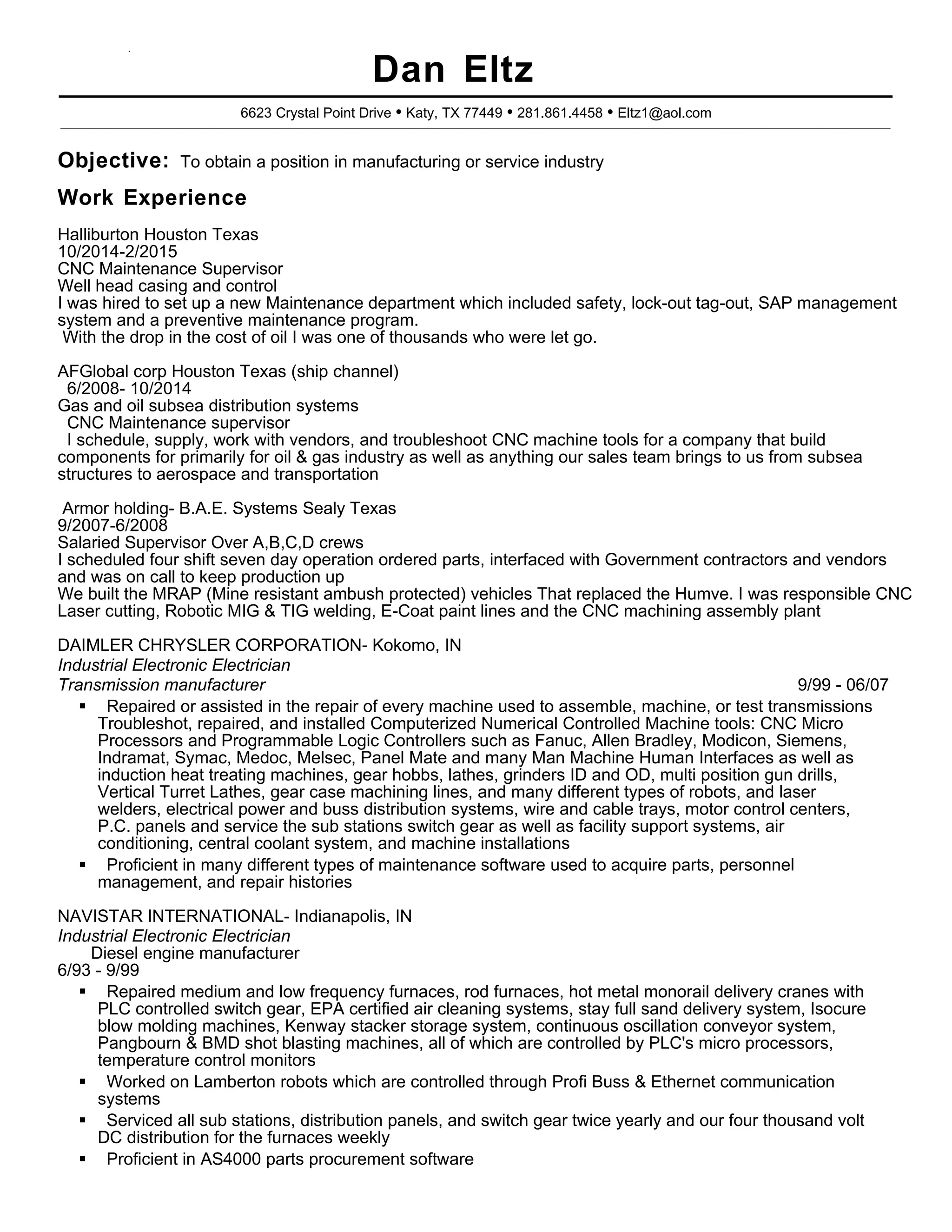

Dan Eltz has over 40 years of experience in manufacturing maintenance roles. He has a history of success as a CNC maintenance supervisor and salaried supervisor, keeping production up at various oil and gas, aerospace, and automotive companies. Most recently, he was let go from Halliburton due to reductions amid low oil prices. He is proficient in many computerized systems including SAP, CNC machines, PLCs, and manufacturing software. He is looking for a new position in manufacturing or services.