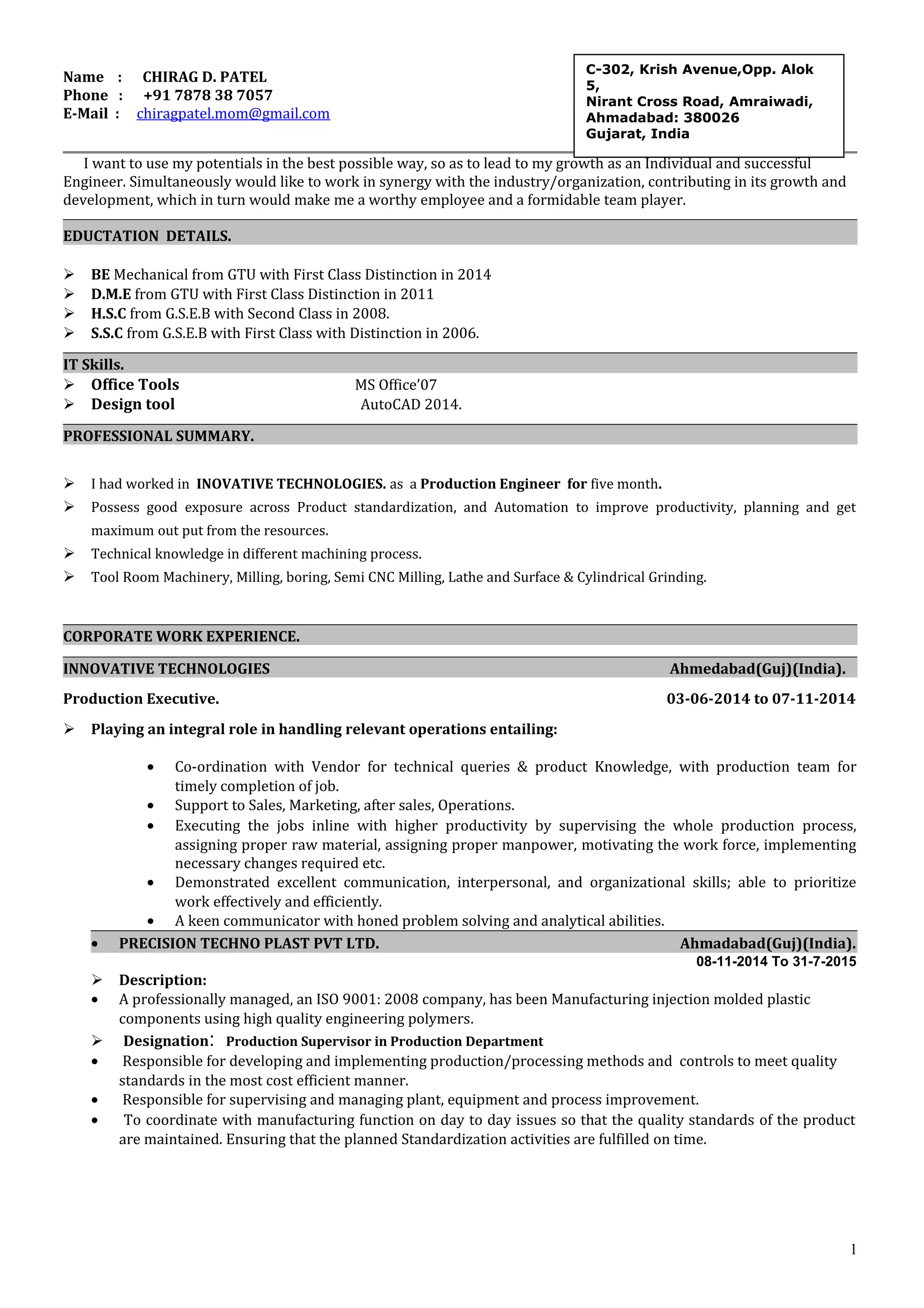

Chirag Patel is seeking new opportunities as an engineer. He has a BE in Mechanical Engineering from GTU with distinction and over 5 years of experience in production engineering roles. His experience includes working as a Production Engineer, Production Supervisor, and Store Manager focusing on production planning and quality control. He is proficient in CAD software and ERP systems. He aims to contribute to an organization's growth while further developing his skills.