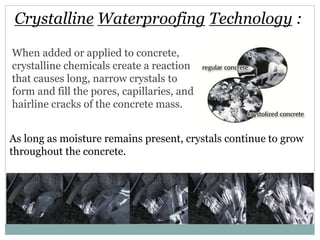

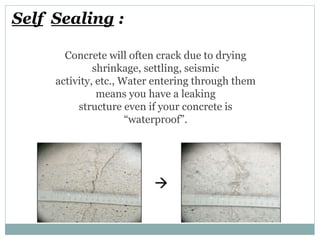

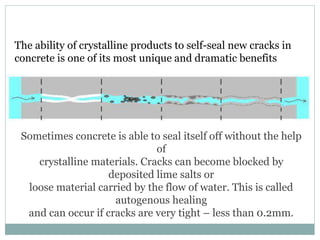

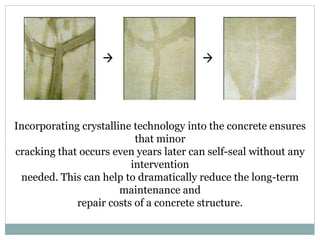

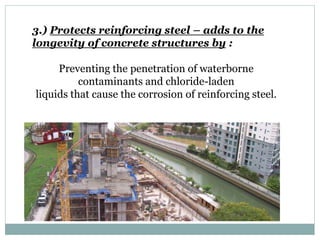

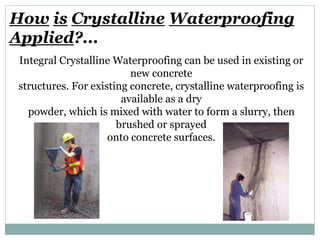

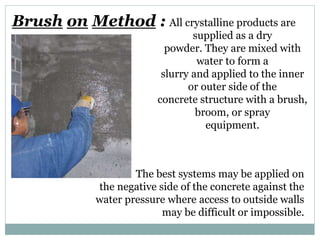

Crystalline waterproofing works by creating crystals within the pores and cracks in concrete to block the movement of water. When added to concrete during the mixing or application process, crystalline chemicals react to form long crystals throughout the concrete mass. This seals the concrete and allows it to self-seal any future cracks without additional treatment. Crystalline waterproofing provides a permanent waterproofing solution, can be used for blind-wall applications, protects reinforcing steel from corrosion, and allows for faster construction schedules.