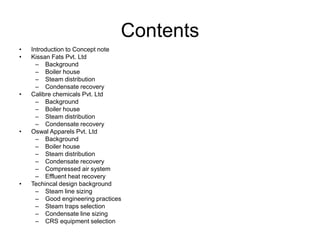

This document provides concept notes for designing utility distribution systems for three companies - Kissan Fats Pvt. Ltd, Calibre Chemicals Pvt. Ltd, and Oswal Apparels Pvt. Ltd. It discusses the background of each plant, proposed modifications to boiler houses, steam distribution, condensate recovery, and other relevant technical details. Key considerations covered include operability, maintenance, safety, energy efficiency, and accommodating future expansion. Technical aspects like line sizing, engineering best practices, and steam trap selection are also outlined.