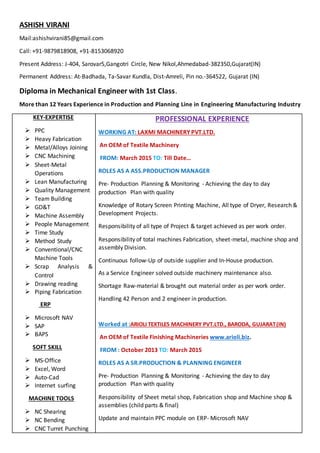

This document contains the resume of Ashish Virani. He has over 12 years of experience in production and planning roles in engineering manufacturing industries. He holds a Diploma in Mechanical Engineering and has expertise in areas such as production planning and control, CNC machining, quality management, and people management. Currently, he works as an Assistant Production Manager at Laxmi Machinery Pvt. Ltd., where he is responsible for pre-production planning and monitoring. Previously he has worked at Arioli Textiles Machinery Pvt. Ltd. and Batliboi Ltd. in senior production and planning roles.