This document is a user manual for OMRON's SMARTSTEP A-series servomotors (models R7M-A@) and servo drivers (models R7D-AP@). It provides warnings and precautions for safely installing, operating, and maintaining the products. The manual describes the components, specifications, functions, wiring, parameter settings, troubleshooting, and other instructions to ensure proper use of the servomotors and servo drivers.

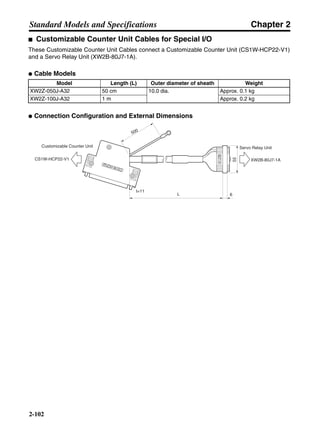

![Chapter 3

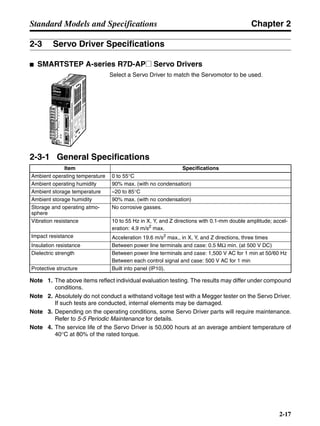

3-37

System Design and Installation

3-3 Regenerative Energy Absorption

The Servo Drivers have internal regenerative energy absorption circuitry for absorbing

the regenerative energy produced during time such as Servomotor deceleration, and

thus preventing the DC voltage from increasing. An overvoltage error is generated,

however, if the amount of regenerative energy from the Servomotor is too large. If this

occurs, measures must be taken to reduce the regenerative energy produced by

changing operating patterns, and so on, or to improve the regenerative energy

absorption capacity by connecting external regeneration resistance.

3-3-1 Regenerative Energy Calculation

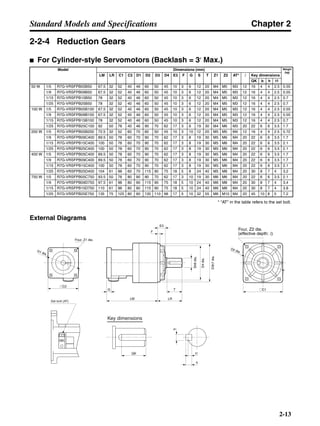

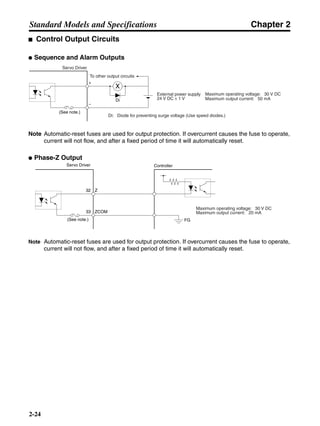

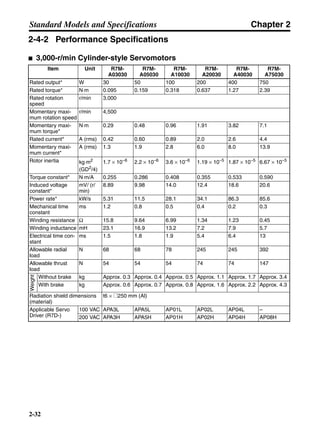

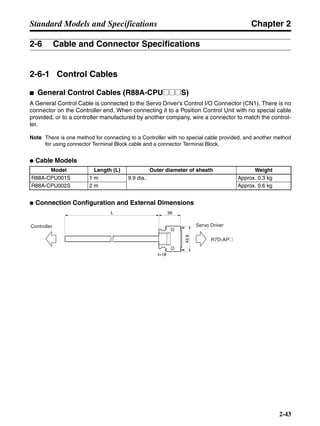

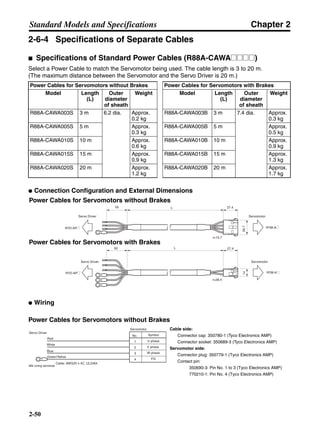

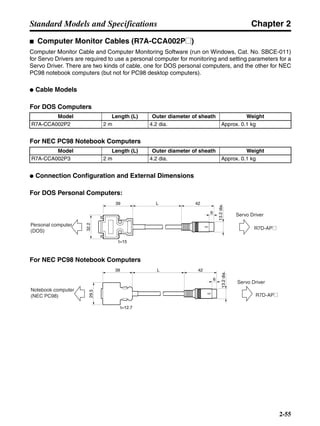

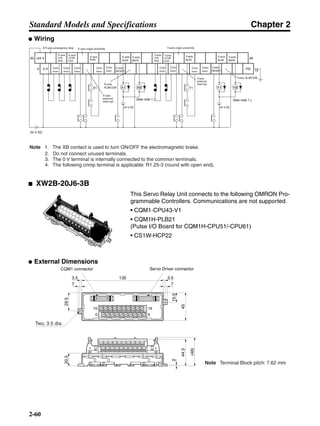

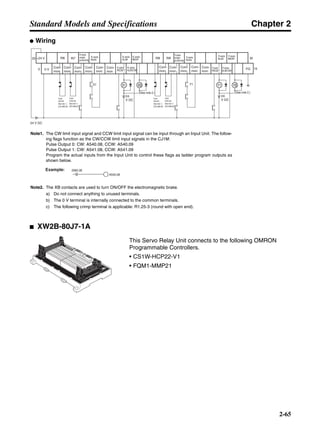

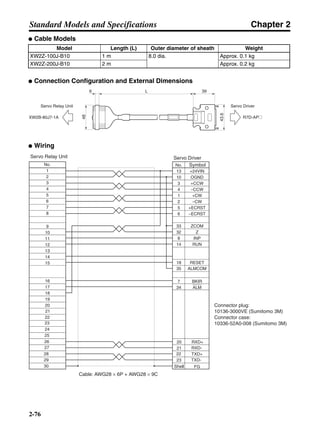

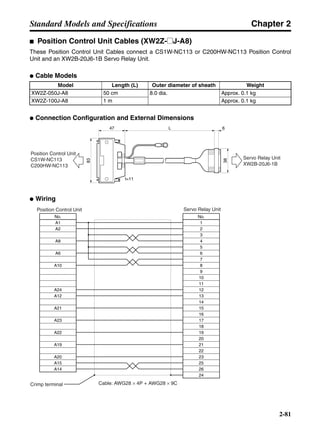

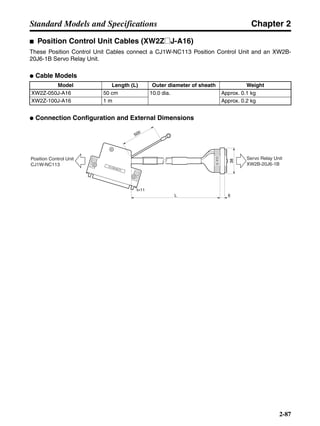

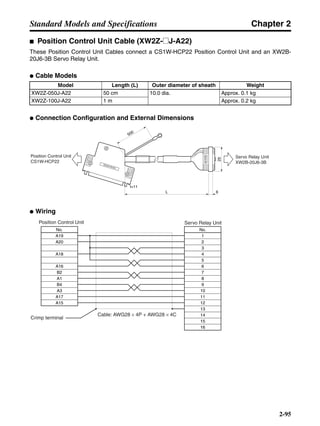

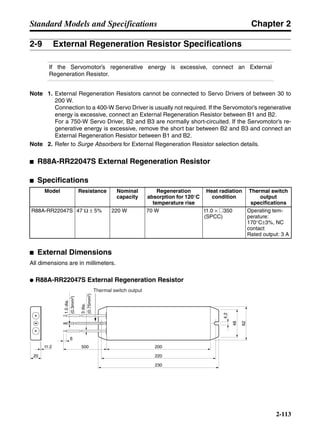

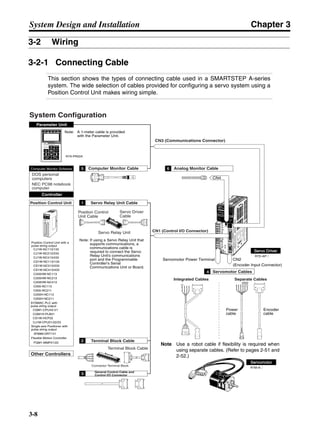

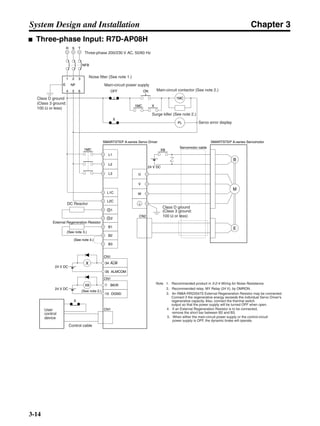

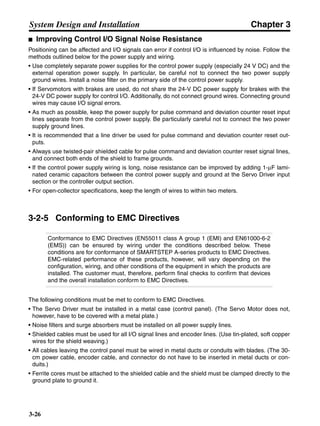

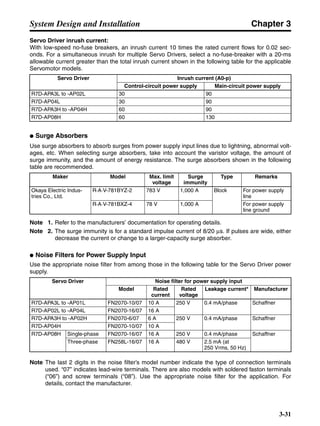

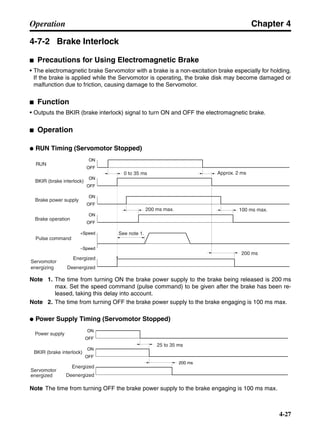

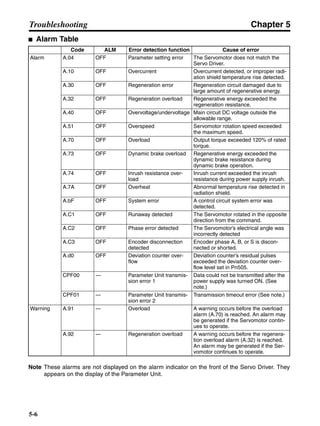

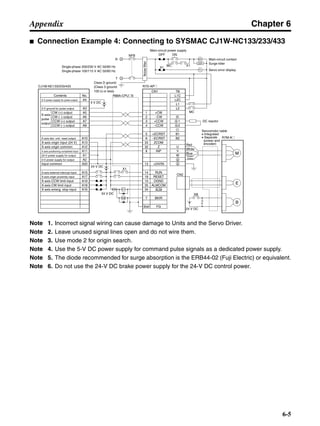

■ Horizontal Axis

Note In the output torque graph, acceleration in the positive direction is shown as positive, and

acceleration in the negative direction is shown as negative.

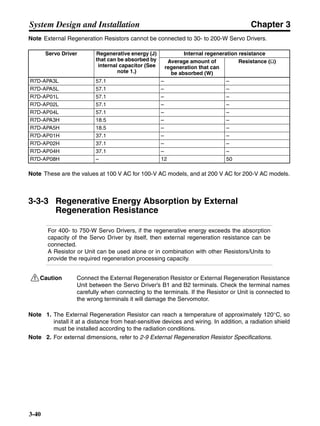

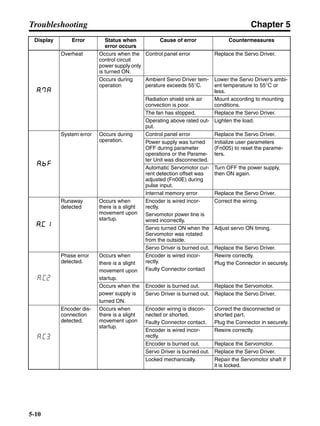

• The regenerative energy values for Eg1 and Eg2 are derived from the following equations.

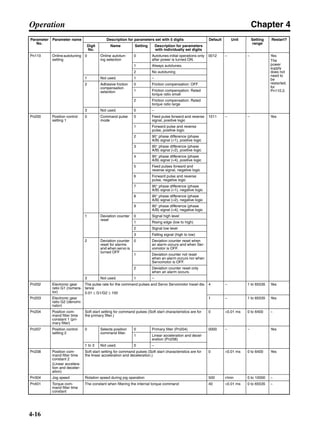

Servomotor operation

Servomotor output torque

+N1

−N2

TD1

TD2

t1 t2

T

Eg1

Eg2

N1, N2: Rotation speed at beginning of deceleration [r/min]

TD1, TD2: Deceleration torque [N·m]

t1, t2: Deceleration time [s]

• Eg1 = • • N1 • TD1 • t1 [J] = 0.0524 • N1 • TD1 • t1 [J]

2 60

60

2π

2π

1

• Eg2 = • • N2 • TD2 • t2 [J] = 0.0524 • N2 • TD2 • t2 [J]

2

1](https://image.slidesharecdn.com/datasheetr7ma10030s1-151021112310-lva1-app6892/85/Datasheet-r7-m-a10030_s1-177-320.jpg)

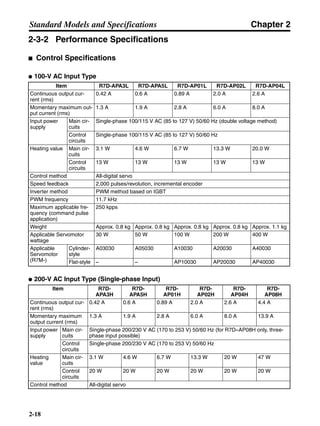

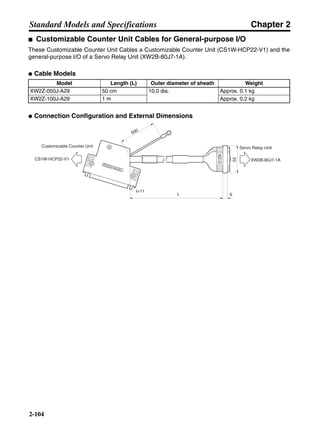

![Chapter 3

3-38

System Design and Installation

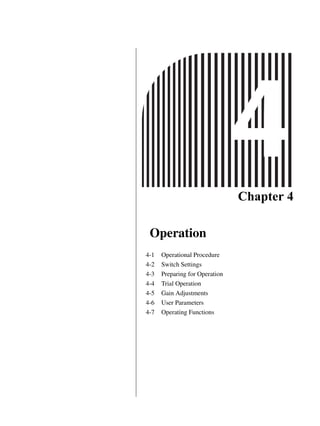

Note There is some loss due to winding resistance, so the actual regenerative energy will be approx-

imately 90% of the values derived from these equations.

• For Servo Driver models with internal capacitors for absorbing regenerative energy (i.e., models of

400 W or less.), the values for both Eg1 or Eg2 (unit: J) must be lower than the Servo Driver’s

regenerative energy absorption capacity. (The capacity varies depending on the model. For details,

refer to 3-3-2 Servo Driver Regenerative Energy Absorption Capacity.)

• For Servo Driver models with internal regeneration resistance for absorbing regenerative energy

(i.e., models of 750 W), the average amount of regeneration Pr (unit: W) must be calculated, and

this value must be lower than the Servo Driver’s regenerative energy absorption capacity. (For

details, refer to 3-3-2 Servo Driver Regenerative Energy Absorption Capacity.)

The average amount of regeneration (Pr) is the power consumed by regeneration resistance in

one cycle of operation.

Pr = (Eg1 + Eg2)/T [W]

T: Operation cycle [s]

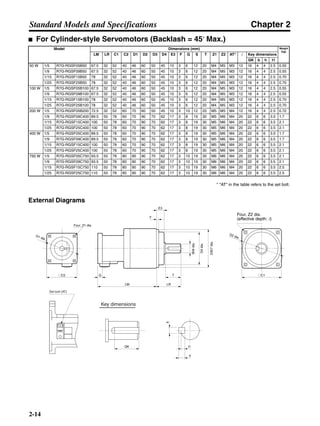

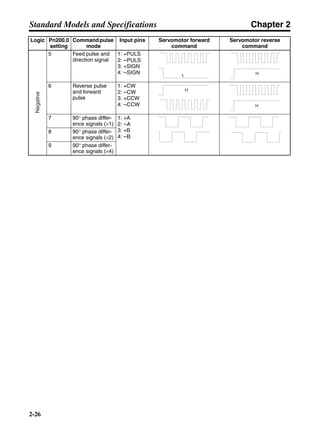

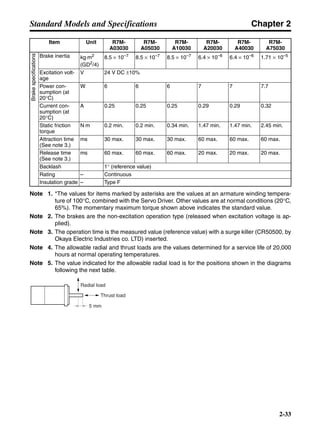

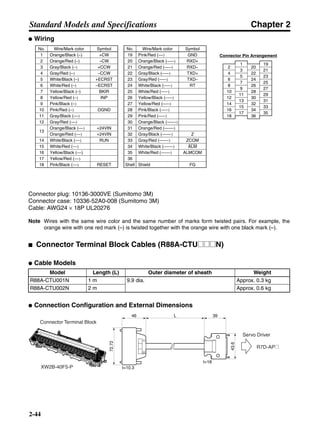

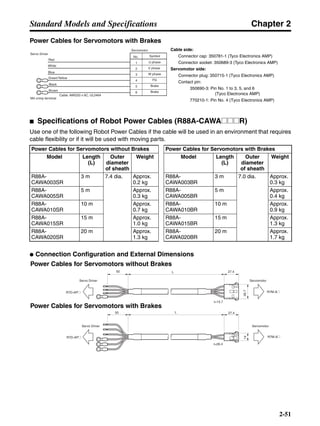

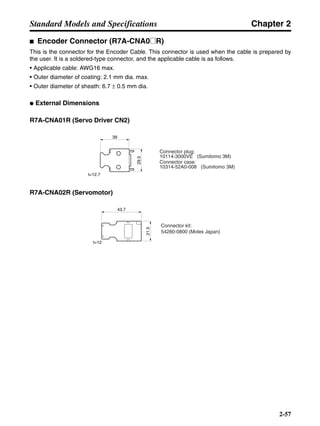

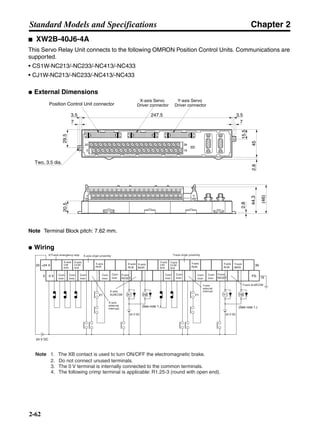

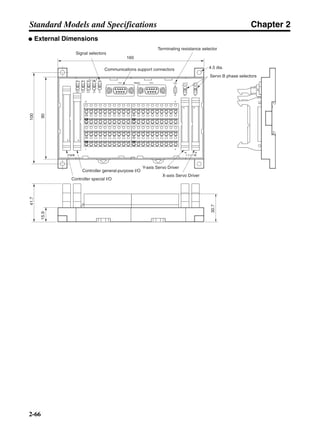

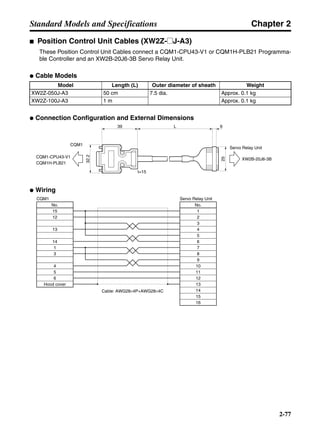

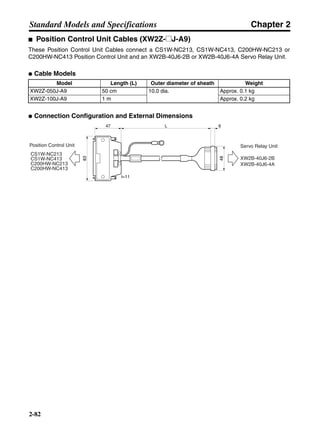

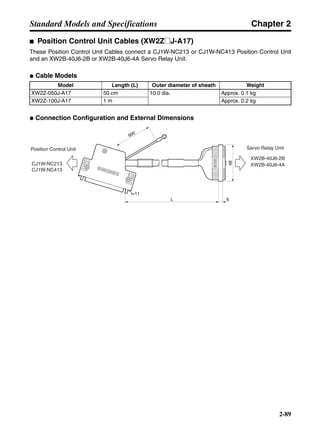

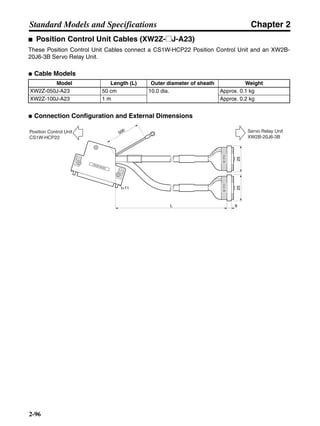

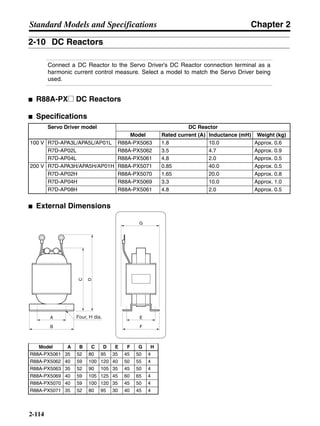

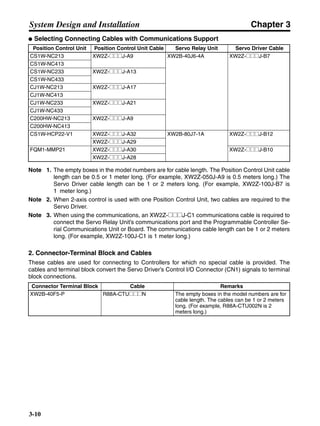

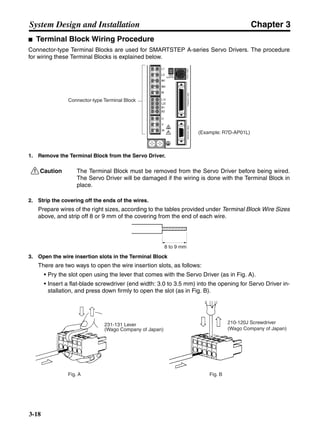

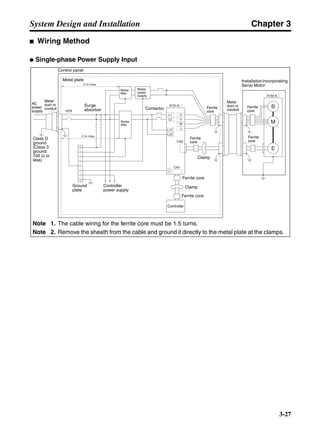

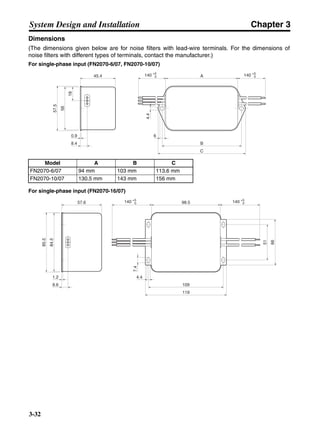

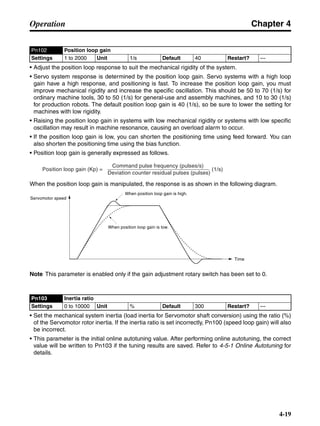

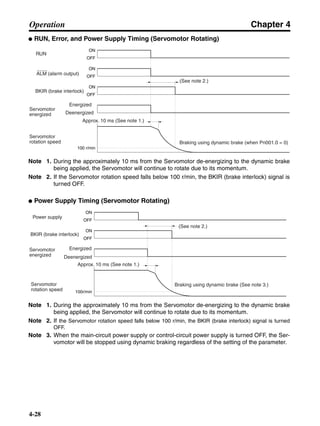

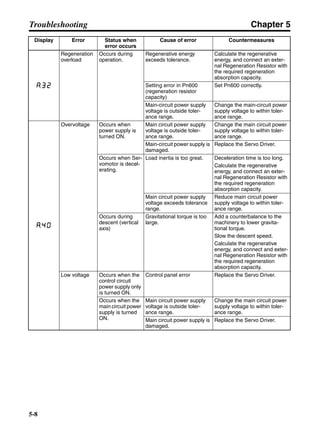

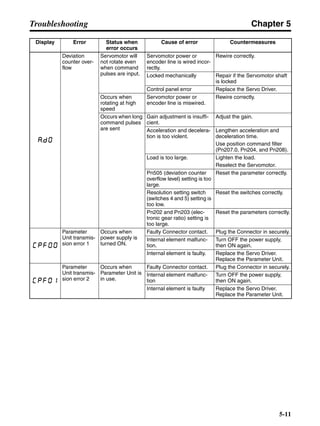

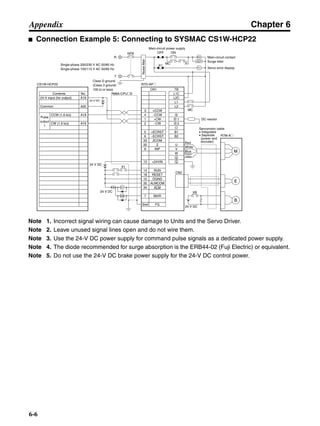

■ Vertical Axis

Note In the output torque graph, acceleration in the positive direction (rise) is shown as positive, and

acceleration in the negative direction (fall) is shown as negative.

• The regenerative energy values for Eg1, Eg2, and Eg3 are derived from the following equations.

Fall

Rise

Servomotor operation

Servomotor output torque

+N1

−N2

t1 t2 t3

T

Eg1

Eg3Eg3

TD2

TL2

TD1

Eg2](https://image.slidesharecdn.com/datasheetr7ma10030s1-151021112310-lva1-app6892/85/Datasheet-r7-m-a10030_s1-178-320.jpg)

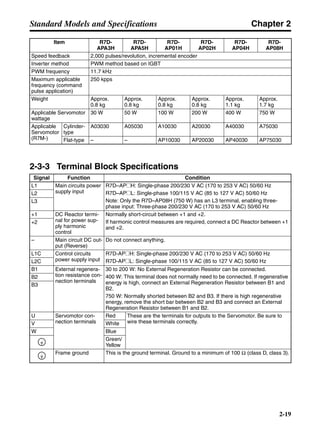

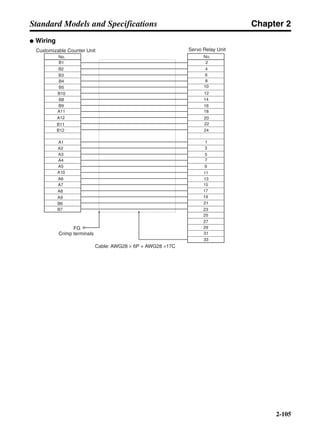

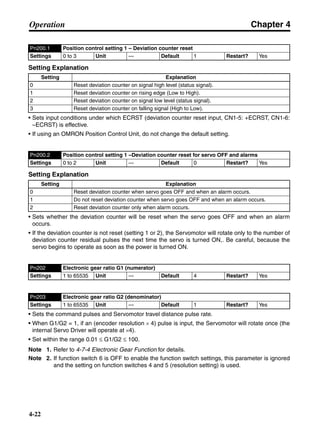

![Chapter 3

3-39

System Design and Installation

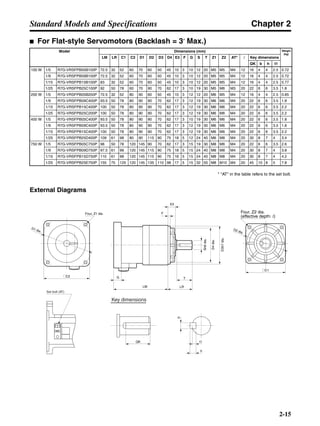

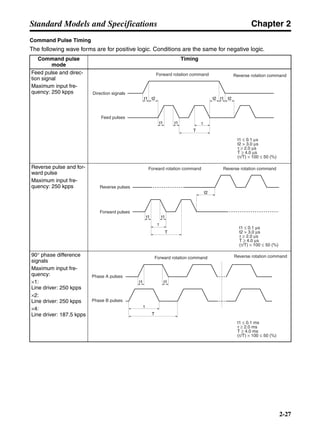

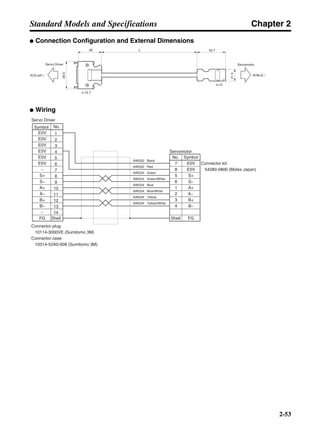

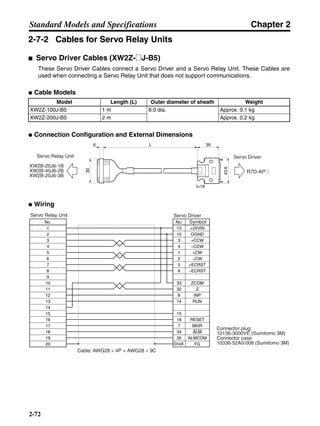

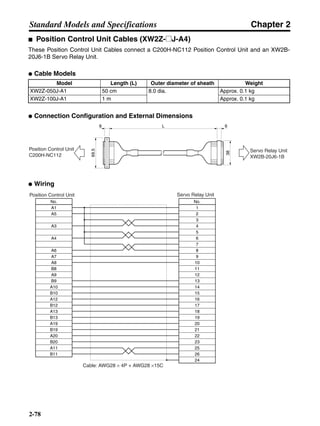

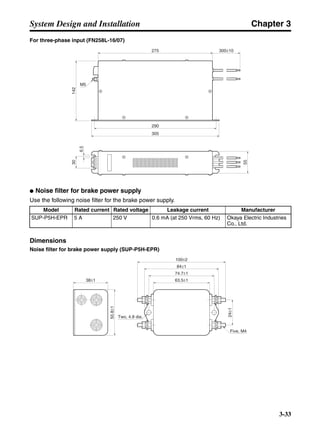

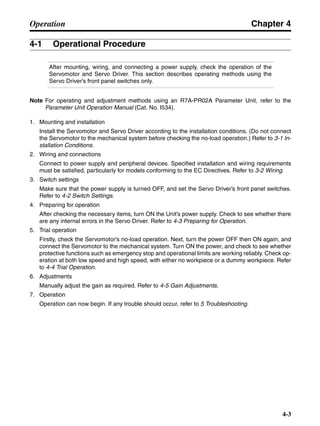

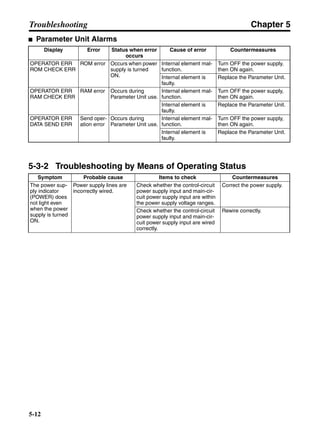

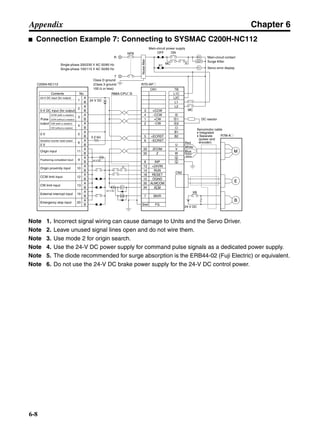

Note There is some loss due to winding resistance, so the actual regenerative energy will be approx-

imately 90% of the values derived from these equations.

• For Servo Driver models with internal capacitors for absorbing regenerative energy (i.e., models of

400 W or less.), the values for both Eg1 or [Eg2+Eg3] (unit: J) must be lower than the Servo Driver’s

regenerative energy absorption capacity. (For details, refer to 3-3-2 Servo Driver Regenerative

Energy Absorption Capacity.)

• For Servo Driver models with internal regeneration resistance for absorbing regenerative energy

(i.e., models of 750 W), the average amount of regeneration Pr (unit: W) must be calculated, and

this value must be lower than the Servo Driver’s regenerative energy absorption capacity. (For

details, refer to 3-3-2 Servo Driver Regenerative Energy Absorption Capacity.)

The average amount of regeneration (Pr) is the power consumed by regeneration resistance in

one cycle of operation.

Pr = (Eg1 + Eg2+ Eg3)/T [W]

T: Operation cycle [s]

3-3-2 Servo Driver Regenerative Energy Absorption Capacity

■ Amount of Internal Regeneration Resistance in Servo Drivers

SMARTSTEP A-series Servo Drivers absorb regenerative energy by means of internal capacitors or

resistors. If the regenerative energy is more than can be processed internally, an overvoltage error is

generated and operation cannot continue. The following table shows the regenerative energy (and

amount of regeneration) that the individual Servo Drivers themselves can absorb. If these values are

exceeded, take the following measures.

• Connect external regeneration resistance (to improve the regeneration processing capacity).

• Reduce the operating rotation speed. (The amount of regeneration is proportional to the square of

the rotation speed.)

• Lengthen the deceleration time (to decrease the regenerative energy produced per time unit).

• Lengthen the operation cycle, i.e., the cycle time (to decrease the average regenerative power).

N1, N2: Rotation speed at beginning of deceleration [r/min]

TD1, TD2: Deceleration torque [N·m]

TL2: Torque when falling [N·m]

t1, t3: Deceleration time [s]

t2: Constant-velocity travel time when falling [s]

• Eg1 = • • N1 • TD1 • t1 [J] = 0.0524 • N1 • TD1 • t1 [J]

2 60

60

2π

2π

1

• Eg2 = • N2 • TL2 • t2 [J] = 0.105 • N2 • TL2 • t2 [J]

60

2π

• Eg3 = • • N2 • TD2 • t3 [J] = 0.0524 • N2 • TD2 • t3 [J]

2

1](https://image.slidesharecdn.com/datasheetr7ma10030s1-151021112310-lva1-app6892/85/Datasheet-r7-m-a10030_s1-179-320.jpg)

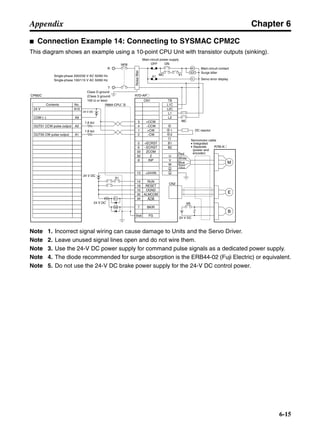

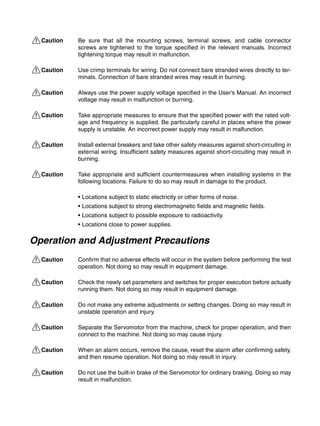

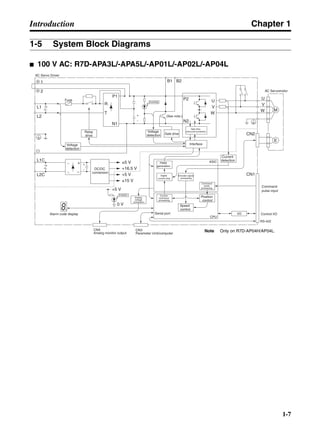

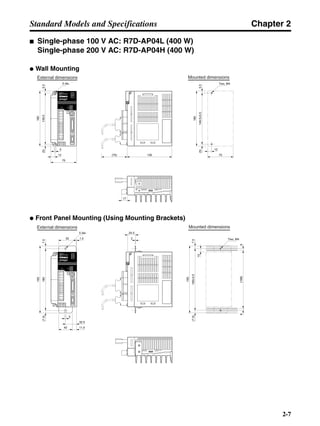

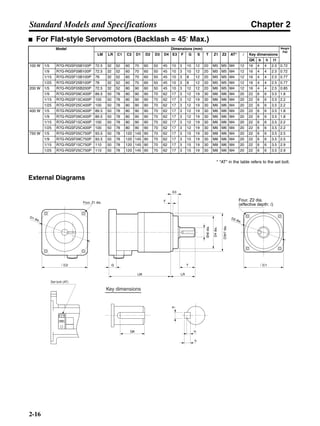

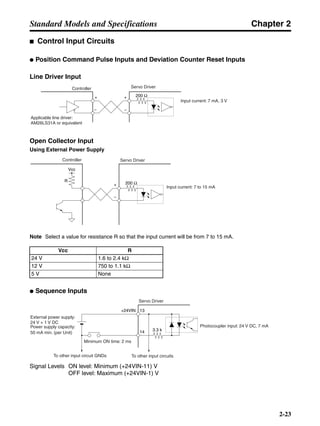

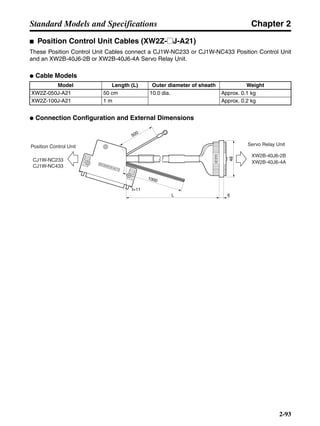

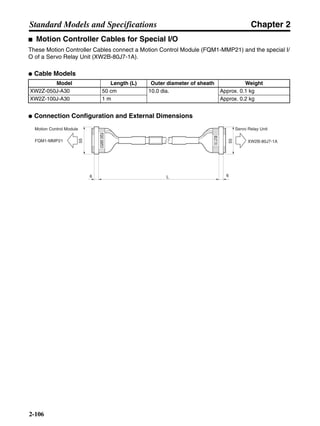

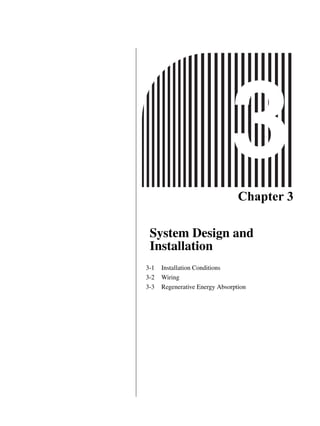

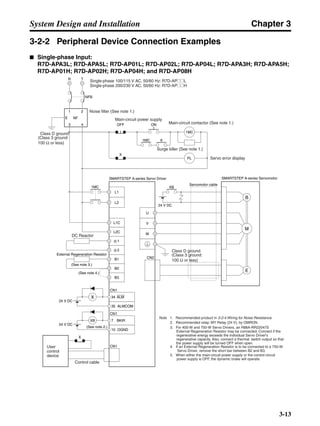

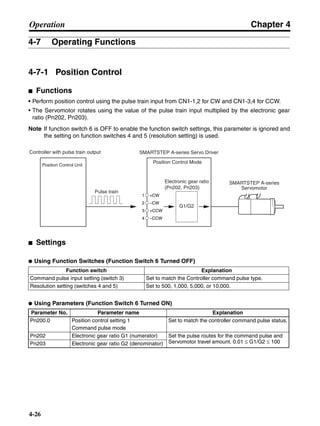

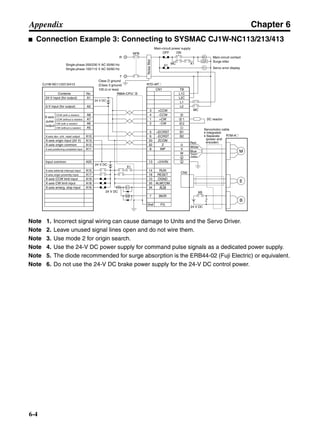

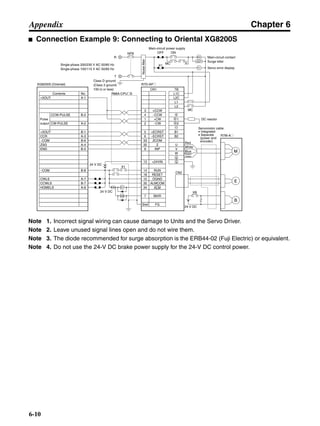

![Chapter 6

6-11

Appendix

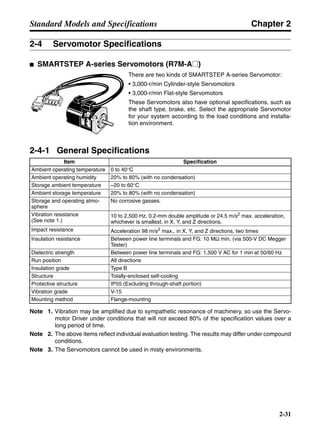

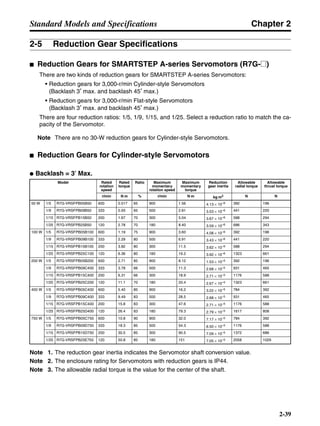

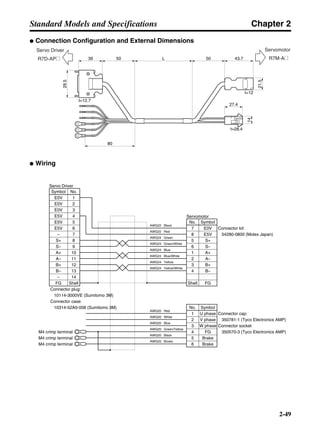

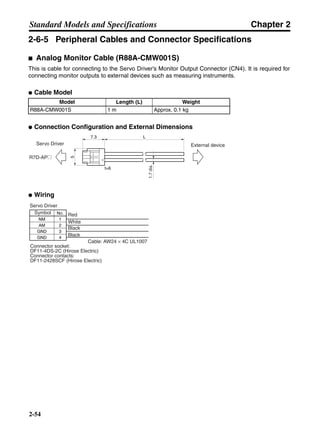

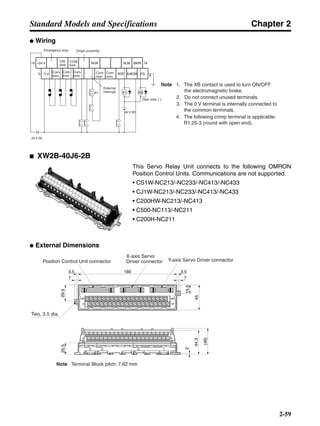

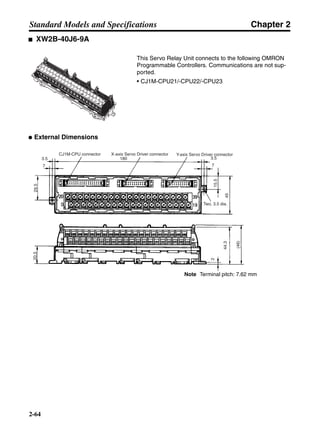

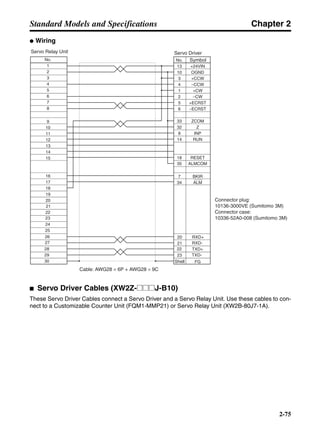

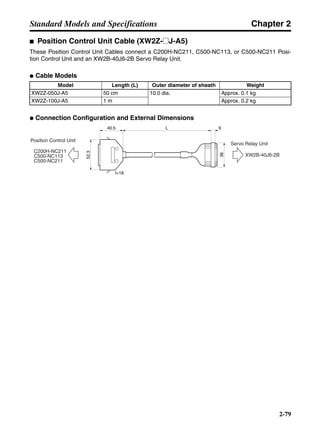

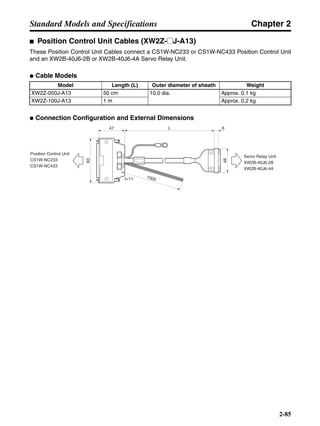

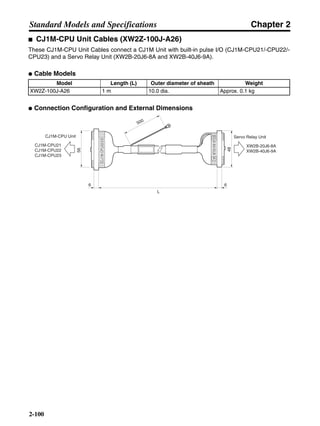

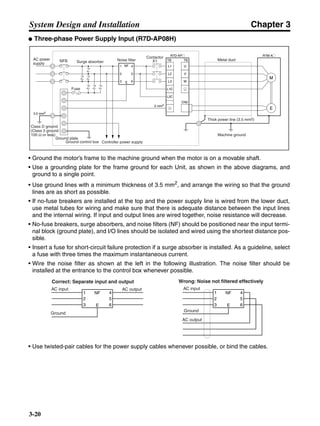

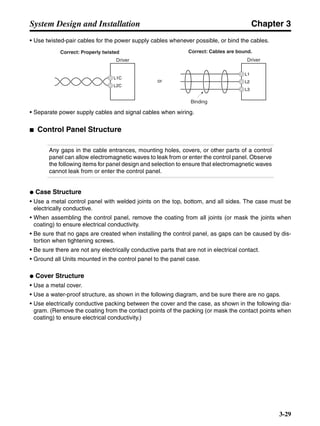

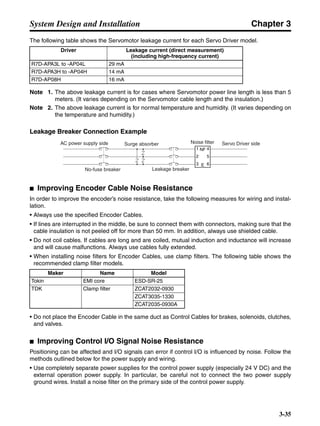

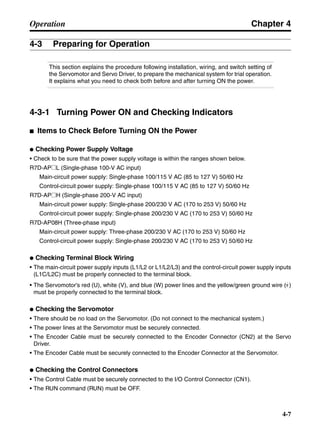

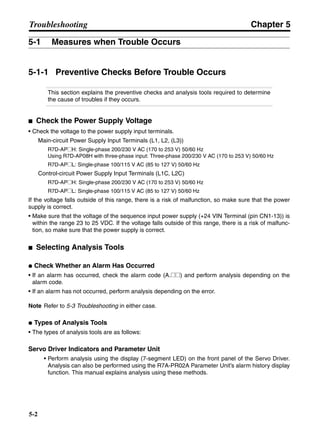

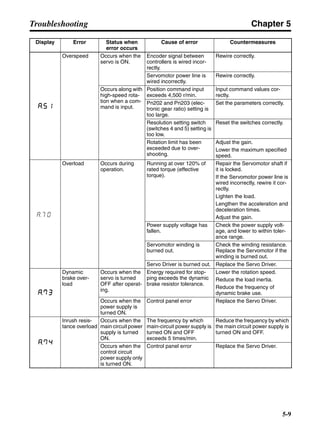

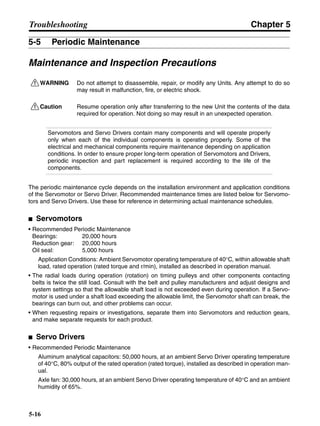

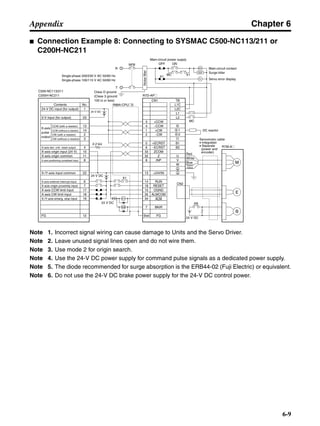

■ Connection Example 10: Connecting to Oriental SG8030J

Note 1. Incorrect signal wiring can cause damage to Units and the Servo Driver.

Note 2. Leave unused signal lines open and do not wire them.

Note 3. The diode recommended for surge absorption is the ERB44-02 (Fuji Electric) or equivalent.

Note 4. Do not use the 24-V DC brake power supply for the 24-V DC control power.

SG8030J (Oriental) R7D-AP@

R7M-A@

Contents No.

CN1 TB

+24V 3

GND

CCW pulse/rotation direction

CW pulse/pulse

Operation mode switching

HOMELS

Start

M0 [CW scan]

M1 [CCW scan]

Emergency stop

2

4

1

2

5

6

33

32

8

13

14

18

10

35

34

7

Shell

3 +CCW

L1C

L2C

L1

L2

B1

B2

U

V

W

1

2

−CCW

+CW

−CW

+ECRST

−ECRST

ZCOM

INP

+24VIN

RUN

RESET

OGND

ALMCOM

ALM

FG

Z

8

7

1

5

6

10

11

9

CN2

M

E

X1

XB

24 V DC

Red

White

Blue

Green/

Yellow

Noisefilter

R

T

Single-phase 200/230 V AC 50/60 Hz

Single-phase 100/115 V AC 50/60 Hz

MC

MC

SUP

NFB ONOFF

X1

X1MC

Main-circuit power supply

Main-circuit contact

Servo error display

Surge killer

X1

24 V DC

DC reactor

PL

B

24 V DC

XB

BKIR

R88A-CPU@S

Class D ground

(Class 3 ground:

100 Ω or less)

+

+

+

− Servomotor cable

• Integrated

• Separate

(power and

encoder)](https://image.slidesharecdn.com/datasheetr7ma10030s1-151021112310-lva1-app6892/85/Datasheet-r7-m-a10030_s1-243-320.jpg)