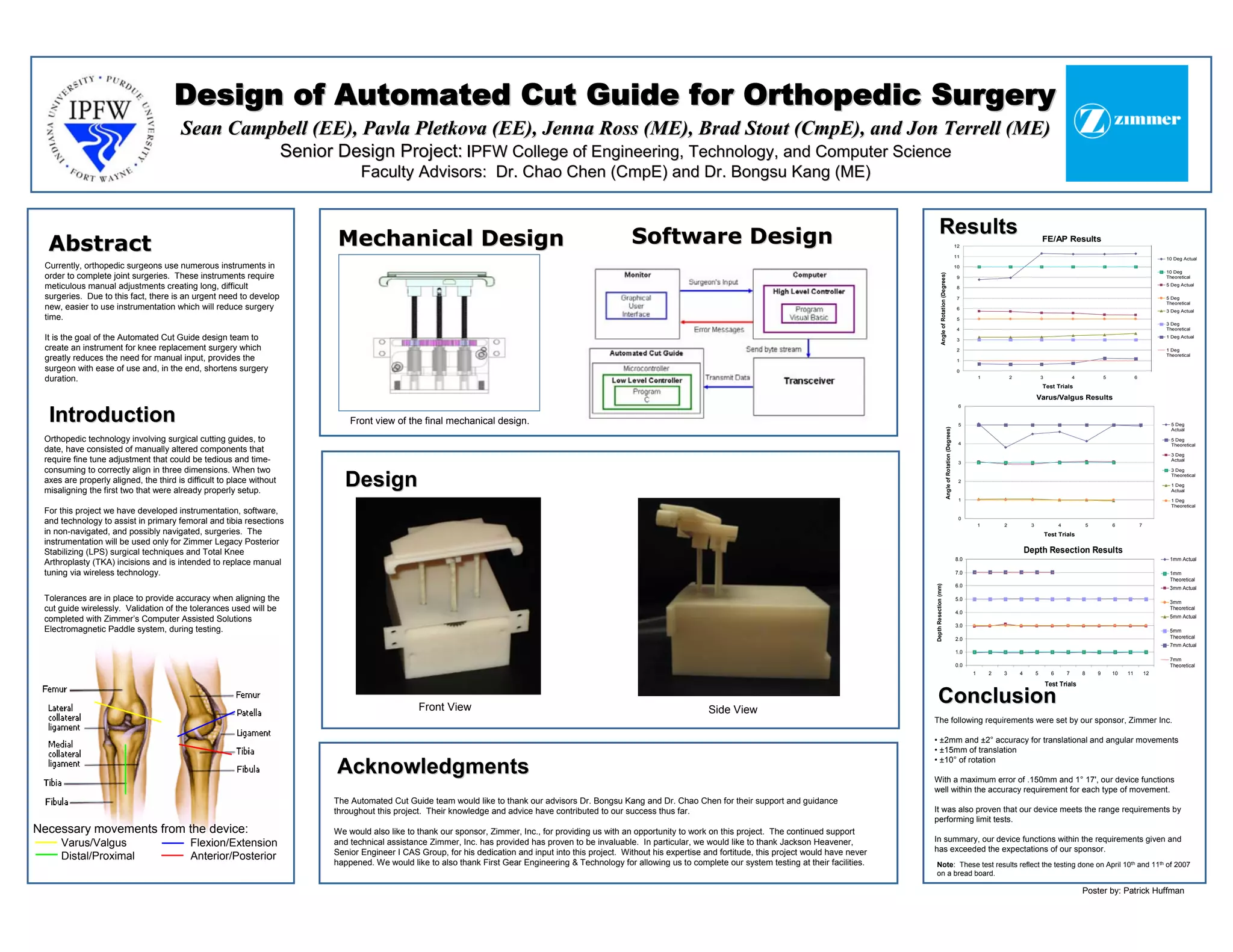

The document describes a project to design an automated cut guide for orthopedic surgery to reduce surgery time. Currently, surgeries require extensive manual adjustments of instruments. The project aims to create a guided instrument for knee replacement surgery that reduces manual input and shortens surgery duration. The device developed guides femoral and tibial bone resections during knee replacement surgery and replaces manual tuning through wireless technology and software. Testing showed the device meets sponsor requirements for translational and rotational accuracy and range of movement.