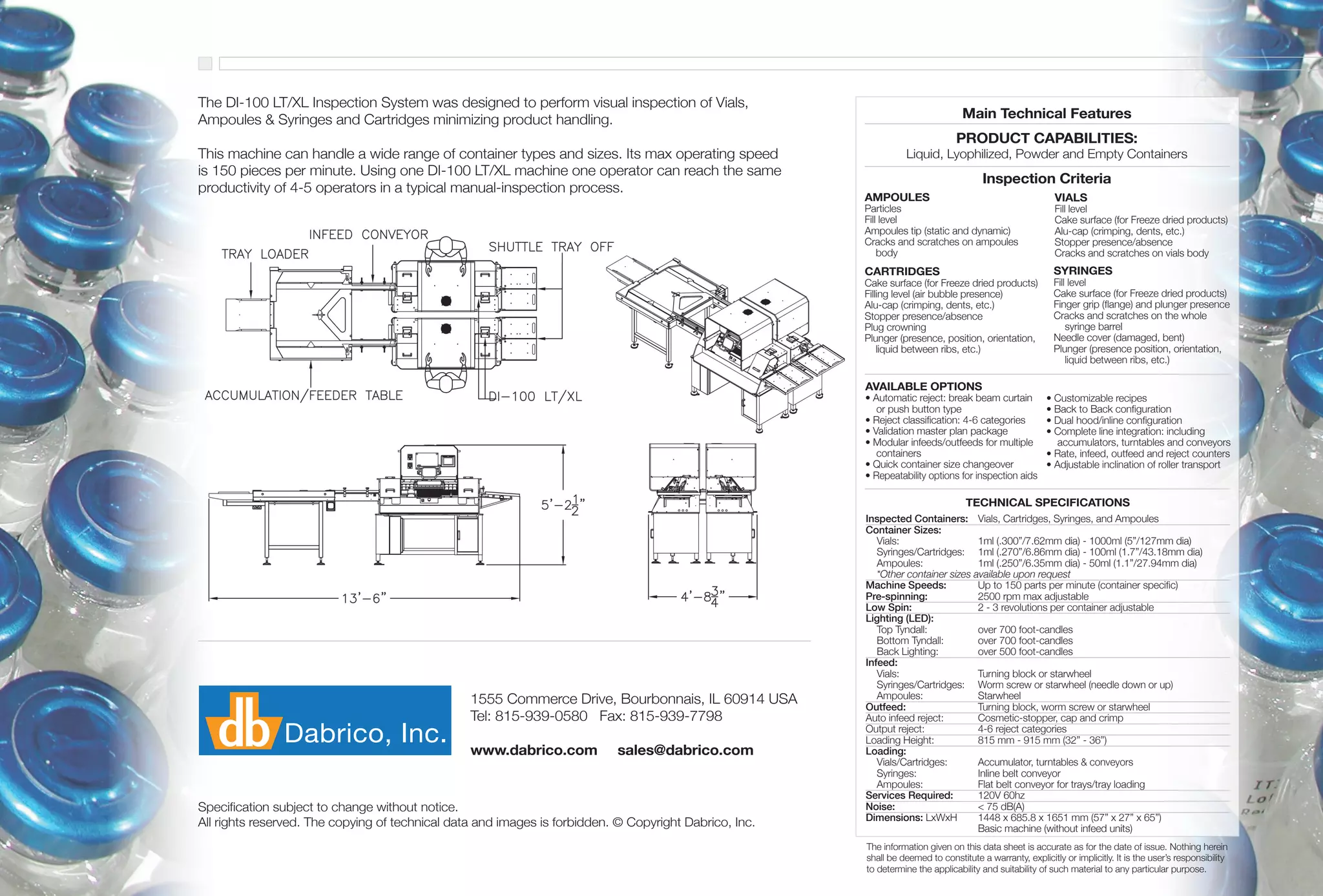

The DI-100 LT/XL inspection system can visually inspect vials, ampoules, syringes and cartridges at speeds up to 150 pieces per minute. It handles a wide range of container types and sizes from 1ml to 1000ml. Using one machine provides the same productivity as 4-5 manual inspectors. The machine inspects for particles, fill levels, cracks, scratches and other defects for different container types.