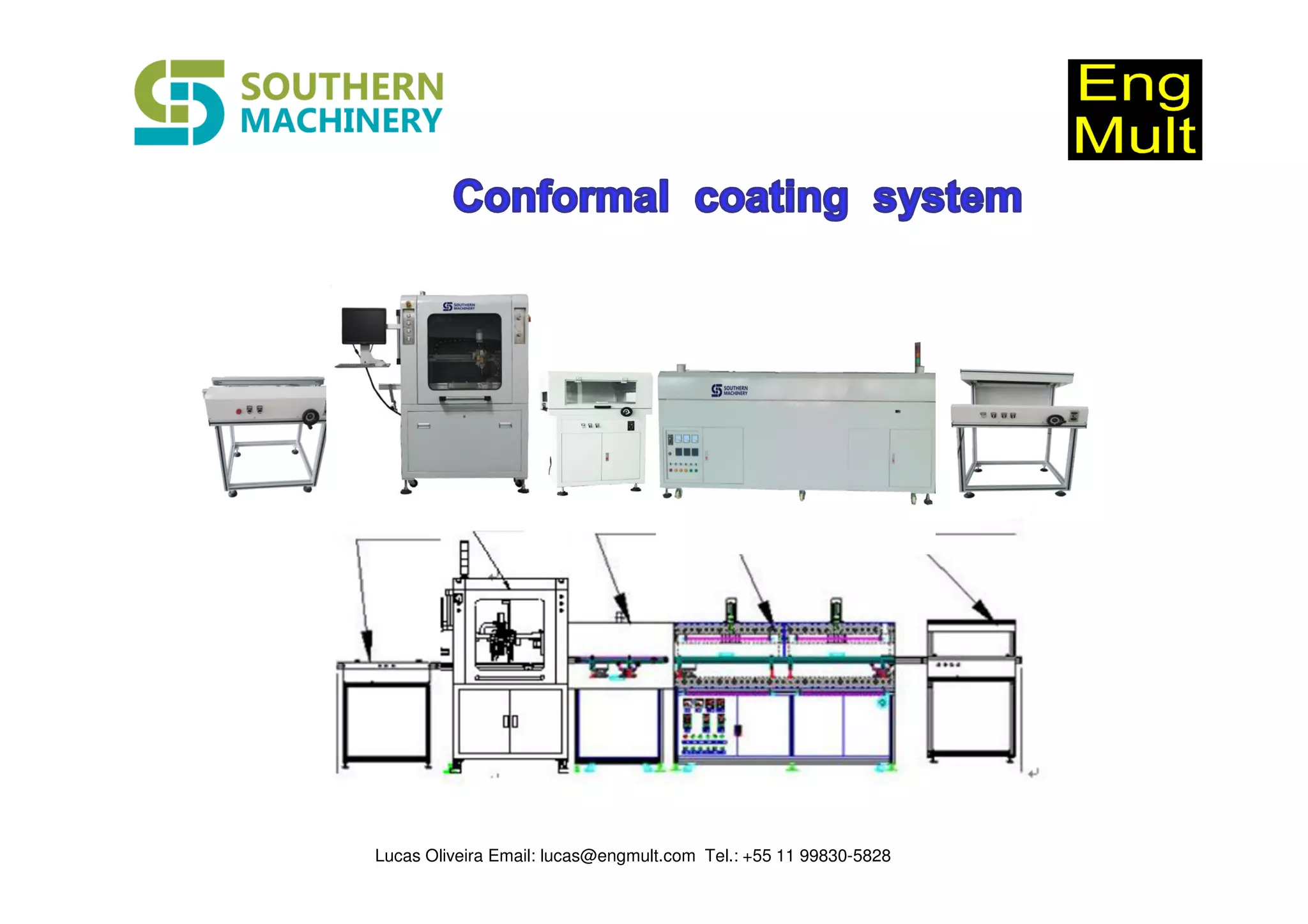

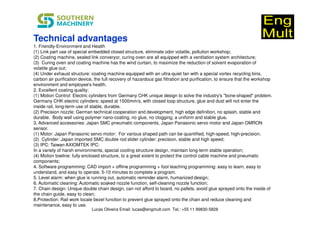

The document discusses an automated selective coating machine. It provides details on the machine's specifications, features, and technical advantages. The machine aims to create a friendly and healthy workshop environment through features like ventilation systems, wind curtains, and exhaust structures. It also offers excellent coating quality through precision nozzles and motion control. The machine is controlled through an IPC and includes advanced accessories from manufacturers like Panasonic, SMC, and OMRON. It can be easily programmed and includes features like automatic cleaning and level alarms.