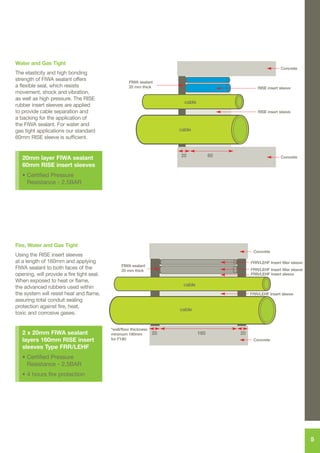

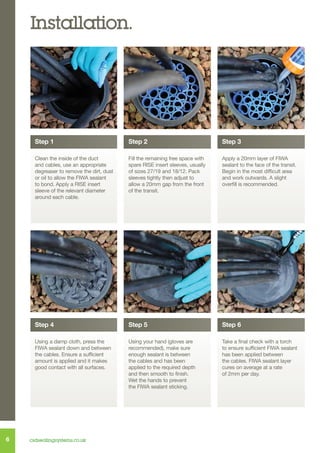

The document details the Rise Duct Seal multi-cable and pipe sealing system, designed for fire, gas, and watertight applications. It highlights the effectiveness, ease of installation, and compliance with safety regulations, emphasizing its flexibility and longevity with a tested lifespan of over 50 years. The product consists of rubber insert sleeves and Fiwa sealant, providing robust protection against fire and hazardous substances while allowing for straightforward cable additions.