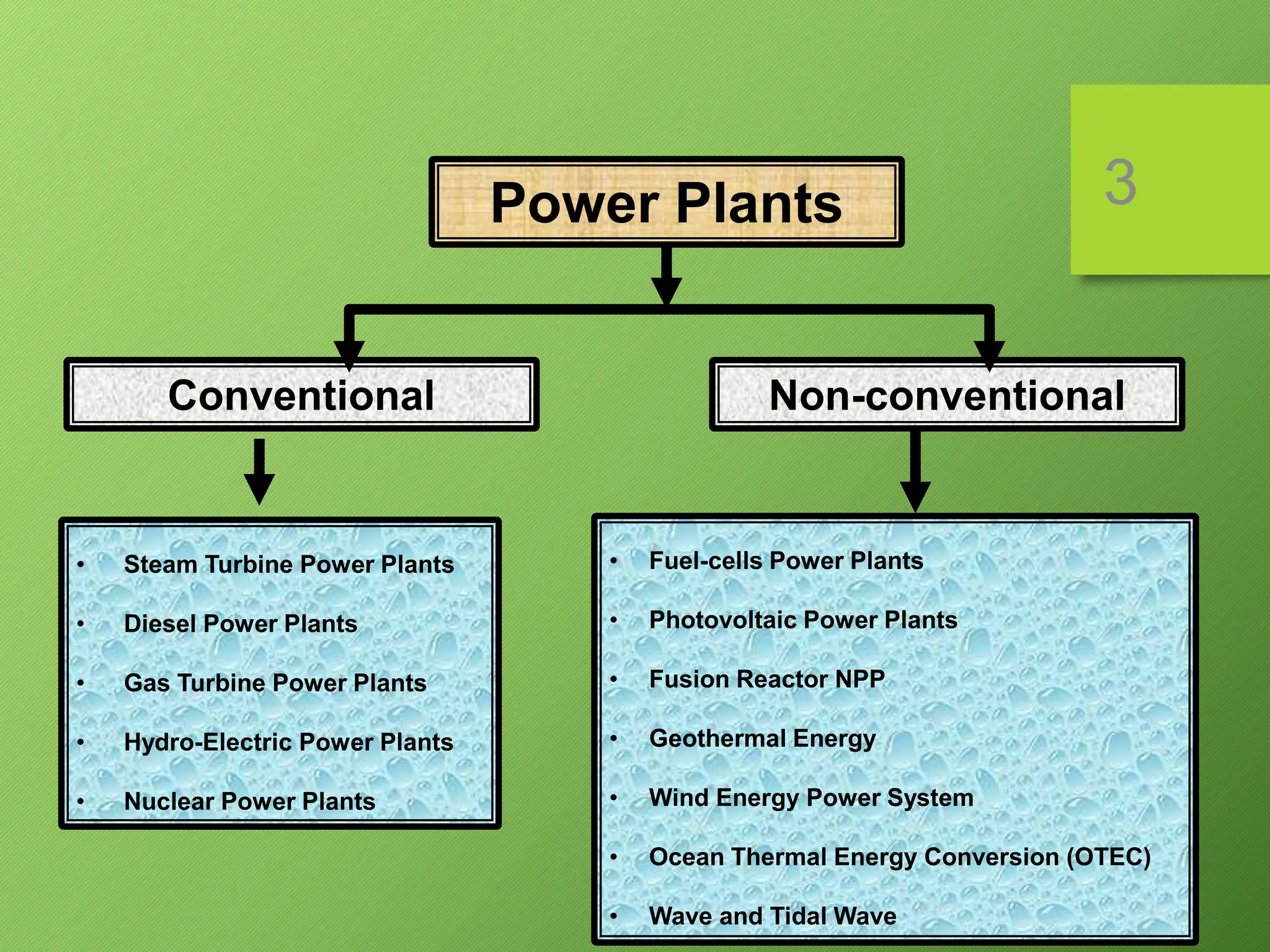

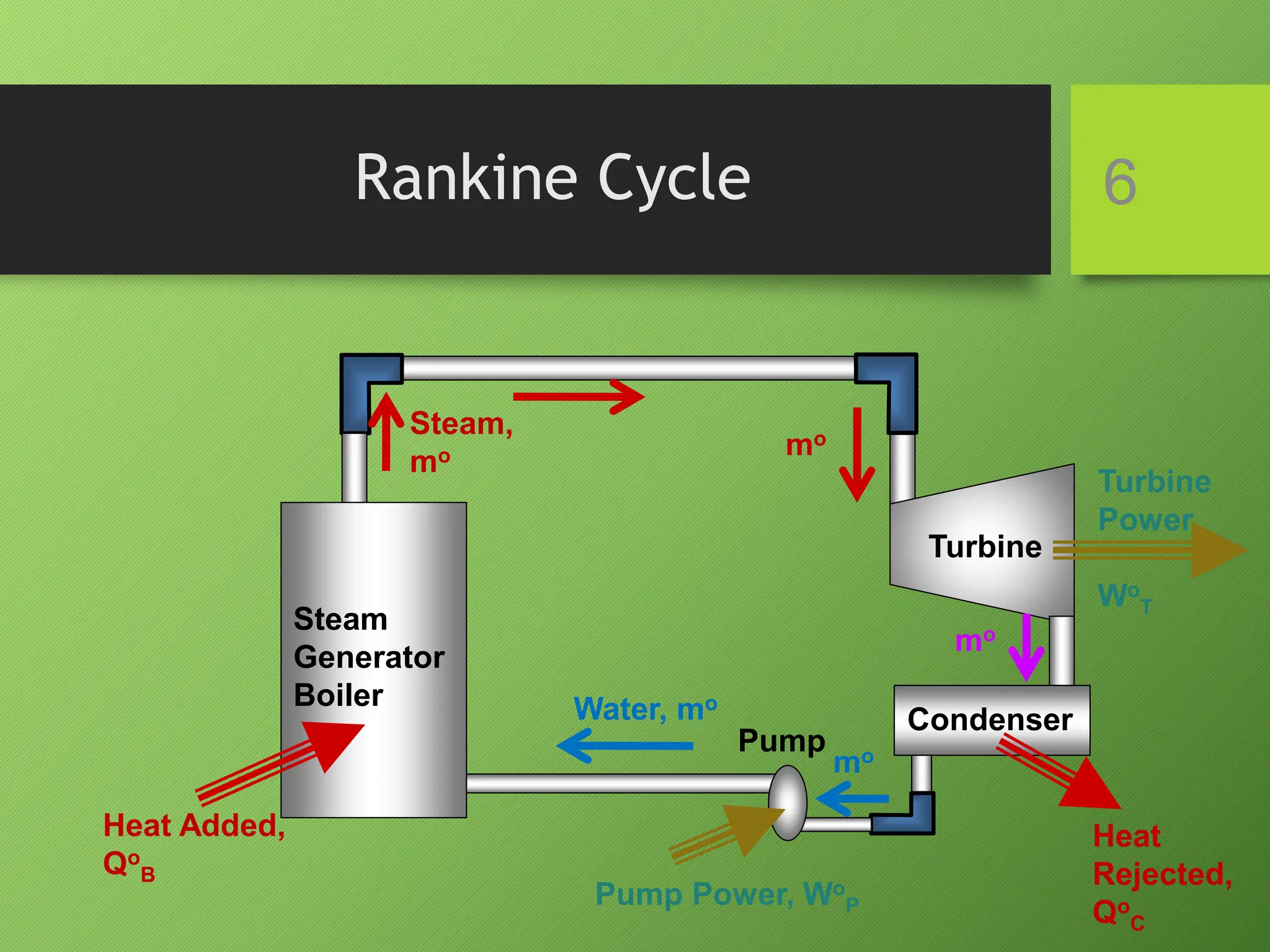

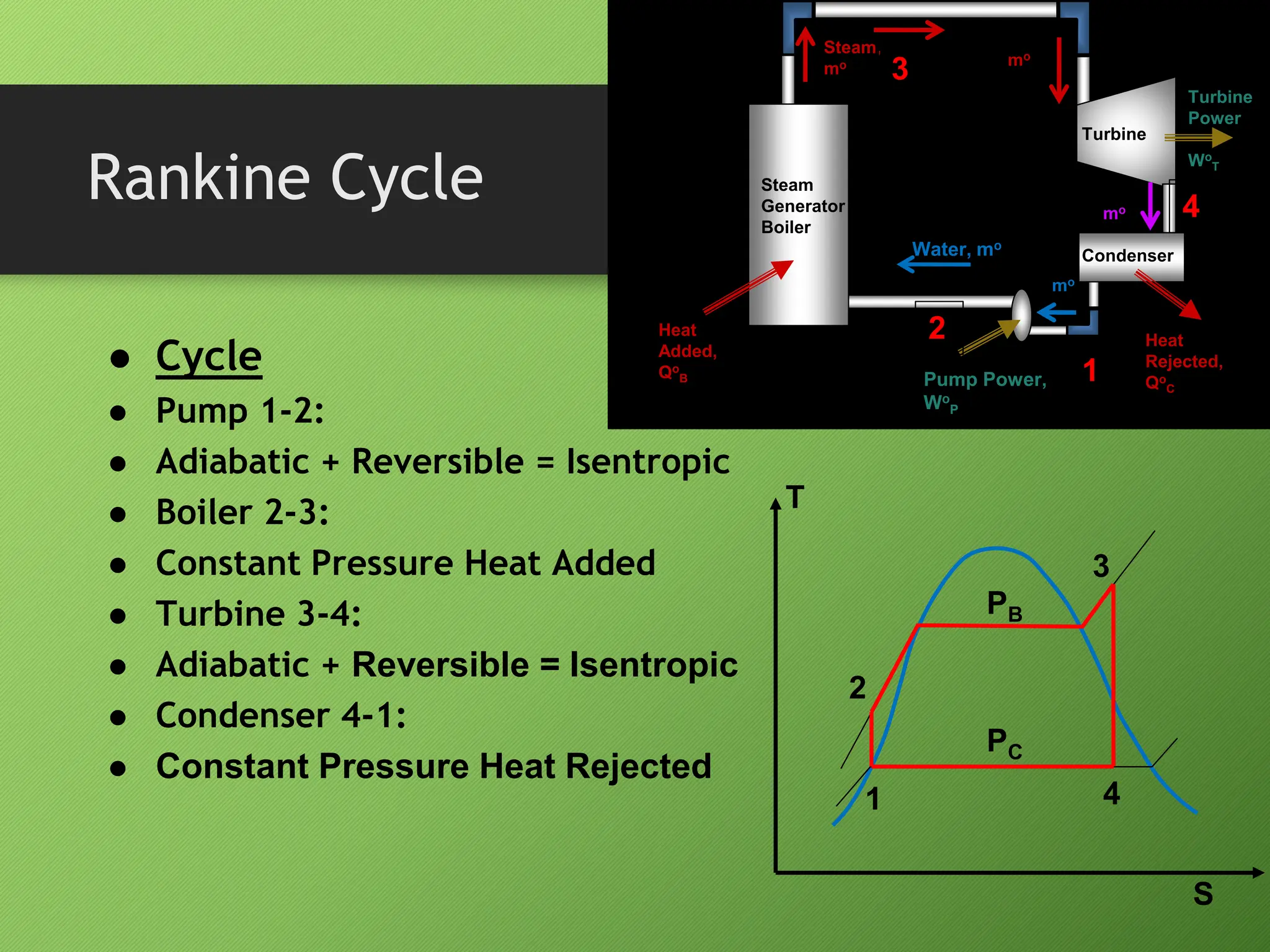

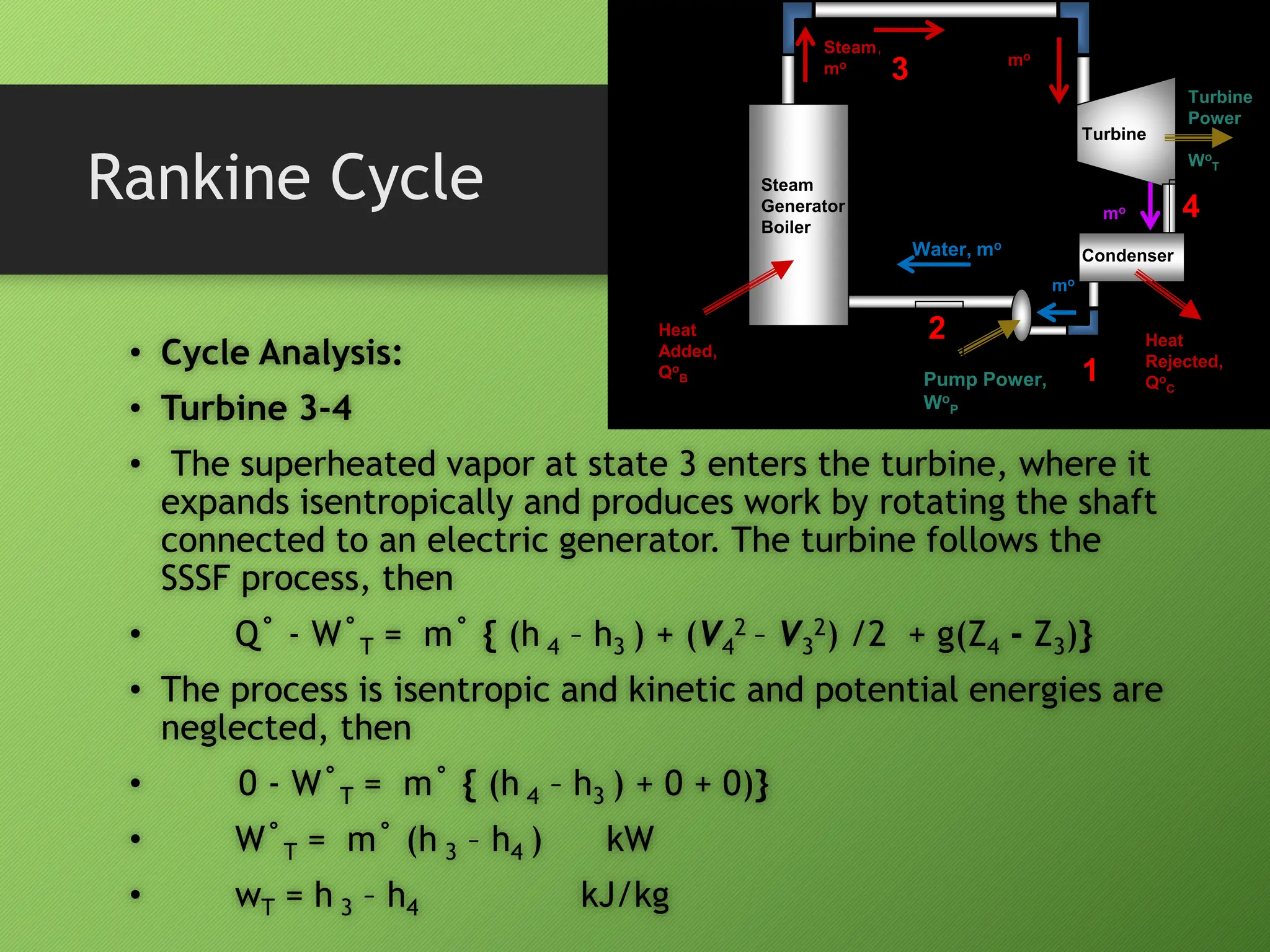

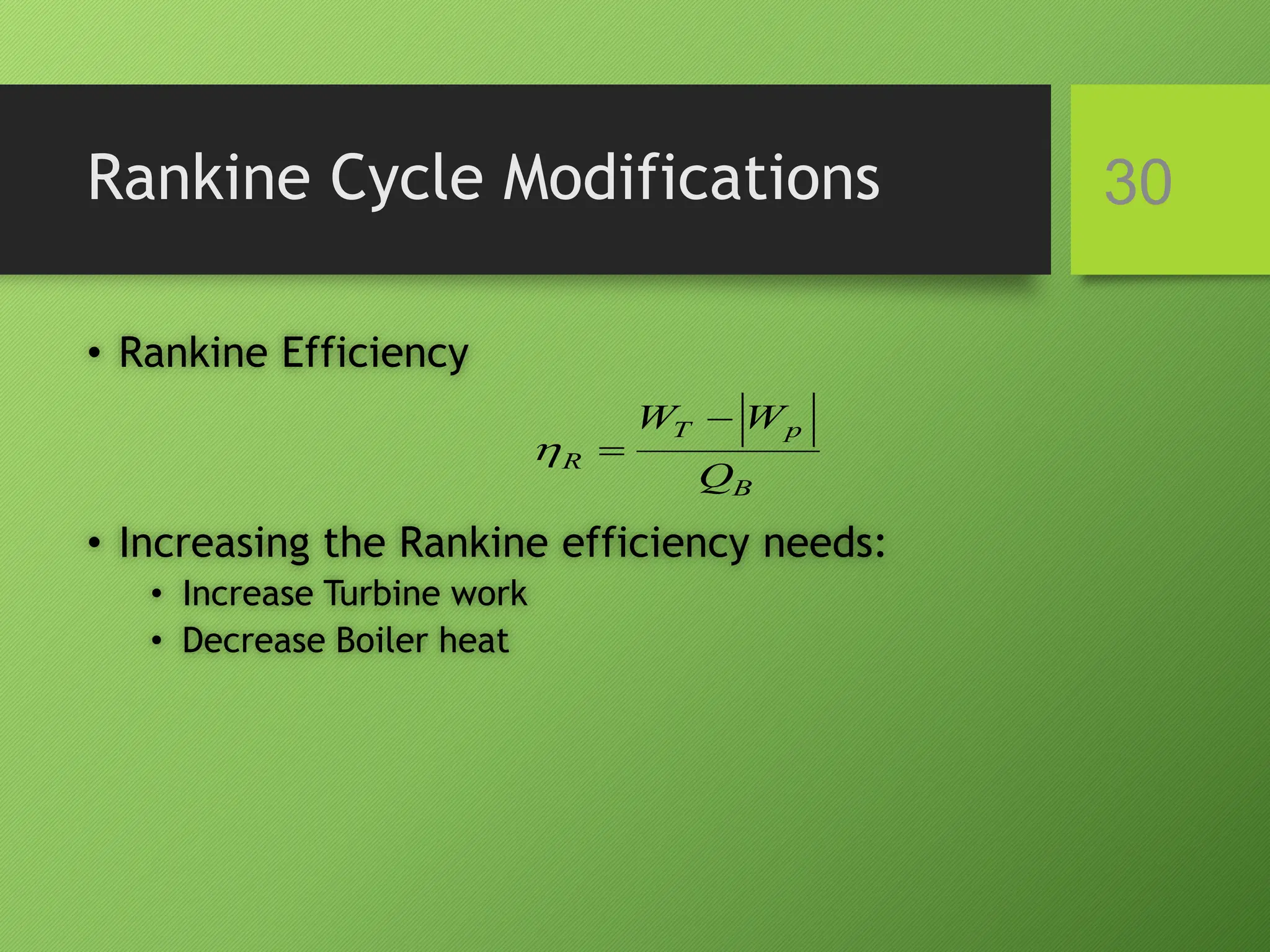

This document provides information about conventional thermal power plants and the Rankine cycle. It describes the key components of a steam power plant that uses the Rankine cycle, including the boiler, turbine, condenser, and pump. It also analyzes each process of the Rankine cycle using the first and second laws of thermodynamics. Additionally, it discusses important parameters for steam power plants such as specific steam consumption, specific fuel consumption, and the cooling water flow rate in the condenser.