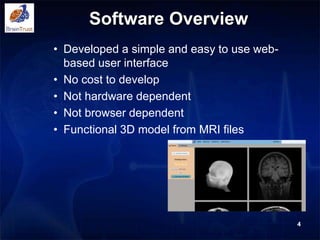

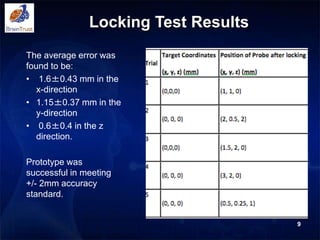

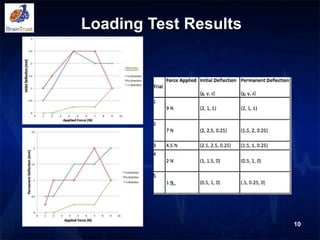

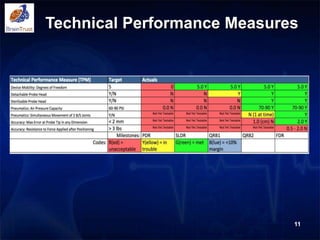

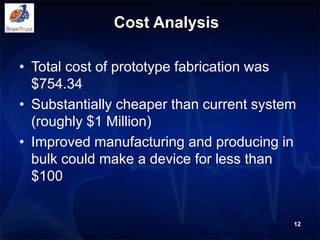

This document describes the development of an image-guided surgical system for intracranial neurosurgery. It includes a web-based software for surgical planning and a mechanical arm to position surgical probes. The software allows uploading of MRI/CT scans and viewing the target in 3D. The articulating arm has 5 degrees of freedom, maintains sterility, and locks probes with sub-2mm accuracy. Testing showed the prototype meets accuracy standards and is substantially cheaper than current methods, with potential to further reduce costs through optimized manufacturing. The system was approved by consulted neurosurgeons.