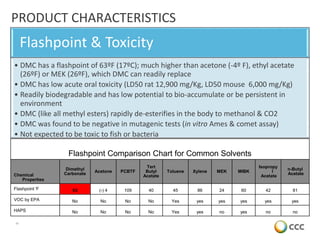

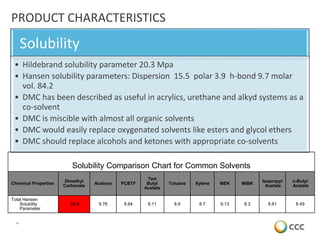

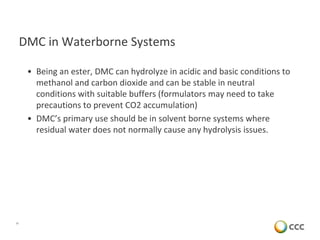

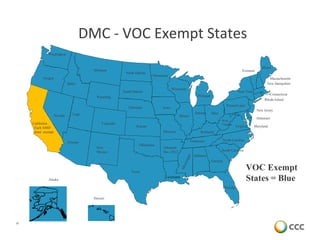

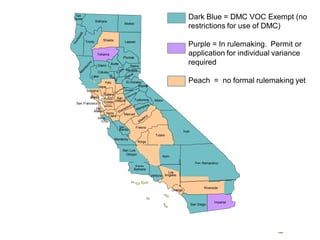

Dimethyl carbonate (DMC) is a VOC-exempt solvent with a history of development and safety recognition, characterized by its low toxicity and environmental friendliness. It is increasingly utilized in various applications, including coatings, inks, and as a biodiesel additive, being noted for its cost-effectiveness and favorable performance characteristics. The EPA classified DMC as a VOC exempt compound, leading to broad acceptance and usage across many states, although some regulatory steps remain in areas like California.