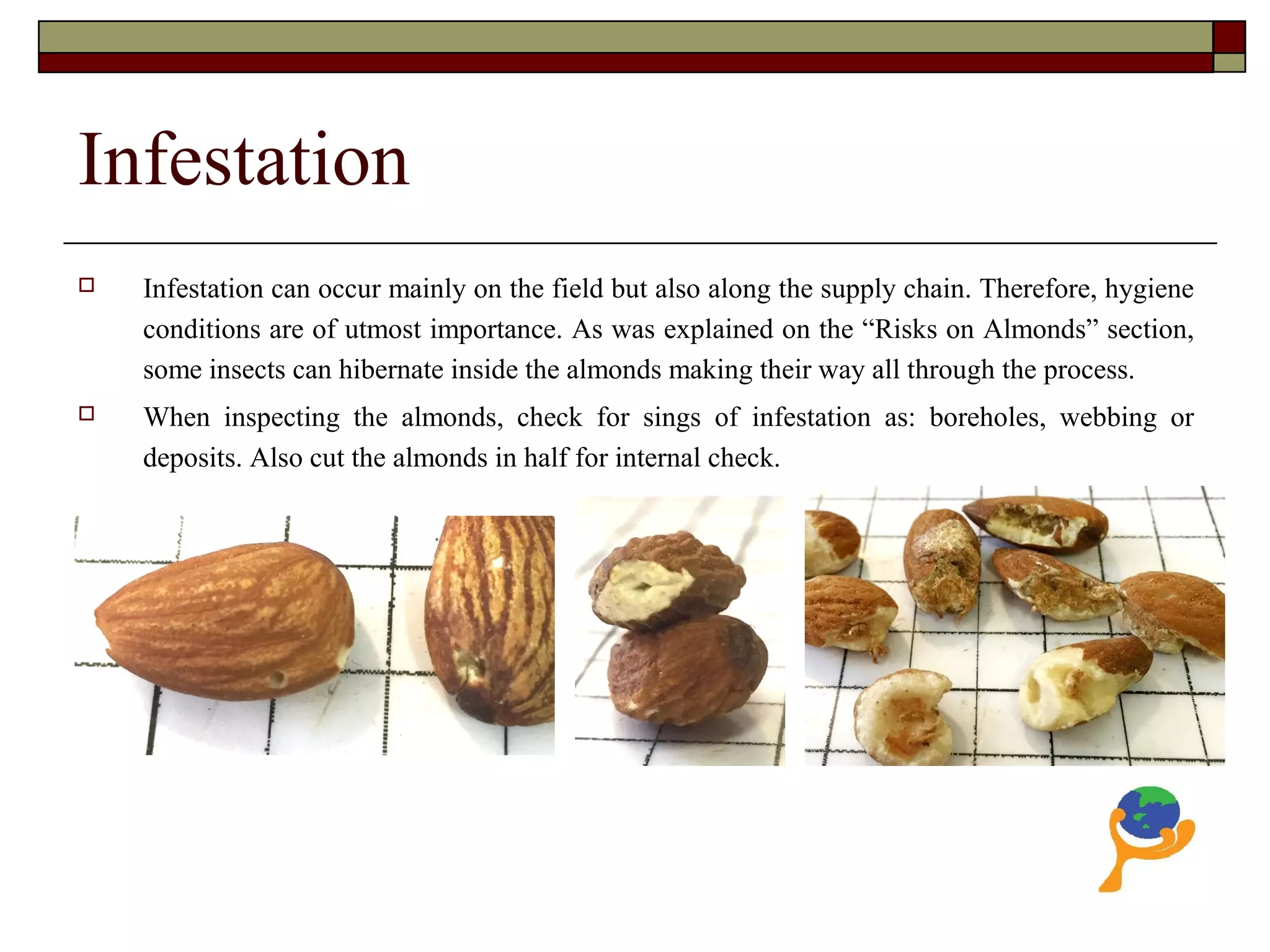

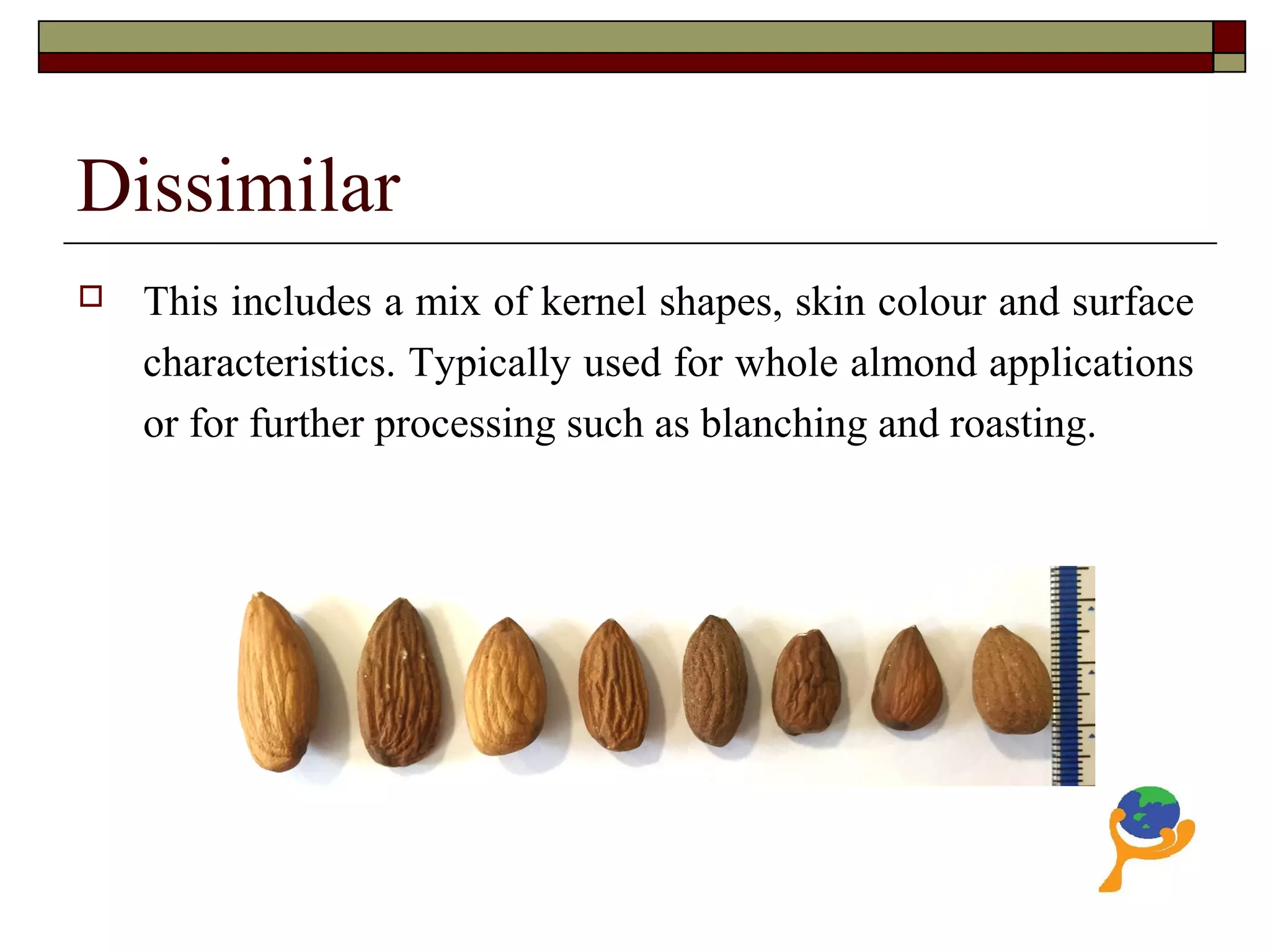

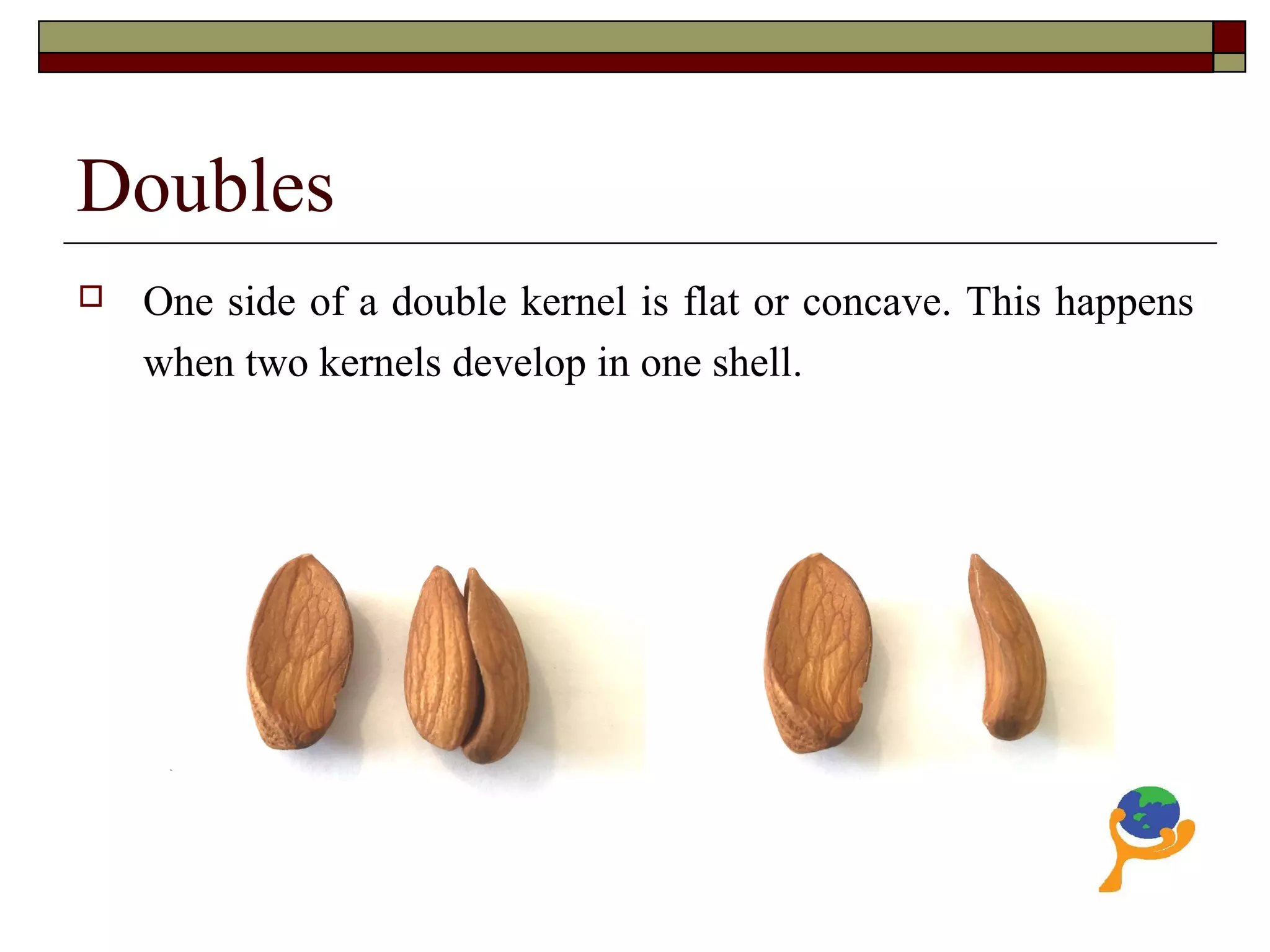

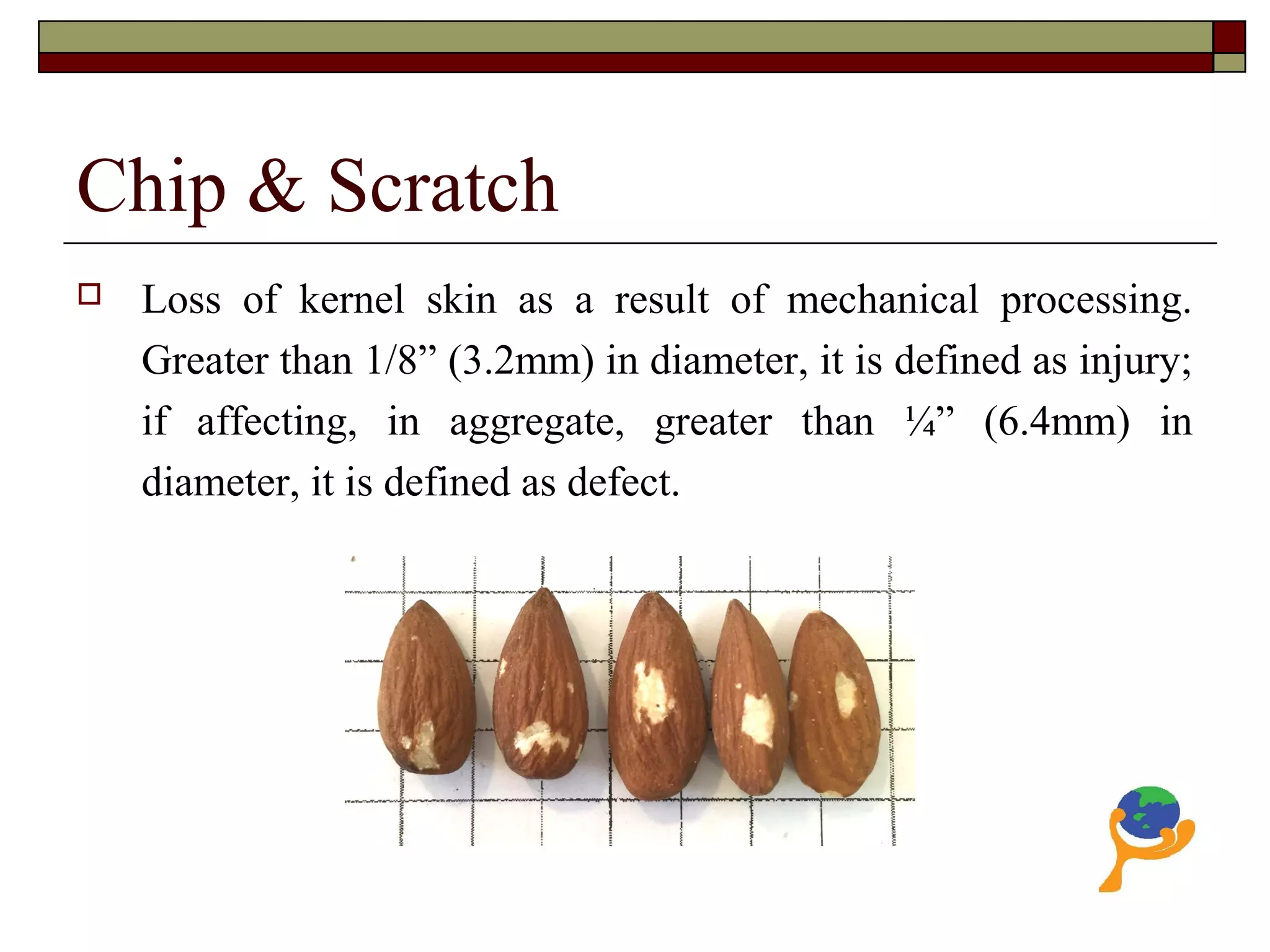

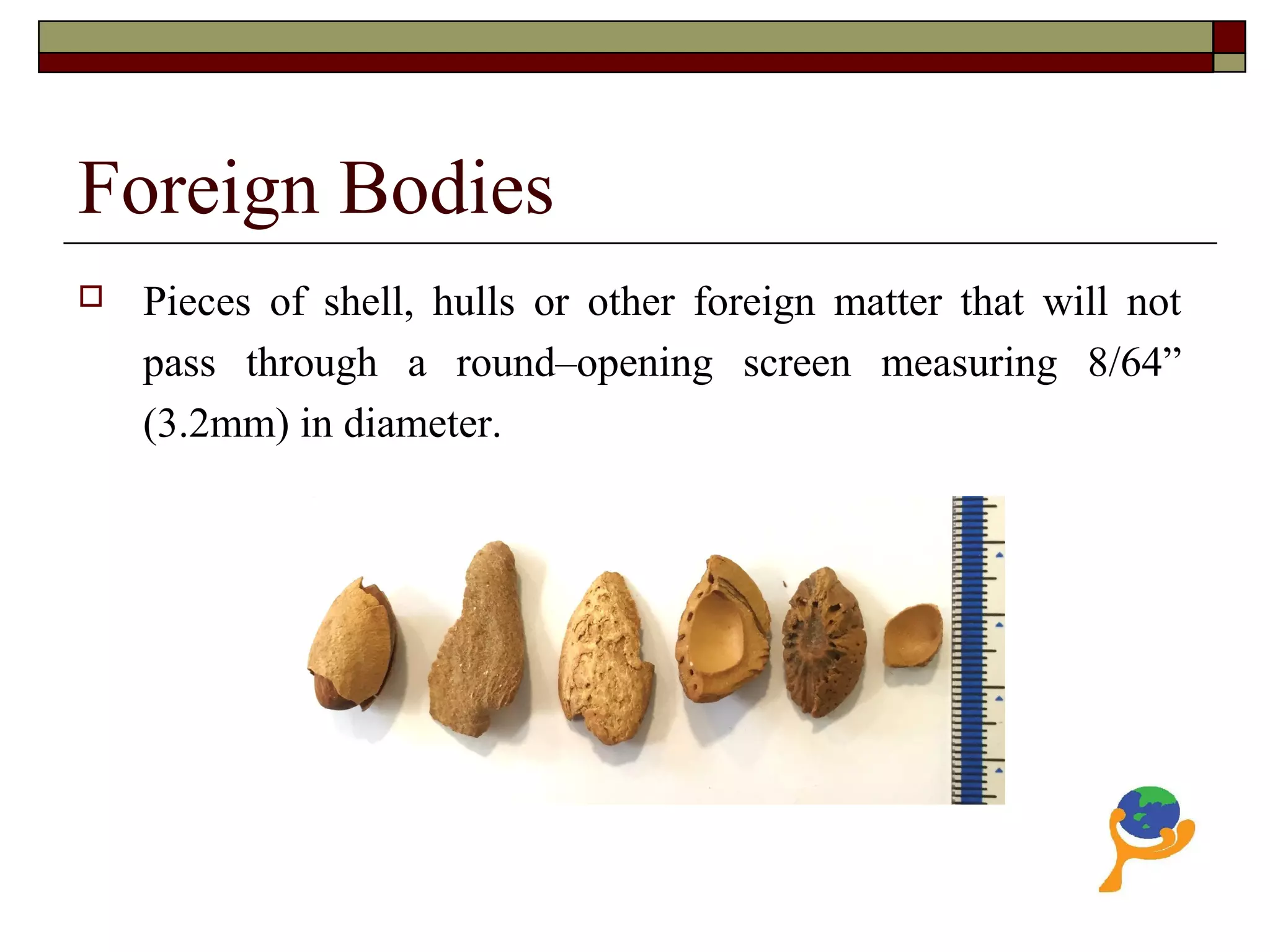

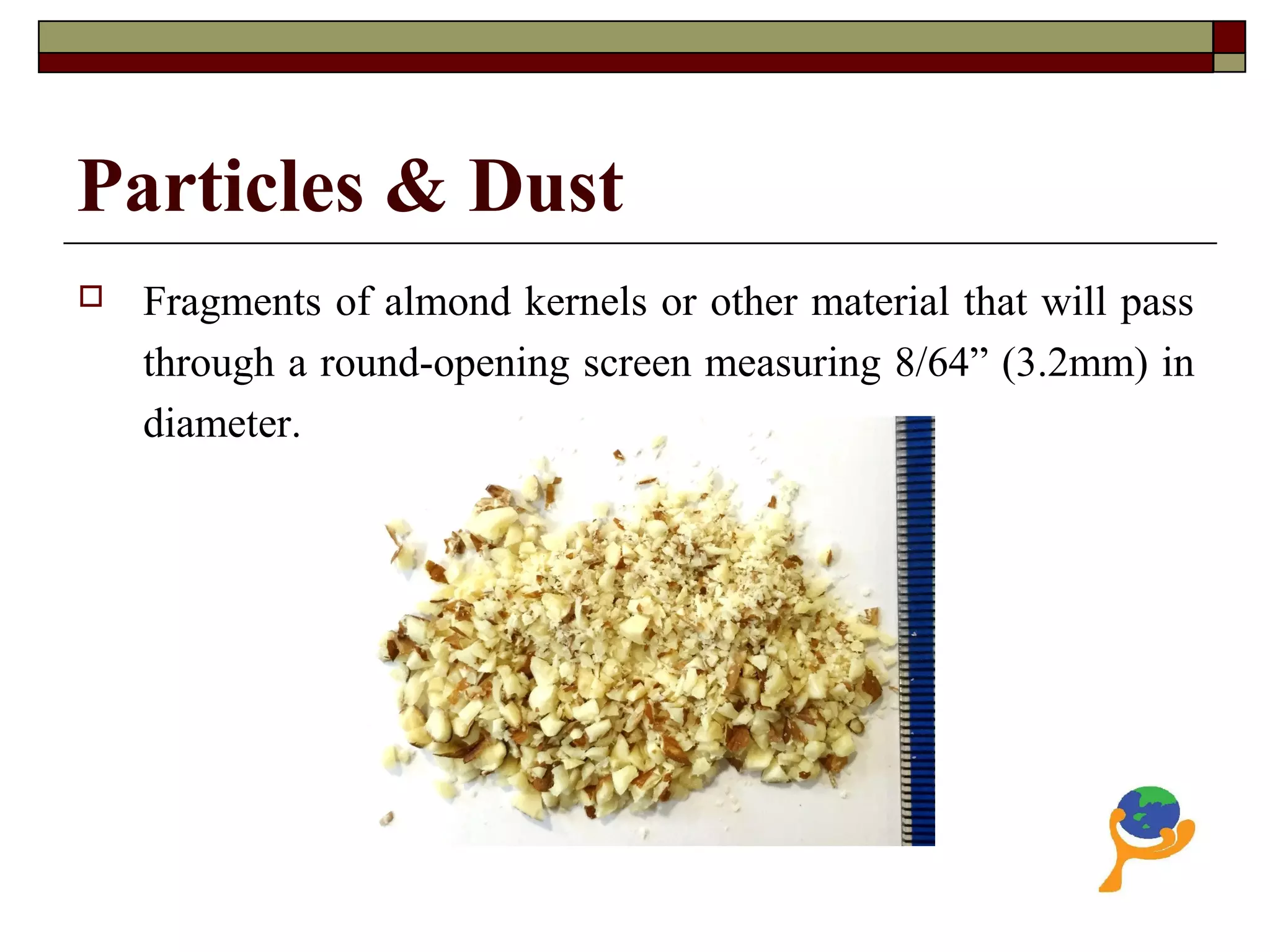

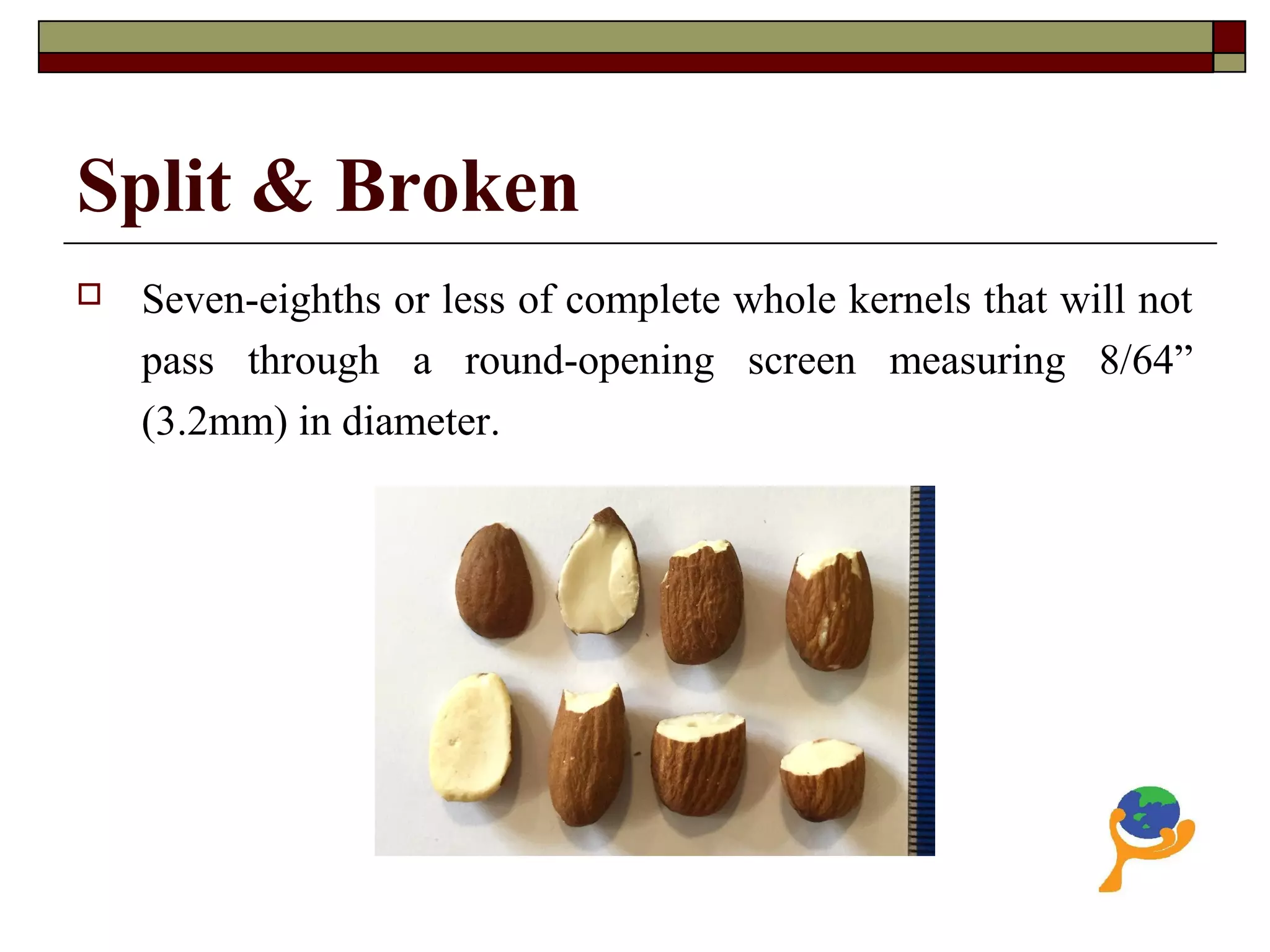

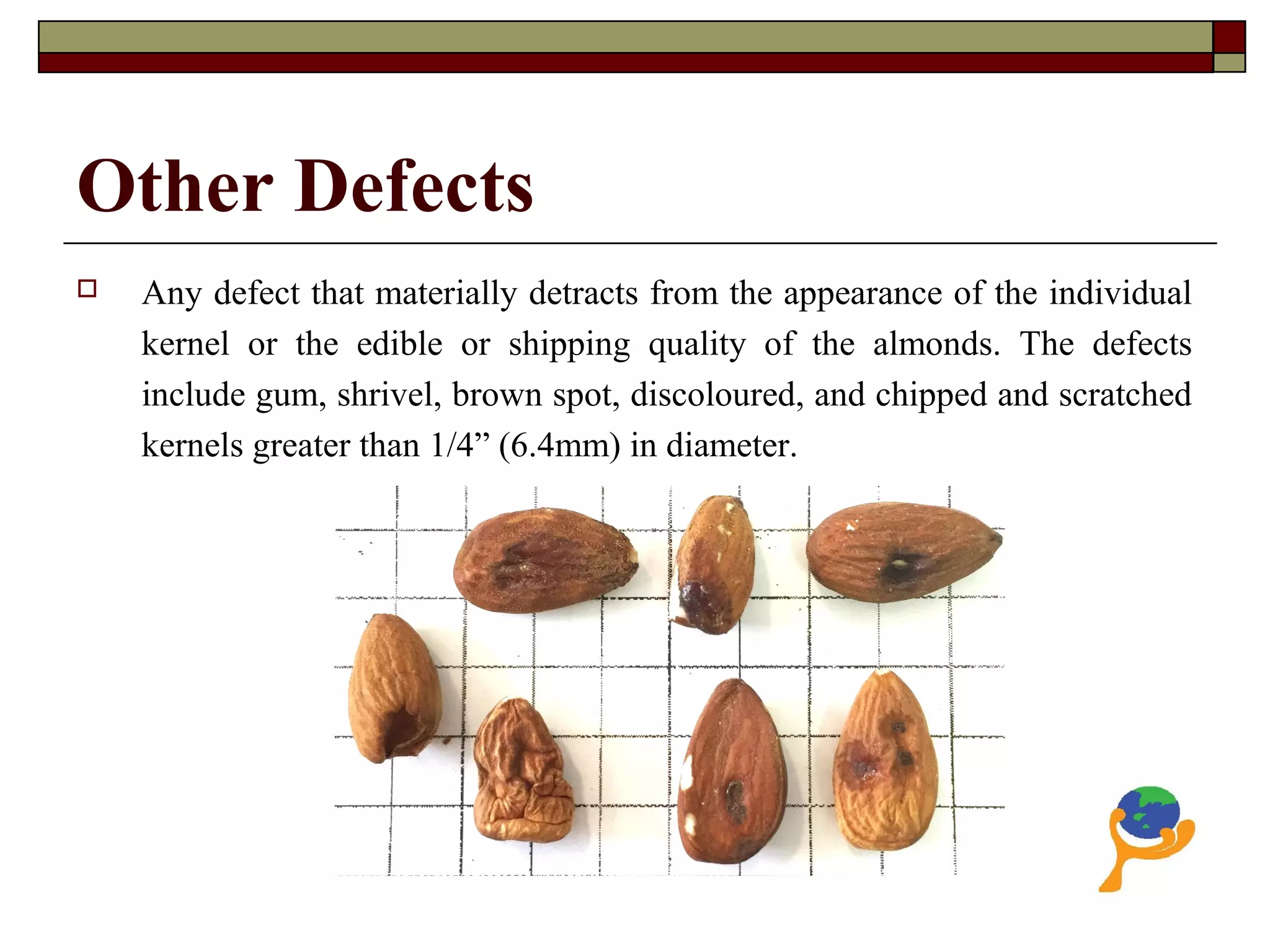

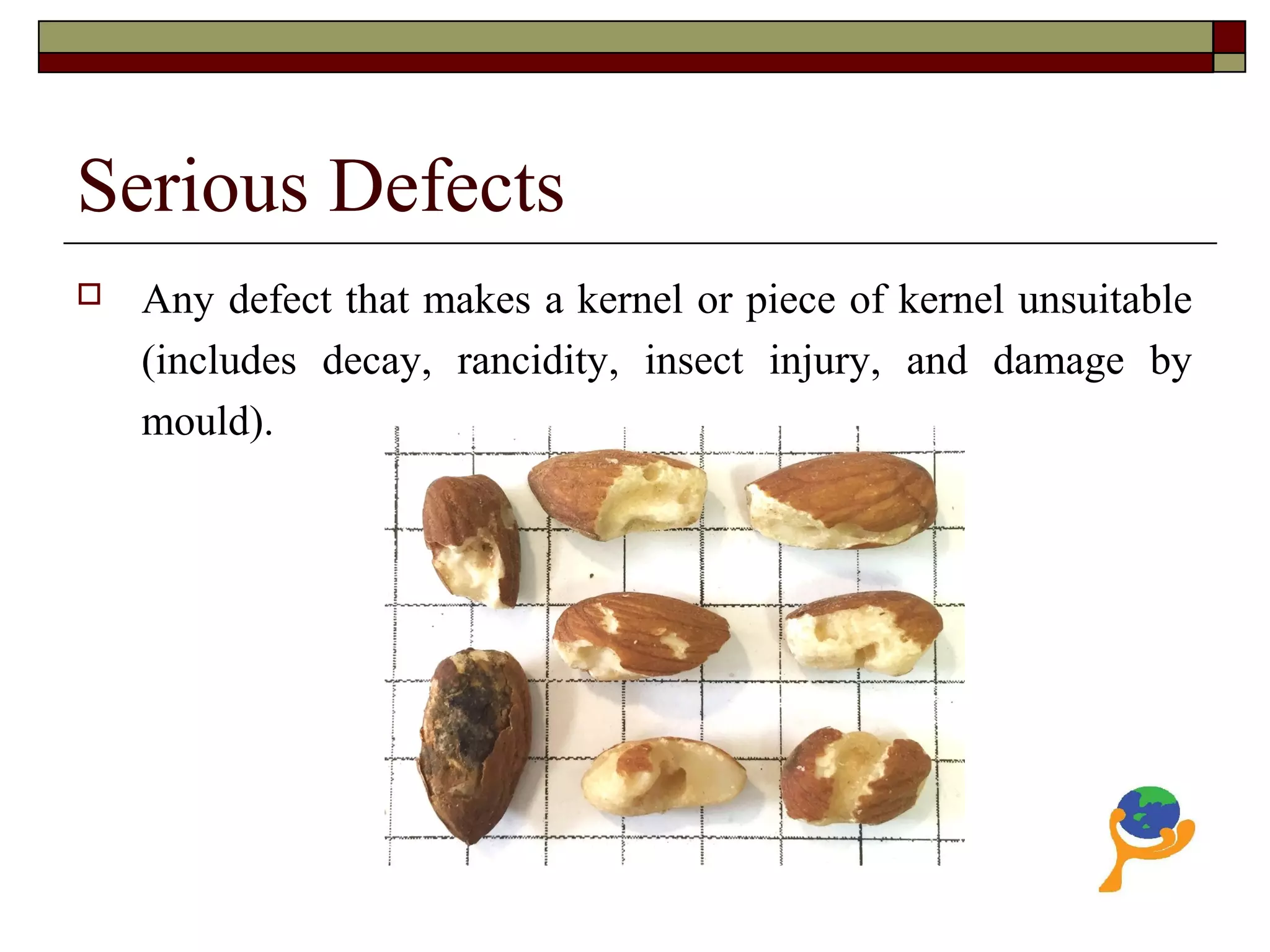

When receiving a shipment of almonds, the document recommends inspecting a random sample to check for possible defects, despite a USDA inspection. It advises taking samples from 2 random cartons per pallet and inspecting 1kg from each for signs of infestation, such as boreholes or webbing. Common defects that may be found include doubles, chips/scratches, foreign materials, or splits/breaks in the almonds. Serious defects like decay or insect damage make the almonds unsuitable. Thorough inspections are important due to risks of infestation throughout the supply chain.