More Related Content

PPTX

Excavation safety as per 1926 subpart P.pptx PDF

Excavation Safety Presentation as part of COSH PPSX

PPT

Excvation Safety for safety officers reference PPT

dftvgebhjijh bed7 gbwe d bwenp dgbwe ubdwueb djhweb jhb wejh b jhwe bdhbwejhb... PDF

PPTX

PPTX

Similar to construction hazards and standards from OSHA

PPT

OSHA Trenching and Excavation Requirements PPTX

PPTX

Excavation and Demolition powerpoint presentation PPT

PPT

Excavation Safety Training Module 1 PPTX

Excavator.pptx training powerpoint safety PPT

Excavation OSHA Safety with safety and OSHA standards PPT

PPT

038 Trenching and Shoring.PPT PPTX

PPTX

1926_ExcavatnTrenchiquesmmmmmmmmmmmmmmmm PPT

03 Safety in Excavation & Blasting for t PPTX

Excavation training module.pptx agar lbh PPT

PPTX

Excavation-Safety-1. Construction safety and health PPT

PPTX

PDF

PDF

PPTX

ASP Study Group_Safety Programs Part Two Revised dec 13 2015.pptx More from msiskenderoglu

PPT

innovative frameworks on social statistics-final PPT

construction scheduling and cost control PPT

CONSTRUCTION SCHEDULING & COST CONTROL PPT

Building technology for construction and buildings PPT

building tech unit 6 Framed buidings.ppt PPT

economy and construction industry in korea PPT

Construction definitions and abbreviations Recently uploaded

PDF

The Science Behind Why Accountability Works in Alcohol Recovery.pdf PPTX

PPTX

Compassionate Hospice Care Services in Orange County, NY PDF

cytokines 2025.pdf -ytokines are small proteins that help control the growth ... PPTX

Cells and Organs of immune system [Autosaved].pptx PDF

Evaluation of Antidepressants (Preclinical & Clinical) PPTX

IRON DEFICIENCY ANEMIA and its importance .pptx PPT

Investigation of an Epidemic ...outbreak investigation PDF

A Guide to Your Benefits: 2026 MVP Medicare Advantage Plans PPTX

The autoclave is also called a steam sterilizer that is commonly used in heal... PDF

MedWorks Advantage Your Trusted Partner in Medical & Surgical Equipment PDF

Reticulin Stain (Gordon & Sweet Method) | Special Stain in Histopathology PDF

Patient lifting robot concept presentation PPTX

Geriatric Health in Nepal: Aging Process, Health Problems, and Care Services PPTX

Ophthalmic lens power and form presentation PPTX

"Strategic Approaches to Enhancing Healthcare Management & Leadership Effecti... PPTX

Prism and Its Uses in Ophthalmic Dispensing PPTX

Corneal Topography: Principles, Techniques, Patterns, and Clinical Applications PPT

National child policy.ppt child health nursing PPTX

PPTS HEALTHCARE.pptx NON-COMMUNICABLE DISEASES construction hazards and standards from OSHA

- 1.

- 2.

2 ©2006 TEEX

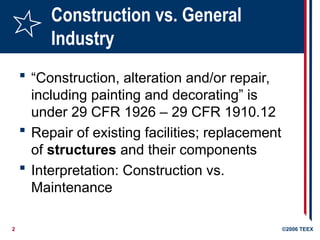

Constructionvs. General

Industry

“Construction, alteration and/or repair,

including painting and decorating” is

under 29 CFR 1926 – 29 CFR 1910.12

Repair of existing facilities; replacement

of structures and their components

Interpretation: Construction vs.

Maintenance

- 3.

3 ©2006 TEEX

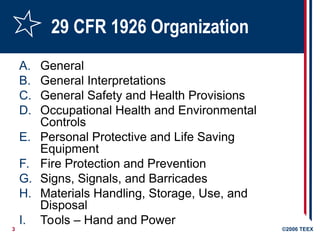

29CFR 1926 Organization

A. General

B. General Interpretations

C. General Safety and Health Provisions

D. Occupational Health and Environmental

Controls

E. Personal Protective and Life Saving

Equipment

F. Fire Protection and Prevention

G. Signs, Signals, and Barricades

H. Materials Handling, Storage, Use, and

Disposal

I. Tools – Hand and Power

- 4.

4 ©2006 TEEX

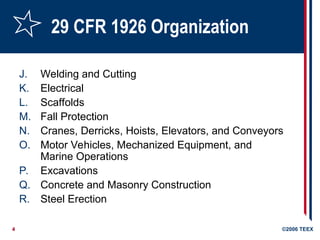

29CFR 1926 Organization

J. Welding and Cutting

K. Electrical

L. Scaffolds

M. Fall Protection

N. Cranes, Derricks, Hoists, Elevators, and Conveyors

O. Motor Vehicles, Mechanized Equipment, and

Marine Operations

P. Excavations

Q. Concrete and Masonry Construction

R. Steel Erection

- 5.

5 ©2006 TEEX

29CFR 1926 Organization

S. Underground Construction, Caissons,

Cofferdams, and Compressed Air

T. Demolition

U. Blasting and the Use of Explosives

V. Power Transmission and Distribution

W. Rollover Protective Structures; Overhead

Protection

X. Ladders

Y. Commercial Diving Operations

Z. Toxic and Hazardous Substances

- 6.

6 ©2006 TEEX

Hazardsand Standards

What hazards are employees exposed to:

When they set up a drilling site?

When they grade land or excavate?

When they clear a site for use?

Regulations in 29 CFR 1926:

Subpart P – Excavations

Subpart O – Motor Vehicles, Mechanized

Equipment, and Marine Operations

If blasting: Subpart O

- 7.

- 8.

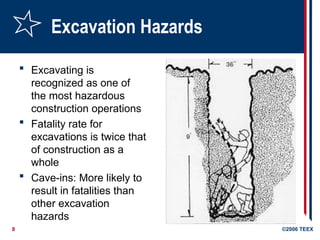

8 ©2006 TEEX

ExcavationHazards

Excavating is

recognized as one of

the most hazardous

construction operations

Fatality rate for

excavations is twice that

of construction as a

whole

Cave-ins: More likely to

result in fatalities than

other excavation

hazards

- 9.

9 ©2006 TEEX

Hazardsof Excavation Work

Cave-ins

Underground utilities

Materials/equipment falling into

excavation sites

Asphyxiation

Explosion

Falls

Drowning

- 10.

10 ©2006 TEEX

SoilMechanics

Unit weight of soils:

Varies with type and moisture content

1 cubic foot can weigh 100 to >140 lbs

1 cubic meter can weigh >3000 lbs

- 11.

- 12.

- 13.

13 ©2006 TEEX

Definitions

Excavation: any man-made cut, cavity,

trench, or depression in an earth

surface, formed by earth removal.

Trench (Trench excavation): a narrow

excavation (in relation to its length)

made below the surface of the ground.

Depth>width; width <15 feet

<15 feet between structure and side

- 14.

14 ©2006 TEEX

Definition– Competent Person

Training, experience, and knowledge of:

Soil analysis

Use of protective systems

Requirements of 29 CFR Part 1926 Subpart P

Ability to detect:

Conditions that could result in cave-ins

Failures in protective systems

Hazardous atmospheres

Other hazards including those associated with confined

spaces

Authority to take prompt corrective measures to

eliminate existing and predictable hazards and to

stop work when required

- 15.

15 ©2006 TEEX

1926.651Specific Excavation

Requirements

a. Remove or support surface

encumbrances (competent person)

b. Determine location of all underground

utilities before opening excavation

OneCall system / 811

Use safe means to determine exact

locations & protect underground utilities

- 16.

16 ©2006 TEEX

1926.651(c)Access & Egress

Structural ramps for access and egress

designed by competent person &

constructed according to design

Bar is higher for equipment ramps

Access & egress ramps designed to

avoid slipping or tripping

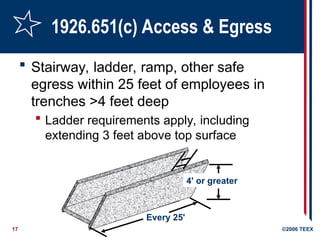

- 17.

17 ©2006 TEEX

1926.651(c)Access & Egress

Stairway, ladder, ramp, other safe

egress within 25 feet of employees in

trenches >4 feet deep

Ladder requirements apply, including

extending 3 feet above top surface

Every 25'

4' or greater

- 18.

18 ©2006 TEEX

1926.651Specific Excavation

Requirements

d. In traffic areas, reflective

vests required

e. No workers underneath

loads handled by lifting or

digging equipment.

f. Barricades, stop logs or

hand signals for mobile

equipment operating near

excavations

- 19.

19 ©2006 TEEX

1926.651(g)Hazardous

atmospheres

In excavations 4 feet or more where

hazardous atmospheres are likely to

exist must test atmosphere before

entering and retest as necessary

Unsafe below 19.5% oxygen

Stay below 20% of lower flammable limits

Ventilation or PPE must be used as

required

Rescue equipment available

- 20.

20 ©2006 TEEX

1926.651(h)Water Accumulation

Precautions required

before working for water

in excavations

Competent Person must

monitor control measures

If diverting surface water,

must take steps to

prevent water from

entering trench

- 21.

21 ©2006 TEEX

1926.651(i)Stability of adjacent

structures

Structures adjacent to excavations must

be supported if stability is affected

No excavation below adjacent footings

unless underpinned, or stable rock, or

approved by PE

No undermining pavements unless

supported

- 22.

22 ©2006 TEEX

1926.651Specific Excavation

Requirements

j. Protect employees from falling rock,

soil, or materials/equipment falling into

excavations.

Keep materials 2 feet from edge

Retaining devices/barricades

k. Inspections by competent person,

daily and as needed during shift

l. Walkways to cross excavations

- 23.

23 ©2006 TEEX

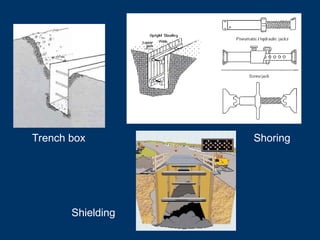

1926.652Requirements for

protective systems

Protection of employees in

excavations

Design of sloping and

benching systems

Design of support

systems, shield systems,

and other protective

systems

Materials and equipment

Installation and removal

- 24.

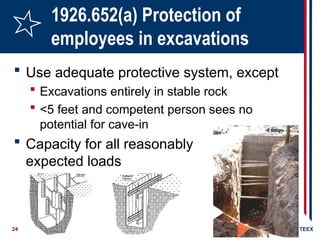

24 ©2006 TEEX

1926.652(a)Protection of

employees in excavations

Use adequate protective system, except

Excavations entirely in stable rock

<5 feet and competent person sees no

potential for cave-in

Capacity for all reasonably

expected loads

- 25.

25 ©2006 TEEX

1926.652(b)and (c) Design of

sloping and benching systems

Four choices for sloping:

Slope for type ‘C’, no steeper than 34°

Use sloping choices from Appendices A, B

Tabulated data determined by a PE

Designed by a PE

For support systems, shield systems, other:

Design using Appendices A, C, D

Manufacturer’s tabulated data

Other tabulated data determined by a PE

Designed by a PE

- 26.

26 ©2006 TEEX

1926.652(d)Materials and

equipment

Materials for protective systems free

from damage & defects

Used according to manufacturer’s

specifications

If damaged,

competent person

must determine

suitability for

continued use

- 27.

27 ©2006 TEEX

1926.652(e)Installation and

removal of support

Support system members securely

connected together

Installed & removed to assure employee

safety

Keep within design

capacity

Remove from bottom

first, and backfill as

you remove

- 28.

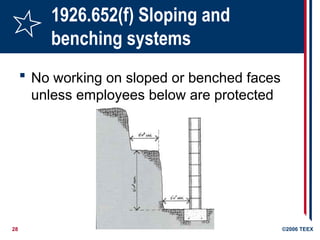

28 ©2006 TEEX

1926.652(f)Sloping and

benching systems

No working on sloped or benched faces

unless employees below are protected

- 29.

29 ©2006 TEEX

1926.652(g)Shield systems

Shield systems not subject to loads

exceeding their capacity

Installed to restrict lateral movement

Employee protection provided while

entering/exiting shields

No employees in trench during installation or

removal of shields

May excavate up to 2 feet below shield with

proper conditions

- 30.

- 31.

31 ©2006 TEEX

1926Subpart P Appendix A -

Soil Classification

A method of categorizing soil and rock

deposits in a hierarchy:

Stable Rock

Type A – cohesive soil >1.5 tsf – with

exceptions

Type B – cohesive soil >.5-1.5 tsf or

granular, disturbed, vibrated, fissured,

layered

Type C – cohesive soil <.5 tsf or granular,

submerged, layered…

- 32.

- 33.

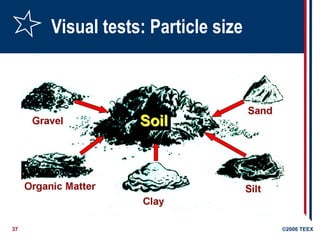

33 ©2006 TEEX

Soils- Types & Particle Size

Gravel

larger than 2 millimeters

Sand

Between 0.075 and 2 millimeters

Silt

Between 0.002 and 0.075 millimeters

Clay

Smaller than 0.002 millimeters

.

- 34.

34 ©2006 TEEX

Additionalsoil classification

Layered geological strata: based on

weakest layer

May be classified individually if weaker

is on top of stronger

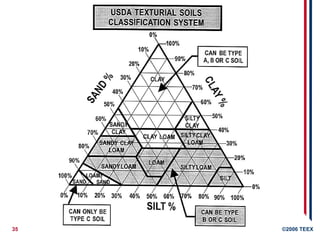

- 35.

- 36.

36 ©2006 TEEX

1926Subpart P Appendix A -

Soil Classification

Each soil and rock deposit shall be

classified by a competent person

Classification made based on at least

one visual and one manual analysis

- 37.

- 38.

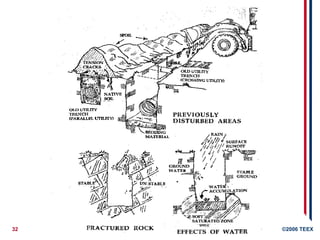

38 ©2006 TEEX

Visualtests

Clumping

Cracks or spalling

Existing utilities/previously disturbed soil

Layers and slope

Water in surface, seeping, water table

Vibration sources

- 39.

39 ©2006 TEEX

Manualtests

Plasticity

Dry strength

Thumb penetration

Pocket penetrometer or shearvane

Drying test

- 40.

- 41.

41 ©2006 TEEX

Organizationof Subpart O

1926.600 - Equipment.

1926.601 - Motor vehicles.

1926.602 - Material handling equipment.

1926.603 - Pile driving equipment.

1926.604 - Site clearing.

1926.605 - Marine operations and equipment.

1926.606 - Definitions applicable to this

subpart.

- 42.

42 ©2006 TEEX

1926.600(a)Equipment - General

Requirements

Lights/reflectors on unattended equipment

next to highway

Protection for tire changes on split rims

Elevated equipment: protect from falling

Parking brake, plus chocks for inclines

Batteries: by Subpart K

Cab glass: safety glass with no visible

distortion

Movement around power lines or transmitters

Stops for railroad cars on spurs

- 43.

43 ©2006 TEEX

1926.601– Motor Vehicles

a. Coverage.

Motor vehicles that operate within an off-

highway jobsite, not open to public traffic

Not for material handling equipment

covered under 1926.602.

- 44.

44 ©2006 TEEX

1926.601(b)General

requirements

Brake system in operable condition:

Service brake system

Emergency brake system

Parking brake system

2 headlights & 2 taillights if needed,

depending on visibility

Brake lights regardless of visibility

- 45.

45 ©2006 TEEX

1926.601(b)General

requirements

Audible warning device (horn)

Obstructed rear view: must have

Reverse signal alarm audible above

surrounding noise level or

Backed up only when observer signals that

it is safe

Windshields & powered wipers on cabs

Fix cracked glass

Defogger/defroster where necessary

- 46.

46 ©2006 TEEX

1926.601(b)General

requirements

Haulage vehicles: cab shield and/or

canopy adequate to protect the operator

from shifting or falling materials

Secure tools and material from

movement in compartments with

employees

Seats firmly secured and adequate for

employees being carried

- 47.

47 ©2006 TEEX

1926.601(b)General

requirements

Seat belts and anchorages meeting 49

CFR Part 571

Dump bodies supported, locked into

position for maintenance or inspection

Latch on hoisting/dumping devices to

prevent accidental operation

Trip handle of dump truck tailgate:

operator must be clear when dumping

- 48.

48 ©2006 TEEX

1926.601(b)General

requirements

Rubber-tired equipment must have

fenders or mud flaps

Vehicles checked at beginning of shift:

All brake systems

Tires

Horn

Steering

Coupling

Seat belt

Controls

Safety devices

Lights/reflectors

Wipers/defrosters

Fire extinguishers

- 49.

49 ©2006 TEEX

1926.602– Material Handling

Equipment

Application:

Scrapers, loaders, crawler or wheel

tractors, bulldozers, off-highway trucks,

graders, agricultural and industrial tractors,

and similar equipment

Compactors and rubber-tired "skid-steer"

equipment: reserved

- 50.

50 ©2006 TEEX

1926.602(a)(2)Seat belts

Provided and must meet standards

Not necessary for standup operations

Not necessary for equipment without

roll-over protective structure (ROPS) or

canopy protection

ROPS: See 1926 Subpart W

- 51.

51 ©2006 TEEX

1926.602(a)Earthmoving

equipment; General

Access roadways and grades

Must be constructed and maintained for

safe movement of equipment involved

Emergency access ramps or berms to

restrain and control runaway vehicles

Service braking system

Capable of stopping and holding fully

loaded equipment

SAE standards apply

- 52.

52 ©2006 TEEX

1926.602(a)Earthmoving

equipment; General

Fenders on pneumatic-tired earth-

moving equipment >15 mph

Suspended pending reevaluation

ROPS and overhead protection: Subpart

W

Horns for bidirectional machines

Reverse signal alarm

Guard all scissor points

- 53.

53 ©2006 TEEX

1926.602(b)Excavating and

other equipment

Seatbelts for tractor operation

Power Crane and Shovel Associations

Standards No. 1 and No. 2 of 1968, and

No. 3 of 1969 adopted

- 54.

54 ©2006 TEEX

1926.602(c)Lifting and hauling

equipment

Other than that covered by Subpart N

1926.600 and:

Ratings clearly visible and not exceeded

No modifications or additions without

manufacturer’s written approval

Multiple trucks together: proportion of load

must not exceed capacity

Steering knobs not attached unless

spinning prevented

- 55.

55 ©2006 TEEX

1926.602(c)Lifting and hauling

equipment

Overhead guards for high lift rider

industrial trucks

ANSI B56.1-1969

Riding on industrial trucks:

No unauthorized personnel

Safe place to ride

- 56.

56 ©2006 TEEX

1926.602(c)(1)(viii)Lifting

Personnel

Only where designed for that purpose

by manufacturer! (interpretation)

Safety platform secured to lifting

carriage or forks

Riding personnel must be able to shut

off power to truck

Falling object protection

- 57.

- 58.

58 ©2006 TEEX

1926.603Pile driving equipment

General requirements

Barges or floats: 1926.605

Pile driving equipment

- 59.

59 ©2006 TEEX

1926.604Site clearing

Protect from toxic/irritant plants

Instruct in first aid treatment

Rollover guards

Overhead and rear canopy guards:

At least 1/8” steel plate or 1/4” wire mesh

with up to 1” openings

Rear of canopy: at least 1/4” wire mesh

with up to 1” openings

- 60.

60 ©2006 TEEX

1926.605Marine operations and

equipment

Material handling: 1918, Longshoring

Access to barges

Working surfaces of barges

First-aid and lifesaving equipment

Commercial diving operations: 1926

Subpart T

- 61.

61 ©2006 TEEX

1926Subpart W: Rollover

Protective Structures (ROPS)

This construction equipment must have

ROPS meeting minimum performance

standards:

Rubber-tired, self-propelled scrapers

Rubber-tired front-end loaders

Rubber-tired dozers

Wheel-type agricultural and industrial tractors

Crawler tractors

Crawler-type loaders

Motor graders, with or without attachments

NOT sideboom pipe laying tractors

- 62.

62 ©2006 TEEX

RolloverProtective Structures

Purpose: Prevent complete overturn;

minimize possibility of crushed operator

Driver could still be crushed if not

wearing a seatbelt!

Also in subpart W:

Testing provisions

Rule for overhead protection

- 63.

- 64.

64 ©2006 TEEX

Applicationof Scaffold

Regulations

What is a scaffold?

What is covered by 29 CFR 1926

Subpart L?

Where are scaffolds used in oil and

gas?