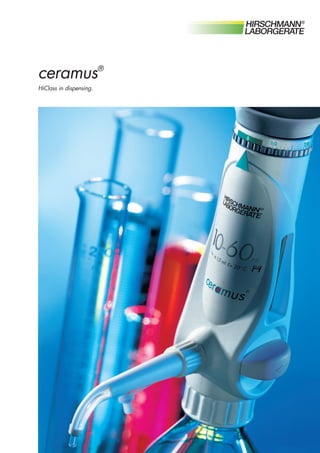

n Consistent and precise dispensing results are achieved through a ceramic piston, graduated gauge, and digital volumetric adjustment device calibrated for a lifetime.

n The device provides rapid, simple, safe, and reproducible volumetric adjustment from 0.2 ml to 60 ml for fixed and variable volumes.

n An individual certificate of quality is provided for each device to ensure the highest level of assurance in measurement results.