenGL) - Data exchange standards - IGES, STEP, CALS etc. -

communication standards. (Chapter - 3)

Unit IV Fundamental of CNC and Part Programing

Introduction to NC systems and CNC - Machine axis and Co-ordinate system - CNC machine

tools- Principle of operation CNC- Construction features including structure- Drives and CNC

controllers- 2D and 3D machining on CNC- Introduction of Part Programming, types - Detailed

Manual part programming on Lathe & Milling machines using G codes and M codes - Cutting

Cycles, Loops, Sub program and Macros- Introduction of CAM package. (Chapter - 4)

Unit V Cellular Manufacturing and Flexible

Manufacturing System (FMS)

Group Technology(GT),Part Families - Parts Classification and coding - Simple Problems in

Opitz Part Coding system - Production flow Analysis - Cellular Manufacturing - Composite part

concept - Types of Flexibility - FMS - FMS Components - FMS Application & Benefits - FMS

Planning and Control - Quantitative analysis in FMS. (Chapter - 5)

(iv)](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-4-2048.jpg)

![1.1 Introduction to CAD

· CAD (Computer Aided Design) is the use of computer software to design and

document a product's design process.

· Engineering drawing entails the use of graphical symbols such as points, lines,

curves, planes and shapes.

· Essentially, it gives detailed description about any component in a graphical form.

· The use of orthographic projections was formally introduced by the French

mathematician Gaspard Monge in the eighteenth century.

· Since visual objects transcend languages, engineering drawings have evolved and

become popular over the years.

· While earlier engineering drawings were handmade, studies have shown that

engineering designs are quite complicated.

· A solution to many engineering problems requires a combination of organization,

analysis, problem solving principles and a graphical representation of the

problem.

· Objects in engineering are represented by a technical drawing (also called as

drafting) that represents designs and specifications of the physical object and data

relationships.

· CAD is used to design, develop and optimize products.

· While it is very versatile, CAD is extensively used in the design of tools and

equipment required in the manufacturing process as well as in the construction

domain.

· CAD enables design engineers to layout and to develop their work on a computer

screen, print and save it for future editing.

· When it was introduced first, CAD was not exactly an economic proposition

because the machines at those times were very costly.

· The increasing computer power in the later part of the twentieth century, with the

arrival of minicomputer and subsequently the microprocessor, has allowed

engineers to use CAD files that are an accurate representation of the

dimensions / properties of the object.

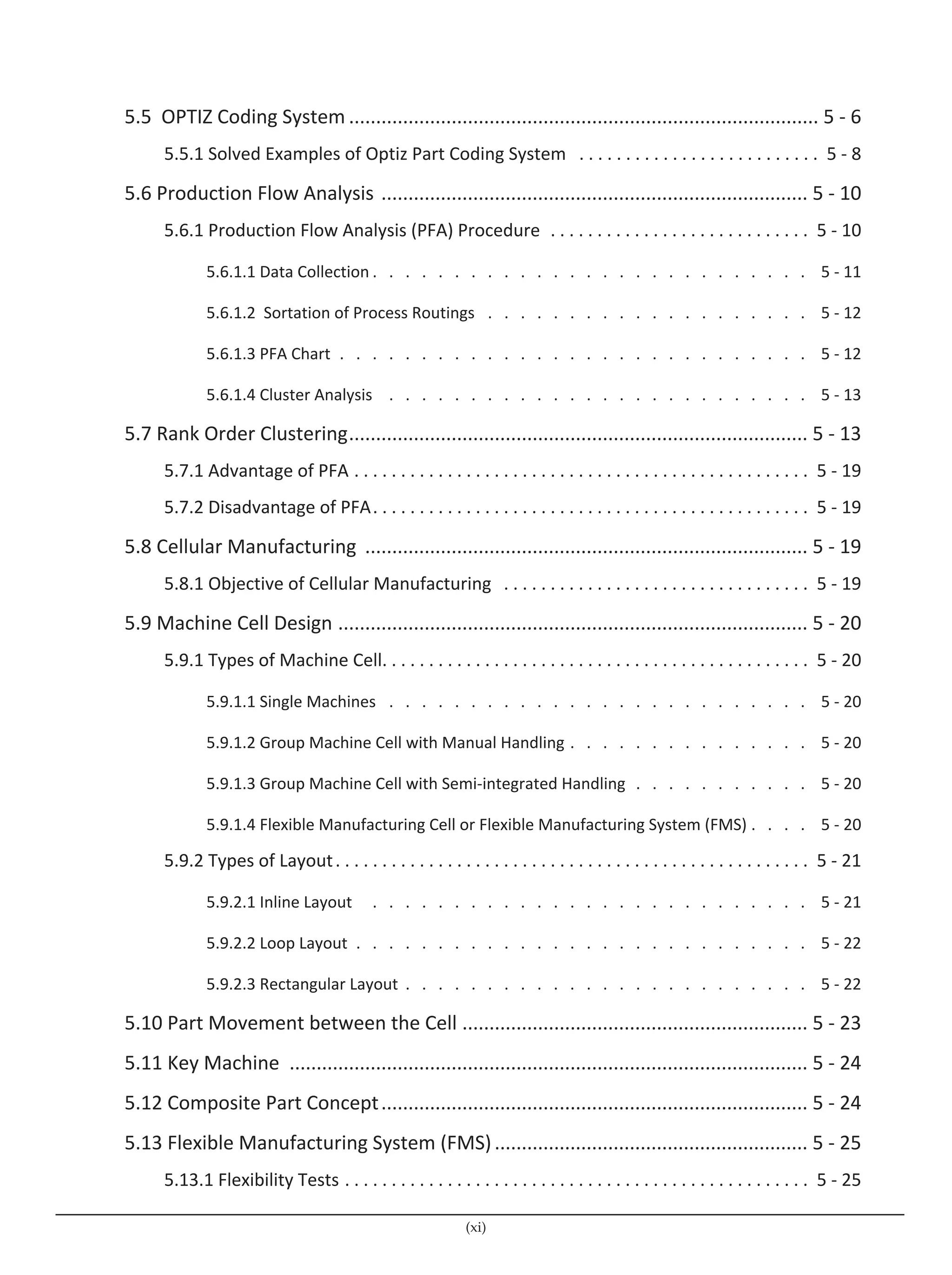

1.2 Product Cycle + [AU : Dec.-18]

· In the design and manufacture of a product various activities and functions must

be accomplished. These activities and functions are referred to as the

"Product Cycle".

· The product cycle includes all the activities starting from identification for

product to deliver the finished product to the customer. Fig. 1.2.1 explains

various stages in product life cycle. Fig. 1.2.2 depicts various steps in the product

cycle and Fig. 1.2.3 explains product cycle in in a detailed manner.

1 - 2 Computer Aided Design and Manufacturing

Introduction](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-14-2048.jpg)

![· Parts that pass the quality control inspection are assembled, functionally tested,

packaged, labeled, and shipped to customers.

· Market feedback is usually incorporated into the design process.

· This feedback give birth to a closed-loop product cycle.

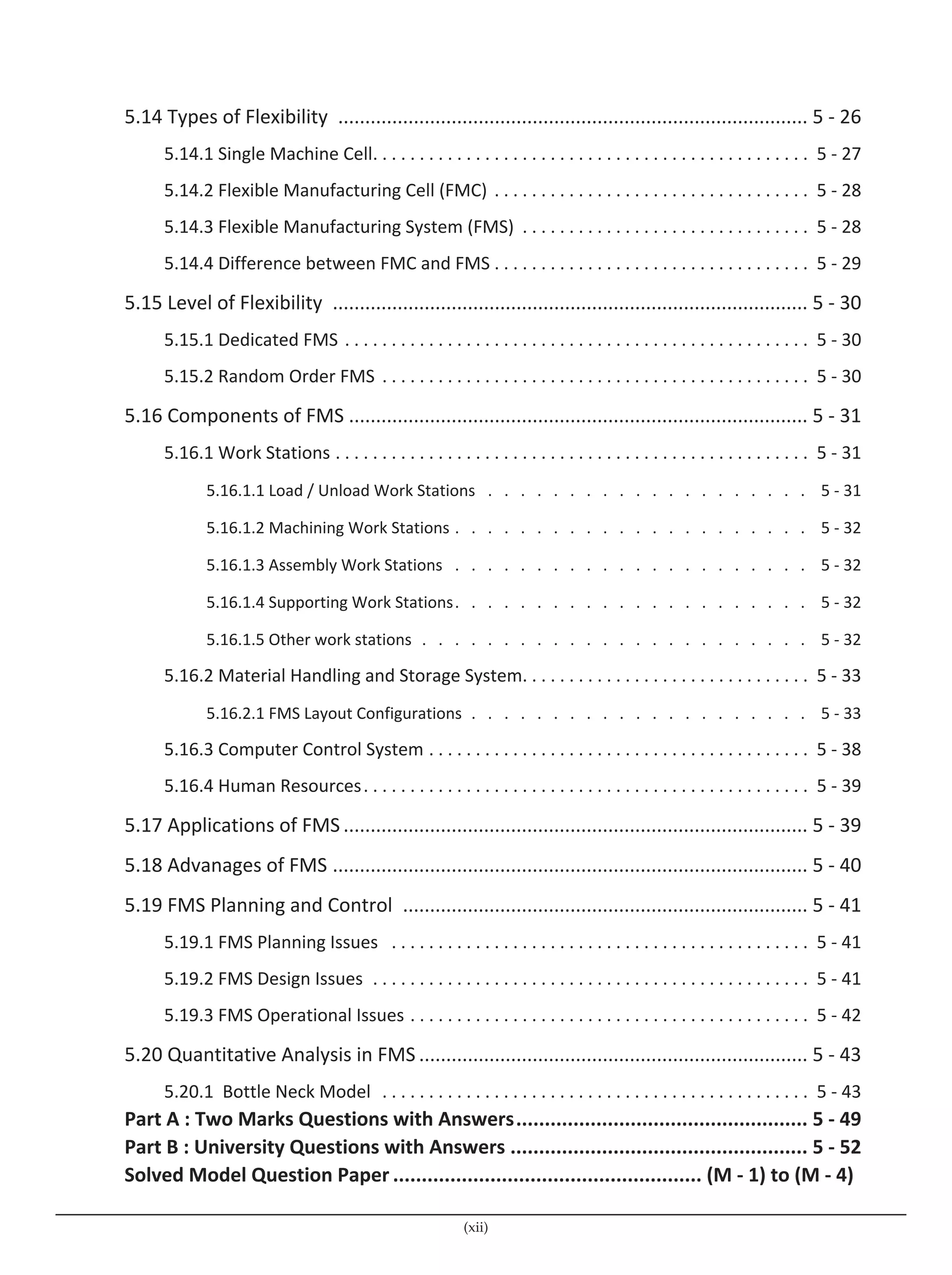

1.3 Design Process + [AU : Dec.-16]

Engineering design process :

· The engineering design process is the formulation of a plan to help an engineer

build a product with a specified performance goal. It is a decision making process

in which the basic sciences, mathematics, and engineering sciences are applied to

convert resources optimally to meet a stated objective. Fig. 1.3.1 explains

engineering design process in a detailed manner.

· The fundamental elements of the design process are the establishment of

objectives and criteria, synthesis, analysis, construction, testing and evaluation.

· The engineering design process is a multi-step process including the research,

conceptualization, feasibility assessment, establishing design requirements,

preliminary design, detailed design, production planning and tool design and

finally production.

1 - 5 Computer Aided Design and Manufacturing

Introduction

Design

need

Design definitions,

specifications and

requirements

Collecting relevant

design information

and feasibility study

Analysis

Design

communication

and documentation

Design

evaluation

Design

optimization

Design

analysis

Design

modeling and

simulation

Design

conceptualization

The CAD process

Synthesis

The design process

The manufacturing process

The CAM process

Process

planning

Production

planning

Design and

procurement

of new tools

Order

material

NC, CNC,

DNC

programming

Production

Quality

control

Packaging Shipping

Marketing

Fig. 1.2.3 Product cycle](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-17-2048.jpg)

![· Presentation : After the product design passing through the evaluation stage,

drawings, diagrams, material specification, assembly lists, bill of materials etc.

which are required for product manufacturing are prepared and given to process

planning department and production department.

1.4 Sequential and Concurrent Engineering + [AU : May-17, Dec.-18]

Sequential Engineering (Over The Wall Engineering)

· In sequential engineering design has been carried out as a sequential set of

activities with distinct non-overlapping phases as shown in Fig. 1.4.1.

· Sequential engineering is the term used to describe the method of production in a

linear format. The different steps are done one after another, with all attention

and resources focused on that one task. After it is completed it is left alone and

everything is concentrated on the next task.

· In such an approach, the life-cycle of a product starts with the identification of

the need for that product. These needs are converted into product requirements

which are passed on to the design department.

1 - 8 Computer Aided Design and Manufacturing

Introduction

Recognition of need

Definition of problem

Synthesis

Analysis and optimization

Evaluation

Presentation

Success

Change the design

Can the design be improved

Design impossible for the

given specification

Fails No

Yes

Fig. 1.3.2 Shigley's design process](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-20-2048.jpg)

![Sr. No. Sequential engineering Concurrent engineering

1. Sequential engineering is the term

used to explain the method of

production in a linear system. The

various steps are done one after

another, with all attention and

resources focused on that single

task.

In concurrent engineering, various tasks

are handled at the same time, and not

essentially in the standard order. This

means that info found out later in the

course can be added to earlier parts,

improving them, and also saving time.

2. Sequential engineering is a system

by which a group within an

organization works sequentially to

create new products and services.

Concurrent engineering is a method by

which several groups within an

organization work simultaneously to create

new products and services.

3. The sequential engineering is a

linear product design process during

which all stages of manufacturing

operate in serial.

The concurrent engineering is a non-linear

product design process during which all

stages of manufacturing operate at the

same time.

4. Both process and product design

run in serial and take place in the

different time.

Both product and process design run in

parallel and take place in the same time.

5. Process and product are not

matched to attain optimal matching.

Process and product are coordinated to

attain optimal matching of requirements for

effective quality and delivery.

6. Decision making done by only

group of experts.

Decision making involves full team

involvement.

1.5 Computer Aided Design (CAD) + [AU : May-17]

The conventional design process has been accomplished on drawing boards with

design being documented in the form of a detailed engineering drawing. This process is

iterative in nature and is time consuming. The computer can be beneficially used in the

design process. The various tasks performed by a modern computer aided design system

can be grouped into four functional areas.

i) Geometric modeling

ii) Engineering analysis

iii) Design review and evaluation

iv) Automated drafting.

i) Geometric Modeling

· The geometric modeling is concerned with computer compatible mathematical

description of geometry of an object.

· The mathematical description should be such that the image of the object can be

displayed and manipulated in the computer terminal, modification on the

1 - 12 Computer Aided Design and Manufacturing

Introduction](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-24-2048.jpg)

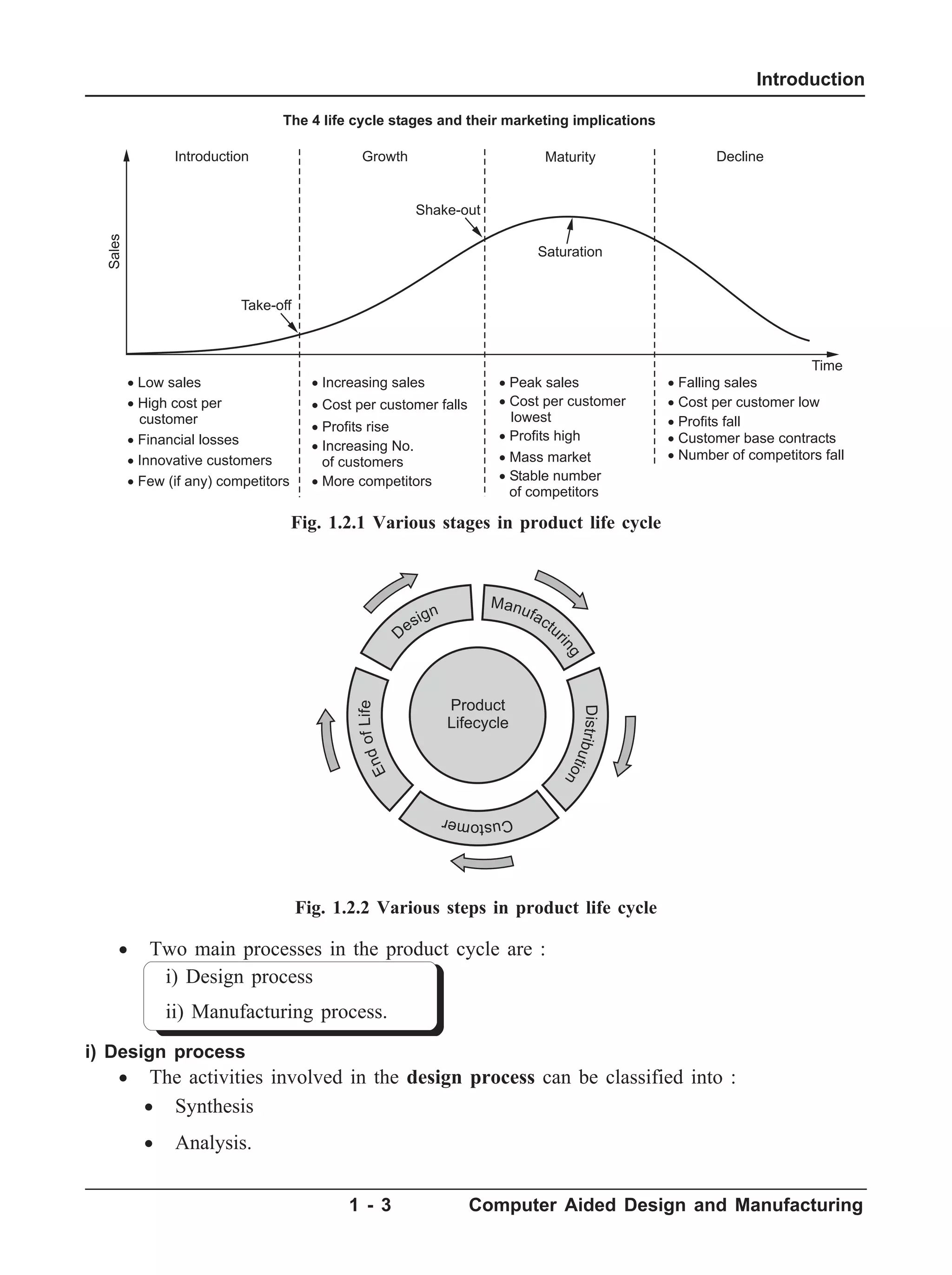

![· A user co-ordinate system is one in which the designer can specify his own

coordinates for a specific design application.

· These screen independent coordinates can have large or small numeric range, or

even negative values, so that the model can be represented in a natural way.

· It may, however, happen that the picture is too crowded with several features to

be viewed clearly on the display screen.

· Therefore, the designer may want to view only a portion of the image, enclosed

in a rectangular region called a window.

· Different parts of the drawing can thus be selected for viewing by placing the

windows.

· Portions inside the window can be enlarged, reduced or edited depending upon

the requirements. Fig. 1.8.2 (a) depicts the use of windowing to enlarge an image.

View Port

· It may be sometimes desirable to display different portions or views of the

drawing in different regions of the screen.

· A portion of the screen where the contents of the window are displayed is called

a view port. Fig. 1.8.2 (b) explains a view port.

1.9 2D Transformations + [AU : Dec.-17]

· Geometric transformations provide a means by which an image can be enlarged

in size, or reduced, rotated, or moved.

· These changes are brought about by changing the co-ordinates of the picture to a

new set of values depending upon the requirements.

· The basic transformations are translation, scaling, rotation, reflection or mirror

and shear.

1 - 20 Computer Aided Design and Manufacturing

Introduction

Window

Original

drawing

65,50

130,100 View port 1

View port 4 View port 3

View port 2

(a) Window (b) View port

Fig. 1.8.2](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-32-2048.jpg)

![a) 2D Translation

· This moves a geometric entity in space in such a way that the new entity is

parallel at all points to the old entity. Translation of a point is shown in

Fig. 1.9.1.

· Let's consider a point on the object, represented by P which is translated along X

and Y axes by DX and DY respectively to a new position P '.

· The new coordinates after transformation are given by following equations.

P' = [x', y' ] …(1.9.1)

x' = [x+Dx] …(1.9.2)

y' = [y+Dy] …(1.9.3)

[P'] =

¢

¢

é

ë

ê

ù

û

ú

x

y

=

x x

y y

+

+

é

ë

ê

ù

û

ú

D

D

=

x

y

é

ë

ê

ù

û

ú +

D

D

x

y

é

ë

ê

ù

û

ú …(1.9.4)

2D Translation of an object

Fig. 1.9.2 explains the transformation of a rectangle. Consider a rectangle of

coordinates (1,1), (4,1), (1,5) and (4,5). The rectangle is translated by 3 units along

x-direction (Dx) and 3 units along y-direction (Dy). (See Fig. 1.9.2 on next page)

b) 2D Scaling

· Scaling is the transformation applied to change the scale of an entity.

· To achieve scaling, the original coordinates would be multiplied uniformly by the

scaling factors.

Sx = Scaling factor along x-direction

Sy = Scaling factor along y-direction

Ts = Scaling matrix

· The scaling operations could be explained by the equations stated below.

¢

P = [x', y' ]=[Sx ´ X, Sy ´ Y] …(1.9.5)

1 - 21 Computer Aided Design and Manufacturing

Introduction

P

P Z

Y

X

X

P'

X'

Y'

Z'

Y

Fig. 1.9.1 Translation of a point](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-33-2048.jpg)

![[ ¢

P ] =

S 0

0 S

x

y

x

y

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú …(1.9.6)

[Ts] =

S 0

0 S

x

y

é

ë

ê

ù

û

ú …(1.9.7)

[ ¢

P ] = [Ts] × [P] …(1.9.8)

· Fig. 1.9.3 depicts the scaling of an

object.

c) 2D Rotation

· Rotation is another important

geometric transformation. The

final position and orientation of a

geometric entity is decided by the

angle of rotation (q) and the base

point about which the rotation, is

to be done.

· If rotation is made in clockwise

direction 'q' is considered as

1 - 22 Computer Aided Design and Manufacturing

Introduction

0 1 2 3 4 5 6 7 8 9 10

X

(1, 1) (4, 1)

(1, 5) (4, 5)

(5, 4) (8, 4)

(5, 8) (8, 8)

Y

0

1

2

3

4

5

6

7

8

9

10

Original rectangle

After translation

Fig. 1.9.2 2D Translation of an object

X

SX

SY

Y

P

P'

Y

X

Fig. 1.9.3 2D Scaling of an object](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-34-2048.jpg)

![negative and if rotation is made in counter clockwise (anti-clockwise) direction

' q' is considered as positive.

· Fig. 1.9.4 depicts rotation of an object.

· To develop the transformation matrix for transformation, consider a point P

located in XY-plane, being rotated in the counter clockwise direction to the new

position, ¢

P by an angle 'q' as shown in Fig. 1.9.4. The new position ¢

P is given

by

¢

P = [ ¢

x , ¢

y ]

· From the figure the original position is specified by

x = r cos a

y = r sin a

· The new position ¢

P is specified by

¢

x = r cos ( +

a q) = r cos q cos a – r sin q sin a

= x cos q – y sin q

Also, ¢

y = r sin ( +

a q) = r sin q cos a + r cos q sin a

= x sin q + y cos q

· Thus the transformation matrix for a rotation operation could be derived as

follows,

[P ]

¢ =

¢

¢

é

ë

ê

ù

û

ú

x

y

=

cos sin

sin cos

x

y

q q

q q

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú …(1.9.9)

· The rotation matrix is given as TR .

1 - 23 Computer Aided Design and Manufacturing

Introduction

X'

X

P'

r

P

X

Y

Y'

Y

0

Fig. 1.9.4 2D rotation of an objects](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-35-2048.jpg)

![[TR ] =

cos sin

sin cos

q q

q q

-

é

ë

ê

ù

û

ú …(1.9.10)

[P ]

¢ = [T [P]

R ]× (1.9.11)

d) 2D Shearing

· A shearing transformation produces distortion of an object or an entire image.

There are two types of shears : X-shear and Y-shear.

· A transformation that slants the shape of an object is called the shear

transformation.

· One shifts X coordinates values and other shifts Y coordinate values. However;

in both the cases only one coordinate changes its coordinates and other preserves

its values.

· Shearing is also termed as skewing.

· The X-shear as shown in the Fig. 1.9.5 (a), preserves the Y coordinate and

changes are made to X coordinates, which causes the vertical lines to tilt right or

left.

1 - 24 Computer Aided Design and Manufacturing

Introduction

11 12 13

After X-shear

Original part

D1

A1

B1

A B

E1

C1

C

D

0 1 2 3 4 5 6 7 8 9 10

X

Y

0

1

2

3

4

5

6

7

8

9

10

E

Fig. 1.9.5 (a) X-Shear](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-36-2048.jpg)

![· For reflection about x-axis the y coordinate will be negative and the following

equations should be utilized,

¢

P = [X , Y ]

¢ ¢ = [X, – Y] …(1.9.16)

[P ]

¢ =

1 0

0 1

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

x

y

…(1.9.17)

The translation matrix is given as,

[T ]

m =

1 0

0 1

-

é

ë

ê

ù

û

ú …(1.9.18)

[P ]

¢ = [T ] [P]

m × …(1.9.19)

· For reflection about y-axis the x coordinate will be negative and the following

equations should be utilized,

¢

P = [X , Y ]

¢ ¢ = [X, – Y] …(1.9.20)

[P ]

¢ =

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

1 0

0 1

x

y

…(1.9.21)

The translation matrix is given as,

[T ]

m =

-

é

ë

ê

ù

û

ú

1 0

0 1

…(1.9.22)

[P ]

¢ = [T ] [P]

m × …(1.9.23)

· Thus the general form of reflection matrix could be written as,

[T ]

m =

±

±

é

ë

ê

ù

û

ú

1 0

0 1

…(1.9.24)

1 - 26 Computer Aided Design and Manufacturing

Introduction

(a) Reflection about X-Axis

P

Y

X

Y

–

Y

P'

– X X

Y

X

P

P'

(b) Reflection about Y-axis

Fig. 1.9.6](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-38-2048.jpg)

![1.9.1 Homogeneous Coordinates

Concatenation of Transformations

· Sometimes it becomes necessary to combine the individual transformations in

order to achieve the required results. In such cases the combined transformation

matrix can be obtained by multiplying the respective transformation matrices as

shown below,

[P ]

¢ = [T ][T ][T ]...[T ][T ][T ]

n n 1 n 2 3 2 1

- - …(1.9.25)

· In order to concatenate the transformation, all the transformation matrices should

be multiplicative type. The following form known as homogeneous form should

be used to convert the translation matrix into a multiplication type.

[P ]

¢ =

¢

¢

é

ë

ê

ê

ê

ù

û

ú

ú

ú

x

y

1

=

1 0 0

0 1 0

D D

X Y 1

x

y

1

é

ë

ê

ê

ê

ù

û

ú

ú

ú

é

ë

ê

ê

ê

ù

û

ú

ú

ú

…(1.9.26)

· The three dimensional representation of a two dimensional plane is called

homogeneous coordinates and the transformation using the homogeneous

co-ordinates is called homogeneous transformation.

· The translation matrix in homogeneous form is,

[T] =

1 0 0

0 1 0

D D

X Y 1

é

ë

ê

ê

ê

ù

û

ú

ú

ú

· The Scaling matrix in homogeneous form is,

[S] =

S 0 0

0 S 0

0 0 1

x

y

é

ë

ê

ê

ê

ù

û

ú

ú

ú

· The Rotation matrix in homogeneous form is,

[T ]

R =

cos sin

sin cos

q q

q q

0

0

0 0 1

-

é

ë

ê

ê

ê

ù

û

ú

ú

ú

Need for homogeneous transformation

· Consider the need for rotating an object about an arbitrary point as shown in

Fig. 1.9.7.

· The transformation given earlier for rotation is about the origin of the axes

system.

· To derive the necessary transformation matrix, the following complex procedure

would be required.

i) Translate the point 'P' to 'O', the origin of the axes system.

1 - 27 Computer Aided Design and Manufacturing

Introduction](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-39-2048.jpg)

![ii) Rotate the object by the given angle 'q'.

iii) Translate the point back to its original position from origin.

· The following homogeneous transformation matrices should be used for the

translation operation,

i) Translate the point from point 'P' to origin 'O'

[T ]

1 = [T] =

1 0 0

0 1 0

1

- -

é

ë

ê

ê

ê

ù

û

ú

ú

ú

D D

X Y

ii) Rotate the object by the given angle 'q'.

[T ]

2 = [T ]

R =

cos sin

sin cos

q q

q q

0

0

0 0 1

-

é

ë

ê

ê

ê

ù

û

ú

ú

ú

iii) Translate the point back to its original position from origin.

[T ]

3 = [T] =

1 0 0

0 1 0

1

D D

X Y

é

ë

ê

ê

ê

ù

û

ú

ú

ú

iv) Final Transformation matrix after concatenation,

[T] = [T ] [T ] [T ]

1 2 3

´ ´

1 - 28 Computer Aided Design and Manufacturing

Introduction

A

X

Y

r

r

P'

P

O

Y

X

Fig. 1.9.7 Rotation of an object about an arbitrary point](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-40-2048.jpg)

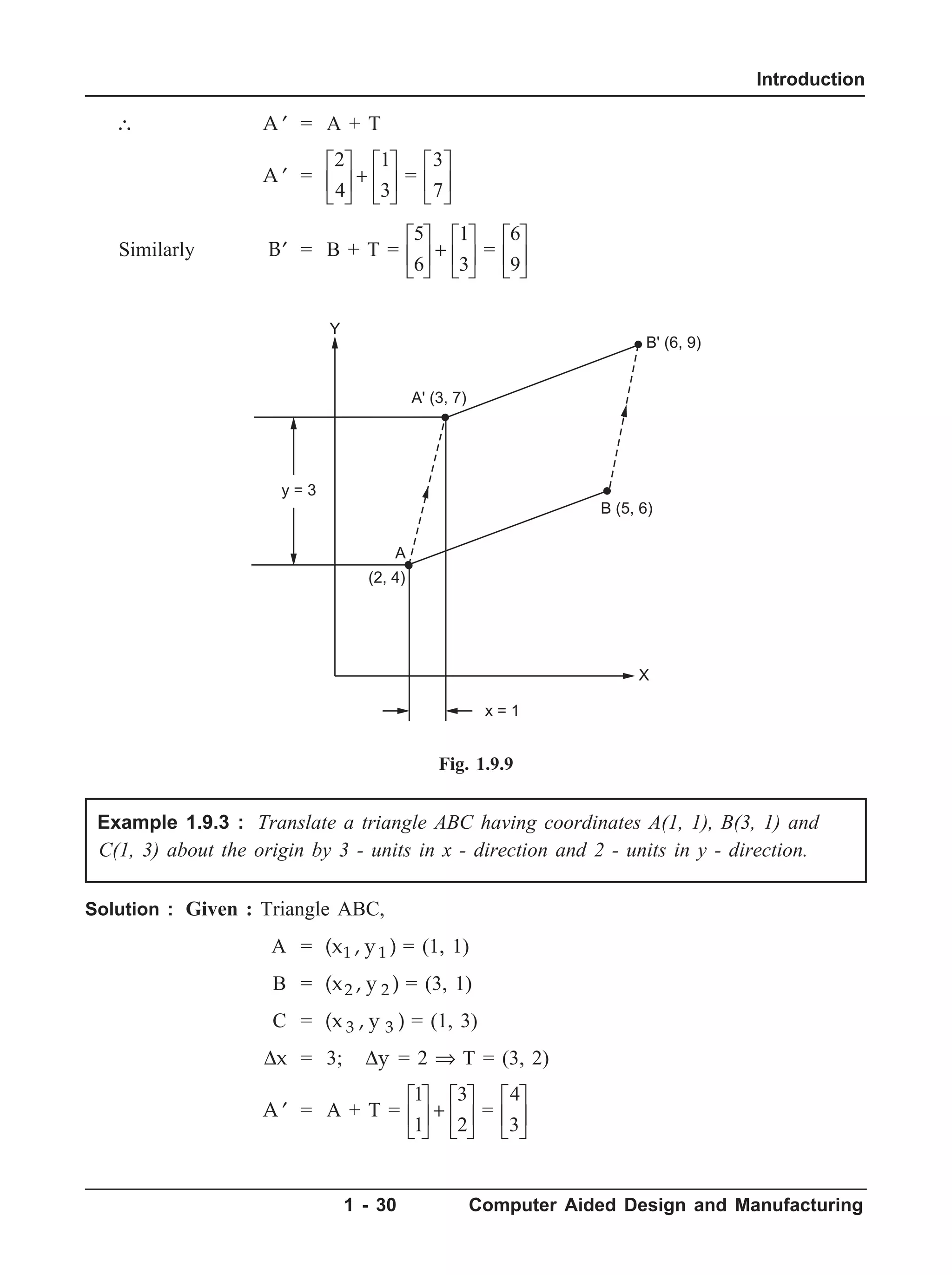

![¢

B = B + T =

3

1

3

2

é

ë

ê

ù

û

ú +

é

ë

ê

ù

û

ú =

6

3

é

ë

ê

ù

û

ú

¢

C = C + T =

1

3

3

2

é

ë

ê

ù

û

ú +

é

ë

ê

ù

û

ú =

4

5

é

ë

ê

ù

û

ú

Example 1.9.4 : A rectangular lamina ABCD having co-ordinates A(2, 2), B(4, 2),

C(4, 5) and D(2, 5) is translated by 4 units in x - direction and 4 units in y - direction.

Find out the translated coordinates and plot the rectangle before and after translation.

Solution : Given : Rectangle ABCD,

A (2, 2) = (x , y )

1 1

B (4, 2) = (x , y )

2 2

C (4, 5) = (x , y )

3 3

D (2, 5) = (x , y )

4 4

Dx = 4; Dy = 4 Þ T( , )

D D

x y = (4, 4)

[A] = [A] + [T] =

2

2

4

4

é

ë

ê

ù

û

ú +

é

ë

ê

ù

û

ú =

6

6

é

ë

ê

ù

û

ú

[B ]

¢ = [B] + [T] =

4

2

4

4

é

ë

ê

ù

û

ú +

é

ë

ê

ù

û

ú =

8

6

é

ë

ê

ù

û

ú

1 - 31 Computer Aided Design and Manufacturing

Introduction

x = 3

y = 2

C (1, 3)

A' (4, 3)

B (3, 1)

A (1, 1)

B' (6, 3)

C' (4, 5)

X

Y

Fig. 1.9.10](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-43-2048.jpg)

![[C ]

¢ = [C] + [T] =

4

5

4

4

é

ë

ê

ù

û

ú +

é

ë

ê

ù

û

ú =

8

9

é

ë

ê

ù

û

ú

[D ]

¢ = [D] + [T] =

2

5

4

4

é

ë

ê

ù

û

ú +

é

ë

ê

ù

û

ú =

6

9

é

ë

ê

ù

û

ú

Example 1.9.5 : A polygon ABCD is having the coordinates A(2, 3), B(6, 3), C(6, 6),

D(2, 6). Scale the polygon by 2 units along x-axis and y-axis.

Solution : Given :

Polygon ABCD ® A(x , y )

1 1 = (2, 3)

B(x , y )

2 2 = (6, 3)

C(x , y )

3 3 = (6, 6)

D(x , y )

4 4 = (2, 6)

Scaling factor ® S = (S ,S )

x y = (2, 2)

Scaling matrix, [S] =

S 0

0 S

x

y

é

ë

ê

ù

û

ú =

2 0

0 2

é

ë

ê

ù

û

ú

1 - 32 Computer Aided Design and Manufacturing

Introduction

(6, 9)

(6, 6)

C' (8, 9)

x = 4

(2, 5)

(2, 2)

C (4, 5)

B (4, 2)

A

D

(8, 6)

B'

D'

y = 4

A'

X

Y

Fig. 1.9.11](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-44-2048.jpg)

![[A]¢ = [S] ´ [A]

=

2 0

0 2

2

3

é

ë

ê

ù

û

ú ´

é

ë

ê

ù

û

ú =

4

6

é

ë

ê

ù

û

ú

[B]¢ = [S] ´ [B] Þ

=

2 0

0 2

6

3

é

ë

ê

ù

û

ú ´

é

ë

ê

ù

û

ú =

12

6

é

ë

ê

ù

û

ú

[C]¢ = [S] ´ [C]

=

2 0

0 2

6

6

é

ë

ê

ù

û

ú ´

é

ë

ê

ù

û

ú =

12

12

é

ë

ê

ù

û

ú

[D]¢ = [S] ´ [D]

=

2 0

0 2

2

6

é

ë

ê

ù

û

ú ´

é

ë

ê

ù

û

ú =

4

12

é

ë

ê

ù

û

ú

1 - 33 Computer Aided Design and Manufacturing

Introduction

X

Y

A (2, 3)

D (2, 6)

A' (4, 6)

C (6, 6)

B' (12, 6)

C' (12, 12)

D' (4, 12)

B (6, 3)

Fig. 1.9.12](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-45-2048.jpg)

![Example 1.9.6 : Rotate the point P(6, 8) about the origin at an angle 30 ° in

anti-clock wise direction and obtain the new position of the point.

Solution : Given

P(x , y )

1 1 = (6, 8) ; q = 30°

¢

P =

¢

¢

é

ë

ê

ù

û

ú

x

y

1

1

=

cos sin

sin cos

q q

q q

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

x

y

1

1

=

cos sin

sin cos

30 30

30 30

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

6

8

Þ [P ]

¢ =

1.196

9.928

é

ë

ê

ù

û

ú

Example 1.9.7 : A triangle ABC, A(5, 2), B(3, 5), C(7, 5). Find the transformed

position if,

i) The triangle is rotated by 45 ° in clockwise direction.

ii) The triangle is rotated by 60 ° in anti-clockwise direction.

Solution : Given : DABC Þ A(5, 2)

(x , y )

,

B(3, 5)

(x , y )

,

C(7, 5)

(x , y )

1 1 2 2 3 3

i) Rotated by 45 ° in clockwise direction :

q = – 45°

[A]¢ =

¢

¢

é

ë

ê

ù

û

ú

x

y

1

1

=

cos( ) sin( )

sin( ) cos( )

- ° - - °

- ° - °

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

45 45

45 45

5

2ú

1 - 34 Computer Aided Design and Manufacturing

Introduction

Y

X

30° =

P' (1.196, 9.28)

P(6, 8)

Fig. 1.9.13](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-46-2048.jpg)

![Þ [A]¢ =

4.97

2.12

-

é

ë

ê

ù

û

ú

Similarly, [B]¢ =

¢

¢

é

ë

ê

ù

û

ú

x

y

2

2

=

cos( ) sin( )

sin( ) cos( )

- ° - - °

- ° - °

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

45 45

45 45

3

5ú

Þ [B]¢ =

5.65

1.41

é

ë

ê

ù

û

ú

Similarly, [C]¢ =

¢

¢

é

ë

ê

ù

û

ú

x

y

3

3

=

cos( ) sin( )

sin( ) cos( )

- ° - - °

- ° - °

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

45 45

45 45

7

5ú

Þ [C]¢ =

8.48

1.414

-

é

ë

ê

ù

û

ú

ii) Rotated by 60° in anticlockwise direction (counter-clockwise) :

q = 60°

[A]¢¢ =

¢¢

¢¢

é

ë

ê

ù

û

ú

x

y

1

1

=

cos sin

sin cos

60 60

60 60

5

2

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

Þ [A]¢¢ =

0.767

5.330

é

ë

ê

ù

û

ú

Similarly, [B]¢¢ =

¢¢

¢¢

é

ë

ê

ù

û

ú

x

y

2

2

=

cos sin

sin cos

60 60

60 60

3

5

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

Þ [B]¢¢ =

-

é

ë

ê

ù

û

ú

2.830

5.098

Similarly, [C]¢¢ =

¢¢

¢¢

é

ë

ê

ù

û

ú

x

y

3

3

=

cos sin

sin cos

60 60

60 60

7

5

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

Þ [C]¢¢ =

-

é

ë

ê

ù

û

ú

0.83

8.562

1 - 35 Computer Aided Design and Manufacturing

Introduction](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-47-2048.jpg)

4 4 :

x4 = – 10 cos 60

= – 5 units

1 - 37 Computer Aided Design and Manufacturing

Introduction

Y

A (0, 0)

X

y2

x2

l = 10

30°

(x , y )

2 2

B

Fig. 1.9.16

Y

A (0, 0)

X

y2

x2

(x , y )

2 2

(x , y )

3 3

10 sin 60

B

60°

30°

30°

l = 10

10 cos 60

Fig. 1.9.17

Y

X

l=10 10 sin 60

– 10 cos 60

D(x , y )

4 4

60°

Fig. 1.9.18](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-49-2048.jpg)

![y 4 = 10 sin 60 = 8.66 units

D(x , y )

4 4 = (– 5, 8.66)

i) Rotate the square by 30° clockwise :

q = – 30°

[A]¢ =

cos( ) sin( )

sin( ) cos( )

- - -

- -

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

30 30

30 30

0

0

=

0

0

é

ë

ê

ù

û

ú

[B]¢ =

cos( ) sin( )

sin( ) cos( )

- - -

- -

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

30 30

30 30 5

8.66

=

9.99 ~ 10

0.0001~ 0

é

ë

ê

ù

û

ú

Þ [B]¢ =

10

0

é

ë

ê

ù

û

ú

[C]¢ =

cos( ) sin( )

sin( ) cos( )

- - -

- -

é

ë

ê

ù

û

ú

é

ë

30 30

30 30

3.66

13.66

ê

ù

û

ú =

10

10

é

ë

ê

ù

û

ú

[D]¢ =

cos( ) sin( )

sin( ) cos( )

- - -

- -

é

ë

ê

ù

û

ú

-

é

ë

ê

ù

û

30 30

30 30

5

8.66ú =

0

10

é

ë

ê

ù

û

ú

iii) Square is rotated by 60° in counter clockwise direction :

q = 60°

[A]¢¢ =

cos sin

sin cos

60 60

60 60

0

0

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú =

0

0

é

ë

ê

ù

û

ú

[B]¢¢ =

cos sin

sin cos

60 60

60 60

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

8.66

5

=

0

10

é

ë

ê

ù

û

ú

[C]¢¢ =

cos sin

sin cos

60 60

60 60

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

3.66

13.66

=

-

é

ë

ê

ù

û

ú

10

10

[D]¢¢ =

cos sin

sin cos

60 60

60 60

5

-

é

ë

ê

ù

û

ú

-

é

ë

ê

ù

û

ú

8.66

=

-

é

ë

ê

ù

û

ú

10

0

1 - 38 Computer Aided Design and Manufacturing

Introduction](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-50-2048.jpg)

![Example 1.9.9 : For a planar lamina ABCD with A(3, 5), B(2, 2), C(8, 2) and D(4, 5)

in XY plane with point P(4, 3) in the inetrior is to be

i) Translated by a translation matrix [T] =

8

5

é

ë

ê

ù

û

ú

ii) Rotated by 60° in counter clockwise direction.

1 - 39 Computer Aided Design and Manufacturing

Introduction

60° 30°

D''

(–10, 0)

B' (10, 0)

C' (10, 10)

C

(3.66, 13.66)

C"

(–10, 10) D' B''

(0, 10)

B

A (0, 0)

A', A"

Fig. 1.9.19

A (3, 5) D(4, 5)

P

(4, 3)

B (2, 2) C (8, 2)

Fig. 1.9.20](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-51-2048.jpg)

![Sol. : i) Translation :

[T] =

D

D

x

y

é

ë

ê

ù

û

ú =

8

5

é

ë

ê

ù

û

ú

Dx = 8; Dy = 5

[A]¢ =

x

y

x

y

1

1

é

ë

ê

ù

û

ú +

é

ë

ê

ù

û

ú

D

D

=

3

5

8

5

é

ë

ê

ù

û

ú +

é

ë

ê

ù

û

ú =

11

10

é

ë

ê

ù

û

ú

[B]¢ =

x

y

x

y

2

2

é

ë

ê

ù

û

ú +

é

ë

ê

ù

û

ú

D

D

=

2

2

8

5

é

ë

ê

ù

û

ú +

é

ë

ê

ù

û

ú =

10

7

é

ë

ê

ù

û

ú

[C]¢ =

x

y

x

y

3

3

é

ë

ê

ù

û

ú +

é

ë

ê

ù

û

ú

D

D

=

8

2

8

5

é

ë

ê

ù

û

ú +

é

ë

ê

ù

û

ú =

16

7

é

ë

ê

ù

û

ú

[D]¢ =

x

y

x

y

4

4

é

ë

ê

ù

û

ú +

é

ë

ê

ù

û

ú

D

D

=

4

5

8

5

é

ë

ê

ù

û

ú +

é

ë

ê

ù

û

ú =

12

10

é

ë

ê

ù

û

ú

[P]¢ =

4

3

x

y

é

ë

ê

ù

û

ú +

é

ë

ê

ù

û

ú

D

D

=

4

3

8

5

é

ë

ê

ù

û

ú +

é

ë

ê

ù

û

ú =

12

8

é

ë

ê

ù

û

ú

ii) Rotate through 60° in counter clockwise direction :

q = 60°

[A]¢¢ =

cos sin

sin cos

60 60

60 60

3

5

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú =

-

é

ë

ê

ù

û

ú

2.83

5.09

[B]¢¢ =

cos sin

sin cos

60 60

60 60

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

2

2

=

-

é

ë

ê

ù

û

ú

0.732

2.732

[C]¢¢ =

cos sin

sin cos

60 60

60 60

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

8

2

=

2.26

7.93

é

ë

ê

ù

û

ú

[D]¢¢ =

cos sin

sin cos

60 60

60 60

4

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

5

=

-

é

ë

ê

ù

û

ú

2.33

5.96

[P]¢¢ =

cos sin

sin cos

60 60

60 60

4

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

3

=

-

é

ë

ê

ù

û

ú

0.59

4.96

1 - 40 Computer Aided Design and Manufacturing

Introduction](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-52-2048.jpg)

![Example 1.9.10 : Derive an appropriate 2D transformation method to reflect the

rectangle ABCD, A(3, 4), B(7, 4), C(7, 6), D(3, 6). Reflect about i) X-axis, ii) Y-axis.

Solution : i) For reflection about X-axis :

[A]¢ =

1 0

0 1

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

x

y

1

1

Þ [A]¢ =

1 0

0 1

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

3

4

=

3

4

-

é

ë

ê

ù

û

ú

[B]¢ =

1 0

0 1

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

7

4

=

7

4

-

é

ë

ê

ù

û

ú

[C]¢ =

1 0

0 1

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

7

6

=

7

6

-

é

ë

ê

ù

û

ú

[D]¢ =

1 0

0 1

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

3

6

=

3

6

-

é

ë

ê

ù

û

ú

1 - 42 Computer Aided Design and Manufacturing

Introduction

A

(3, 4)

B

D' C'

(7, 4)

(3, – 6) (7, – 6)

D

(3, 6)

C

(7, 6)

A'

(3, – 4) B'(7, – 4)

X

Y

Y

X

Fig. 1.9.22](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-54-2048.jpg)

![ii) Reflection about Y-axis :

[A]¢ =

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

1 0

0 1

x

y

1

1

Þ [A]¢ =

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

1 0

0 1

3

4

=

-

é

ë

ê

ù

û

ú

3

4

[B]¢ =

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

1 0

0 1

7

4

=

-

é

ë

ê

ù

û

ú

7

4

[C]¢ =

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

1 0

0 1

7

6

=

-

é

ë

ê

ù

û

ú

7

6

[D]¢ =

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

1 0

0 1

3

6

=

-

é

ë

ê

ù

û

ú

3

6

iii) About origin :

[A]¢¢¢ =

-

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

1 0

0 1

x

y

1

1

1 - 43 Computer Aided Design and Manufacturing

Introduction

(–7, 6)

D''(–3, 6) D(3, 6)

A''(–3, 4)

(–7, 4)

A(3, 4) B(7, 4)

C(7, 6)

X

Y

Y

X

C''

B''

Fig. 1.9.23](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-55-2048.jpg)

![Þ [A]¢¢¢ =

-

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

1 0

0 1

3

4

=

-

-

é

ë

ê

ù

û

ú

3

4

[B]¢¢¢ =

-

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

1 0

0 1

7

4

=

-

-

é

ë

ê

ù

û

ú

7

4

[C]¢¢¢ =

-

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

1 0

0 1

7

6

=

-

-

é

ë

ê

ù

û

ú

7

6

[D]¢¢¢ =

-

-

é

ë

ê

ù

û

ú

é

ë

ê

ù

û

ú

1 0

0 1

3

6

=

-

-

é

ë

ê

ù

û

ú

3

6

2-D Transformation Problems based on Homogeneous Coordinate System

(Concatenation)

Example 1.9.11 : A rectangle ABCD has coordinates A(2, 3), B(6, 3), C(6, 6) and

D(2, 6). Calculate the combined transformation matrix (concatenation) for the following

operations. Also find the resultant coordinates.

i) Translation by 2 units in x - direction and 3 units in y - direction.

ii) Scaling by 4 - units in x - direction and 2 - units in y - direction.

iii) Rotation by 30 ° in counter clockwise direction about z - axis, passing through a

point (3, 3).

1 - 44 Computer Aided Design and Manufacturing

Introduction

C''' (–7,–6) D''' (–3,–6)

B''' (–7,–4) A''' (–3,–4)

A

(3, 4) B (7, 4)

D

(3, 6) C (7, 6)

X

Y

O

Y

X

Fig. 1.9.24](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-56-2048.jpg)

2 3 =

1 0 0

0 1 0

2 3 0

é

ë

ê

ê

ê

ù

û

ú

ú

ú

ii) Scaling matrix in homoeneous form,

[ ]

' S '

( , )

4 2 Given, Sx = 4

Sy = 2

[S]( , )

4 2 =

4 0 0

0 2 0

0 0 1

é

ë

ê

ê

ê

ù

û

ú

ú

ú

iii) Rotation matrix in homoeneous form,

[R]Þ at point (3, 3)

Note : In normal cases rotation is done with suspect to origin.

· But in this problem rotation has to be made at point (3, 3), which is not possible

by normal method.

· Therefore, initially the rectangle will be tanslated to origin, it will be rotated at

origin.

· After rotating at origin, the retangle will be translated back to point (3, 3).

Procedure for rotation at (3, 3)

Step 1 : Translate rectangle ABCD at origin [T ]

1 .

Step 2 : Rotate rectangle ABCD at origin [T ]

11 .

Step 3 : Translate rectangle ABCD from origin [T ]

111 to point [3, 3].

Step 4 : Final rotation matrix [R] = [ ] [ ] [ ]

T T T

1 11 111

´ ´

1 - 45 Computer Aided Design and Manufacturing

Introduction](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-57-2048.jpg)

![Step 1 : Translation matrix for translating ABCD to origin form point (3, 3) [T ]

I

Here, DxI = – 3, DyI = – 3

[TI ] =

1 0 0

0 1 0

1

1 0 0

0 1 0

3 3 1

D D

x y

I I

é

ë

ê

ê

ê

ù

û

ú

ú

ú

é

ë

ê

ê

ê

ù

û

ú

ú

ú

– –

Step 2 : Rotate rectangle ABCD at origin [T ]

II .

Here, q = 30° (counter - clockwise)

[TII ] =

cos sin

– sin cos

cos sin

– sin

q q

q q

0

0

0 1

30 30 0

30

0

é

ë

ê

ê

ê

ù

û

ú

ú

ú

= cos30 0

0 0 1

é

ë

ê

ê

ê

ù

û

ú

ú

ú

Þ [T] =

0866 0 5 0

0 5 0866 0

0 0 1

. .

– . .

é

ë

ê

ê

ê

ù

û

ú

ú

ú

Step 3 : Translate ABCD from origin to (3, 3) [T]III

Here DxIII = 3 ; DyIII = 3

[T]III =

1 0 0

0 1 0

1

D D

x y

III III

é

ë

ê

ê

ê

ù

û

ú

ú

ú

é

ë

ê

ê

ê

ù

û

ú

ú

ú

1 0 0

0 1 0

3 3 1

Rotation matrix at (3, 3) in homogeneous form Þ [R]

[R] = [T] [T]

I II III

´ ´

[ ]

T

=

1 0 0

0 1 0

3 3 1

0866 0 5 0

0 5 0866 0

0 0 1

– –

. .

– . .

é

ë

ê

ê

ê

ù

û

ú

ú

ú

´

é

ë

ê

ê

ê

ù

û

ú

ú

ú

´

é

ë

ê

ê

ê

ù

û

ú

ú

ú

1 0 0

0 1 0

3 3 1

Þ [R] =

0.866 0.5 0

–0.5 0.866 0

1. 902 – 1.908 1

é

ë

ê

ê

ê

ù

û

ú

ú

ú

So we obtained all the three matrixes for evaluating the combined matrix [ ]

m

[T](2,3) =

1 0 0

0 1 0

2 3 0

é

ë

ê

ê

ê

ù

û

ú

ú

ú

1 - 46 Computer Aided Design and Manufacturing

Introduction](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-58-2048.jpg)

=

4 0 0

0 2 0

0 0 1

é

ë

ê

ê

ê

ù

û

ú

ú

ú

[R]( = 30 )

q ° =

0866 0 5 0

0 5 0866 0

1902 1098 1

. .

– . .

. – .

é

ë

ê

ê

ê

ù

û

ú

ú

ú

Combined transformation matrix [ ]

Tc

[ ]

Tc = [T] [S] [R]

(2,3) (4,2) ( = 30 )

´ ´ °

q

=

1 0 0

0 1 0

2 3 0

4 0 0

0 2 0

0 0 1

0866 0 5 0

é

ë

ê

ê

ê

ù

û

ú

ú

ú

´

é

ë

ê

ê

ê

ù

û

ú

ú

ú

´

. .

–0 5 0866 0

1902 1098 1

. .

. – .

é

ë

ê

ê

ê

ù

û

ú

ú

ú

Þ [T ]

c =

3.464 2 0

–1 1.732 0

5.93 8.098 1

é

ë

ê

ê

ê

ù

û

ú

ú

ú

To find the resultant co-ordinates after combined transformations operations.

Given, A B C D Þ A (x , y )

1 1 = (2, 3)

B (x , y )

2 2 = (6, 3)

C (x , y )

3 3 = (6, 6)

D (x , y )

4 4 = (2, 6)

Coordinates an homogeneous form,

A

B

C

D

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

=

x y

x y

x y

x y

1 1

2 2

3 3

4 4

1

1

1

1

2 3 1

6 3 1

6 6 1

2 6 1

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

=

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

Resultant co-ordinates (After transformation)

¢

¢

¢

¢

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

A

B

C

D

=

A

B

C

D

[Tc

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

´ ] =

2 3 1

6 3 1

6 6 1

2 6 1

3464 2 0

1 1732 0

593 8098 1

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

´

.

– .

. .

é

ë

ê

ê

ê

ù

û

ú

ú

ú

1 - 47 Computer Aided Design and Manufacturing

Introduction

4 × 3 × 3 × 3](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-59-2048.jpg)

![· In this problem rectangle ABCD has to scaled to 3/4 of its size.

Sx = 0.75 and Sy = 0.75

· Scaling has to be done such that centre point (4, 4.5) remains at same position.

· This is not possible by normal means of scaling operation.

· Here scaling can be performed only with repect to origin.

· So initially translate ABCD to orgin, perform scaling at origin and translate back

to point (4, 4.5).

Procedure for performing scaling at (4, 4.5)

Step 1 : Translate ABCD from (4, 4.5) to origin (0, 0) [TI ]

Step 2 : Scale ABCD at orgin (0, 0) [TII ]

Step 3 : Translate ABCD from orgin (0, 0) and point (4, 4.5) [T ]

III

Step 4 : Evaluate scaling matrix [S]

[ ]( . , . )

S 0 75 0 75 = [T ] [T ] [T ]

I II III

´ ´

Step 5 : Find out the resultant co-ordinates after scaling.

Step 1 : Translate ABCD from (4, 4.5) to (0, 0)

Here, DxI = –4 and DyI = – 4.5

[ ]

TI in homogeneous form,

[TI ] =

1 0 0

0 1 0

0

D D

x y

I I

é

ë

ê

ê

ê

ù

û

ú

ú

ú - -

é

ë

ê

ê

ê

ù

û

ú

ú

ú

1 0 0

0 1 0

4.5 4.5 1

Step 2 : Scaling to

3

4

of its size at origin (0,0)

Here, Sx = 0.75; Sy = 0.75

[S] in homogeneous form,

[TII ] =

S

S

0 0

0.75 0 0

0 0.75 0

0 0 1

x

y

0 0

0 0

1

é

ë

ê

ê

ê

ù

û

ú

ú

ú

=

é

ë

ê

ê

ê

ù

û

ú

ú

ú

Step 3 : Translation of ABCD to (4, 4.5) from (0, 0) [T]III

Here Dx = 4 ; Dy = 4.5

1 - 49 Computer Aided Design and Manufacturing

Introduction](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-61-2048.jpg)

![[T]III =

1 0 0

0 1 0

1

D D

x y

é

ë

ê

ê

ê

ù

û

ú

ú

ú

=

é

ë

ê

ê

ê

ù

û

ú

ú

ú

1 0 0

0 1 0

4 4.5 1

Final scaling matrix [S] 3

4

,

3

4

æ

è

ç

ö

ø

÷

[S] = [T ] T [T ]

I II III

´ ´

[ ]

=

1 0 0

0 1 0

–4 –4.5 1

0.75 0 0

–0.5 0.75 0

0 0 1

é

ë

ê

ê

ê

ù

û

ú

ú

ú

´

é

ë

ê

ê

ê

ù

û

ú

ú

ú

´

é

ë

ê

ê

ê

ù

û

ú

ú

ú

1 0 0

0 1 0

4 4.5 1

Þ [

,

S] 3

4

3

4

æ

è

ç

ö

ø

÷

=

0.75 0 0

0 0.75 0

1 1.125 1

é

ë

ê

ê

ê

ù

û

ú

ú

ú

Resultant Co-ordinates

Given, A (x , y )

1 1 = (2, 3)

B (x , y )

2 2 = (6, 3)

C (x , y )

3 3 = (6, 6)

D (x , y )

4 4 = (2, 6)

ABCD in homogeneous form,

A

B

C

D

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

=

x y

x y

x y

x y

1 1

2 2

3 3

4 4

1

1

1

1

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

=

é

ë

ê

ê

ê

2 3 1

6 3 1

6 6 1

2 6 1

ê

ù

û

ú

ú

ú

ú

Resultant Co-ordinates

¢

¢

¢

¢

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

A

B

C

D

=

A

B

C

D

[S

ì

í

ï

ï

î

ï

ï

ü

ý

ï

ï

þ

ï

ï

´ ]( / , / )

3 4 3 4

Þ

¢

¢

¢

¢

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

A

B

C

D

=

2 3 1

6 3 1

6 6 1

2 6 1

075 0 0

0 075 0

1 1125 1

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

´

é

ë

ê

ê

ê

ù

.

.

. û

ú

ú

ú

=

2.5 3.375 1

5.5 3.375 1

5.5 5.625 1

2.5 5.625 1

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

1 - 50 Computer Aided Design and Manufacturing

Introduction](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-62-2048.jpg)

![¢

A = (2.5, 3.375)

¢

B = (5.5, 3.375)

¢

C = (5.5, 5.625)

¢

D = (2.5, 5.625)

1.10 3D Transformations

· It is often necessary to display objects in

3-D on the graphics screen.

· The transformation matrices developed

for 2-dimensions can be extended to 3-D.

· Fig. 1.10.1 represents 3D translation of a

donut.

3D Translation

· 3D translation matrix is explained by,

[T] =

1 0 0 0

0 1 0 0

0 0 1 0

1

D D D

x y z

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

· D D

x y

, and Dy explains distance of translation along x, y and z direction

respectively.

1 - 51 Computer Aided Design and Manufacturing

Introduction

Y

X

D(2, 6)

D' (2.5, 5.625) C' (5.5, 5.625)

A' (2.5, 3.375) B' (5.5, 3.375)

C(6, 6)

A(2, 3) B(6, 3)

P (4, 4.5)

Fig. 1.9.26

Fig. 1.10.1.3D Translation of a donut](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-63-2048.jpg)

![3D Scaling

· 3D scaling matrix is explained by,

[ ]

Ts =

S

S

S

x

y

y

0 0 0

0 0 0

0 0 0

0 0 0 1

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

· S ,S and S

x y z represents the scaling factors along x, y and z direction

respectively.

3D Rotation

· 3D rotation matrices are given by,

i) Rotation along Z-axis by angle 'q'

[ ]

Rz =

cos

cos

1

q q

q q

sin

– sin

0 0

0 0

0 0 0

0 0 0 1

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

ii) Rotation along X-axis by angle 'f'

[ ]

Rx =

1

cos

cos

0 0 0

0 0

0 0

0 0 0 1

f f

f f

– sin

sin

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

iii) Rotation along X-axis by angle 'f'

[ ]

Ry =

cos

cos

f f

f f

0 0

0 1 0 0

0 0

0 0 0 1

sin

sin

é

ë

ê

ê

ê

ê

ù

û

ú

ú

ú

ú

1.11 Line Drawing + [AU : Dec.-16, May-18]

· Straight line segments are used a great deal in computer generated pictures.

· The following criteria have been stipulated for line drawing displays :

i) Lines should appear straight

ii) Lines should terminate accurately

iii) Lines should have constant density

iv) Line density should be independent of length and angle

v) Line should be drawn rapidly

1 - 52 Computer Aided Design and Manufacturing

Introduction](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-64-2048.jpg)

![· If ei < 0 ® Increment x by 1 and keep 'y' as it is.

· The results could be tabulated as below.

No. of Steps x y Error

0 3 3 0

1 4 4 –8

2 5 4 0

3 6 5 –8

4 7 5 0

5 8 6 – 8

6 9 6 0

7 10 7 – 8

8 11 7 0

Step 5 : Plot the points

1.12 Clipping + [AU : Dec.-16, 17]

· Various projections of an object's geometry can be defining views.

· A view requires a view window.

1 - 62 Computer Aided Design and Manufacturing

Introduction

0 1 2 3 4 5 6 7 8 9 10 11

1

2

3

4

5

6

7

Fig. 1.11.7](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-74-2048.jpg)

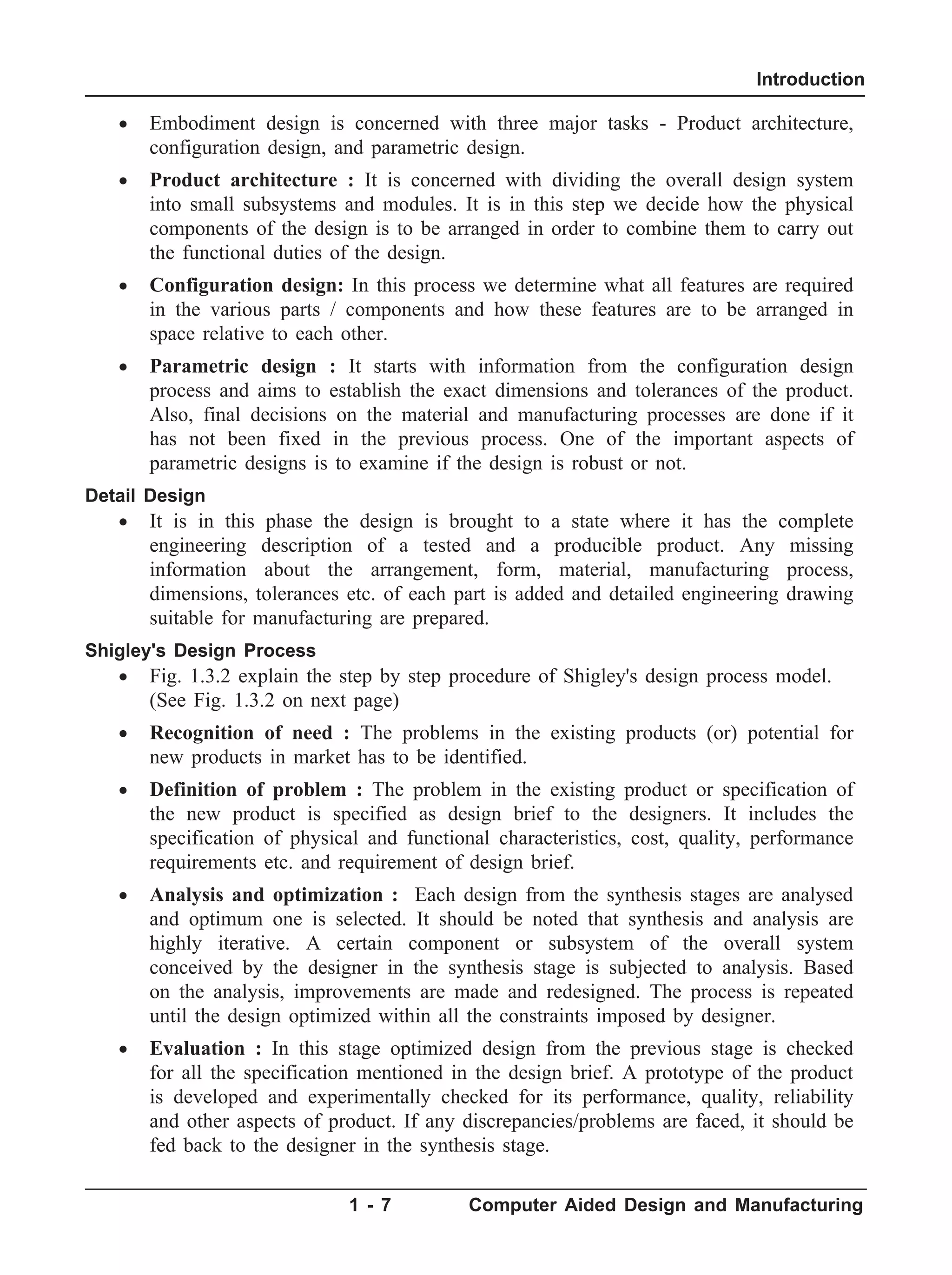

![v. Text Clipping

Text clipping can be of two types :

a) All or none string-clipping : In this

clipping as shown in figure, if all the

string is inside a clip window, it will

be kept. Otherwise, the string is

discarded.

b) All or none character-clipping : In this clipping as shown in figure, only those

characters that are not completely inside the window will be discarded.

1.13 Viewing Transformation + [AU : Dec.-16, May-18]

· The process that converts object coordinates in WCS to normalized device

coordinates is called window-to-view port mapping or normalization

transformation.

· The process that maps normalized device coordinates to discrete device / image

coordinates is called workstation transformation, which is essentially a second

window-to-view port mapping, with a workstation window in the normalized

device coordinate system and a workstation view port in the device coordinate

system.

· Collectively, these two coordinate-mapping operations are referred to as viewing

transformation.

· The step by step procedure for viewing transformation is shown in Fig. 1.13.1.

1 - 69 Computer Aided Design and Manufacturing

Introduction

STRING 1

STRING 2

Widow

Fig. 1.12.11 All or none string-clipping

STRING 1

STRING

2

Widow

ING 1

STRING 4

Widow

STRING 1 STRING 4 TRING 1

STR

Fig. 1.12.12 All or none character-clipping

2D Object

data

Window

transformation

Clipping

Computer

display

Frame

buffer

Scan

conversion

Visaport

transformation

Object

transformation

a b c

d

f e

Fig. 1.13.1 Viewing transformation](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-81-2048.jpg)

![· Inventory control is an important aspect for the growth of company.

· Stores inventory is the heart of an industry.

· Inventory control or stock control can be broadly defined as "the activity of

checking a shop's stock".

· Major field of application of inventory control :

· In operations management, logistics and supply chain management, the

technological system and the programmed software necessary for managing

inventory.

· In economics and operations management, the inventory control problem, which

aims to reduce overhead cost without hurting sales. It answers the 3 basic

questions of any supply chain : When ? Where ? How much ?

· In the field of loss prevention, systems designed to introduce technical barriers

to shoplifting.

(iii) Quality Control

· Quality control is a process by which entities review the quality of all factors

involved in production.

· Visual inspection is a major component of quality control, where a physical

product is examined visually and the inspectors will provide list of unacceptable

products with defects such as cracks or surface blemishes.

· ISO 9000 defines quality control as "A part of quality management focused on

fulfilling quality requirements". This approach places an emphasis on three

aspects,

i. Elements such as controls, job management, defined and well managed

processes, performance and integrity criteria, and identification of records.

ii. Competence, such as knowledge, skills, experience, and qualifications.

iii. Soft elements, such as personnel, integrity, confidence, organizational culture,

motivation, team spirit, and quality relationships.

1.16 Types of Production Systems + [AU : May-17]

The production system of an organization is that part, which produces products of an

organization. It is that activity whereby resources, flowing within a defined system are

combined and transformed in a controlled manner to add value in accordance with the

policies communicated by management.

The production system has the following characteristics :

· Production is an organized activity, so every production system has an objective.

· The system transforms the various inputs to useful outputs.

1 - 80 Computer Aided Design and Manufacturing

Introduction](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-92-2048.jpg)

![· Any fault in flow of production is immediately corrected otherwise it will stop

the whole production process.

Suitability of Flow/Mass Production :

· There must be continuity in demand for the product.

· The products, materials and equipment must be standardized because the flow of

line is inflexible.

· The operations should be well defined.

· It should be possible to maintain certain quality standards.

· It should be possible to find time taken at each operation so that flow of work is

standardized.

· The process of stages of production should be continuous.

Advantages of Mass Production

A properly planned flow production method, results in the following advantages :

· The product is standardized and any deviation in quality etc. is detected at the

spot.

· There will be accuracy in product design and quality.

· It will help in reducing direct labour cost.

· There will be no need of work-in-progress because products will automatically

pass on from operation to operation.

· Since flow of work is simplified there will be lesser need for control.

· A weakness in any operation comes to the notice immediately.

· There may not be any need of keeping work-in-progress, hence storage cost is

reduced.

1.17 Manufacturing Models and Metrics + [AU : Dec.-16, May-17]

· Manufacturing metrics are effectively utilized to quantitatively measure the

performance of a manufacturing company.

· It is used to track the performance of a company in successive periods

(eg. Months and years)

· It provides the facility to try new technologies and new systems to determine the

merits, identify problems with performance, compare alternate methods and make

good decisions.

· Manufacturing metrics can be divided into two basic categories :

a) Production performance measures

b) Manufacturing costs

1 - 84 Computer Aided Design and Manufacturing

Introduction](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-96-2048.jpg)

![homogeneous coordinate with an example of matrix. How may a general rotation

transformation be expressed in terms of a combination of other transformation.

19. What is meant by interactive computer graphics ? Explain its various elements

20. Briefly explain the clipping and line drawing with an example.

21. Explain and bring out their differences between CAD and CAM.

22. Explain break-even analysis.

23. Explain briefly the types of production systems.

24. Explain the manufacturing models and metrics in detail.

Part A : Two Marks Question with Answers

Q.1 State any two benefits of CAD. + [ AU : May 2017 ]

Ans. : · Efficiency, effectiveness and creativity of the designer are drastically improved.

· Faster, Consistent and More accurate.

· Easy modification (copy) and Improvement (Edit).

· Inspecting tolerance and interface is easy.

· Use of standard components from part library makes fast modeling.

· 3D visualization of model in several orientations eliminates prototype.

Q.2 What is concurrent engineering. + [ AU : Dec. 2016, May 2017 ]

Ans. : In concurrent engineering, various tasks are handled at the same time, and not

essentially in the standard order. This means that info found out later in the course can be

added to earlier parts, improving them, and also saving time. Concurrent engineering is a

method by which several groups within an organization work simultaneously to create new

products and services.

Q.3 What are the advantages of concurrent engineering ? + [ AU : May 2018 ]

Ans. : · Both product and process design run in parallel and take place in the same time.

· Process and Product are coordinated to attain optimal matching of requirements for

effective quality and delivery.

· Decision making involves full team involvement.

· Reduced lead times to market

· Reduced cost

· Higher quality

· Greater customer satisfaction

· Increased market share

1 - 104 Computer Aided Design and Manufacturing

Introduction](https://image.slidesharecdn.com/computeraideddesignandmanufacturing-230312165102-6775893a/75/Computer-Aided-Design-and-Manufacturing-pdf-116-2048.jpg)

![Q.4 What is meant by concatenation transformation ?

+ [ AU : Dec. 2018, May 2018 ]

Ans. : Sometimes it becomes necessary to combine the individual transformations in order to

achieve the required results. In such cases the combined transformation matrix can be obtained

by multiplying the respective transformation matrices as shown below,

[P ]

¢ = [T ] [T ] [T ]........[T ] [T ] [T ]

n n 1 n 2 3 2 1

- -

Q.5 List the various activities involved in product development.

+ [ AU : Dec. 2018 ]

Ans. : i. Design process

· Synthesis

· Analysis

ii. Manufacturing process.

· Process planning

· Process control

Q.6 What is meant by homogeneous coordinates? + [AU : Dec. 2016 ]

Ans. : · The three dimensional representation of a two dimensional plane is called

homogeneous coordinates and the transformation using the homogeneous co-ordinates is called

homogeneous transformation.

· In order to concatenate the transformation, all the transformation matrices should be

multiplicative type. The following form known as homogeneous form which should

be used to convert the translation matrix into a multiplicative type.

[P ]

¢ =

x

y

1

¢

¢

é

ë

ê

ê

ê

ù

û

ú

ú

ú

=

1 0 0

0 1 0

1

D D

X Y

x

y

1

é

ë

ê

ê

ê

ù

û

ú

ú

ú

é

ë

ê

ê

ê

ù

û

ú

ú

ú

Q.7 What do you mean by synthesis of design ? + [AU : Dec. 2016 ]

Ans. : · The philosophy, functionality, and uniqueness of the product are all determined during

synthesis.