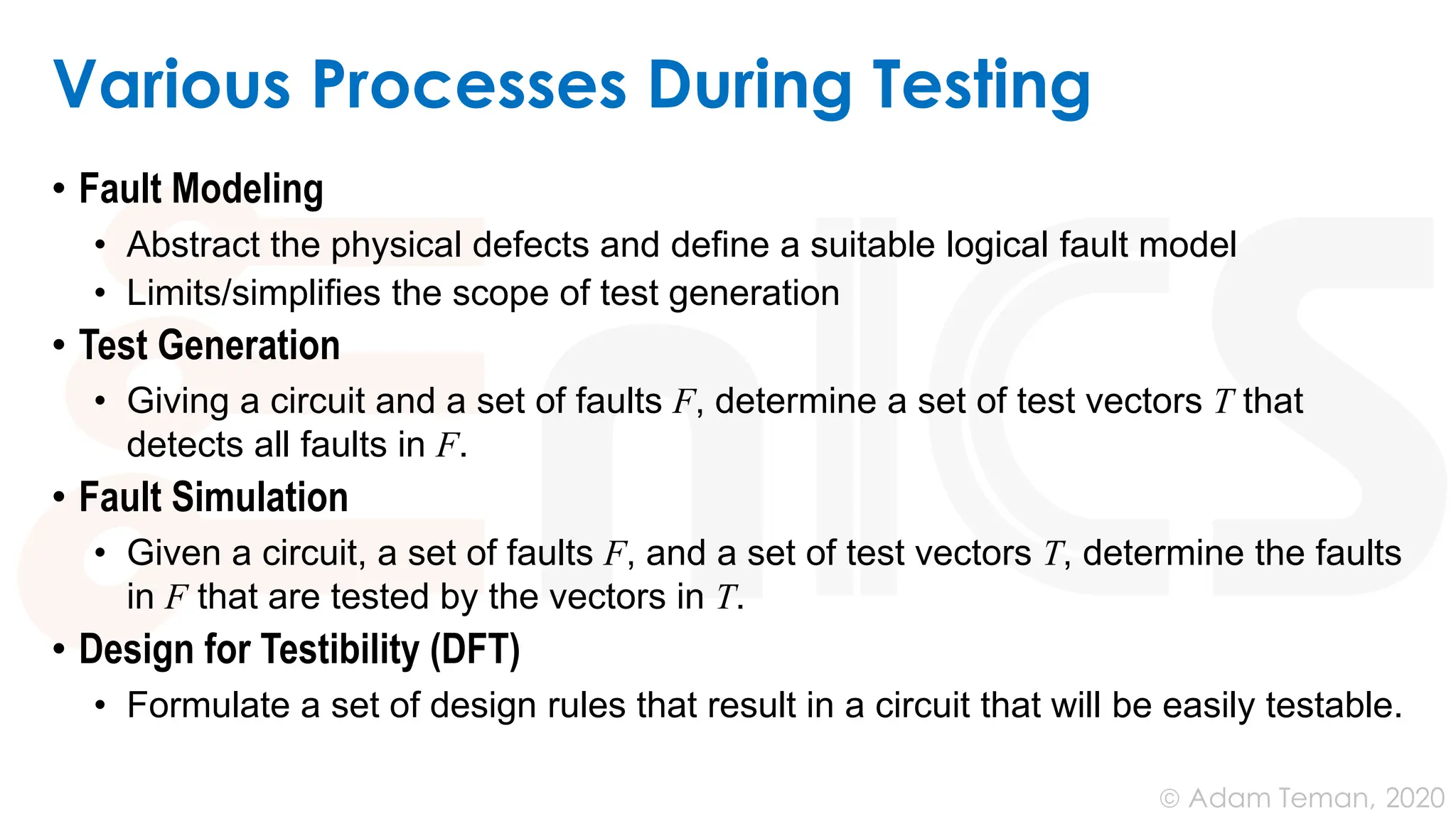

This document discusses design for test (DFT) and integrated circuit testing. It covers:

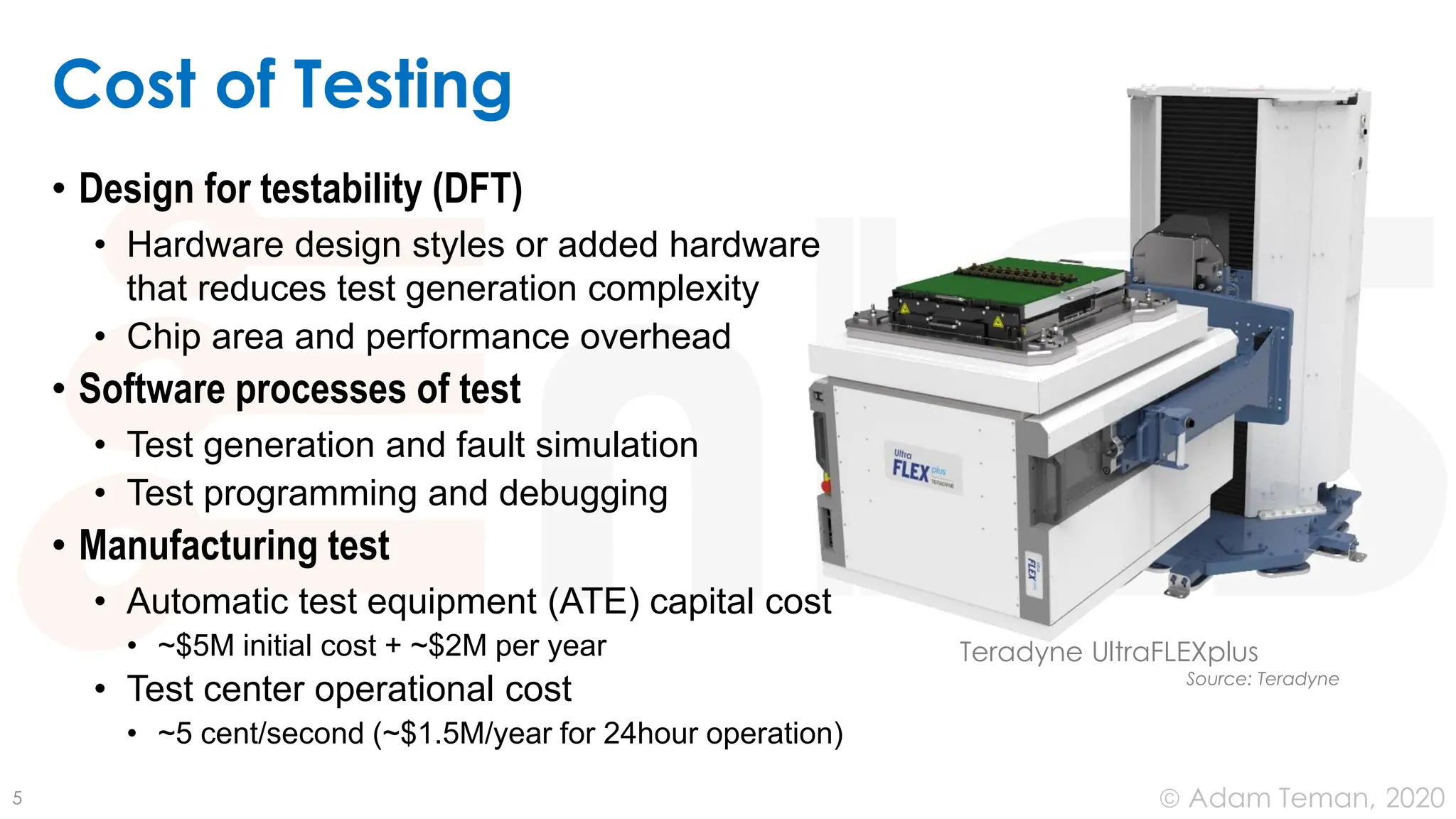

- The costs of testing including automatic test equipment, test generation software, and the high costs of defects found after manufacturing.

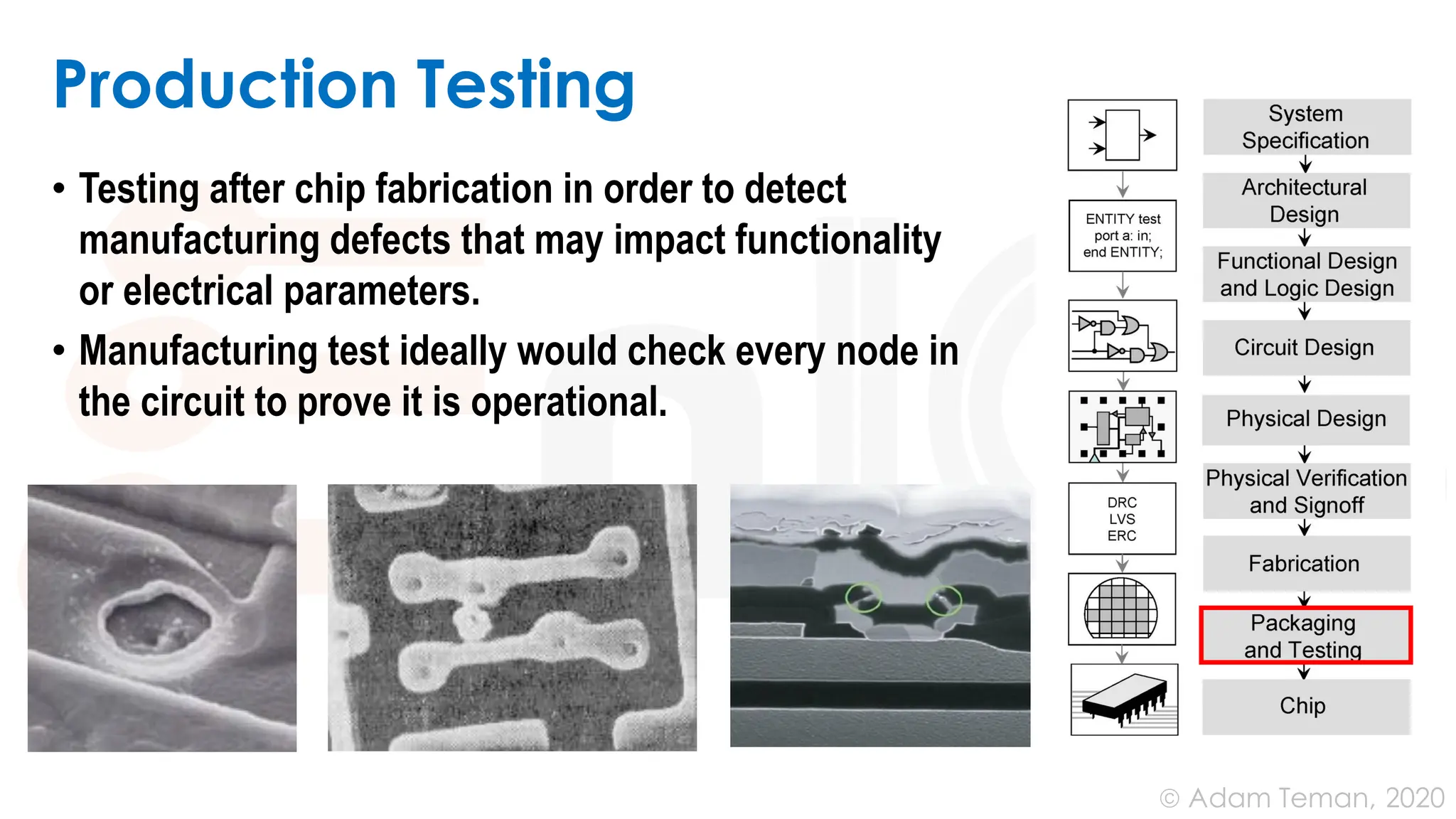

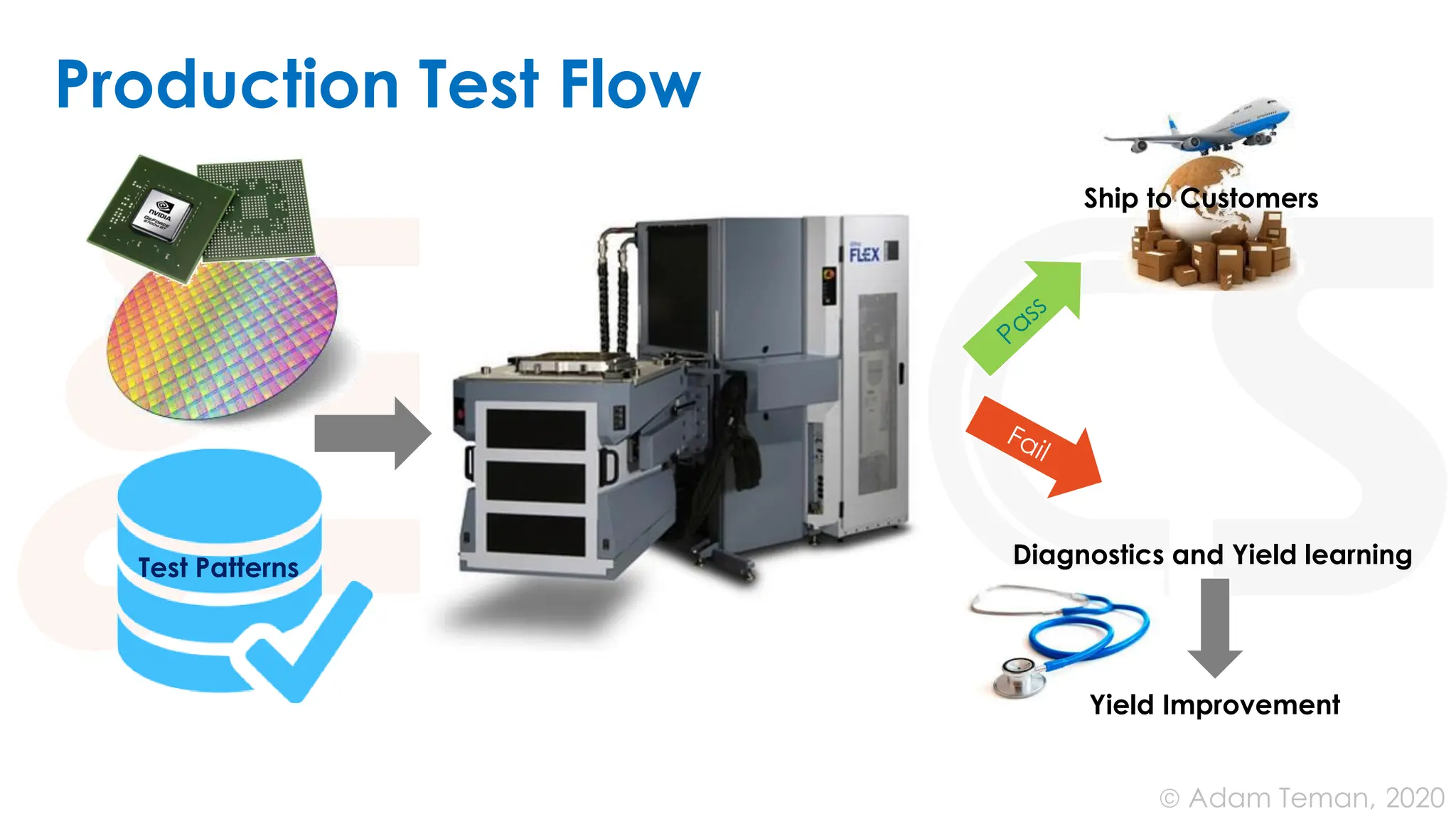

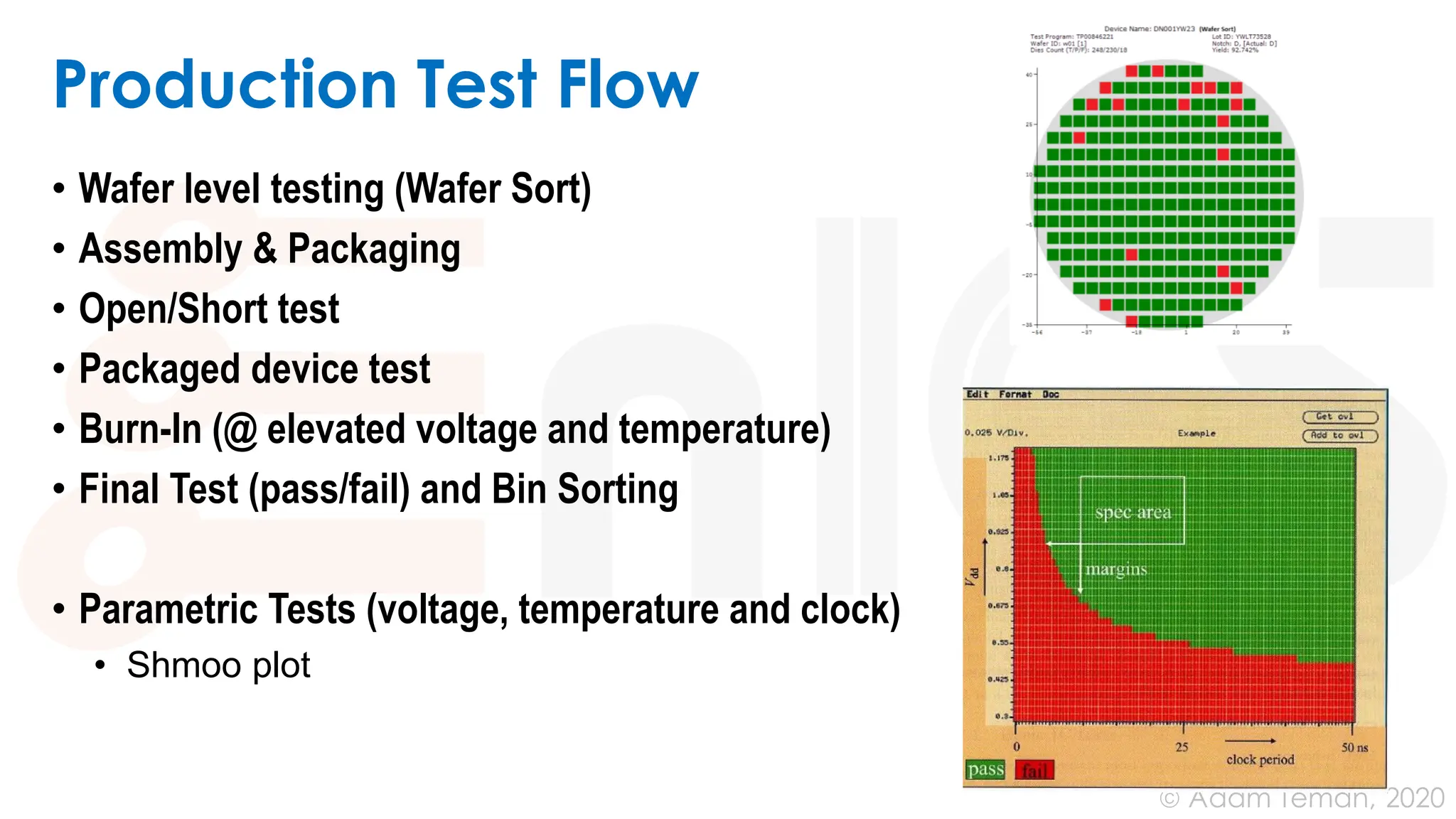

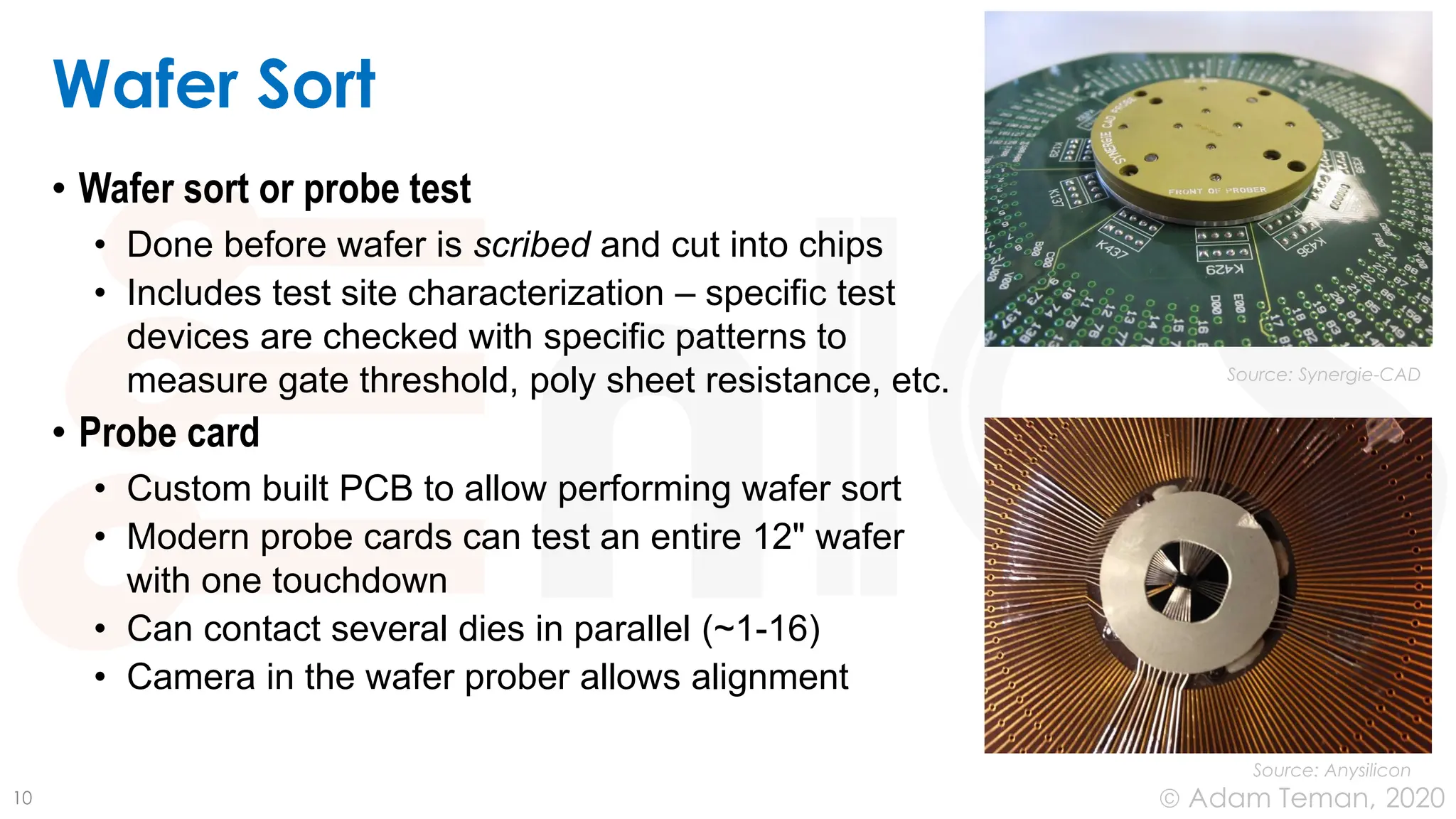

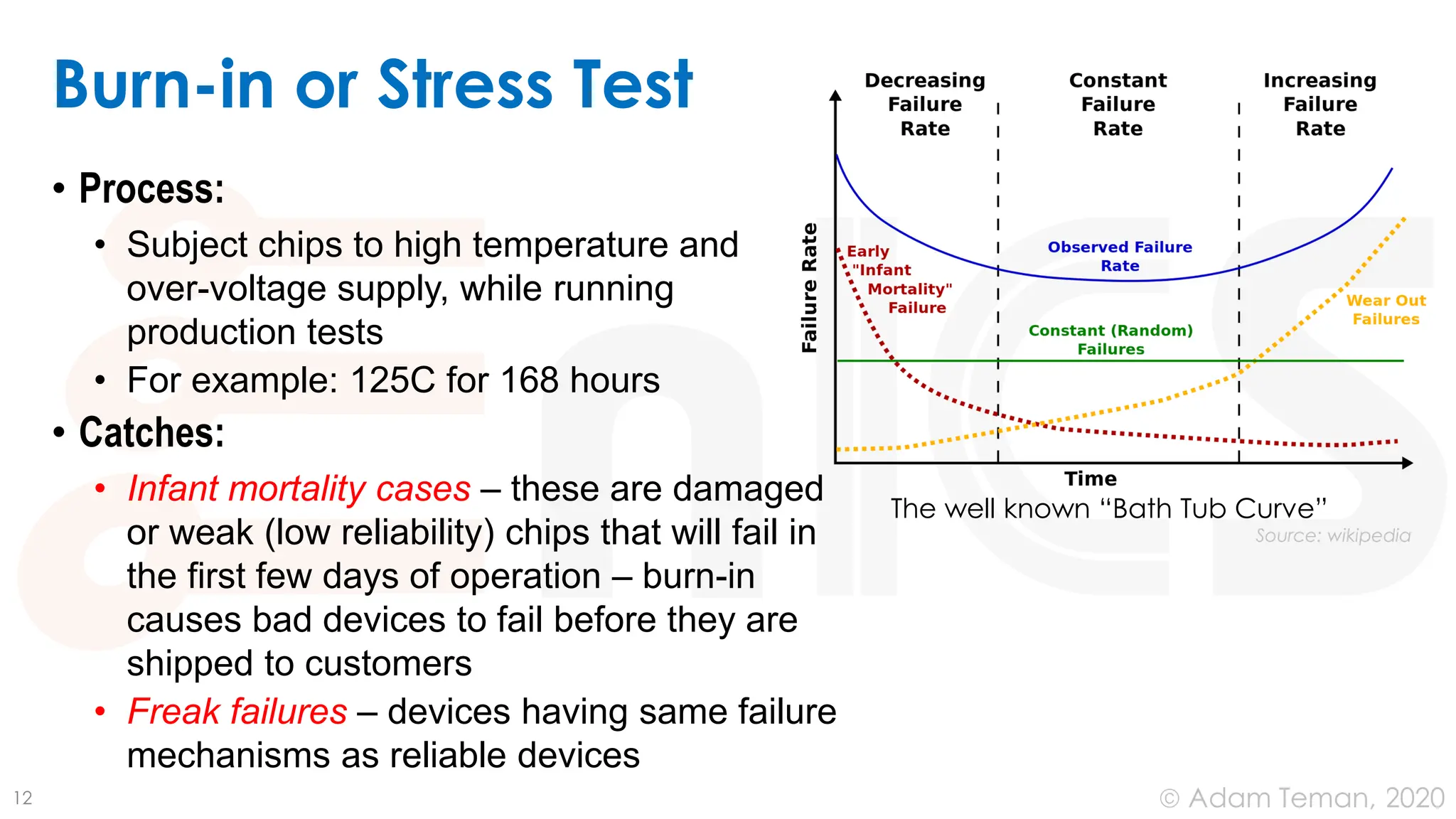

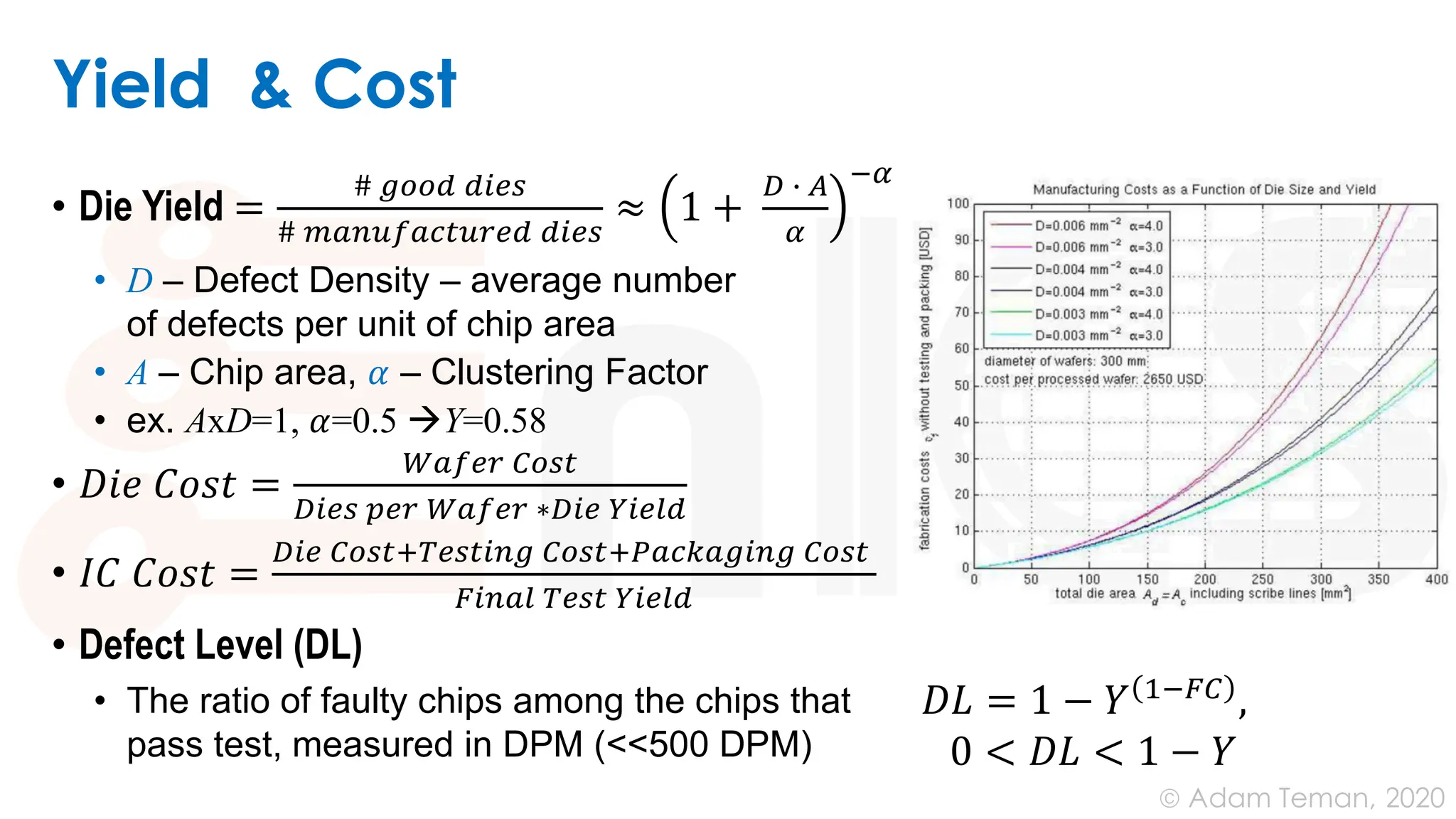

- The production test flow including wafer sorting, assembly and packaging tests, burn-in testing, and final testing before product is shipped.

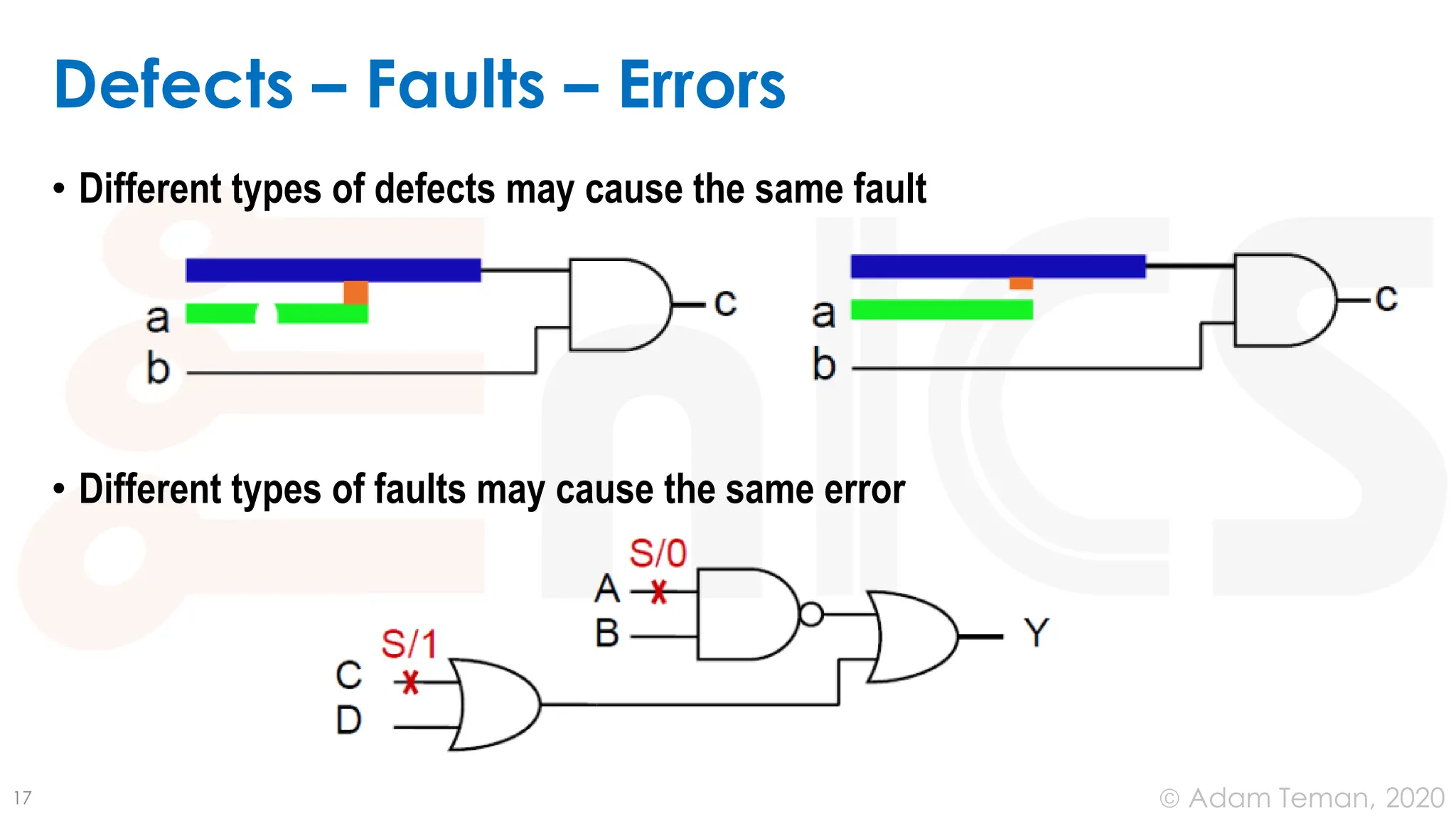

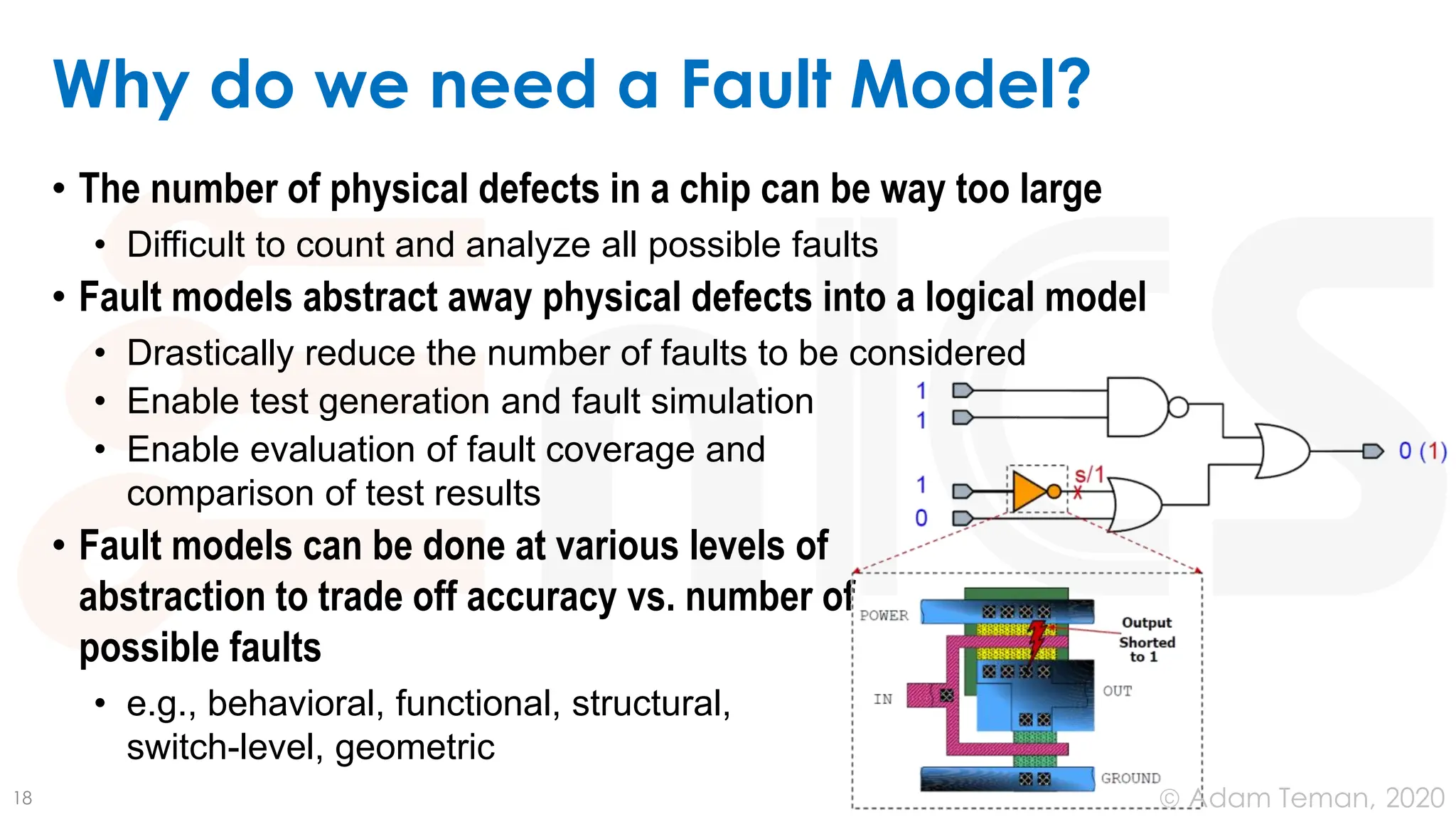

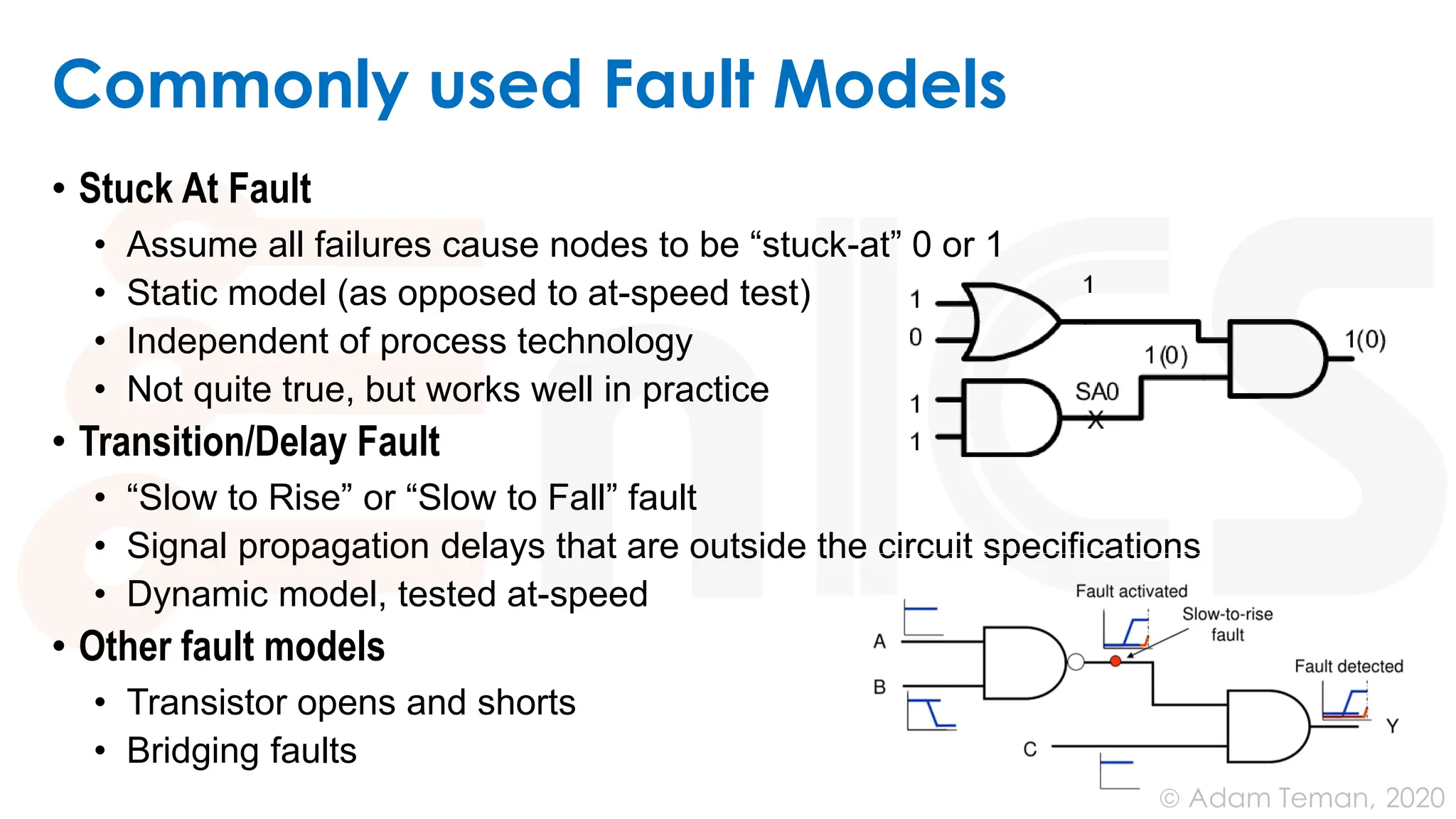

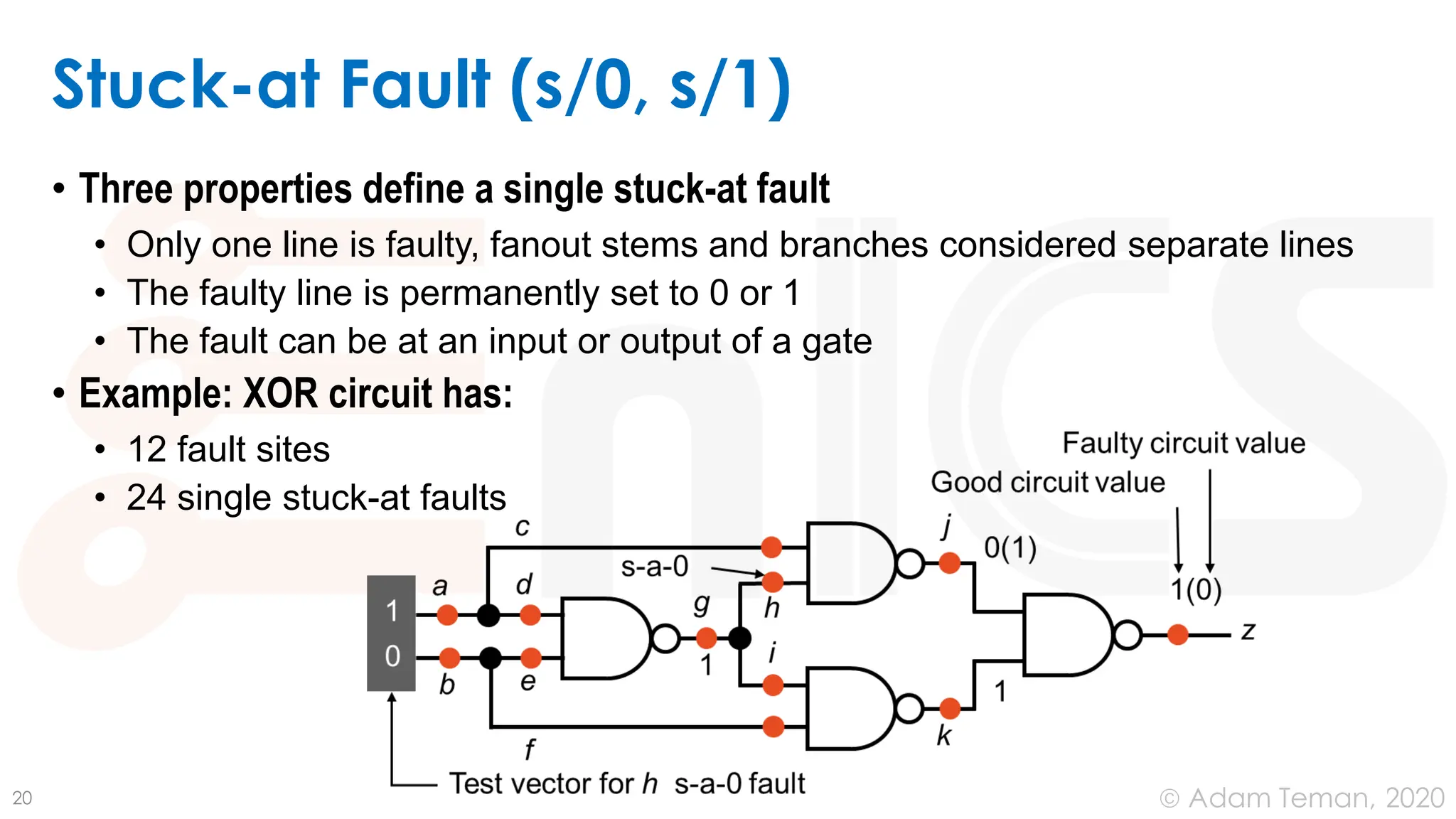

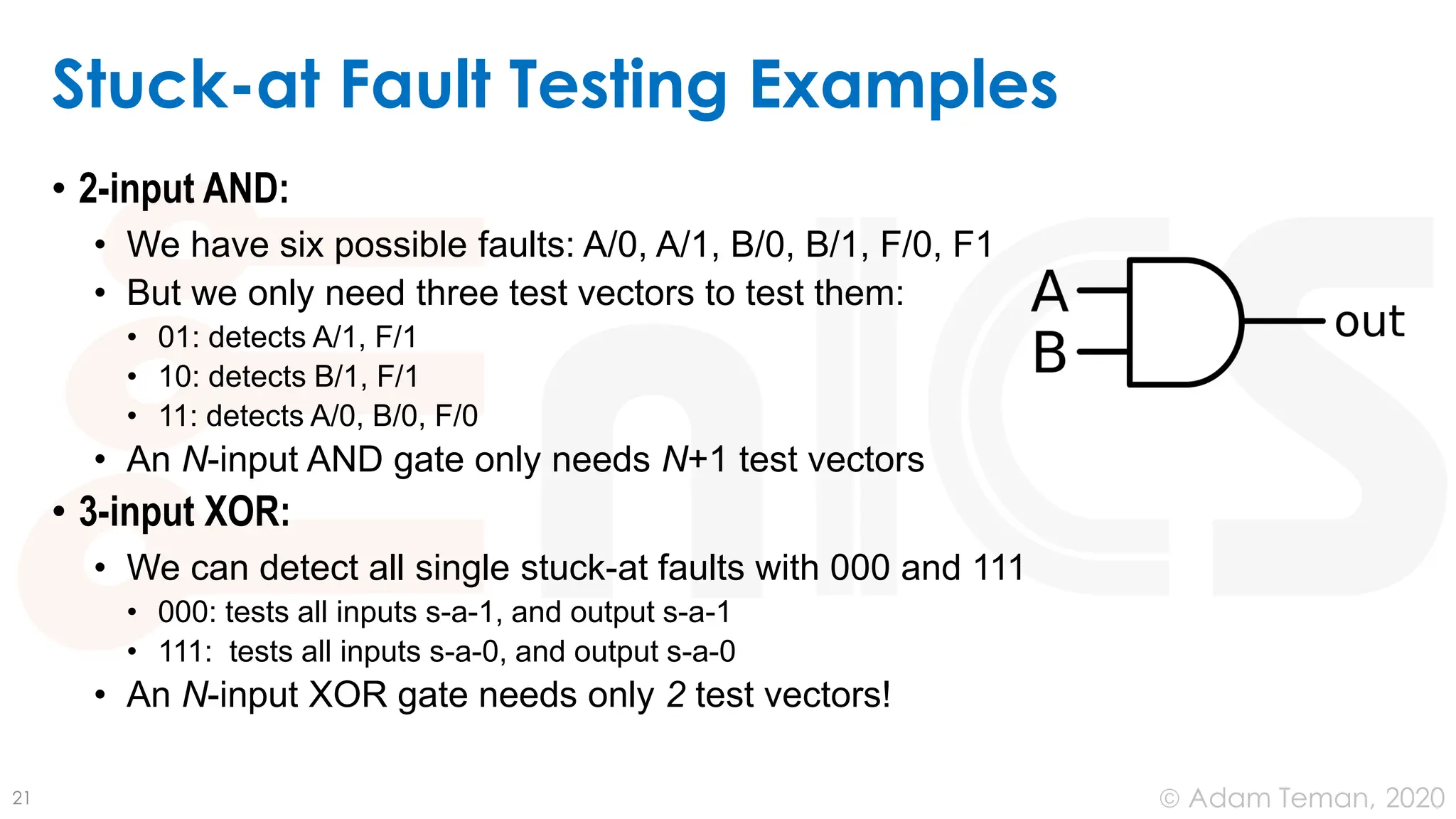

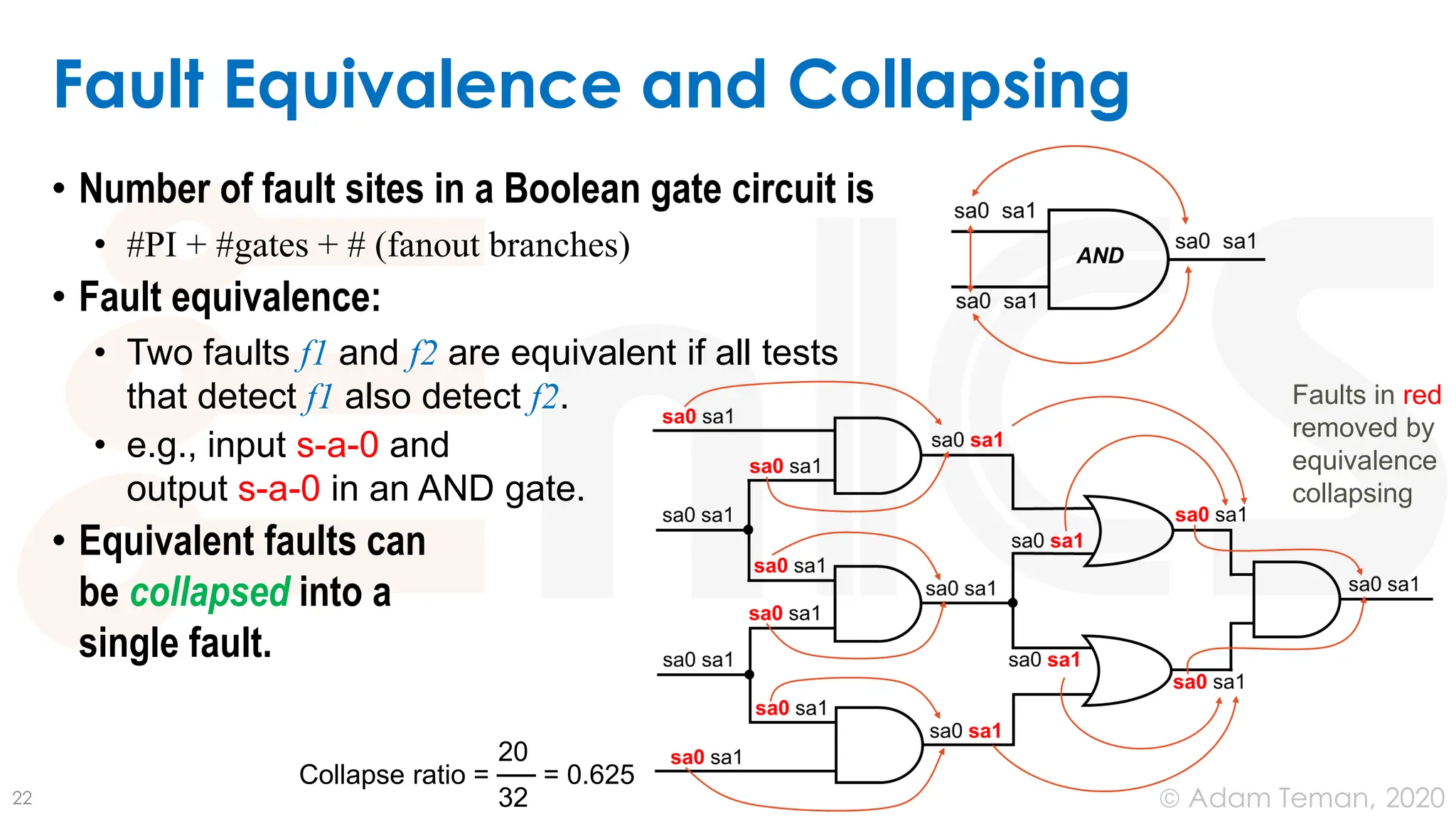

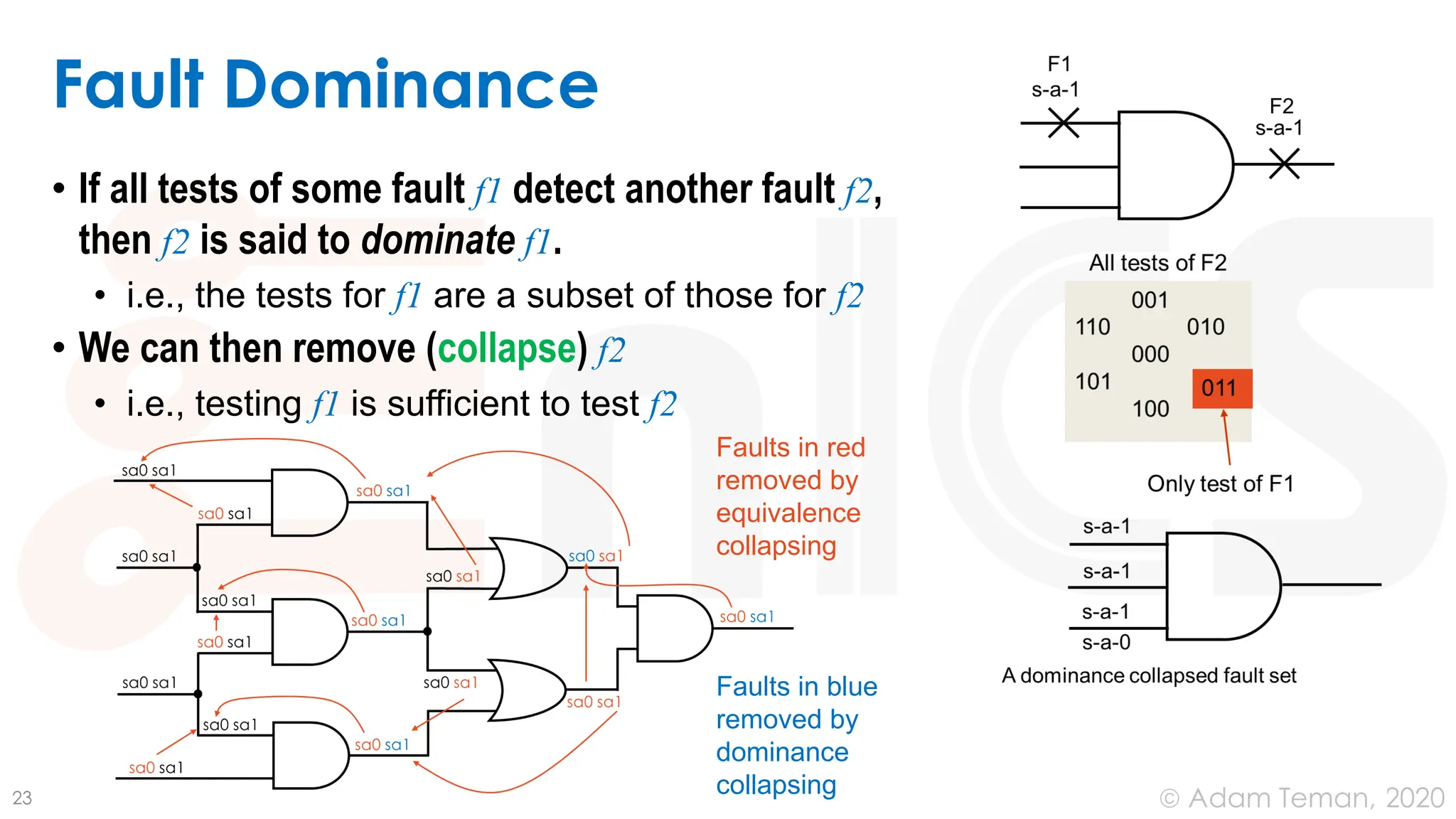

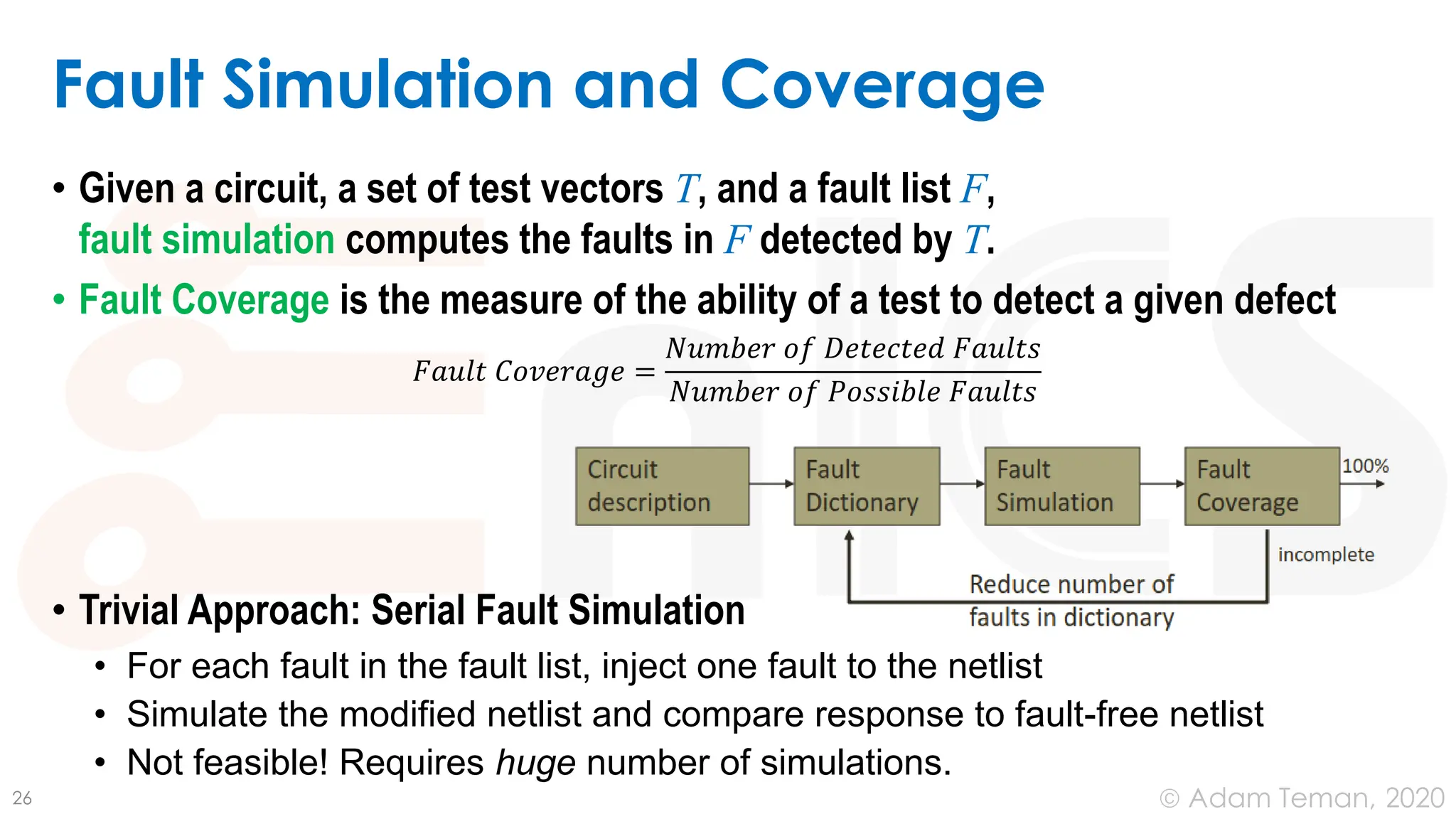

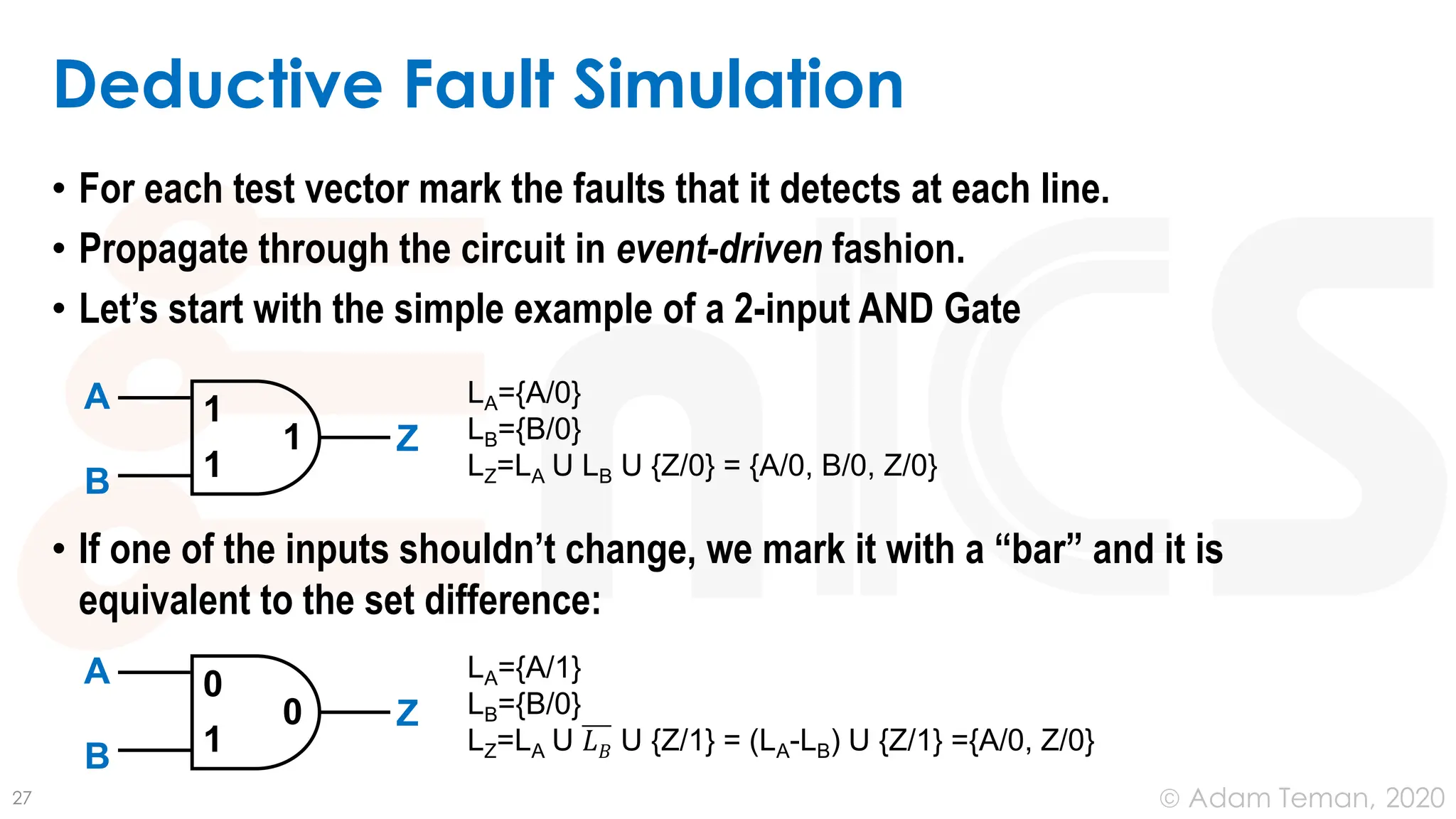

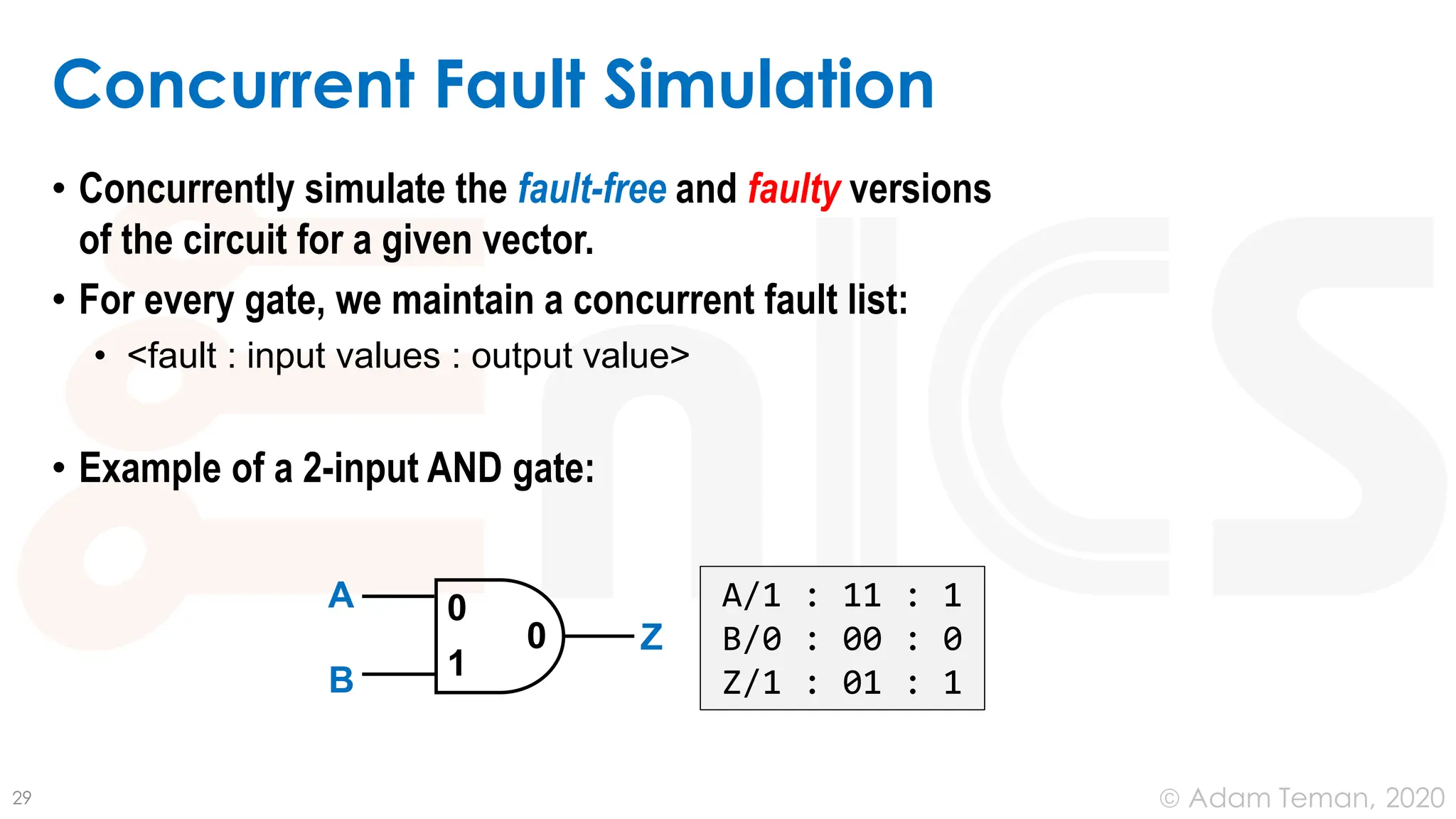

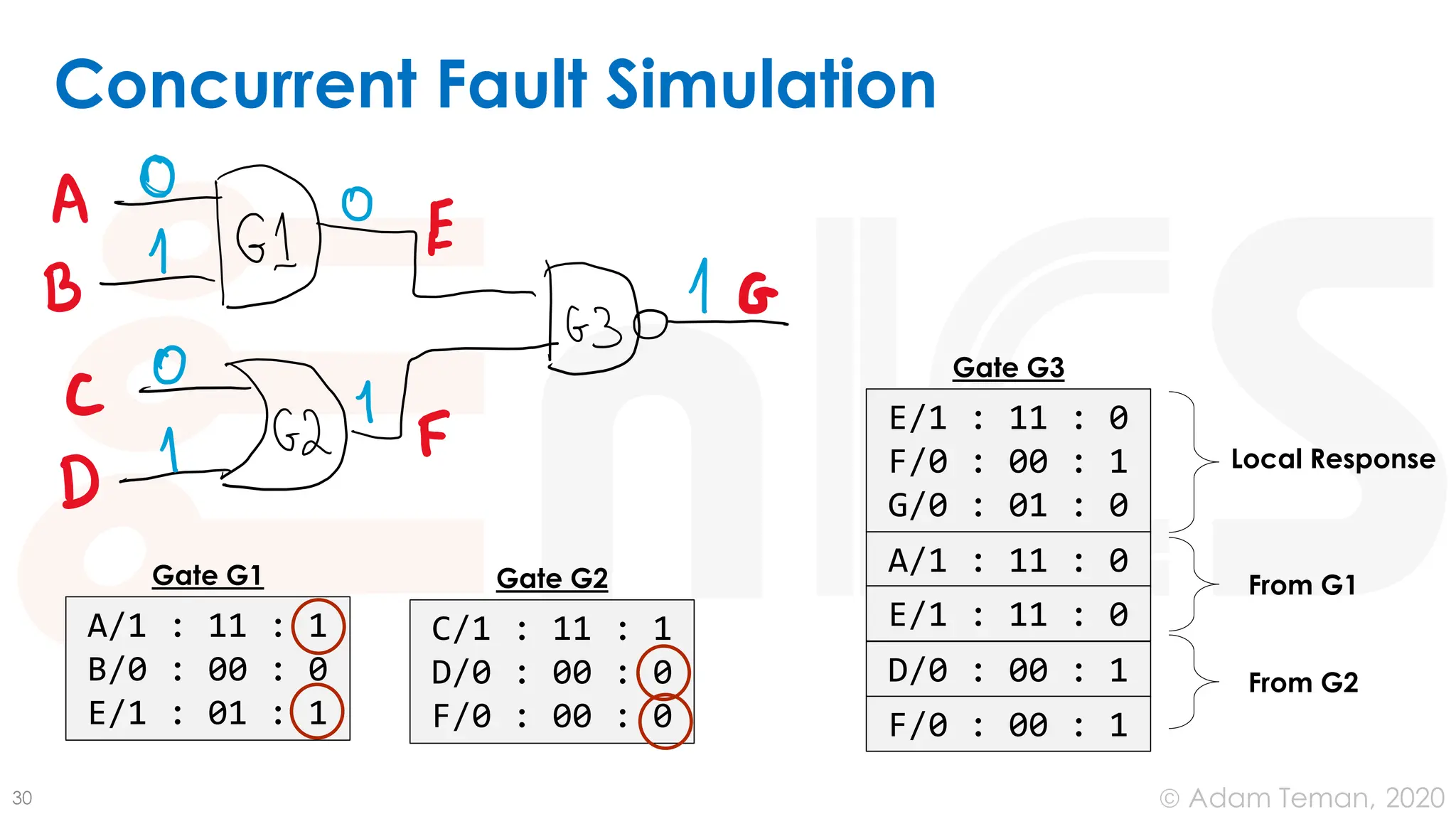

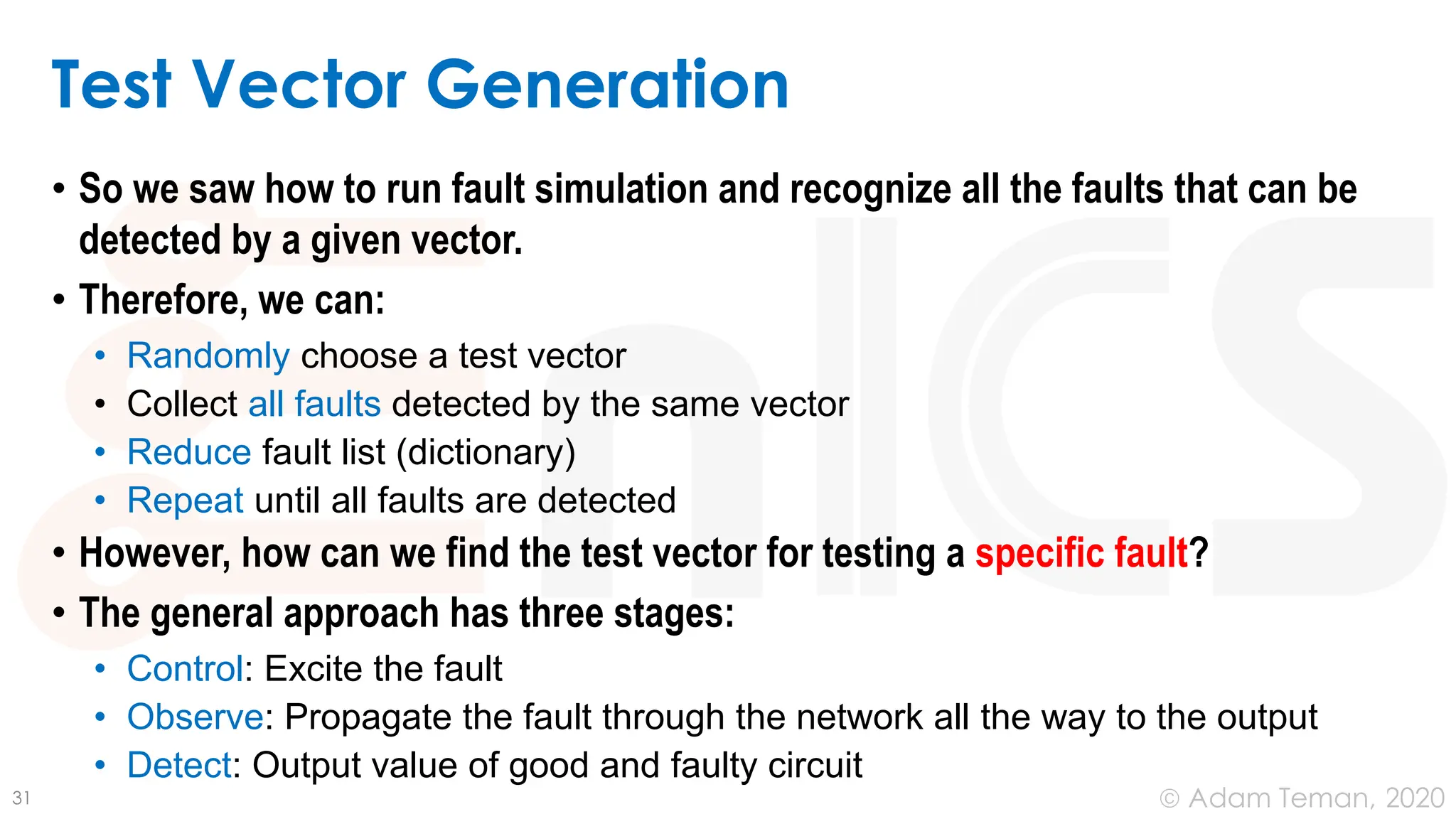

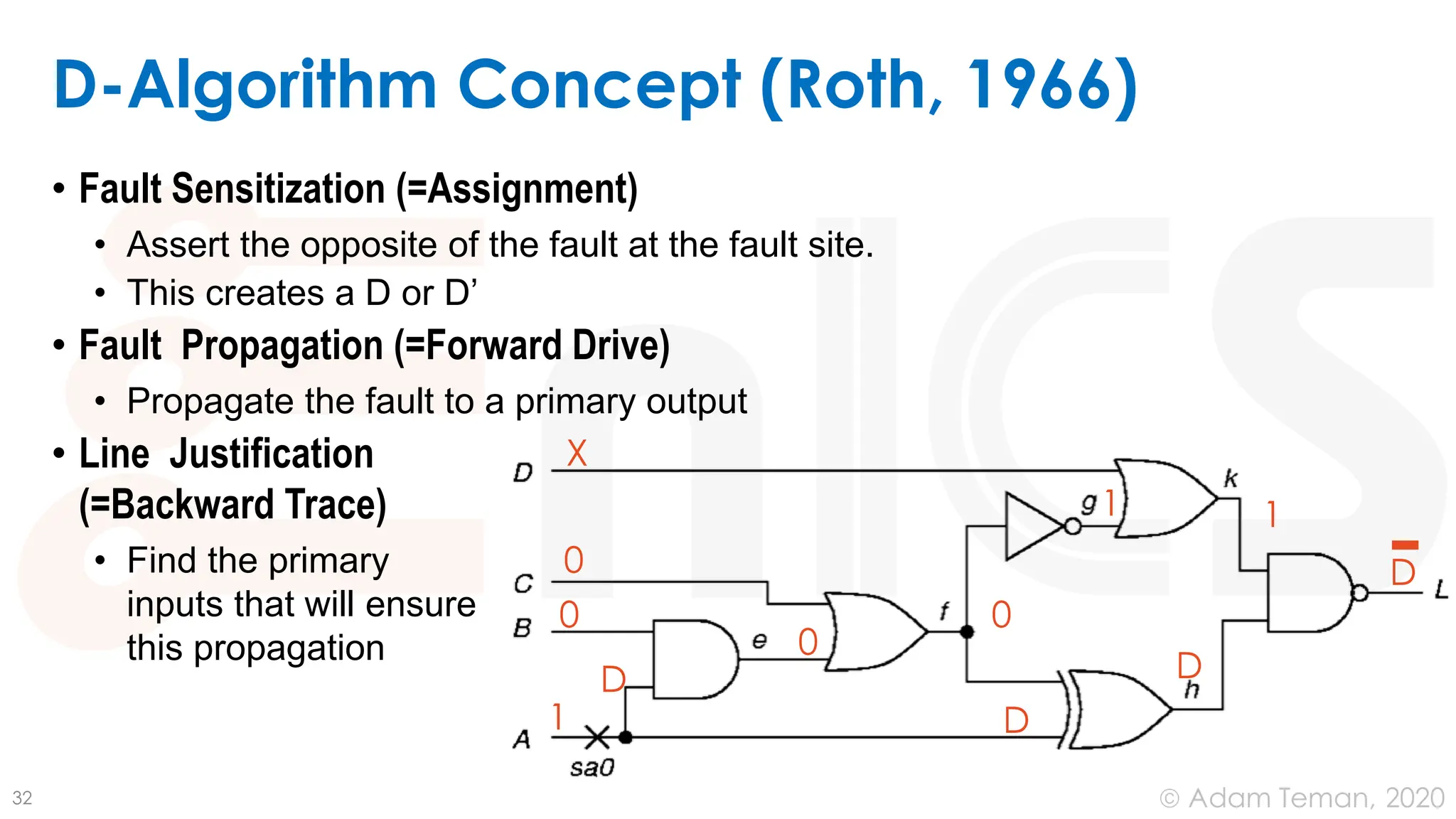

- Common fault models like stuck-at faults that are used to model defects and simplify testing. Deductive and concurrent fault simulation techniques are also discussed.